Cooking aid for preparing chemical fiber pulp

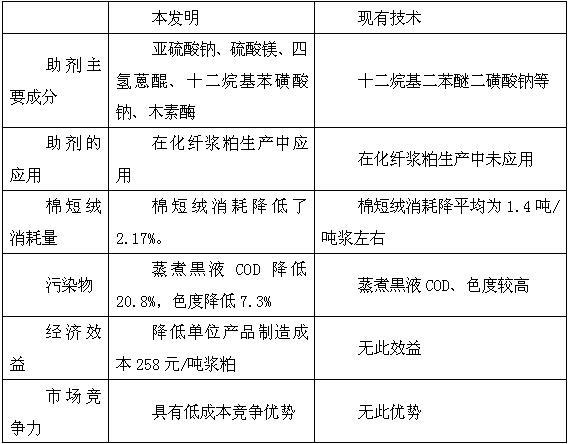

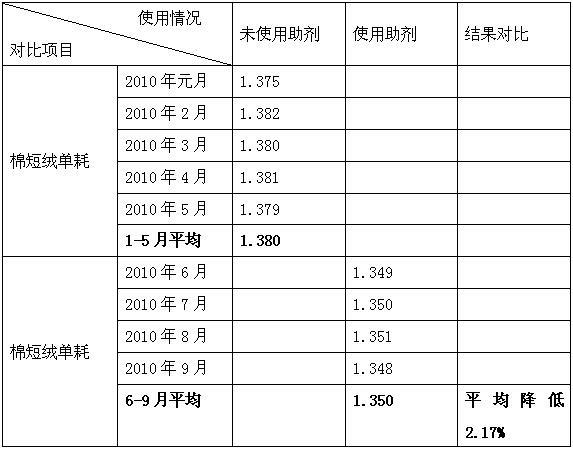

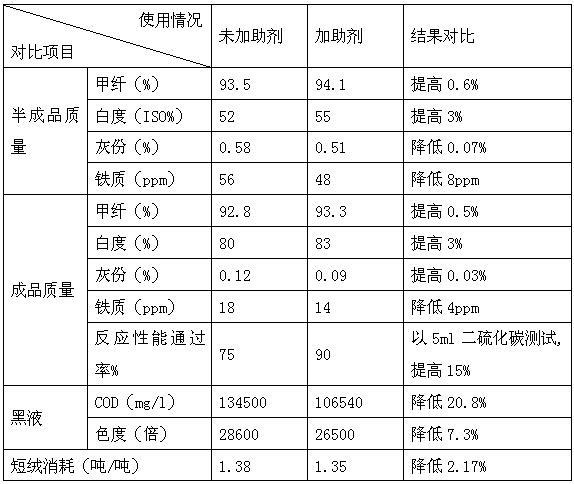

A cooking aid and chemical fiber pulp technology, which is applied in the fields of cellulose raw material pulping, fiber raw material processing, textile and paper making, etc., can solve the problems of insufficient environmental protection, and the cooking aid cannot be cooked with chemical fiber pulp, so as to save resources. , Improve chemical reaction performance, improve the effect of half pulp whiteness and bleachability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A. Cotton opening: Add cotton linters into the cotton opener, after being shredded by large and small licker-in rollers, it is blown into the cyclone separator by air;

[0039] B. Configure environmentally friendly cooking compound additives: weigh sodium sulfite, magnesium sulfate, tetrahydroanthraquinone, sodium dodecylbenzenesulfonate, and ligninase according to the following weight percentages: sodium sulfite 3%, magnesium sulfate 10%, 50% tetrahydroanthraquinone, 30% sodium dodecylbenzenesulfonate, 7% ligninase; uniformly mix solid-phase sodium sulfite, magnesium sulfate, tetrahydroanthraquinone and sodium dodecylbenzenesulfonate to prepare into compound additives;

[0040] C. Configure environment-friendly cooking compound auxiliary liquid: add the compound auxiliary with a weight of 0.3% of the weight of cotton linters into the auxiliary dissolving tank filled with water 4 times the weight of the compound auxiliary, and then add it to step B The weighed ligninas...

Embodiment 2

[0045] A. Cotton opening: Add cotton linters into the cotton opener, after being shredded by large and small licker-in rollers, it is blown into the cyclone separator by air;

[0046]B. Configure environmentally friendly cooking compound additives: weigh sodium sulfite, magnesium sulfate, tetrahydroanthraquinone, sodium dodecylbenzenesulfonate, and ligninase according to the following weight percentages: sodium sulfite 20%, magnesium sulfate 1%, 60% tetrahydroanthraquinone, 15% sodium dodecylbenzenesulfonate, 4% ligninase; uniformly mix solid-phase sodium sulfite, magnesium sulfate, tetrahydroanthraquinone and sodium dodecylbenzenesulfonate to prepare into compound additives;

[0047] C. Configure environment-friendly cooking compound auxiliary liquid: add the compound auxiliary with a weight of 5% of the weight of cotton linters into the auxiliary dissolving tank filled with water 7 times the weight of the compound auxiliary, and then add it to step B The weighed ligninase i...

Embodiment 3

[0052] A. Cotton opening: Add cotton linters into the cotton opener, after being shredded by large and small licker-in rollers, it is blown into the cyclone separator by air;

[0053] B. Configure environmentally friendly cooking compound additives: weigh sodium sulfite, magnesium sulfate, tetrahydroanthraquinone, sodium dodecylbenzenesulfonate, and ligninase according to the following weight percentages: sodium sulfite 20%, magnesium sulfate 10%, 55% tetrahydroanthraquinone, 5% sodium dodecylbenzenesulfonate, 10% ligninase; uniformly mix solid-phase sodium sulfite, magnesium sulfate, tetrahydroanthraquinone, sodium dodecylbenzenesulfonate, and prepare into compound additives;

[0054] C. Configure environment-friendly cooking compound auxiliary liquid: add the compound auxiliary with a weight of 2.7% of the weight of cotton linters into the auxiliary dissolving tank filled with water 5 times the weight of the compound auxiliary, and then add it to step B The weighed ligninas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com