Patents

Literature

103results about How to "High fiber content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paper-making-stage bamboo wood pulp plate denaturalization producing technique

ActiveCN101148836ADip evenlyFully impregnatedPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscose fiber

The present invention provides denaturating production process of paper-making bamboo pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making bamboo pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

Production method for preparing bamboo dissolving pulp by utilizing natural-color unbleached bamboo pulp in a modifying way

ActiveCN101736637AShort processShorten the production cyclePulp de-wateringPulp beating/refining methodsDissolving pulpAlpha-Cellulose

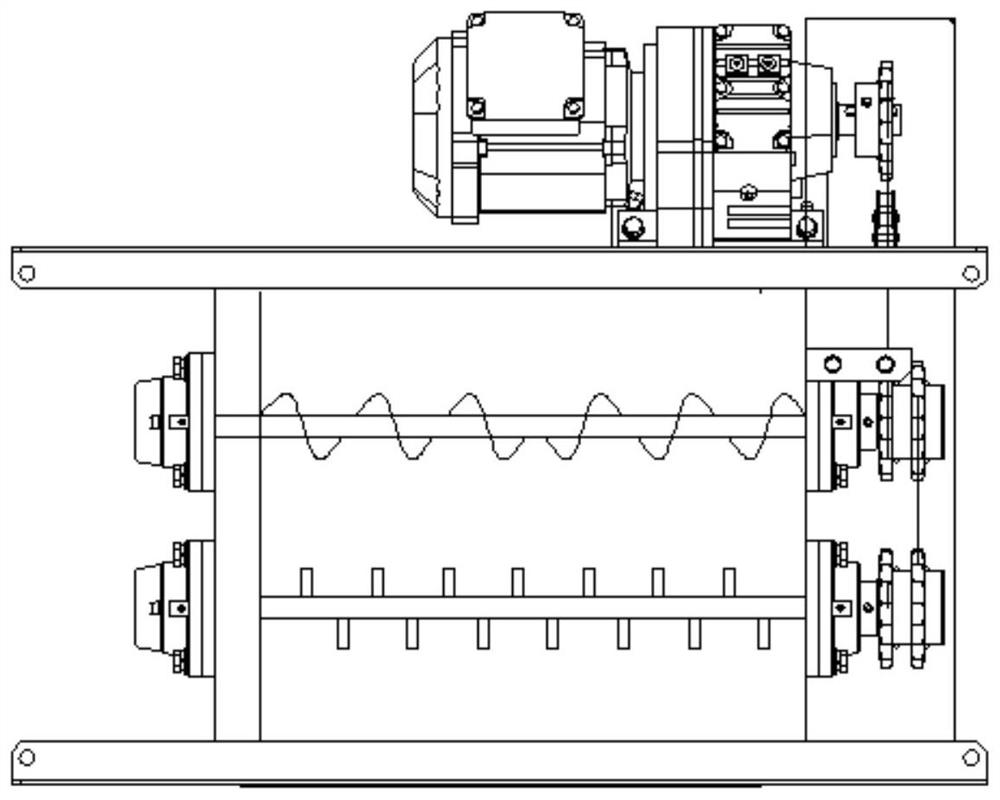

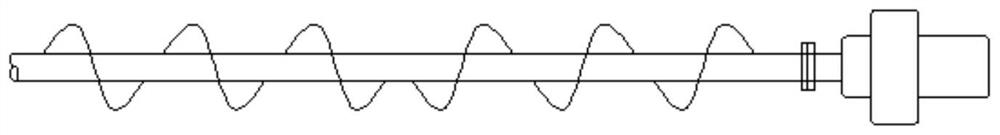

The invention discloses a production method for preparing bamboo dissolving pulp by utilizing natural-color unbleached bamboo pulp in a modifying way, overcoming the defect of poor reaction property of products prepared by an alkali refining method. The production method comprises the following steps of: concentrating and dewatering dredged natural-color unbleached bamboo pulp, and delivering to a double-helix roller type pulp grinder; continuously dewatering in the pulp grinder, and adding liquid medicine; continuously concentrating and kneading the pulp and mixing the pulp with the liquid medicine in the pulp grinder; then delivering the pulp to a stewing machine; and after stewing is completed, conducting subsequent procedures including washing and bleaching till paper making. The invention reduces the preparation cost, enhances the quality of products and increases resource supplying sources; in addition, the bamboo pulp prepared by the production method not only has higher content of alpha-celluloses, but also has good reaction property, and is suitable for filament and staple fibers.

Owner:YIBIN GRACE GROUP CO LTD

Stewing process for preparing wood dissolving pulp by natural-color unbleached wood pulp in a modifying way

ActiveCN101736632AShort processShorten the production cyclePaper material treatmentDissolving pulpProcess conditions

The invention discloses a stewing process for preparing wood dissolving pulp by utilizing natural-color unbleached papermaking-grade wood pulp in a modifying way, overcoming the defect of poor reaction property of products prepared by an alkali refining method. The stewing process conditions of natural-color unbleached wood pulp in a stewing device are as follows: liquor ratio is 1:2.5-7.0; alkali charge includes 10-50% of NaOH and 0.1-50% of Na2S; a temperature increasing condition comprises the following steps of: increasing temperature to 115-130 DEG C for 30-60 minutes, and keeping the temperature for 30-120 minutes; continuously increasing the temperature to 135-150 DEG C for 30-60 minutes, and keeping the temperature for 120-180 minutes; after the temperature is kept, continuously increasing the temperature to 165-175 DEG C, and keeping the temperature for 30-180 minutes; after the temperature is kept, reducing the temperature, and discharging; and stewing to end after the discharging. The wood pulp produced by the stewing process not only has higher content of alpha-celluloses, but also has good reaction property, and is suitable for filament and staple fibers.

Owner:YIBIN GRACE GROUP CO LTD

Production process of bamboo-dissolving pulp

ActiveCN102127877AIncreased alkali consumptionExtended cook cycleCellulose material pulpingAcid treatmentManufacturing engineering

The invention provides a production process of bamboo-dissolving pulp, relating to a treatment method in the field of textile chemical fiber. The process comprises the following procedures of: preparing materials; steaming and pre-hydrolyzing; exchanging steaming and boiling; hermetically screening; bleaching in oxygen-alkali; carrying out acid treatment; manufacturing paper with pulp; and the like. The bamboo-dissolving pulp produced by the invention has the advantages of good product quality, uniform viscosity, high alphacellulose content, high whiteness, yellowing resistance, low pentaose content and good reaction performance and is favorable to production of post-procedures, chlorine-free bleaching and environment-friendly production.

Owner:YIBIN GRACE GROUP CO LTD

A kind of brewing method of kudzu root wine

ActiveCN102268344AAntibacterialSolving the Difficulty of Poor Importability in Making LiquorAlcoholic beverage preparationBiotechnologyNutrition

The invention discloses a brewing method of kudzuvine root wine. The brewing method is characterized by comprising the following steps: saccharifying rhizomes of leaguminosae plant kudzuvine used as a main raw material and indica rice used as an auxiliary material in different vats by using Chinese yeast and rice wine koji; and mixing mashes and distilling, and cellaring and ageing, and then blending so as to obtain the kudzuvine root wine. By using the method, the difficulty that distilled spirit prepared from kudzuvine root by a production plant in the past few years has poor mouth feel is solved; and the kudzuvine root wine prepared by the method provided by the invention has pure taste, and also completely maintains the nutrient and medical efficiencies of the kudzuvine root, such as blood circulation invigorating and sterilizing function on a human body and the function of improving the immunity of a human body. In the method provided by the invention, the kudzuvine root is used as the raw material, and raw materials such as cavings and the like in the traditional brewing are replaced by the kudzuvine root because the kudzuvine root has high fiber contents. The white spirit brewed by the method is mellow and unique, is rich in wine quality and is sweet and delightful. According to the invention, the processing technology is simple, has high operability and high economic and social benefits.

Owner:刘海燕

Paper-making-stage wood pulp plate denaturalization producing technique

ActiveCN101148835AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscose fiber

The present invention provides denaturating production process of paper-making wood pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making wood pulp sheet in a paging device, alkali dipping in 6-18 % concentration alkali solution in a dip vat to form 2.5-8 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

Method for preparing wood dissolving pulp by modifying true color unbleached wood pulp

InactiveCN101818460AShort processShorten the production cyclePulp de-wateringInorganic compound additionDissolving pulpSilk fiber

The invention discloses a production method for preparing wood dissolving pulp by modifying true color unbleached wood pulp, overcoming the defects of poor reaction property of a product prepared by using an alkali refining method. The method comprises the following steps of: concentrating and dewatering defibered unbleached true color wood pulp and then sending the pulp into a double-helix roll type refiner; continuing to dewatering in the refiner and adding liquid medicine; finishing continued concentrating, kneading and liquid medicine mixing working procedures on the pulp in the refiner, and then conveying the pulp into a digester; and entering subsequent working procedures comprising washing and bleaching after steaming and boiling until manufacturing paper with pulp. The invention reduces the preparation cost, improves the product quality and enlarges the resource supply source. The wood pulp dregs prepared by the method has higher alpha-cellulose content and good reaction property and is suitable for long and short silk fibers.

Owner:YIBIN GRACE GROUP CO LTD

Paper-making-stage high viscosity wood pulp plate denaturalization producing technique

ActiveCN101148832AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpHemicelluloseViscosity

The present invention provides denaturating production process of paper-making high viscosity wood pulp sheet pulp superior to available denaturated wood pulp sheet producing process. The denaturating production process includes the following steps: paging paper-making high viscosity wood pulp sheet in a paging device, alkali dipping in 8-18 % concentration alkali solution in a dip vat to form 2.5-4.5 % concentration pulp, extruding in a extrude, debonding fiber, digesting, washing, depurating, bleaching, washing for the second time, and fishing pulp. The process can obtain high quality wood pulp of soluble viscose fiber stably and has wide material source.

Owner:YIBIN GRACE GROUP CO LTD

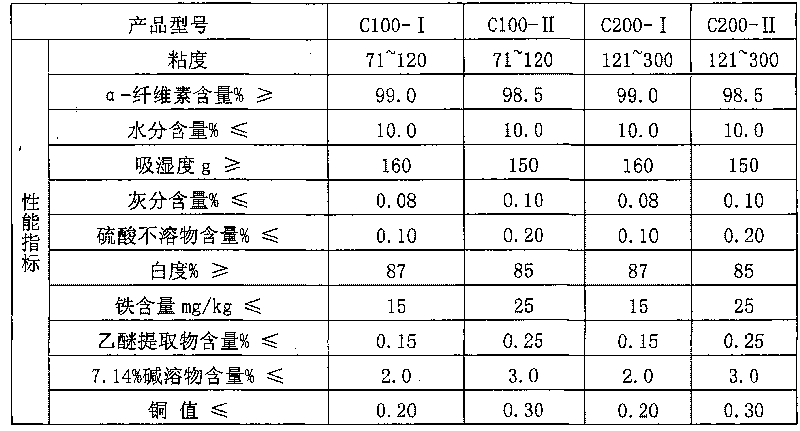

Low-viscosity cotton pulp used for producing cellulose ether-esters and method for making the same

The present invention discloses a low-viscosity cotton pulp for producing cellulose ether ester and preparation method of said cotton pulp. Said invention uses cotton linters as raw material, and its preparation method includes the following steps: preparing material, digesting, washing material, beating, bleaching, removing sand, water-washing and pulp-making, etc.

Owner:CHTC HELON

Modified papermaking grade wood pulp production process

InactiveCN102277759ADip evenlyMeet production requirementsPulp bleachingPulping with inorganic basesCellulosePapermaking

The invention discloses a production process of modified paper-making grade wood pulp, which comprises the following steps: (1) preparing materials, feeding paper-making grade wood pulp boards into a hydraulic pulper, dispersing and dispersing through alkali spraying and agitator, After being sent to the press for extrusion and dehydration, it is sent to steaming balls; (2) cooking, the impregnated slurry enters steaming balls for cooking, and caustic soda is added; (3) chlorination, the cooked slurry is chlorinated, and added Hydrochloric acid, liquid chlorine, caustic soda; (4) bleaching, the chlorinated slurry is sent to the bleaching tank for bleaching; (5) acid treatment, adding hydrochloric acid for acid treatment, spraying into the bleaching tank, and papermaking , Packaged as wood pulp. The invention uses a hydraulic pulper to fully decompose and disperse the slurry, so that the impregnation of the wood fiber and the lye is more uniform, and the uniformity of cooking is greatly improved. Through the cooking process, the content of non-cellulose impurities can be reduced, and the degree of polymerization of cotton fibers can be reduced. Through the chlorination process, part of the colored impurities can be removed, and the content of methyl cellulose can be increased accordingly. Through the bleaching process, the whiteness of cellulose can be improved, and the polymerization can be continuously reduced to remove impurities. Through acid treatment, ash and iron can be removed, and the reaction performance can be improved. The modified papermaking grade wood pulp produced by the invention can meet the index requirement of dissolving wood pulp and meet the production requirement of viscose fiber.

Owner:TANGSHAN SANYOU GRP DONGGUANG PULP CO LTD

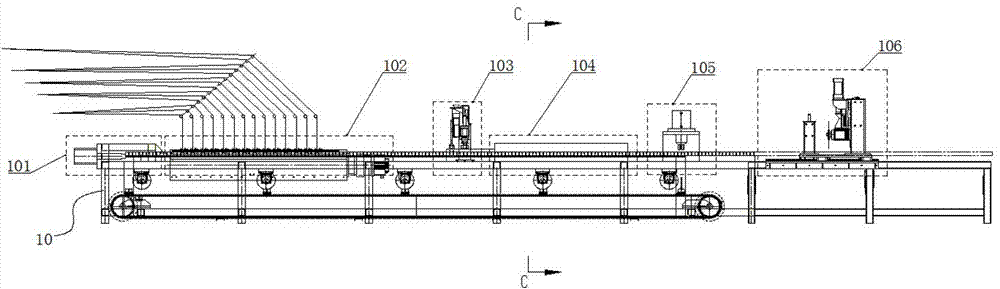

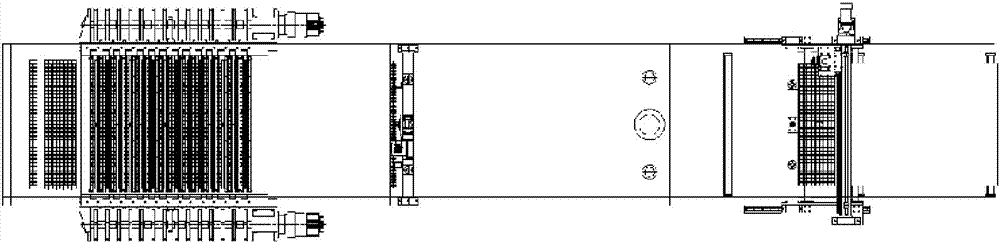

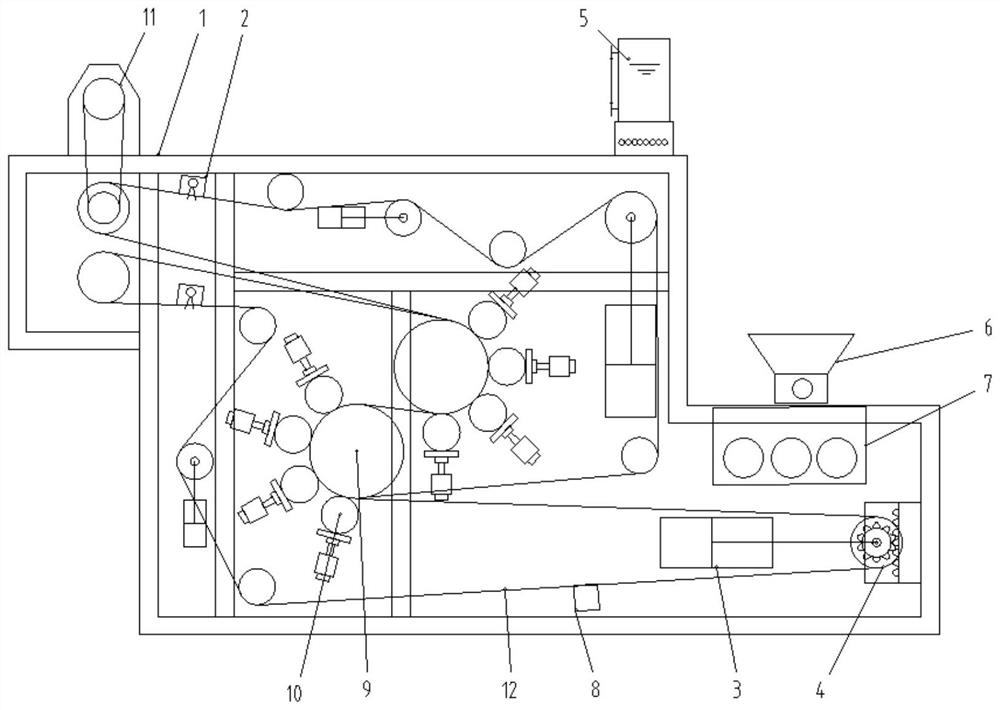

Fiberglass pultrusion grille continuous production line

The invention relates to a fiberglass pultrusion grille continuous production line which is characterized by comprising a rack, a core mould propulsion mechanism, automatic yarn laying mechanisms, a resin mixture injection mechanism, a heating solidification mechanism, a core mould demoulding mechanism, a grille cutting mechanism and a grille mould composed of fixed mould bodies and a plurality of moving core mould bodies; and the fixed mould bodies of the grille mould comprises a reinforcing fiber imbedding section fixed mould body, a resin mixture injection section fixed mould body and a heat solidification section fixed mould body which can be all matched with the moving core mould bodies in a core mould moving guide channel correspondingly to form a closed grille-shaped mold cavity. The fiberglass pultrusion grille continuous production line has the advantages that pultrusion manufacturing is conducted in a tunnel-type fixed mould cavity; the situations that each grille rib can allow more fibers to be placed in, steeping of matrix resin is more uniform and consistent, and materials are in the process state needed by pultrusion at the time of solidification and forming are guaranteed correspondingly, and accordingly continuous pultrusion production of fiber reinforced plastic is achieved finally.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

Bleached grain and grain products and methods of preparation

InactiveUS20070054016A1White colorIncrease volumeDough treatmentEdible seed preservationFiberBaked goods

The present invention describes bleached grain products such as bleached whole wheat flour that are obtained having the color and taste of white flour by bleaching whole wheat kernels prior to conventional flour milling. The wheat kernels are treated with a peroxide solution to lighten the color of the bran layers. The bleached grain kernels can be tempered and milled into whole grain flours having 10% to 12% dietary fiber from the bran but which are white in color and bland in flavor. The whitened, high fiber whole wheat flours can be used to prepare good tasting, and nutritious products such as baked goods such as breads and pastries as well as pasta product, and ready-to-eat cereals or grain based snacks.

Owner:METZGER LLOYD E

Semi-dull high-strength low-elongation viscose fiber as well as preparation method and application thereof

InactiveCN104846458AGood skin affinityHigh strengthArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceSpinning

The invention provides a semi-dull high-strength low-elongation viscose fiber as well as a preparation method and application thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, directional polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has an index system that the dry fracture strength is more than or equal to 3.20cN / dtex, the wet fracture strength is more than or equal to 1.70cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.6cN / dtex, the dry elongation at break is 13.0-16%, and the wet elongation at break is 16.0-21.0%. The semi-dull high-strength viscose fiber provided by the invention is prepared by virtue of technical innovation, and is a novel fiber variety which has an index system different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows high and strong fiber characteristics and also shows skin affinity stronger than that of cotton fibers, so that the semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, the development and the industrial upgrading of downstream novel textiles can be promoted while the processability of the downstream process of the viscose fiber is improved, and the semi-dull high-strength low-elongation viscose fiber can be well applied to the field of producing underclothes and high-grade woven fabrics.

Owner:YIBIN GRACE GROUP CO LTD +2

Wood pulp denaturalization production process for producing viscose fibers

InactiveCN102943403AHigh fiber contentLow chemical usagePulp bleachingArtificial filaments from viscoseAlpha-CelluloseGram

A wood pulp denaturalization production process for producing viscose fibers is used for solving the problems of high energy consumption, serious pollution, low alpha cellulose content of produced products, poor reactivity and the like of an existing method. The wood pulp denaturalization production process includes the working procedures of wood pulping, repulping, alkali pre-impregnation, cooking, desanding by washing, xylanase treatment, seeping and rinsing, acid treatment, pulp washing and manufacturing paper with pulp. In the working procedure of cooking, 16-22% of alkali is used, 1.75% of additive sulfonate, and the bath ratio is 1:3.5-4. In the working procedure of xylanase treatment, the PH (potential of hydrogen) value is lower than 9, the temperature is 50 DEG C, enzyme is diluted to be 0.125%, reaction time is 1.5-2 hours, the concentration of the pulp is 5-8%, and the dosage of the enzyme is 45-80 grams / ton. The pulp is purified by combining chemical treatment with biological treatment, and compared with a pure chemical method, the process has the advantages that the produced wood pulp is high in alpha cellulose content, the dosage of chemical agents is low, and pollution is less.

Owner:SWAN FIBER

Retinervus luffae fructus pulp for manufacturing viscose fiber and preparation method thereof

InactiveCN102444044AEasy plantingEasy to manageWashing/displacing pulp-treating liquorsDigestersViscoseSlurry

The invention relates to a preparation method of a retinervus luffae fructus pulp for manufacturing viscose fiber, which is characterized in that: the retinervus luffae fructus pulp for manufacturing viscose fiber is prepared by taking retinervus luffae fructus as raw material. The preparation method comprises the steps of preparation of raw materials, boiling, washing, pulp beating, desanding, bleaching, rinsing and pulping. The method specifically comprises the steps of: weighing and adding a fixed amount of pretreated retinervus luffae fructus to a boiler for boiling in alkaline liquid for a certain time; removing residual liquid upon the completion of boiling, then washing the boiled retinervus luffae fructus, pulping in a beater, desanding and bleaching the resultant pulp by chlorination, removing residual liquid and rinsing the pulp, and finally performing pulping on the pulp in a pulp machine to obtain the required retinervus luffae fructus pulp. Compared with traditional pulp-making raw materials like wood or cotton linter, the raw material in the retinervus luffae fructus pulp disclosed by the invention is easier for large-area plantation and development, has simple and convenient production process and low cost, and is an inexpensive raw material easier for large-area development.

Owner:SHANDONG UNIV OF TECH +1

Method for producing acetate fiber bamboo pulp

The invention provides a method for producing acetate fiber bamboo pulp, which overcomes the defect of the traditional acetate fiber bamboo pulp preparing technologywhich combines prehydrolysis and alkaline and sulphite cooking. The method comprises the following steps of: concentrating and dehydrating defibered unbleached natural bamboo pulp, and delivering into a dual screw roller type pulping machine; continuing to dehydrate and adding chemical liquor in the dual screw roller type pulping machine; conducting the processes of continuous concentration, kneading and chemical liquor mixing in the dual screw roller type pulping machine; then conveying the pulp into a reaction chamber to store and react; after reaction, delivering to cook for the second time; and after cooking, performing the processes of washing, bleaching, refining, sand removal, sieving and paper making. As the unbleached natural bamboo pulp has high viscosity, the cooking strength during cooking is controlled, the damage of the chemical liquor to the fiber cell wall is promoted, thereby facilitating the physical liquor permeating and improving the reaction activity.

Owner:YIBIN GRACE GROUP CO LTD

Steaming process for modifying bleaching bamboo paper pulp and bleaching wood paper pulp into dissolving pulp in compound way

ActiveCN102677505AReduce manufacturing costHigh fiber contentPaper recyclingPulping with inorganic basesViscosePulp and paper industry

The invention discloses a steaming process for modifying bleaching bamboo paper pulp and bleaching wood paper pulp into dissolving pulp in a compound way. Compound paper pulp is steamed in a continuous steamer, wherein a continuous steaming pipe of the continuous steamer has three sections, one section connected with a pre-reaction storage bin is provided with steam pipes and a T-shaped pipe, and the other two sections are provided with steam pipes, and steam is introduced into the continuous steamer through the steam pipes; and alkali liquor is added into the continuous steaming pipe through the T-shaped pipe, and the alkali liquor is NaOH and is added in an amount which is 17 to 23 percent of absolute dry weight. According to the steaming process, the bleaching bamboo paper pulp and the bleaching wood paper pulp are used as raw materials, so that the cost for preparing the dissolving pulp is greatly reduced, and requirements on quality of the dissolving pulp for viscose fiber are met.

Owner:YIBIN GRACE GROUP CO LTD

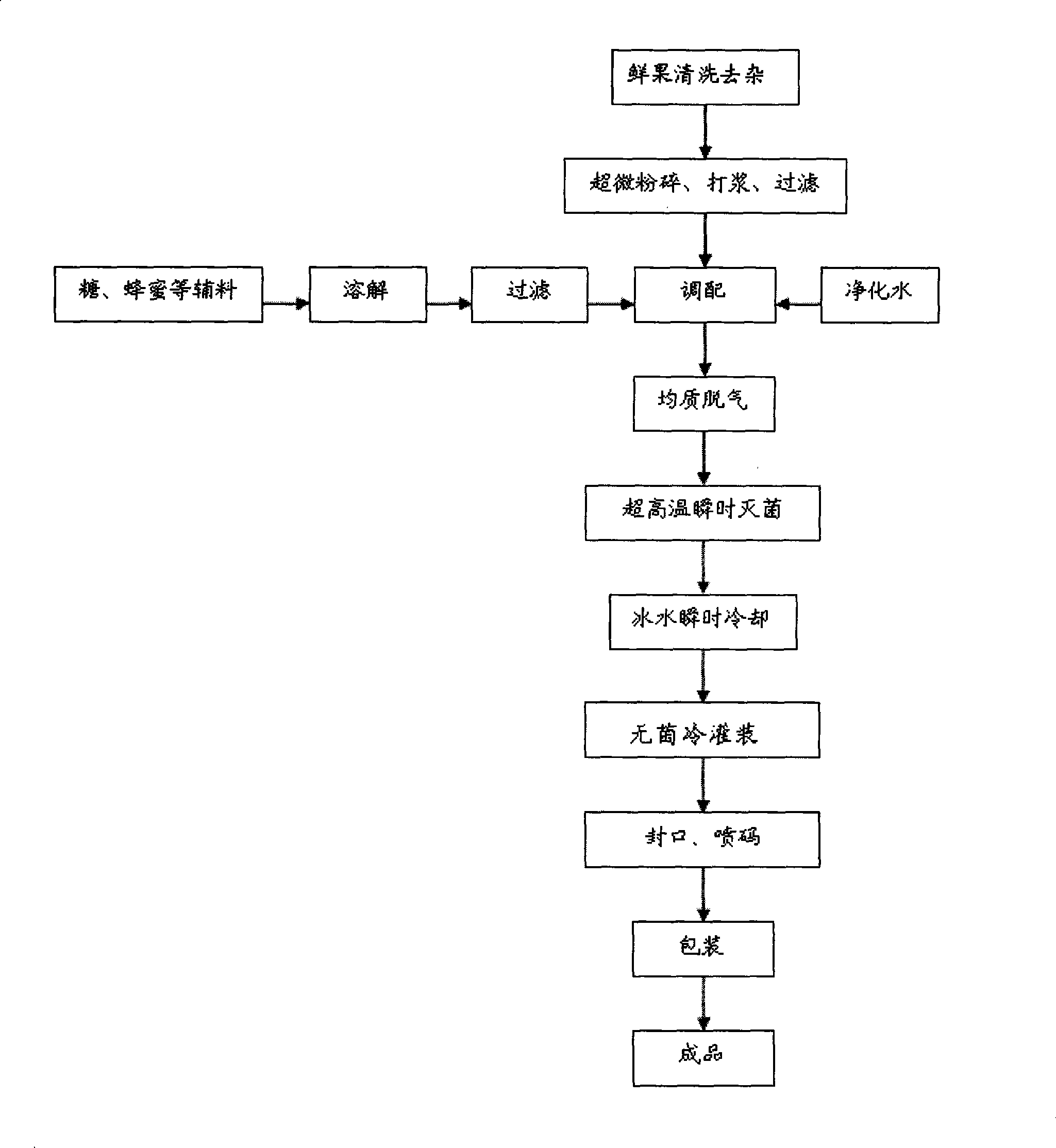

Processing method of fresh blackberry juice

The invention relates to a processing method of fresh blackberry juice. The produced juice has fresh color and good taste and is free of pigment. The fresh blackberry juice is made by pulping 85 to 90 weight percent of 90 percent or above ripe blackberry fruit and 10 to 18 weight percent of 70 to 80 percent ripe blackberry fruit. As an improvement of the invention, the raw fruit is comminuted into superfine particles and pulped and then filtered through screens of 300 meshes. As another improvement of the invention, ultra-high temperature instantaneous sterilization and cold-aseptic filling are applied to the juice. The ultra-high temperature instantaneous sterilization is performed at the temperature of 128 to132 DEG C for 3-5s; and then, the juice is cooled instantaneously with ice water to about 18 to 23 DEG C and then filled under aseptic conditions. The invention eliminates the need of pigment addition and combines fully-natural juice with improved technologies, improving the blackberry taste defect, maintaining natural and fresh nutrients and cool and ruddy rosy luster of the blackberry fruit and lengthening the shelf life of the fresh juice.

Owner:南京新世纪园艺研究所

Manufacturing process of antibacterial bamboo pulp used for high-wet-modulus fibre

ActiveCN102677504ADestruction of natural characteristicsPreserve the deodorizing functionWashing/displacing pulp-treating liquorsPulp de-wateringReaction temperatureOxygen

The invention discloses a manufacturing process of antibacterial bamboo pulp used for high-wet-modulus fibre. The manufacturing process comprises prehydrolysis, cooking, oxygen delignification, vibration frame screen screening, first washing, sand removal, first concentration, bleaching, second washing, thermal basic refining, pressurized screen preliminary sizing, second concentration, sodium hypochlorite bleaching, third washing, acid treatment, fourth washing, sand removal and manufacture, wherein a hydrolysis accessory ingredient is added in a cooker in prehydrolysis. The hydrolysis accessory ingredient is added in the prehydrolysis, so that the reaction temperature of the prehydrolysis and cooking processes is reduced, thus the content fluctuation of alpha-cellulose is small, the quality is stable, the indexes can meet the pulp requirement of high-wet-modulus fibre, and the natural deodorization, antibacterial and ultraviolet resistance functions of the bamboo fiber can be furthest remained.

Owner:YIBIN GRACE GROUP CO LTD

Production technology of cotton pulp for manufacturing cellulose nitrate

ActiveCN110656524AReduce pollutionControl lengthPulp beating methodsDigestersFiberPulp and paper industry

The invention discloses a production technology of a cotton pulp for preparing cellulose nitrate. The cotton pulp has the following indicators: the polymerization degree is 930-980, the whiteness is greater than or equal to 88%, the iron content is less than or equal to 15 ppm, the ash content is less than or equal to 0.08%, the fiber length is 23-32%, the alpha-cellulose content is greater than or equal to 97.5%, the water content is 6-9%, the content of small dusts is less than or equal to 15 mm<2> / 500 g, and the content of B-type dusts is less than or equal to 2 mm<2> / 500 g. The cotton pulpfor cellulose nitrate, prepared by the method, has the advantages of high fiber brooming degree, good strength, high alpha-cellulose content, stable polymerization degree and few dusts, and can be well applied to production of industries of novel medical fillers such as microcrystalline cellulose and explosive nitrocotton, high-grade nitrolacquers and architectural coatings.

Owner:山东银鹰股份有限公司

Method for modified production of viscose fibers by natural-color reed paper pulp

ActiveCN110886123AIncrease contentImprove the effect of bleaching and depolymerizationWashing/displacing pulp-treating liquorsPulp bleachingCelluloseViscose fiber

The invention relates to the technical field of viscose fiber production, and in particular, relates to a method for modified production of viscose fibers by natural-color reed paper pulp, wherein themethod comprises the steps: performing alkali impregnation on the natural-color reed paper pulp by adopting continuous alkali impregnation, gradient concentration and countercurrent alkali return; washing and removing by a two-stage pulp extruder series replacement washing mode and a one-stage mesh belt type pulp washer five-section countercurrent washing mode; removing film-shaped or fragment paper pulp by utilizing the mechanical acting force of a disc mill; carrying out first-stage bleaching and second-stage bleaching polymerization reduction treatment on the pulp; and cleaning and replacing by a countercurrent washing mode. According to the method, the alpha-cellulose content of the reed pulp is improved to the greatest extent, the requirement of viscose production on the alpha-cellulose content of the pulp raw material is met, the next bleaching polymerization reduction effect and the fiber reaction performance of the natural-color reed paper pulp are improved, the dust content of a final product is reduced, the damage to alpha-cellulose is avoided to the maximum extent, the alpha-cellulose content is improved, and meanwhile, silicon is prevented from entering a viscose production system.

Owner:XINJIANG FULIDA FIBER CO LTD

Method for realizing pulp-fiber integrated production by taking paper pulp as raw material

ActiveCN111996828AReduce consumption costReduce labor costsPulp properties modificationPulp bleachingCellulosePapermaking

The invention relates to the technical field of viscose fiber production, in particular to a method for realizing pulp-fiber integrated production by taking paper pulp as a raw material. The method comprises the following steps: mixing bleached paper pulp with soft water for bleaching and polymerization reduction treatment to obtain bleached purified pulp with a mass concentration of 4.5-5%, and dehydrating and extruding the bleached purified pulp by using a wet papermaking machine to obtain wet pulp; after the gram weight and dryness of the wet pulp are stabilized, fully mixing a desired amount of wet pulp with a desired amount of alkali liquor to obtain alkaline mixed pulp porridge; and carrying out secondary impregnation and secondary squeezing on the mixed pulp porridge in an impregnation barrel to obtain alkali cellulose capable of meeting production requirements on mucilage glue. According to the invention, a pulp-fiber integrated process is realized; the energy consumption of the whole process production is reduced; the problem of a high polymerization degree of bleached paper pulp is solved; the ash content and the iron content of the bleached paper pulp are reduced, and the alpha-cellulose content of the paper pulp is increased; the energy consumption and the labor cost of subsequent drying, paper cutting, weighing and packaging of wet pulp are reduced; and the profitsof viscose fiber production enterprises are maximized.

Owner:XINJIANG FULIDA FIBER CO LTD +1

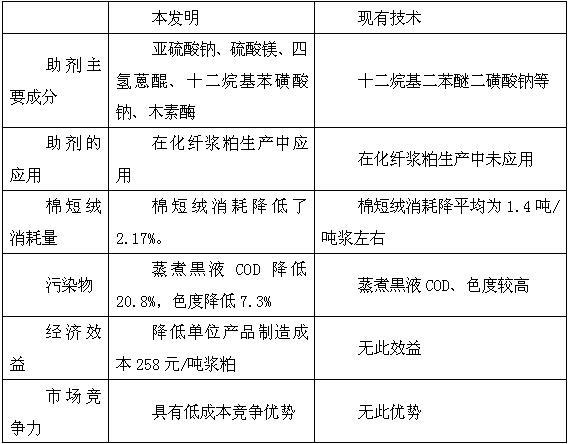

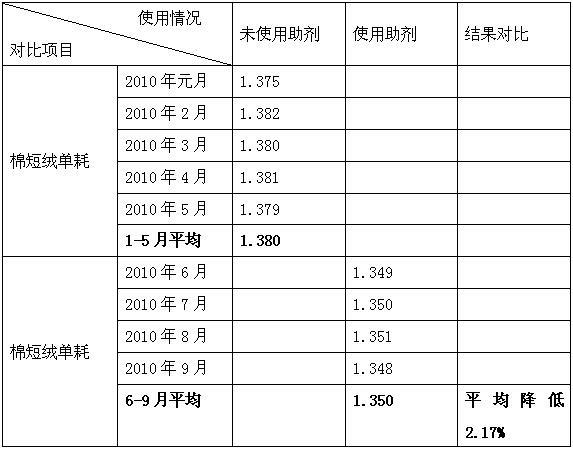

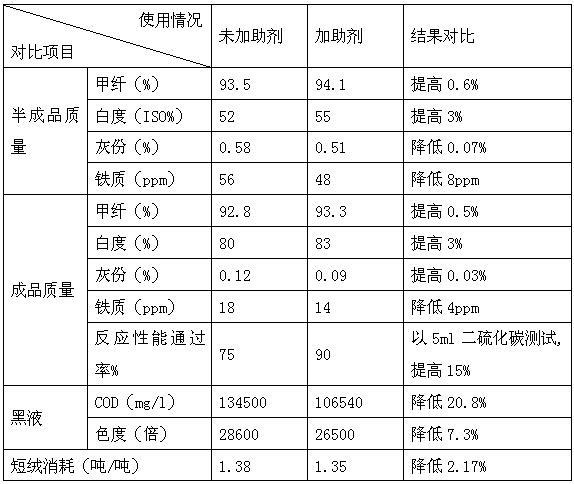

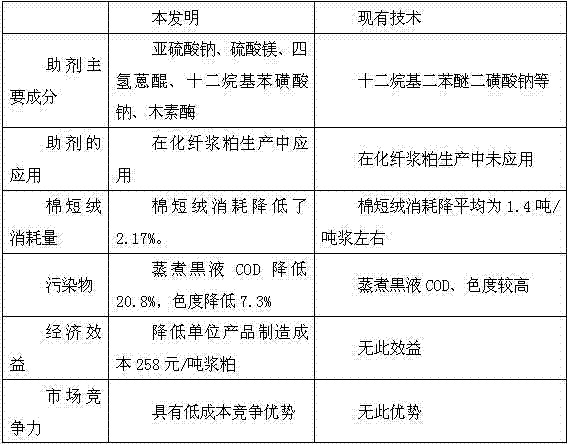

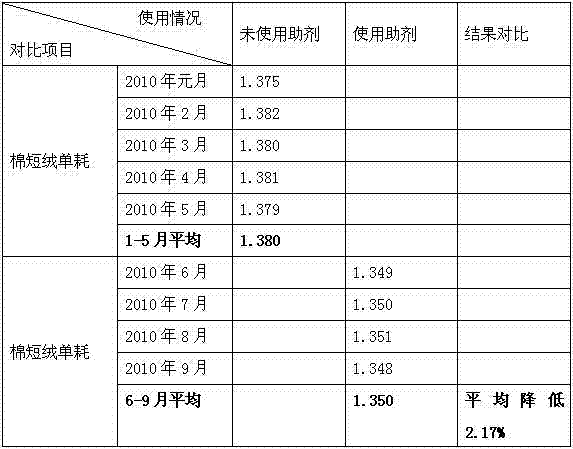

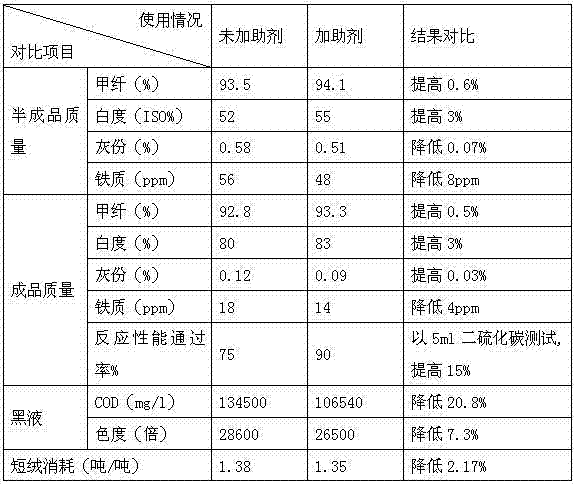

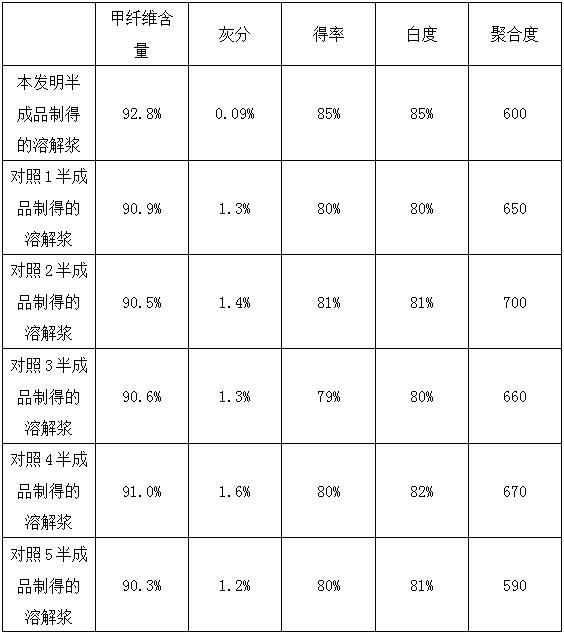

Cooking aid for preparing chemical fiber pulp

InactiveCN102154869ATerminate the peeling reactionHigh yieldCellulose material pulpingCelluloseFiber

The invention relates to a cooking aid for preparing chemical fiber pulp and belongs to the field of the preparation of the chemical fiber pulp in textile industry. The invention aims to solve the problem the cooking aid cannot be used for cooking the chemical fiber pulp and is not environment-friendly enough in the cooking technology and the like, and provides the cooking aid for preparing the chemical fiber pulp. The aid comprises the following components in percentage by weight: 3 to 20 percent of sodium sulfite, 1 to 10 percent of magnesium sulfate, 30 to 60 percent of tetrahydro anthraquinone, 5 to 30 percent of sodium dodecyl benzene sulfonate, and 1 to 10 percent of ligninases. The aid can emulsify and remove wax, protein and fat in the cooking of the chemical fiber pulp, improve the penetration and dispersion of cooking medicinal liquid, control the degradation speed of cellulose, improve the content of alp ha cellulose, selectively remove chormophoric groups, improve the half-stuff whiteness and bleachability, reduce life cycle cost (LCC), improve chemical reaction performance, effectively reduce raw material consumption, and reduce the chemical oxygen demand (COD) and chromaticity of cooking waste liquor and other indexes.

Owner:YIBIN GRACE GROUP CO LTD

Method for preparing chemical fiber pulp

InactiveCN102174756AAvoid emulsificationPrevent removalCellulose material pulpingWaxChemical oxygen demand

The invention relates to a method for preparing chemical fiber pulp, belonging to the field of chemical fiber pulp manufacturing in the spinning industry. The invention aims at solving the problems that a cooking additive cannot be used for cooking chemical fiber pulp in the traditional cooking technology and the traditional cooking technology is not environment-friendly and the like, and provides a method for preparing chemical fiber pulp by using an environment-friendly compound cooking additive. The method comprises the processes of opening cotton, preparing the additive, cooking and the like; the method can be used for emulsifying and removing wax, protein and fat in the cooking process of the chemical fiber pulp and has the advantages of improving the osmosis and dispersion of medicine liquid during cooking, controlling the decomposition speed of the cellulose, improving the alpha cellulose content, selectively removing a chromophoric group, improving half-stuff whiteness and bleachability, reducing LCC (Lignin-Carbohydrate Complex) and others, improving the chemical reaction performance and effectively lowering the raw material consumption and reducing the COD (Chemical Oxygen Demand), chroma and other indexes of the spent liquid during cooking.

Owner:YIBIN GRACE GROUP CO LTD

Material preparation process suitable for utilizing unbleached wood pulp to prepare dissolving pulp in modified mode

InactiveCN102677500AMonotonous performanceUniform shapePretreatment with alkaline reacting compoundsRaw material divisionFiberMaterials preparation

The invention discloses a material preparation process suitable for utilizing unbleached wood pulp to prepare dissolving pulp in a modified mode. The process comprises procedures of raw material preparation, dispersion, slicing, impregnation and the like. Specific to unbleached wood pulp raw materials, special process steps and process control parameters are utilized so that the purposes of improving quality of end products, energy saving and emission reduction can be achieved, armour fiber content, yield and whiteness of the end products can be improved, ash content of the end products is reduced, cost control of chemical liquid drug is facilitated, the curve of temperature rising in the follow-up cooking process is stable, poly reduction is even, prepared semi-finished products are suitable for various cooking modes, and the material preparation process has a wide application range.

Owner:YIBIN GRACE GROUP CO LTD

Semi-dull low-extensibility viscose fiber as well as preparation method and application thereof

InactiveCN104846456AGood air permeabilityImprove dye uptakeArtificial filament washing/dryingArtificial filaments from viscoseWoven fabricViscose fiber

The invention provides a semi-dull low-elongation viscose fiber as well as a preparation method and application thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, directional polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has an index system that the dry fracture strength is more than or equal to 3.10cN / dtex, the wet fracture strength is more than or equal to 1.60cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.55cN / dtex, the dry elongation at break is 12-14.5%, and the wet fracture extensibility is 16.0-21.0%. The semi-dull high-strength viscose fiber provided by the invention is prepared by virtue of technical innovation, is a novel fiber variety which has an index system different from that of ordinary viscose fibers and Modal fibers, shows high and strong fiber characteristics, and also shows skin affinity stronger than that of cotton fibers, so that the viscose fiber can effectively replace the existing differentiation viscose fiber, the development and the industrial upgrading of downstream novel textiles can be promoted while the processability of the downstream process of the viscose fiber is improved, and the semi-dull low-elongation viscose fiber can be well applied to the field of production of jean fabrics.

Owner:YIBIN GRACE GROUP CO LTD +2

Denatured production process of bamboo pulp for producing viscose fiber

InactiveCN102926256AUniform penetrationAvoid damagePretreatment with alkaline reacting compoundsXylanaseViscose fiber

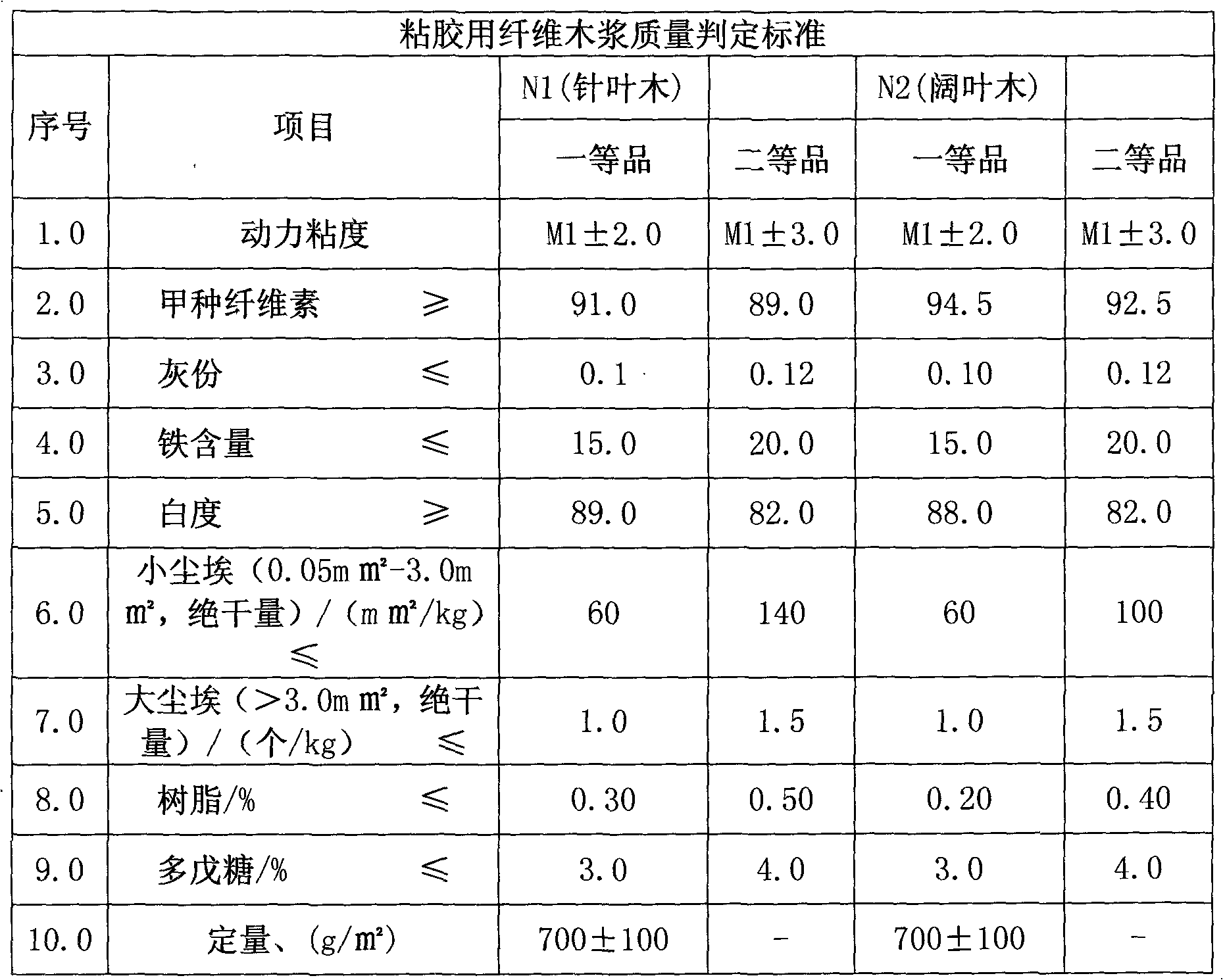

The invention discloses a denatured production process of bamboo pulp for producing viscose fiber, which is used for solving the problems of low methyl fiber, poor reactivity and the like. The denatured production process is characterized in that the process is carried out according to the following procedures of: crushing of pulp boards, preimpregnation of alkali, two-stage insulation and cooking, washing of materials, sand removal, bacterial xylanase treatment, bleaching, acid treatment and sorting; and the process parameters in the bacterial xylanase treatment are as follows: the PH value of pulp is less than 7-9, the temperature is 40-50 DEG C, the enzyme is diluted to be 0.125%, the reaction time is 1.5-2 hours, the concentration of the pulp is 5-8%, and the used amount of the enzyme is 45-80g / t. The bamboo pulp produced by adopting the process has the advantages that the content of methyl fiber is high, the pollution is little, individual viscose spinning of the viscose bamboo pulp product is successful, the filament-forming quality is excellent, the strength and the whiteness of the fiber are obviously improved, and all physical indexes reach the level of first-grade products in the GB / T14463-93 standard.

Owner:SWAN FIBER

Preparation method of decomposition agent for local straw returning to field

InactiveCN107586738AImprove decomposition efficiencyShort degradation timeFungiBacteriaTest tubeDecomposition

The invention discloses a preparation method of a decomposition agent for local straw returning to the field. The method comprises steps as follows: a bacillus subtilis agent fermentation broth is obtained from bacillus subtilis sequentially through slant culture of strains in a test tube, activating culture in a shake flask, fermentation in a seed tank and fermentation in a fermentation tank; anaspergillus niger agent fermentation broth is obtained from aspergillus niger sequentially through slant culture of strains in the test tube, activating culture in the shake flask, fermentation in theseed tank and fermentation in the fermentation tank; a trichoderma reesei agent fermentation broth is obtained from trichoderma reesei sequentially through slant culture of strains in the test tube,activating culture in the shake flask, fermentation in the seed tank and fermentation in the fermentation tank; a saccharomyces cerevisiae fermentation broth is obtained from saccharomyces cerevisiaesequentially through slant culture of strains in the test tube, activating culture in the shake flask, fermentation in the seed tank and fermentation in the fermentation tank; the bacillus subtilis agent fermentation broth, the aspergillus niger agent fermentation broth, the trichoderma reesei agent fermentation broth and the saccharomyces cerevisiae fermentation broth are mixed, and the decomposition agent for local straw returning to the field is obtained. The decomposition agent obtained with the preparation method has high decomposition efficiency and short decomposition time.

Owner:李琳

Cooking process for carrying out composite modification on natural color bamboo paper pulp and cotton paper pulp to form dissolving pulp

InactiveCN102677507ALow manufacturing costHigh fiber contentPulping with acid salts/anhydridesCellulose pulp after-treatment modificationViscose fiberDissolving pulp

The invention discloses a cooking process for carrying out composite modification on natural color bamboo paper pulp and cotton paper pulp to form dissolving pulp. The cotton paper pulp is fed into a digester by a conveyor to be separately cooked; the cooked cotton paper pulp is compounded with the natural color bamboo paper pulp which is subjected to material preparation; the composite paper pulp is fed into a continuous digester to be cooked; a continuous steaming pipe of the continuous digester is provided with three sections; the section connected with a pre-reaction bin is provided with a steam pipe and a T-shaped pipe; the other two sections are provided with steam pipes; steam is filled into the continuous digester through the steam pipes; and alkali liquor is added into the continuous steaming pipe by the T-shaped pipe. According to the invention, the natural color bamboo paper pulp and the cotton paper pulp are used as the raw materials, so that the cost of preparing the dissolving pulp is reduced to a great extent and the quality requirement of the dissolving pulp for viscose is also met.

Owner:YIBIN GRACE GROUP CO LTD

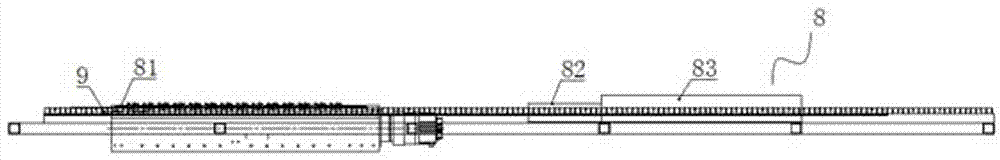

Planetary filter pressing roller belt type deep dehydrator and application method thereof

PendingCN114133127AIncrease moisture contentSolving Disposal ProblemsSludge treatmentGear wheelControl engineering

The invention provides a planetary filter pressing roller belt type deep dehydrator and an application method thereof, the whole equipment provided by the invention adopts a modular design, and the whole equipment is divided into three modules, namely a feeding module, a filter pressing module and a discharging module. The feeding module comprises a material distributing mechanism, an intelligent speed adjusting mechanism, a tensioning mechanism and a gear and rack synchronous tensioning mechanism. The filter pressing module comprises a filter belt tensile deformation monitoring mechanism, a deviation rectifying mechanism, a squeezing mechanism and an automatic cleaning mechanism; the discharging module comprises a driving device and a flushing mechanism. By flexibly adjusting the position of the main compression roller and the using number of the planetary rollers, the pressure acting on materials reaches the ultimate pressure resistance of the materials, pressurized deep dehydration is achieved, and the problem of solid waste disposal is solved.

Owner:上海凌逍环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com