Hot melt adhesive film for adhering sole, and preparation method thereof

A hot melt adhesive film and bonding technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of poor mechanical properties, chemical resistance, water resistance and solvent resistance of the film Problems such as poor performance and low hardness, to achieve the effect of simple operation process

Active Publication Date: 2014-04-30

江阴伟韬塑料新材料有限公司

View PDF5 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Water-based adhesives have disadvantages such as poor film mechanical properties, poor chemical resistance, water resistance, solvent resistance, and low hardness.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

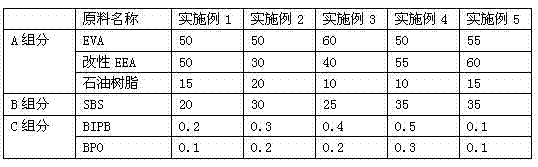

[0045] Example 2, modified EEA is made by mixing EEA and olefin polymer (7256) at a mass ratio of 100:8;

Embodiment 3

[0046] Example 3, modified EEA is made by mixing EEA and olefin polymer (POE7086) at a mass ratio of 100:10;

Embodiment 4

[0047] Example 4, modified EEA is made by mixing EEA and olefin polymer (7256) at a mass ratio of 100:12;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

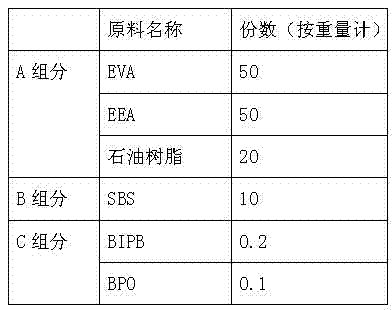

The present invention relates to a hot melt adhesive film for adhering a sole. The hot melt adhesive film comprises the following raw materials by weight: 50-60 parts of ethylene-vinyl acetate (EVA), 30-60 parts of modified ethylene-ethyl acrylate (EEA), 15-35 parts of a styrene-butadiene block copolymer (SBS), 5-20 parts of a terpene resin, 0.1-0.5 part of bis-(tertbutylperoxy isopropyl)benzene (BIPB), and 0.1-0.5 part of benzoyl peroxide (BPO). According to the present invention, the hot melt adhesive film does not contain benzene, toluene, xylene and other harmful solvents, the sole does not require the primer treatment, the operation process is simple, and the environmental requirement requirements are met.

Description

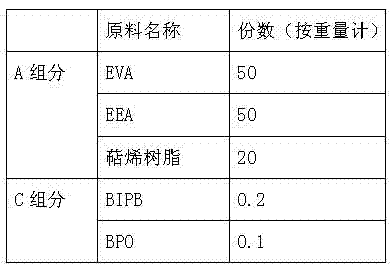

technical field [0001] The invention relates to a hot-melt adhesive film, in particular to an environment-friendly hot-melt adhesive film for bonding shoe material outsoles and midsoles and a preparation method thereof. Background technique [0002] The structure of the sole is quite complex. In a broad sense, it includes all the materials that make up the bottom, such as the outsole, midsole and heel. The common characteristics of general shoe sole materials should be wear-resistant, water-resistant, oil-resistant, heat-resistant, pressure-resistant, impact-resistant, good elasticity, easy to fit the foot shape, not easy to change shape after setting, heat preservation, easy to absorb moisture, etc. bottom, when walking and changing feet, there are various conditions such as braking effect so as not to slip and easy to stop. [0003] The material of the outsole is simply rubber, the most commonly used is SBS, the sole made of SBS instead of vulcanized rubber and polyvinyl ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J7/00C09J123/08C09J153/02C09J145/00C09J11/06

Inventor 吴俊

Owner 江阴伟韬塑料新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com