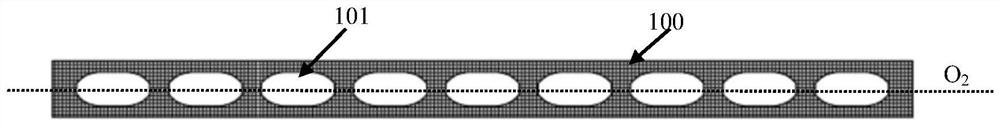

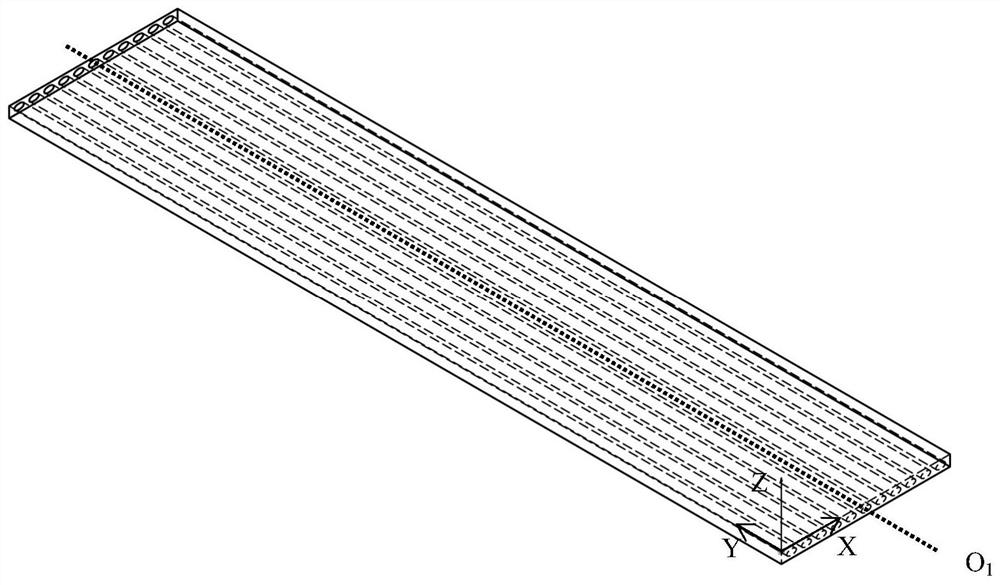

ABS improved hollow plate and preparation method thereof

A hollow plate, ABS resin technology, applied in the field of materials, can solve the problems of inconvenient recycling of silicon materials and backing plates, inability to reduce costs, affecting cutting efficiency, etc., to improve the internal mass molecular arrangement and hardness, reduce processing costs, and prolong The effect of the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: First, 70 parts of Chimei ABS (757) resin particles, 28 parts of PMMA (CM205) resin particles, 1 part of antibacterial agent (DXN-LT30), and 1 part of antioxidant (168) were put into the heating and mixing equipment, and the temperature was constant. Stir at 80°C for 30-60 minutes to mix the materials evenly and remove moisture; then put them into a twin-screw granulator for granulation for later use; send the granulated materials to the counter-rotating twin-screw sheet extruder by vacuum pumping For the transfer hopper above, the temperature of the hopper needs to be constant at 80°C, the temperature of the temperature zone of the extruder is set at 195°C, the temperature of the discharge die head is at 168°C, the feeding speed of the feeder is 45HZ, and the traction speed is 1.1m / min. The thickness of the skin and the thickness of the ribs meet the standards; after being pulled to the positioner, it is cut according to the required length; then it is trimme...

Embodiment 2

[0029] Embodiment 2: At first 75 parts of ABS (275) resin particles, 23 parts of PMMA (304E) resin particles, 1 part of antibacterial agent (DXN-LT30), 1 part of antioxidant (168) are dropped into heating mixing equipment, constant temperature 80 Stir at ℃ for 30-60 minutes to make the materials evenly mixed and remove moisture; then put them into a twin-screw granulator for granulation for later use; send the granulated materials to the counter-rotating twin-screw plate extruder by vacuum pumping The transfer hopper, the hopper needs to be kept at a constant temperature of 80°C, the temperature of the extruder temperature zone is set at 195°C, the temperature of the discharge die head temperature zone is 168°C, the feeding speed of the feeder is 45HZ, and the traction speed is 1.1m / min to ensure the skin of the board. The thickness and rib thickness meet the standards; after being pulled to the locator, cut according to the required length; then the edge is trimmed by the trim...

Embodiment 3

[0030] Embodiment 3: first put 70 parts of ABS (757) resin particles, 28 parts of PMMA (CM205) resin particles, 1 part of antibacterial agent (VK-G01C), 1 part of antioxidant (1010) into heating and mixing equipment, constant temperature 80 Stir at ℃ for 30-60 minutes to make the materials evenly mixed and remove moisture; then put them into a twin-screw granulator for granulation for later use; send the granulated materials to the counter-rotating twin-screw plate extruder by vacuum pumping The transfer hopper, the hopper needs to be kept at a constant temperature of 80°C, the temperature of the temperature zone of the extruder is set at 205°C, the temperature of the discharge die head temperature zone is 175°C, the feeding speed of the feeder is 45HZ, and the pulling speed is 1.1m / min to ensure the skin of the board The thickness and rib thickness meet the standards; after being pulled to the locator, cut according to the required length; then the edge is trimmed by the trimm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com