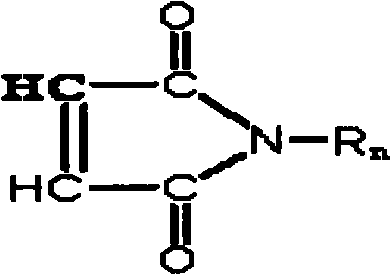

Method for synthesizing latex of heatresistant resin in maleimide class

A technology of maleimide and heat-resistant resin, which is applied in the field of polymer emulsion preparation, can solve the problems of slow reaction speed and discussion of polymerization methods, and achieve the advantages of easy control, shortened production cycle, and low utilization rate of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A. Preparation of Primary Emulsion

[0053] Add 30 parts of desalted water, 0.3 parts of sodium lauryl sulfate, 0.7 parts of styrene, 0.3 parts of acrylonitrile, and 0.1 parts of potassium persulfate into a stirred reactor at 30°C, and start stirring for emulsification. After 30 minutes of emulsification, the temperature of the water phase in the reactor was raised to 78° C. within 30 minutes, and kept at a constant temperature for 10 minutes to form the primary emulsion (a).

[0054] B. Preparation of monomer mixture

[0055] Add 30 parts of N-phenylmaleimide, 44 parts of styrene, 25 parts of acrylonitrile, and 0.1 part of tertiary dodecylmercaptan into the mixing tank at 30°C, start stirring and mix to form a homogeneous monomer mixture ( b).

[0056] C. Preparation of Monomer Emulsion

[0057] Add 130 parts of desalted water, 0.35 parts of potassium persulfate, and 2.7 parts of sodium lauryl sulfate into the emulsifier at 30°C, start stirring and add (b) into the ...

Embodiment 2

[0065] A. Preparation of Primary Emulsion

[0066] Add 30 parts of desalted water, 0.3 parts of sodium lauryl sulfate, 1.0 part of acrylonitrile, and 0.15 parts of potassium persulfate into a reactor equipped with stirring at 30°C, and start stirring for emulsification. After 30 minutes of emulsification, the temperature of the water phase in the reactor was raised to 78° C. within 30 minutes, and kept at a constant temperature for 10 minutes to form the primary emulsion (a).

[0067] B. Preparation of monomer mixture

[0068] Add 30 parts of N-phenylmaleimide, 44 parts of styrene, 25 parts of acrylonitrile, and 0.15 parts of tertiary dodecylmercaptan into the mixing tank at 30°C, start stirring and mix to form a homogeneous monomer mixture ( b).

[0069] C. Preparation of Monomer Emulsion

[0070] Add 130 parts of desalted water, 0.35 parts of potassium persulfate, 1.7 parts of sodium lauryl sulfate and 1.0 part of synthetic fatty acid potassium into the emulsifier at 30°C...

Embodiment 3

[0076] A. Preparation of Primary Emulsion

[0077]Add 30 parts of desalted water, 0.3 parts of sodium lauryl sulfate, 0.7 parts of styrene, 2.3 parts of acrylonitrile, and 0.1 parts of potassium persulfate into a stirred reactor at 30°C, and start stirring for emulsification. After 30 minutes of emulsification, the temperature of the water phase in the reactor was raised to 78° C. within 30 minutes, and kept at a constant temperature for 10 minutes to form the primary emulsion (a).

[0078] B. Preparation of monomer mixture

[0079] Add 30 parts of N-cyclohexylmaleimide, 44 parts of styrene, 23 parts of acrylonitrile, and 0.12 parts of tertiary dodecylmercaptan to the mixing tank at 30°C, start stirring and mix to form a homogeneous monomer mixture ( b).

[0080] C. Preparation of Monomer Emulsion

[0081] Add 130 parts of desalted water, 0.35 parts of potassium persulfate, 1.7 parts of sodium lauryl sulfate and 1.0 part of synthetic fatty acid potassium into the emulsifier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com