Patents

Literature

50results about How to "Improve bleachability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

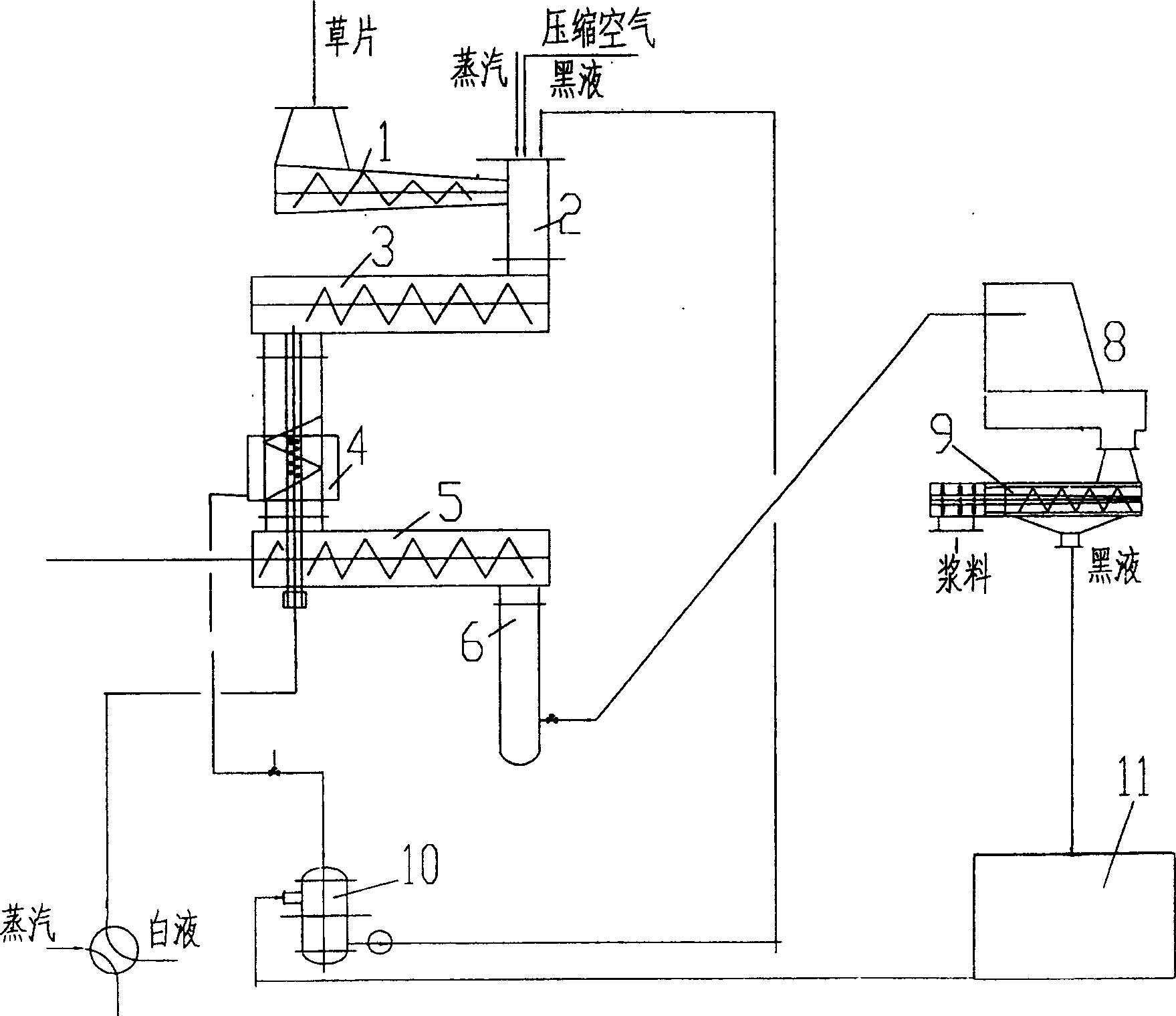

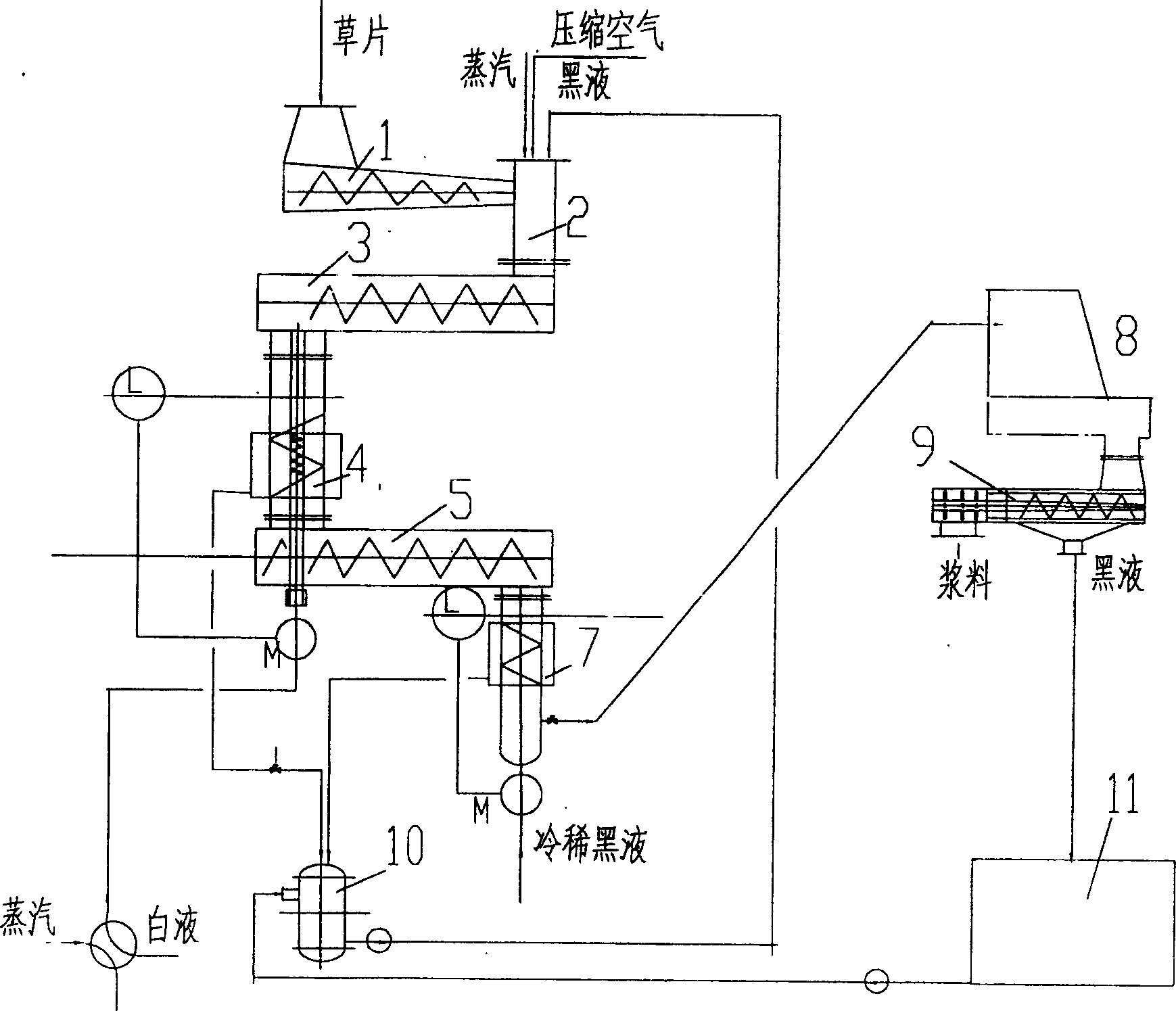

Environmentally-friendly paper making and pulping technique and system with high yield

InactiveCN102242512AReduce adverse effectsImprove wettabilityPretreatment with water/steamPretreatment with alkaline reacting compoundsFiberBlack liquor

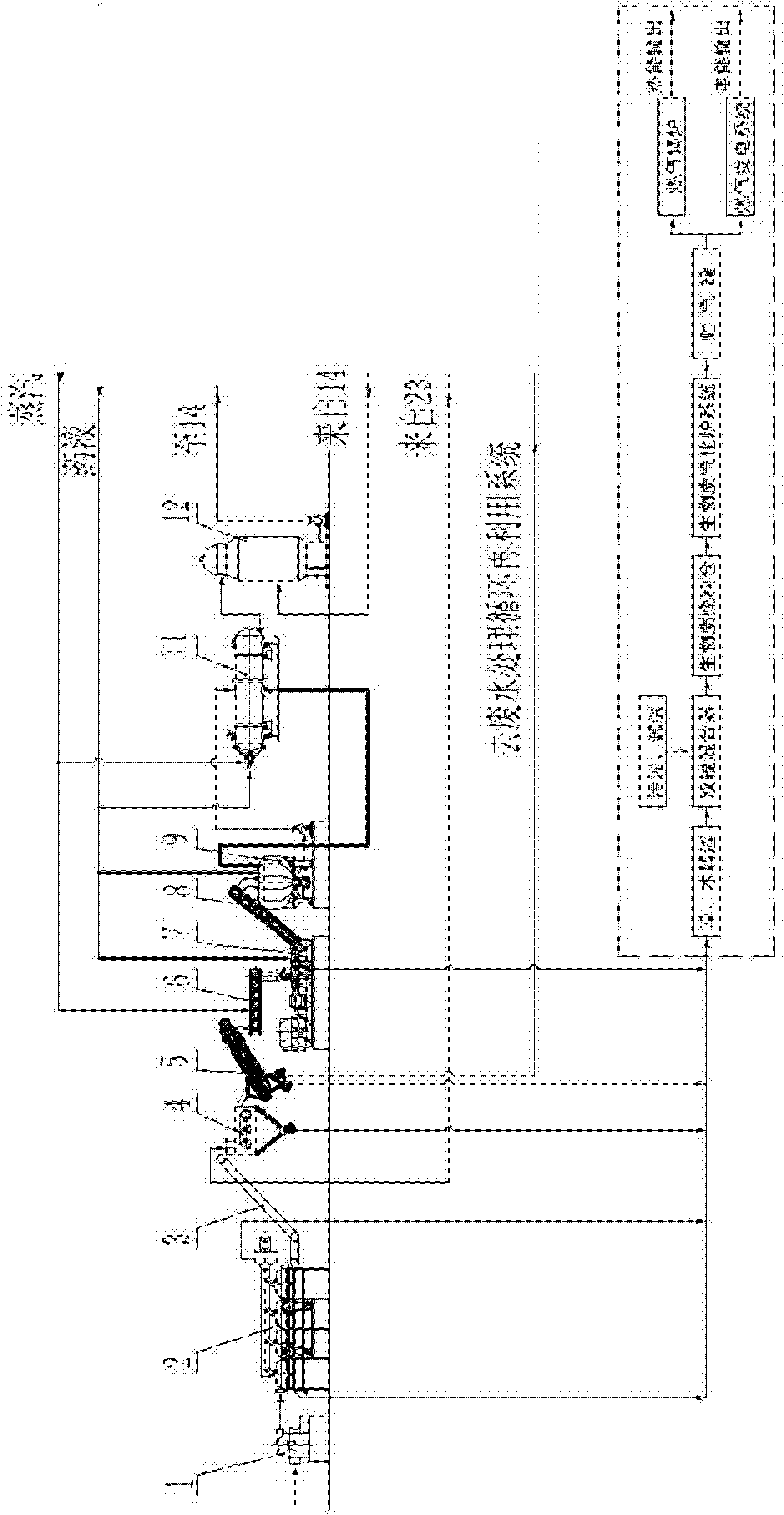

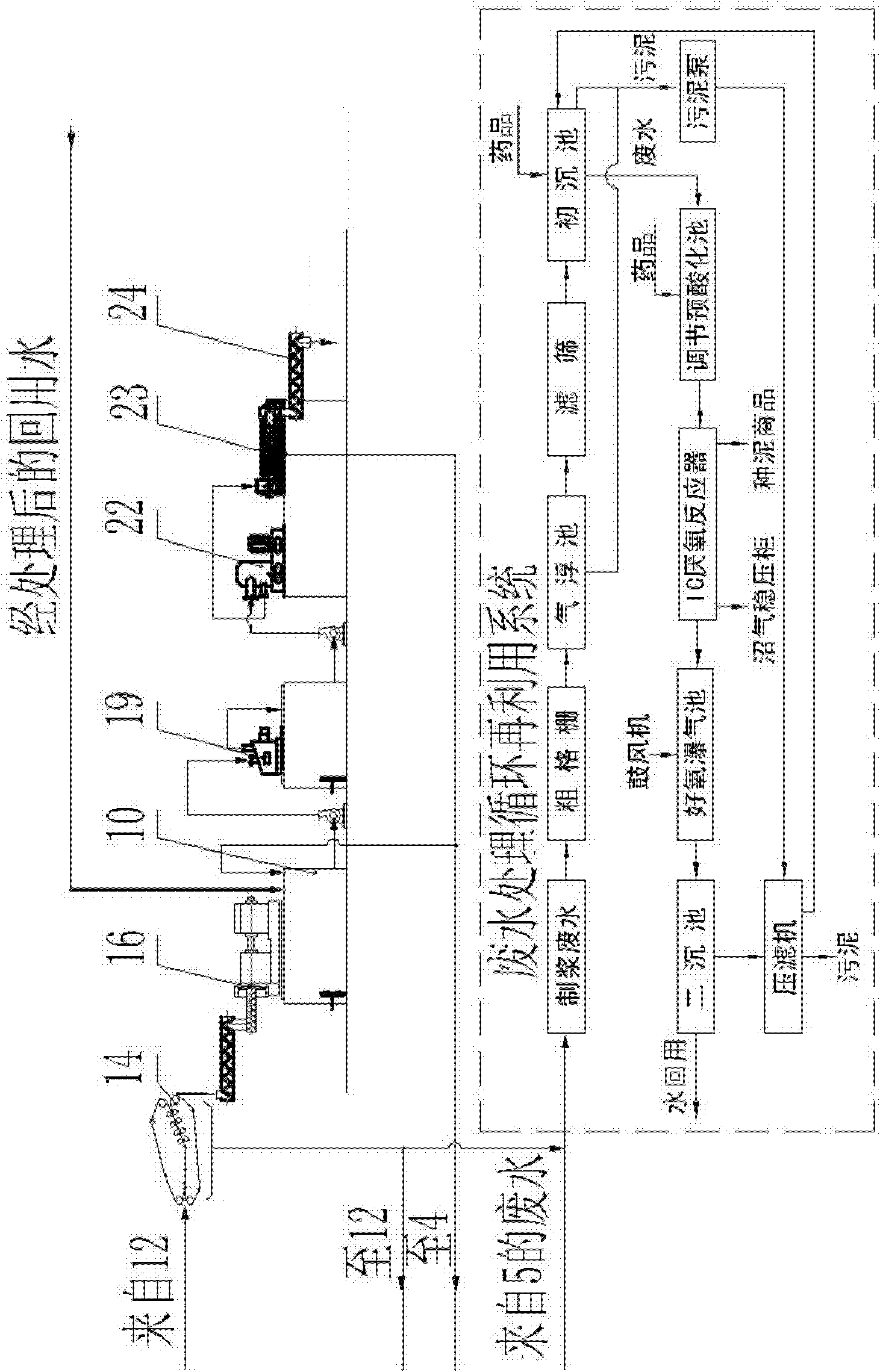

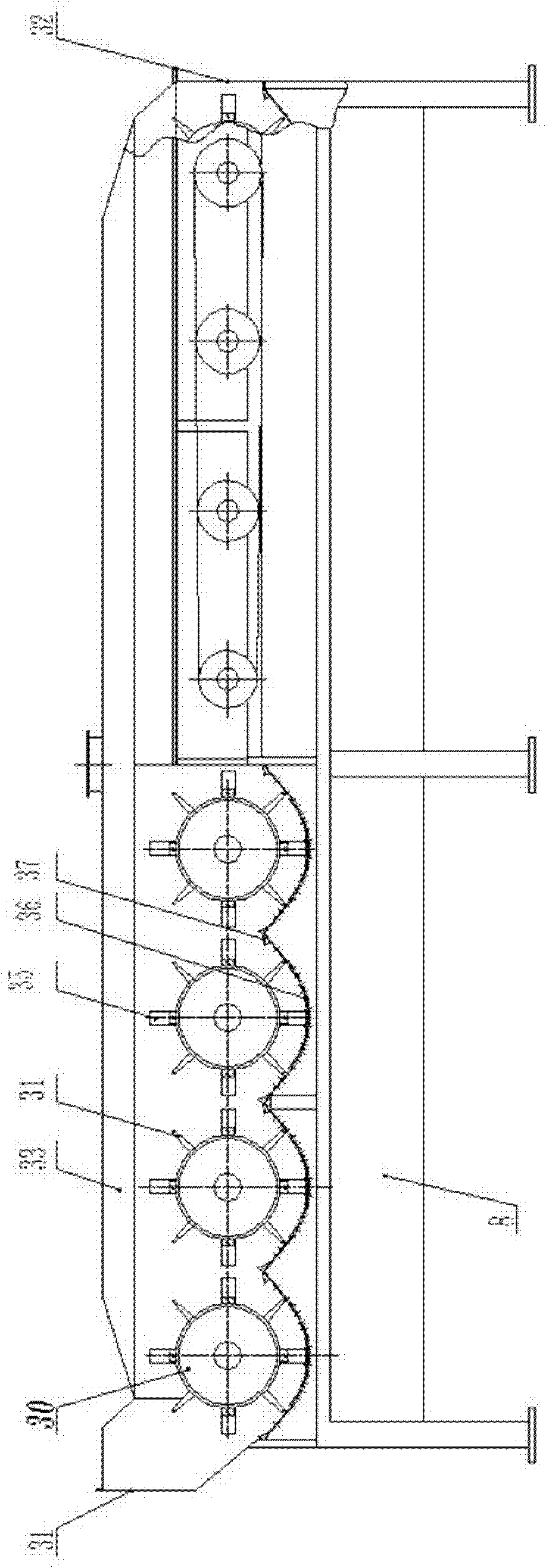

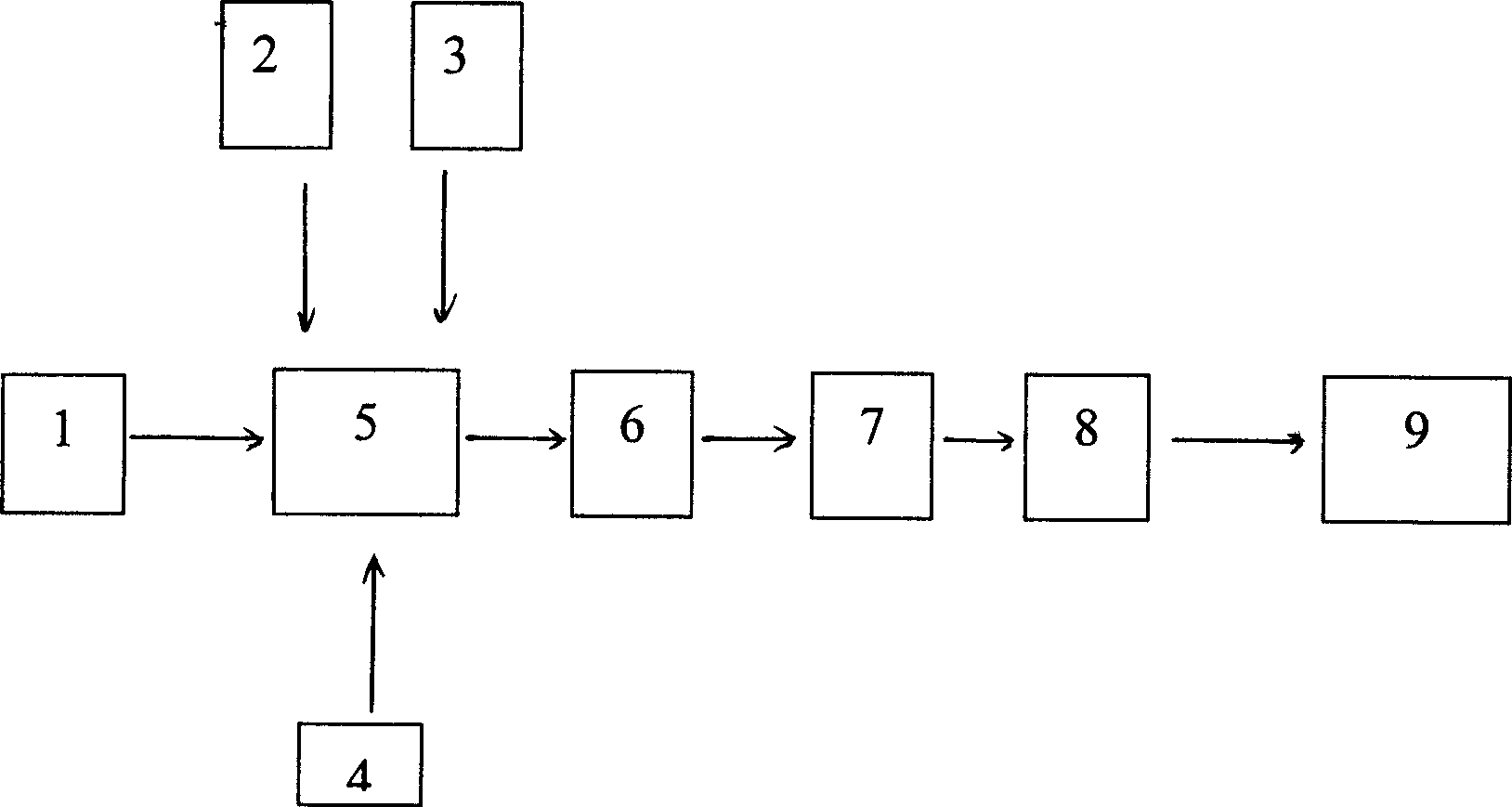

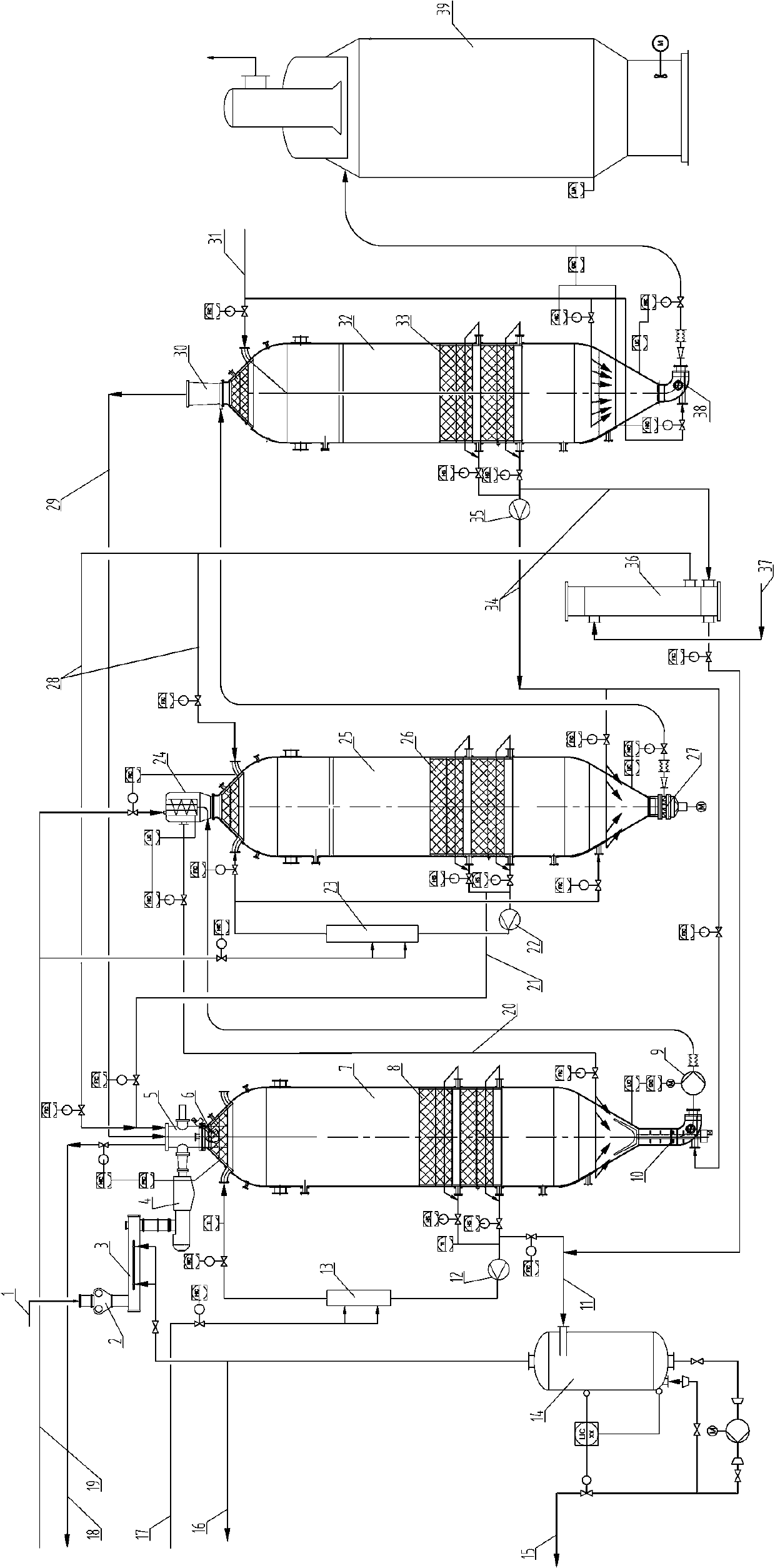

The application of the invention provides an environmentally-friendly paper making and pulping technique with high yield, which comprises a raw material preprocessing stage, a physical fibrillation impregnating processing stage, an impregnating, steaming and bleaching three-section integrated pulping stage and a thickening and dewatering processing stage. An environmentally-friendly paper making and pulping system with high yield realizing the pulping technique comprises a stock cutter, a hammering and fibrillation screening dust remover, a washing dust remover, dewatering conveying equipment, a spiral steaming conveyor, a crashing, extruding and impregnating machine, a stirring and impregnating cabin, a pump pipe and a discharge pipe of a high-enriched steaming, bleaching and pulping all-in-one machine, wherein the pump pipe is connected to the high-enriched steaming bleaching pulping all-in-one machine; the discharge pipe of the high-enriched steaming, bleaching and pulping all-in-one machine is connected to a pulp cabin; the pump pipe of the pulp cabin is connected with a thickening and dewatering machine; the thickening and dewatering machine is output to the high-enriched pulping machine; the output of the high-enriched pulping machine is connected with a screening purifier and a thickening and squeezing machine in sequence. In the invention, the problems of high pollution, high energy consumption, serious shortage of paper making raw material and the like in present pulping and paper making industry can be solved fundamentally; rich plant fiber in the nature can be used, and the technical purposes of efficient bleaching, high yield, no black liquor and low energy consumption can be realized.

Owner:李刚荣 +1

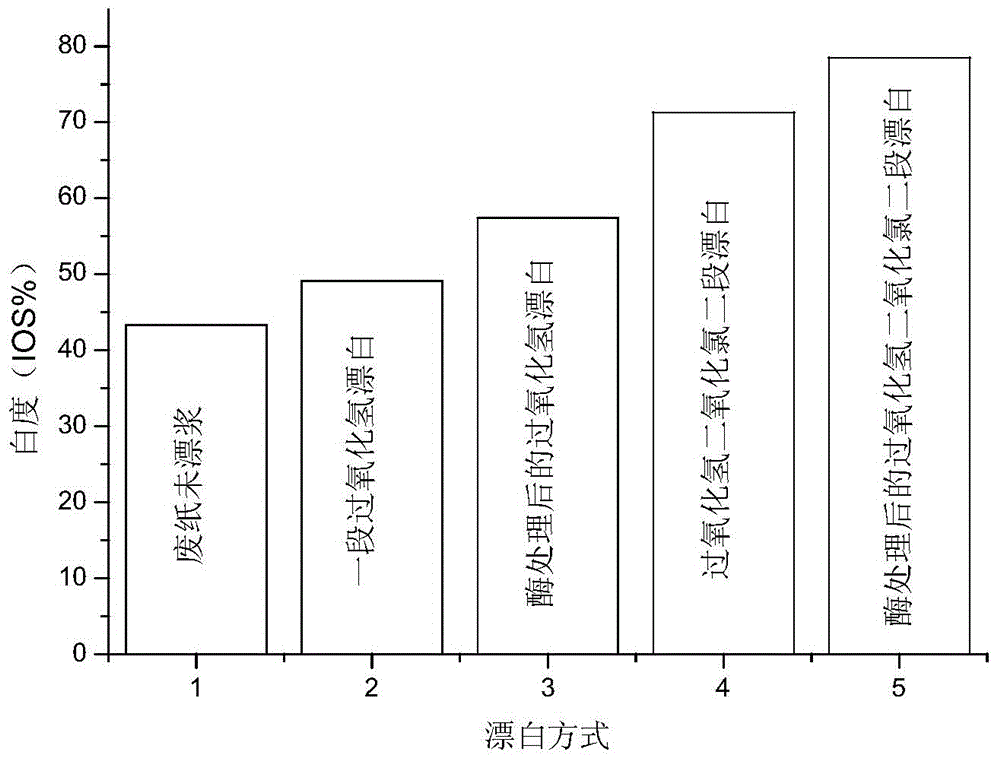

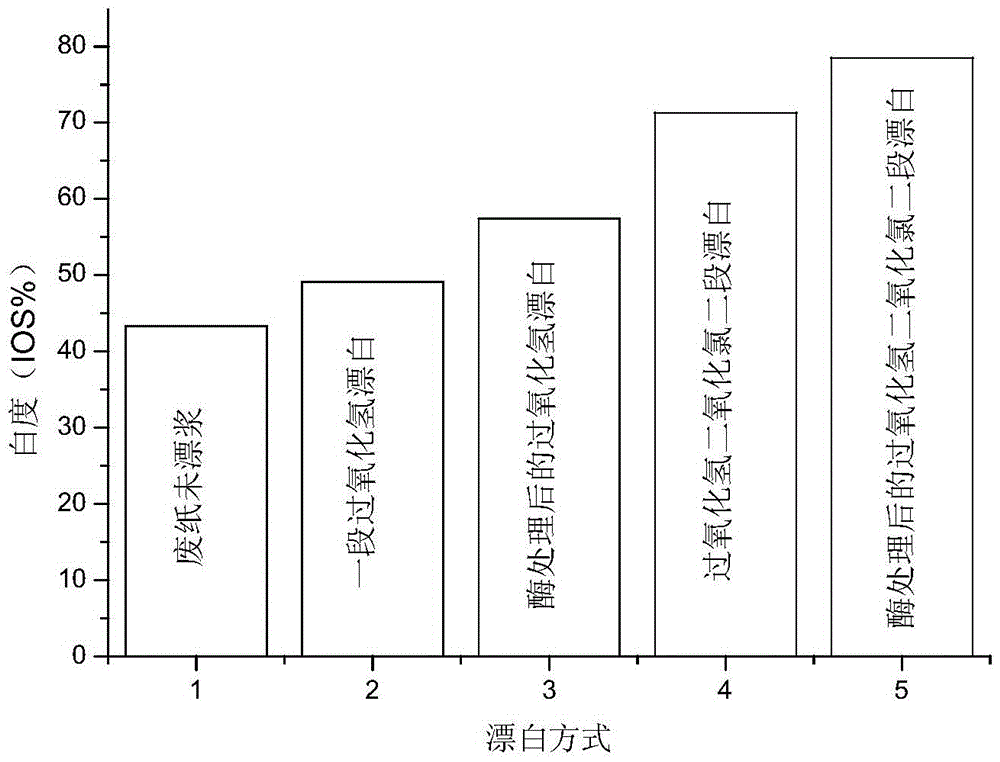

Deinking Technique for news bogus paper through enzyme

InactiveCN1563567AImprove bleachabilityPaper recyclingChemical paints/ink removersDeinkingPulp and paper industry

A waste new print zyme deinking technology includes crushing the pulp, deinking, suspension selection, washing, bleaching among which, deinking agent, laccase, amboceptor are added into the pulped with waste newsprints and waster to be inlet with oxygen and the pulp concentration is controlled at 3%-18%, temperature 20-70deg.C pulping, keeping warmth.

Owner:QILU UNIV OF TECH

Process for enzyme treating before pulping by plant fibre raw material

InactiveCN1793488AAvoid degradationHigh strengthFinely-divided material pretreatmentLiquid ratioPlant fibre

The invention relates to an enzyme processing method before plant fiber raw material pulping. It belongs to paper making field. The includes the following steps: mixing plant fiber raw material and biological enzyme; the biological enzyme contains 0.5-50LAMU laccase, 0.1-5% mediator, and / or 0.5 -50IU xylanase per gram raw material; adding water to make raw material liquid ratio be 1: 4.5-5.5; mechanical grinding the processed enzyme; adding water to make liquid ration be 1:5.5-9.5; and injecting oxygen for 0.5-8h. The processed material can be used to do traditional chemical or mechanical pulp. This can greatly improve paper pulp strength and whiteness.

Owner:QILU UNIV OF TECH

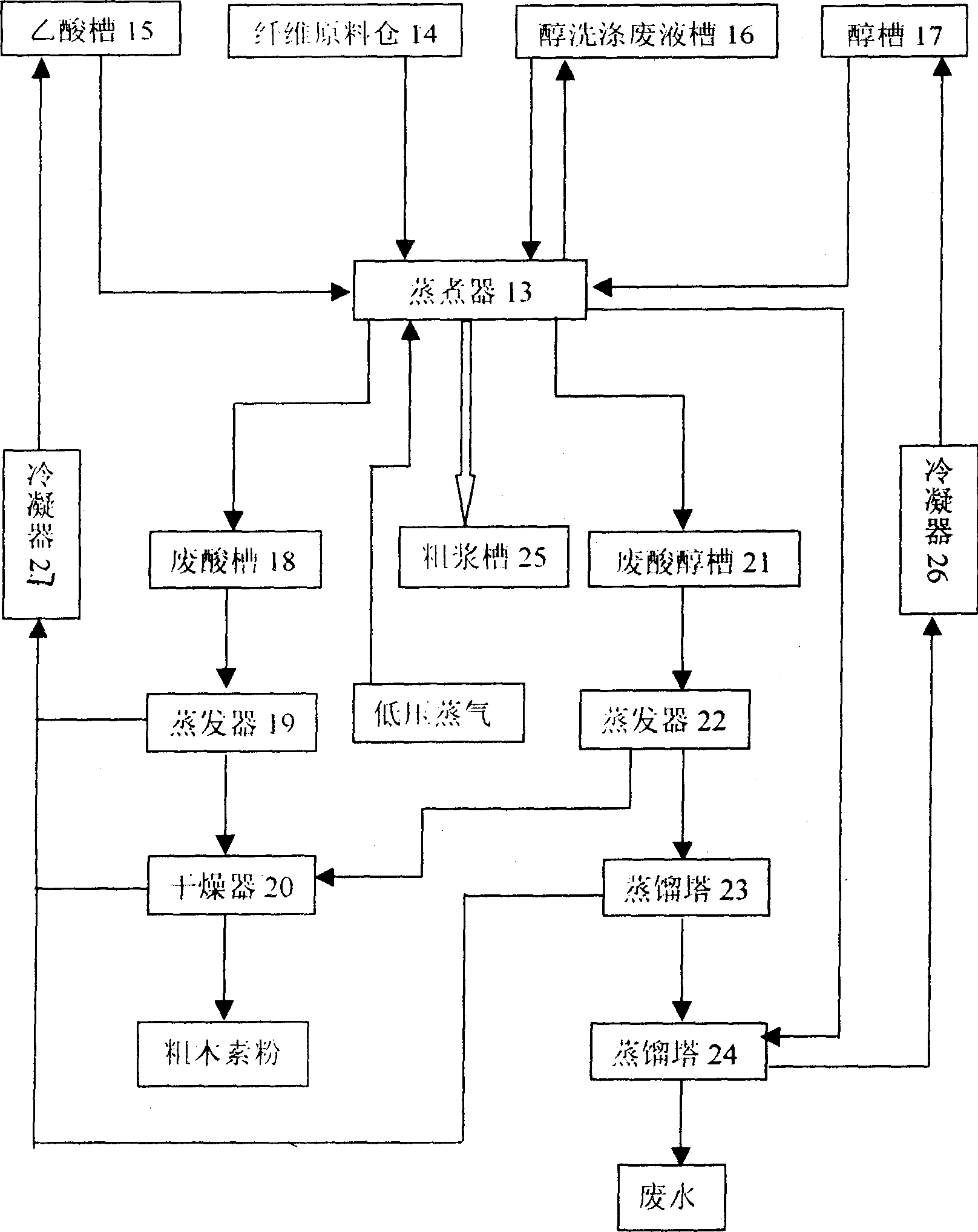

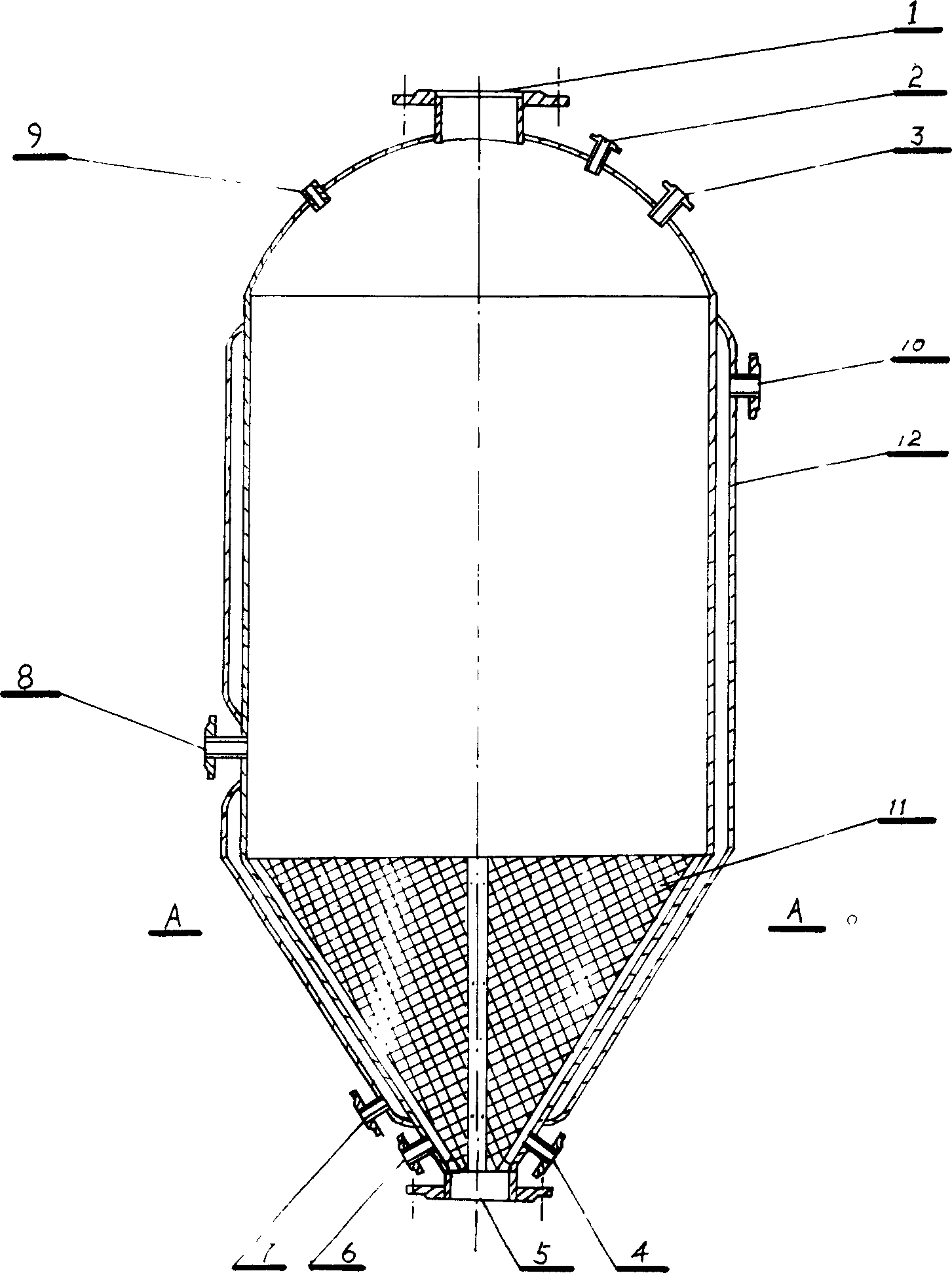

Pulping method of non-wood fibers with no black liquor drained off as well as its boiler

InactiveCN1445412AThe process is simpleGood protectionDigestersCellulose material pulpingCondensed waterChemistry

A process for preparing the pulp of non-woven fibres without black liquid drainage includes such steps as adding raw fibres and acetic acid into the enclosed digester, heating, holding the temp for acertain time, filtering to obtain waste acidic liquid, pumping it to waste acid tank, adding the washing alcohol solution, heating, holding the temp for a certain time, filtering the waste acid-alcohol solution, pumping it to waste acid-alcohol tank, washing fibres with clean alcohol, draining the washing liquid to waste liquid tank, stripping alcohol from fibres by low-pressure steam, adding hotwater to digester, and discharging raw pulp. Said digester has a jacket with steam inlet and condensed water outlet and a filter net at the discharge port.

Owner:SHENGBANG SCI & TECH MIANYANG

Cold-immersion mechanical pulping process for xyloid raw materials

InactiveCN1865582AImprove bleachabilityQuality improvementPulp bleachingPulping with inorganic basesYarnHigh density

The invention discloses a new paper making pulping technology of wood raw material cold-maceration machinery, which comprises the following steps: 1. grinding wood raw material into yarn or dividing yarn through grinding-abrading machine; 2. proceeding cold immersing the raw material in the pool for 1-3 h; 3. washing and shoving; 4. dosing and heating two segmented high-density pulp to bleach; 5. keeping temperature to bleach; 6. washing to extract white to produce high-whiteness paper. The invention saves energy without waste water and gas, which produces high-quality low-cost paper for paper making industry.

Owner:SHANDONG HUALIN ENVIRONMENTAL PROTECTION TECH +1

Middle-or low-pressure exposion method for making pulp with broad-leaf wood

A low-and medium-pressure blasting method for pulping the broad-leaf wood includes proportioning the alkali (1-6 wt%), Na-S compound (1-16 wt%), assistant (0-1 wt%) and broad-leaf wood (rest), stirring at ordinary temp -90 deg.C for 0-24 hr, treating at 140-220 deg.C and 0.8-2.28 MPa for 3-15 min, and sudden blasting. Its advantages are high strength, output rate, whiteness, toughness and rinsability, and low energy consumption.

Owner:SOUTH CHINA UNIV OF TECH +1

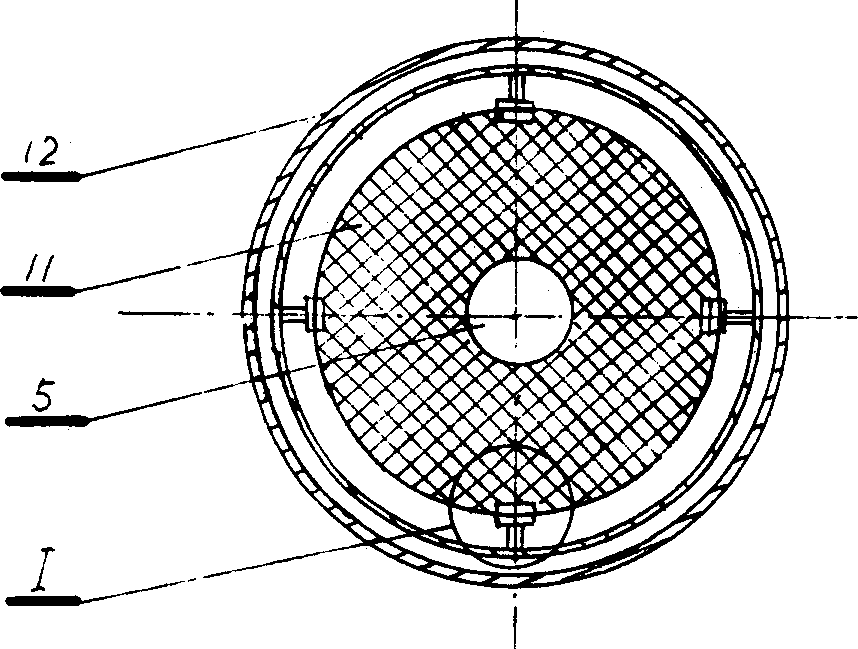

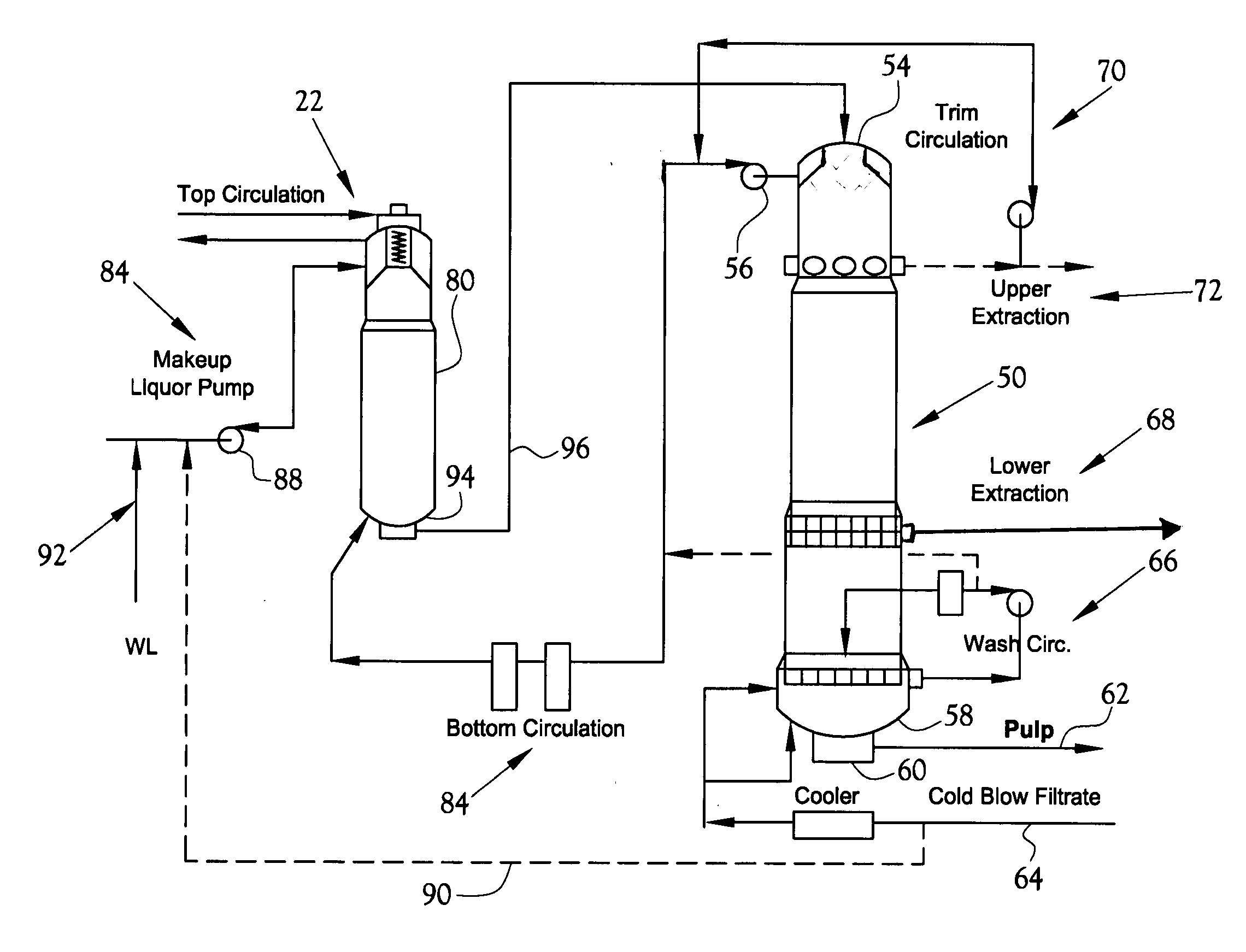

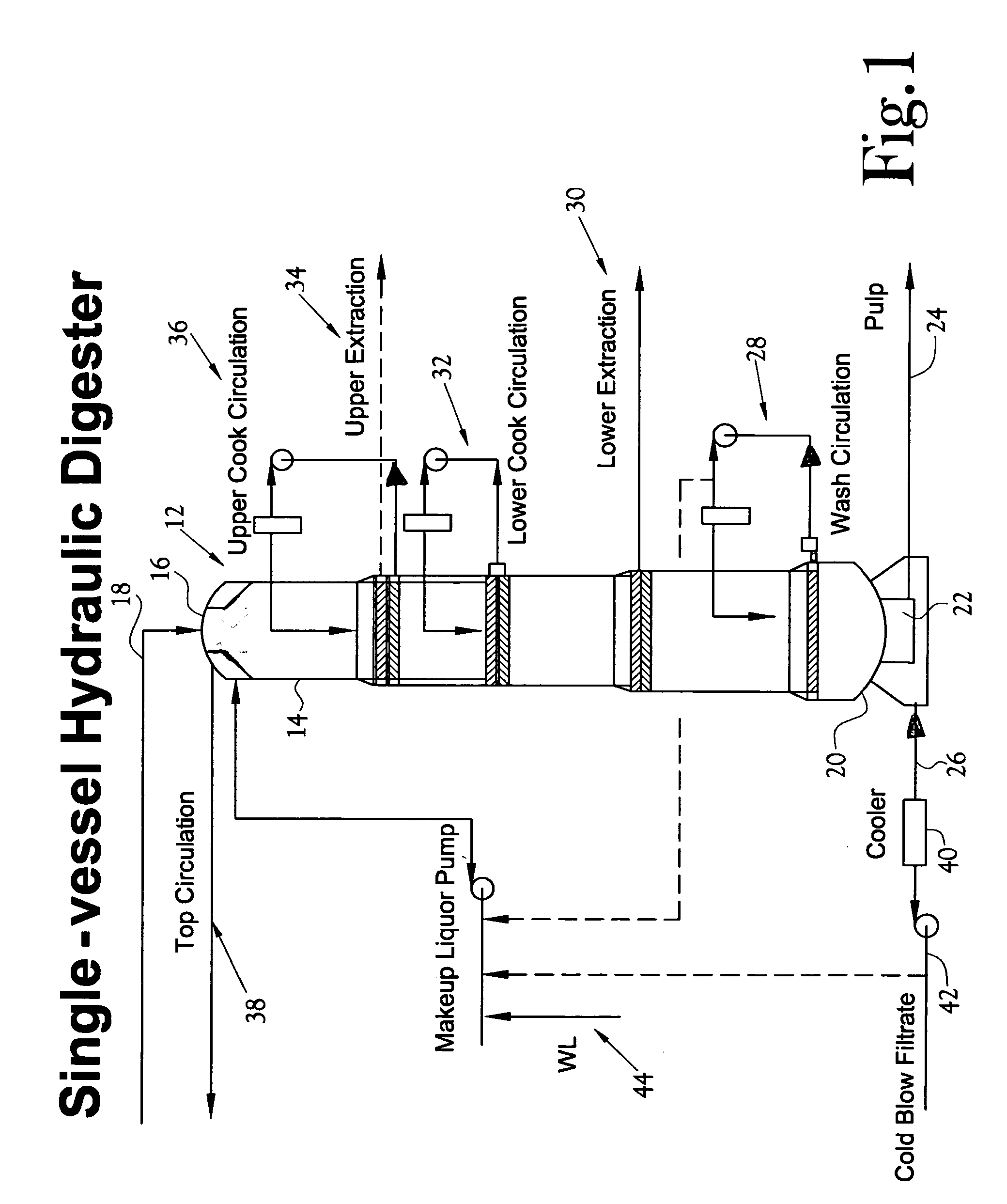

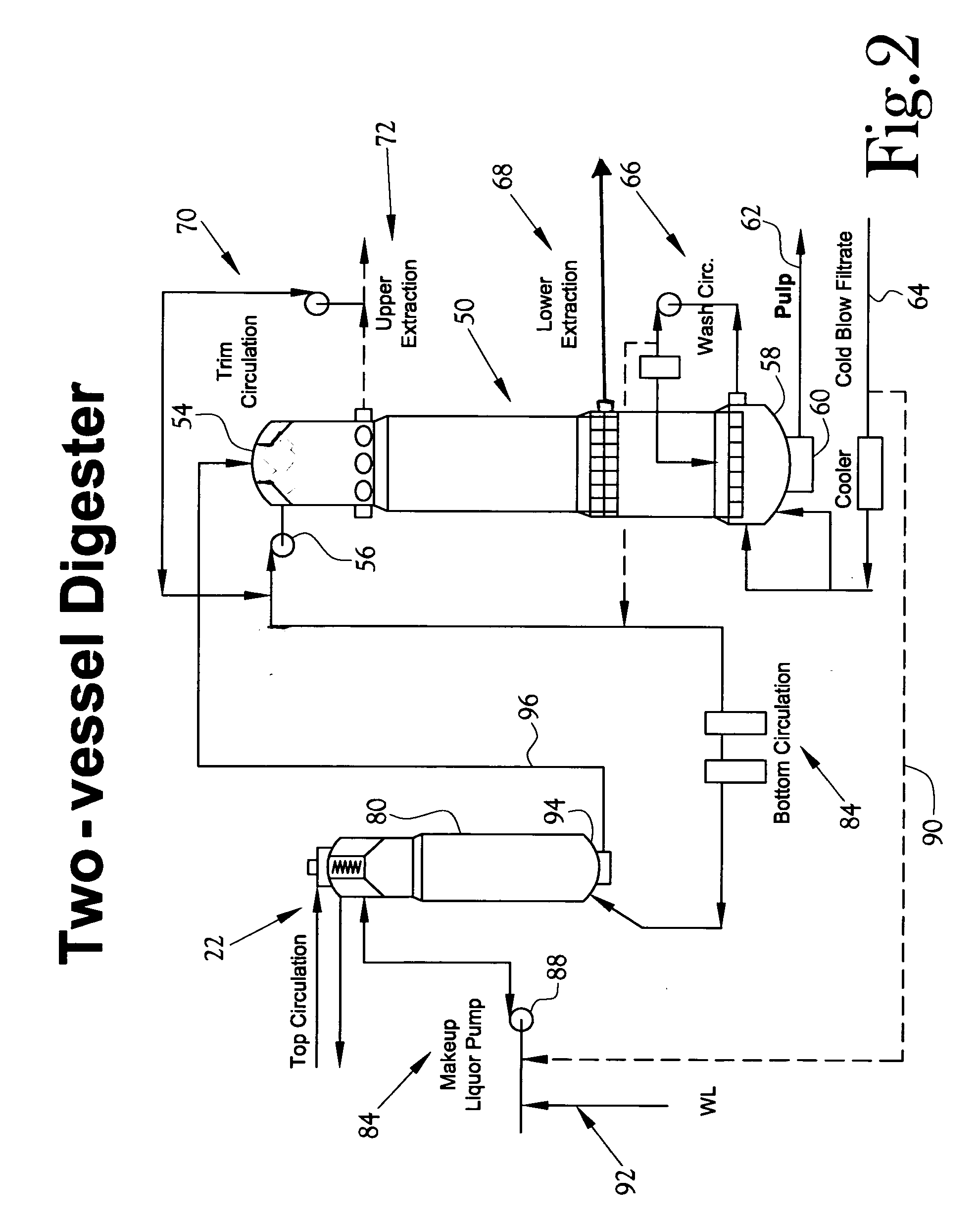

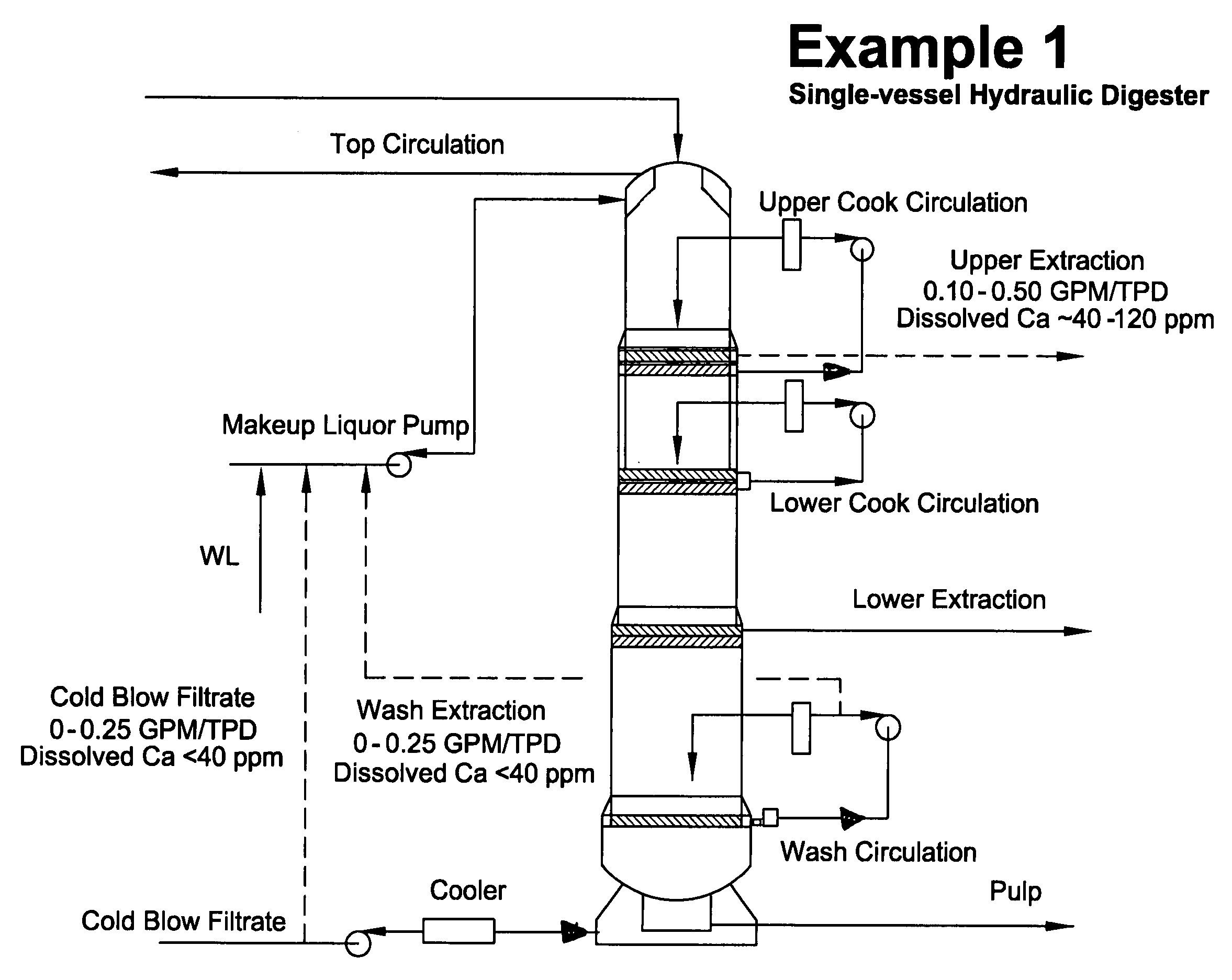

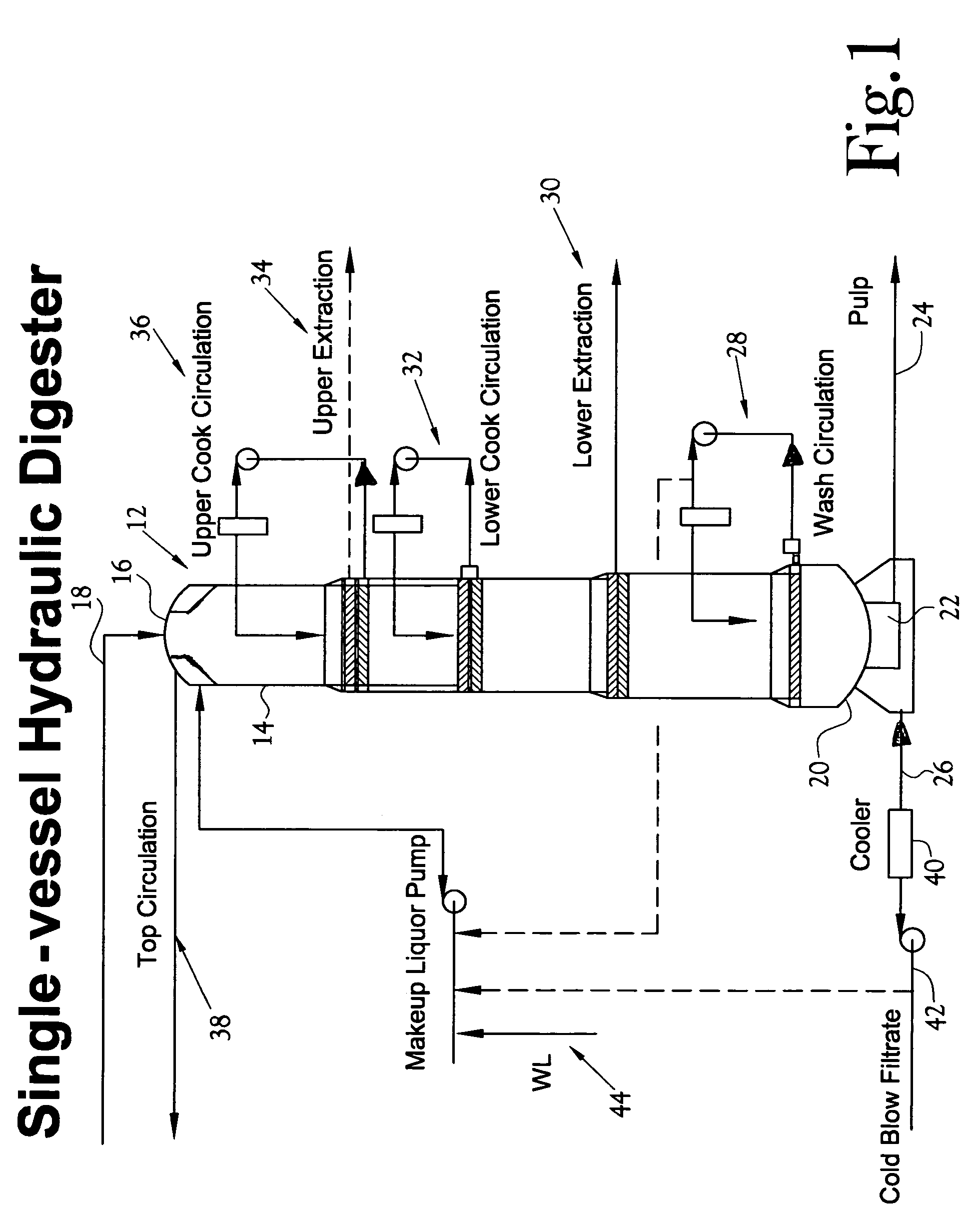

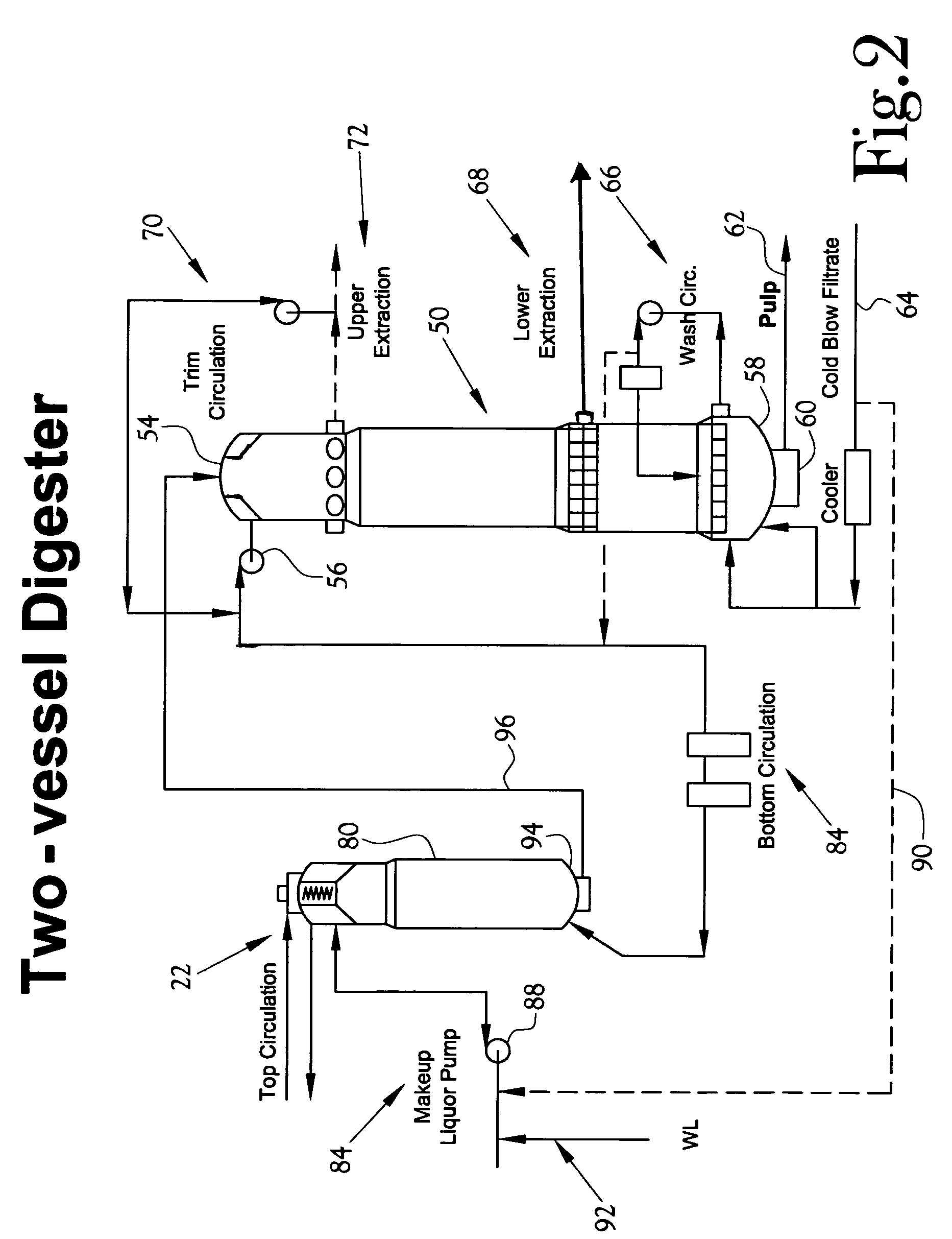

Methods to decrease scaling in digester systems

ActiveUS20050284592A1Reduced calcium carbonate scalingReduction in pulping energy requirementPulp liquor regenerationDigestersCalcium concentrationChemistry

One aspect of this invention relates to a method and digester for reducing the deposition of calcium-based scale in a wood chip digester including extraction from the digester of first and second quantities of cooking liquor having respective first and second calcium concentrations, treating the extracted cooking liquors to produce a cooking liquor having a calcium concentration less that the calcium concentration of the either of the first and second extracted cooking liquors, and, reintroducing the treated cooking liquor to the digester. Another aspect of this invention relates to a method and digester in which through put through the digester is increased by the continuous addition of process liquor into the digester preferably at an upper region of the digester.

Owner:INT PAPER CO

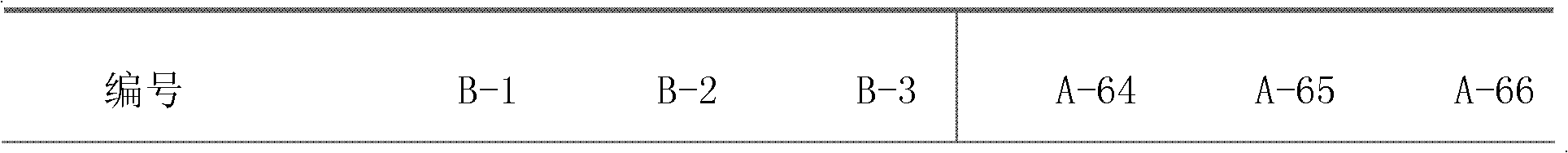

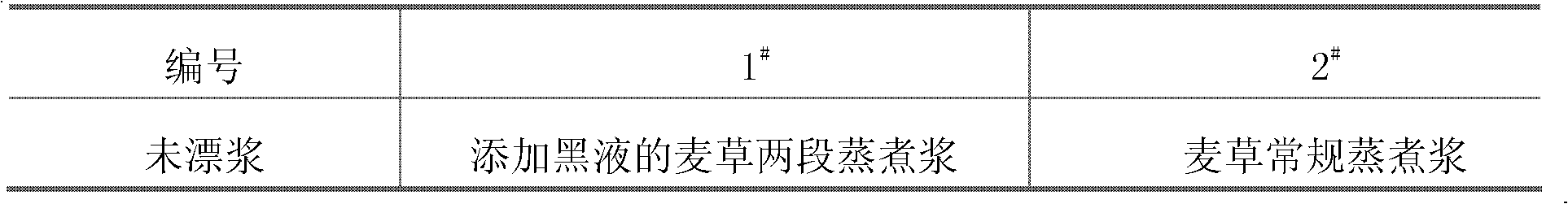

Method for cooking grass raw materials at two stages with soda anthraquinone by adding black liquor

InactiveCN102154873AUniform and stable yieldHigh yieldPulp bleachingPulping with inorganic basesKappa numberBlack liquor

The invention discloses a method for cooking grass raw materials at two stages with soda anthraquinone by adding black liquor. According to the characteristic of quick delignifying of the grass raw materials by adopting alkaline cooking, low temperature and normal pressure are adopted in a first stage, and black liquor is added for cooking at the two stages. A cooking result indicates that the Kappa number of paper pulp, the yield of screened pulp, the residual alkali in the black liquor and the like are uniform and stable, and stable operation can be realized. Compared with the conventional soda anthraquinone cooking method, the two-stage cooking method disclosed by the invention has the advantages: operation can be performed under low temperature condition, and the alkali amount is reduced, the yield of screened pulp is increased and the residue sieving rate is low under the condition that the Kappa number is basically the same. Moreover, O-DQ-P and O-Q-P-P bleaching are performed on pulp obtained by using the two-stage cooking method and the conventional soda anthraquinone cooking method, and the physical property of the pulp is detected. A result indicates that the whiteness and the viscosity of bleach pulp obtained by the two-stage cooking are higher than those of bleach pulp obtained by the conventional cooking, and the bleach pulp has better bleachability and higher mechanical intensity, and can be used for making writing paper, offset printing book paper and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Microwave method for preprocessing pulping raw material

InactiveCN1696396AHigh yieldReduce hardnessRaw material pretreatmentPretreatment methodMicrowave method

The invention relates to a microwave pretreatment method of raw material for making pulp. It is characterized by that firstly, it utilizes microwave to make radiation treatment of material sheet of plant raw material for making pulp by traditional process. After the material sheet of plant raw material is treated by microwave radiation, the relatively-closed internal physical structure channel of plant raw material can be improved, it is favorable for quick and uniform penetration of chemicals for making pulp so as to raise pulp quality.

Owner:HUBEI UNIV OF TECH

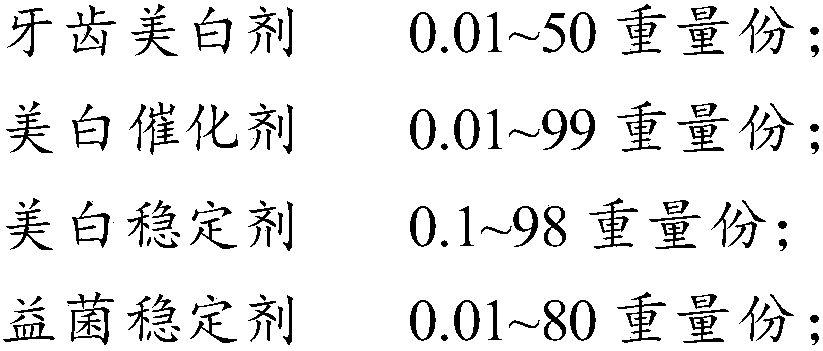

Whitening and tooth-strengthening toothpaste and preparation method thereof

InactiveCN107753325AImprove bleachabilityReduce dosageCosmetic preparationsToilet preparationsCelluloseRare-earth element

The invention provides whitening and tooth-strengthening toothpaste which contains the following components in parts by weight: 0.01-50 parts of a tooth whitening agent, 0.01-99 parts of a whitening catalyst, 0.1-98 parts of a whitening stabilizer and 0.01-80 parts of a probiotics stabilizer. Compared with the prior art, by adding the tooth whitening agent, the whitening catalyst and the whiteningstabilizer into the toothpaste, the tooth whitening agent has powerful decoloration action to blotches and uranidin on the surfaces of teeth; as rare earth elements are taken as the whitening catalyst, dirty colored substances on the teeth are activated, so that the dosage of the tooth whitening agent is reduced; under the action of the probiotics stabilizer, the biological whitening agent can decompose food cellulose in the uranidin, so that the tooth whitening agent penetrates into the uranidin more easily to achieve the purpose of deep whitening or reduce the dosage of the tooth whiteningagent; and the whitening agent and the rare earth elements are effective sterilizing substances, so that wound of damaged skin is astringed, inflammation is diminished, bacteria are killed, and splitting and growth of cells are promoted.

Owner:吉林省亨泰服装洗染科学技术研究所

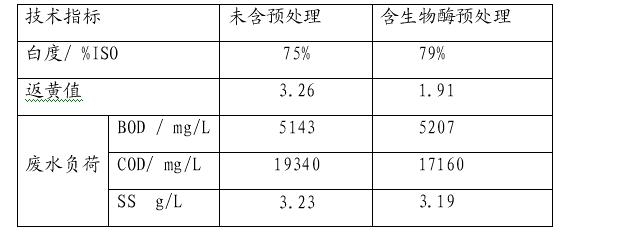

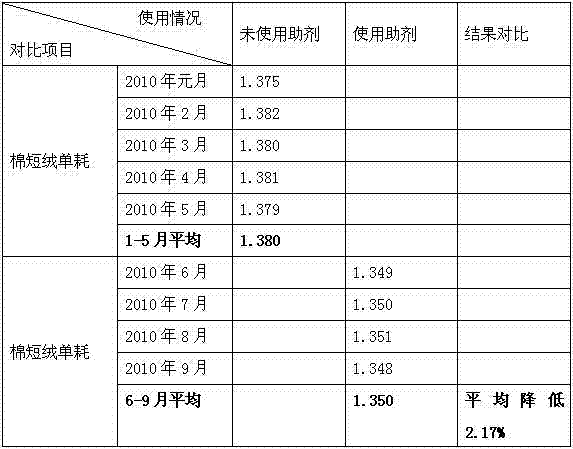

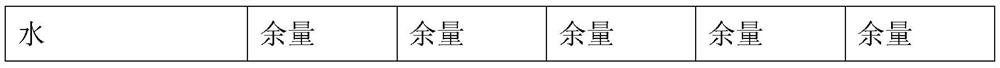

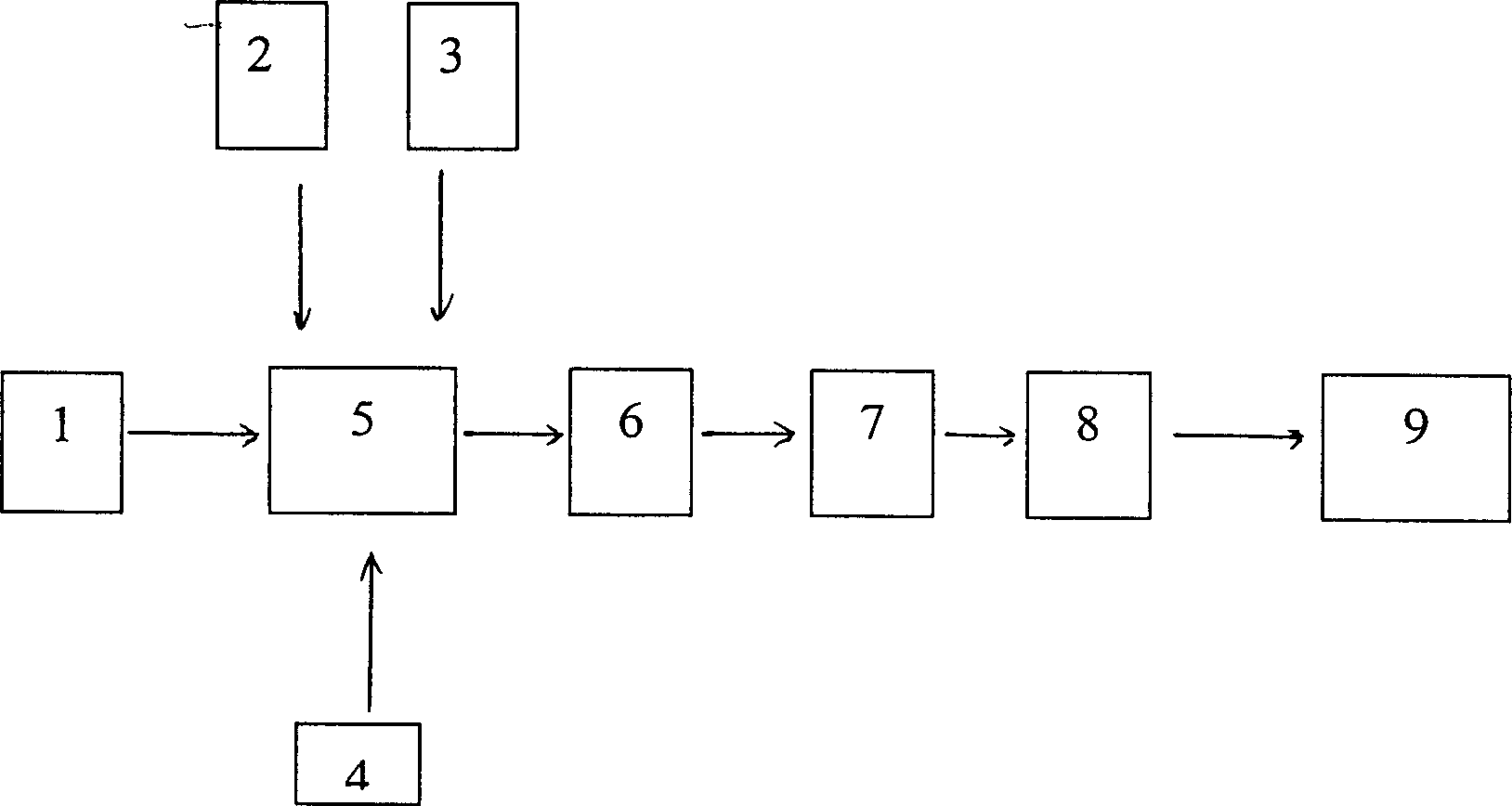

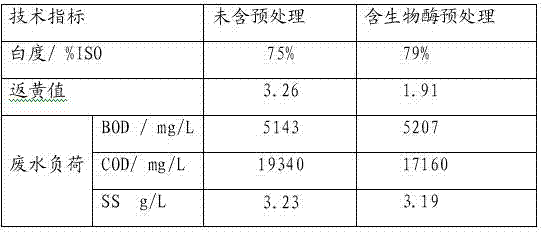

Pretreatment process for cleaning and bleaching chemical mechanical pulp

ActiveCN102154886AImprove bleachabilitySolve the problem of easy yellowingPulp bleachingChemical/chemomechanical pulpActive agentWastewater

The invention relates to a cleaning and bleaching technology suitable for chemical mechanical pulp, particularly alkaline peroxide mechanical pulp (APMP). The process is mainly characterized in that: the APMP is pretreated by adopting compound biological enzyme before H2O2 bleaching, and diffusion of the enzyme in the pulp and role exertion of a laccase / mediator system are improved by using good compatibility of biological surfactant and enzyme preparation, so that the bleaching efficiency of the chemical mechanical pulp is improved, the final bleaching degree of the produced pulp is improved, the whiteness stability of the pulp is good, and the pulp can meet the requirements of paper products with high additional values. Meanwhile, the wastewater pollution load produced by bleaching the pulp is effectively reduced by biological enzyme pretreatment.

Owner:SHANDONG TAIYANGZHIYE +1

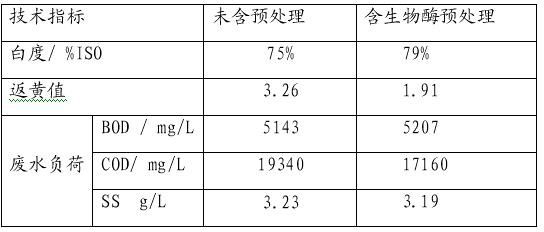

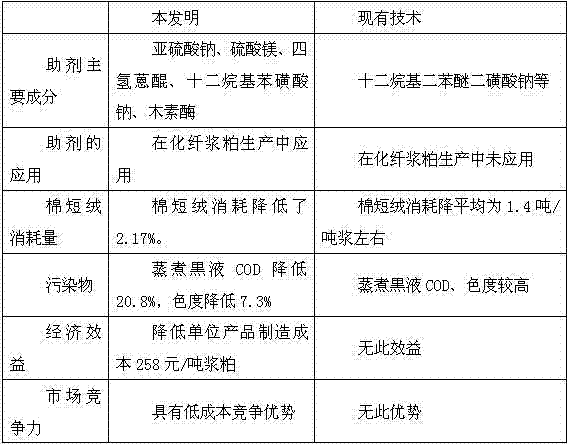

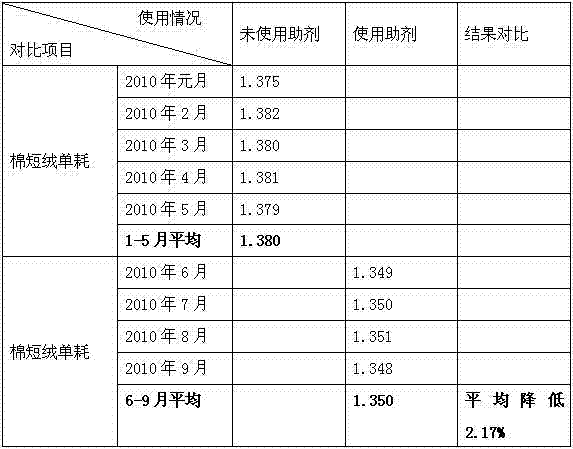

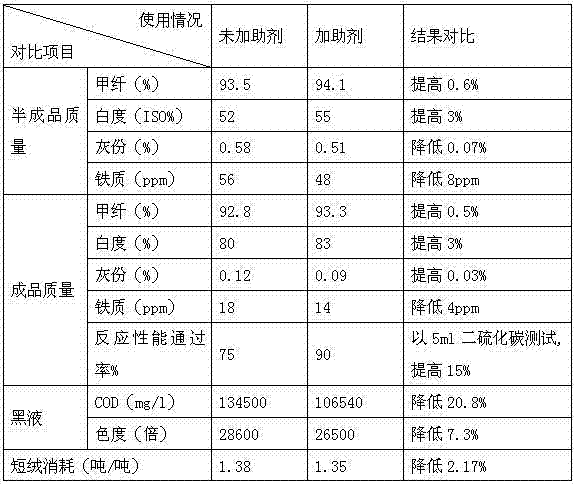

Method for preparing chemical fiber pulp

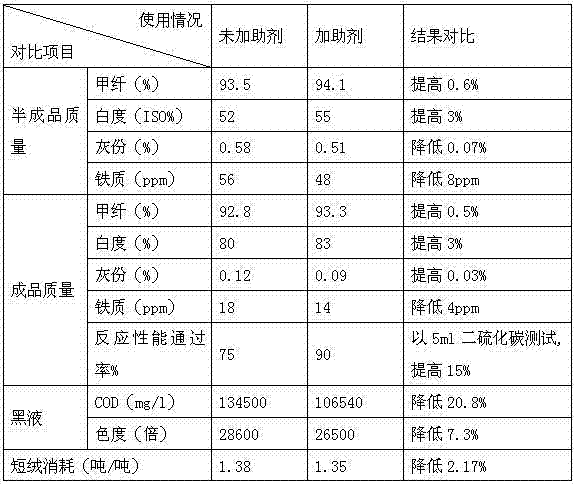

InactiveCN102174756AAvoid emulsificationPrevent removalCellulose material pulpingWaxChemical oxygen demand

The invention relates to a method for preparing chemical fiber pulp, belonging to the field of chemical fiber pulp manufacturing in the spinning industry. The invention aims at solving the problems that a cooking additive cannot be used for cooking chemical fiber pulp in the traditional cooking technology and the traditional cooking technology is not environment-friendly and the like, and provides a method for preparing chemical fiber pulp by using an environment-friendly compound cooking additive. The method comprises the processes of opening cotton, preparing the additive, cooking and the like; the method can be used for emulsifying and removing wax, protein and fat in the cooking process of the chemical fiber pulp and has the advantages of improving the osmosis and dispersion of medicine liquid during cooking, controlling the decomposition speed of the cellulose, improving the alpha cellulose content, selectively removing a chromophoric group, improving half-stuff whiteness and bleachability, reducing LCC (Lignin-Carbohydrate Complex) and others, improving the chemical reaction performance and effectively lowering the raw material consumption and reducing the COD (Chemical Oxygen Demand), chroma and other indexes of the spent liquid during cooking.

Owner:YIBIN GRACE GROUP CO LTD

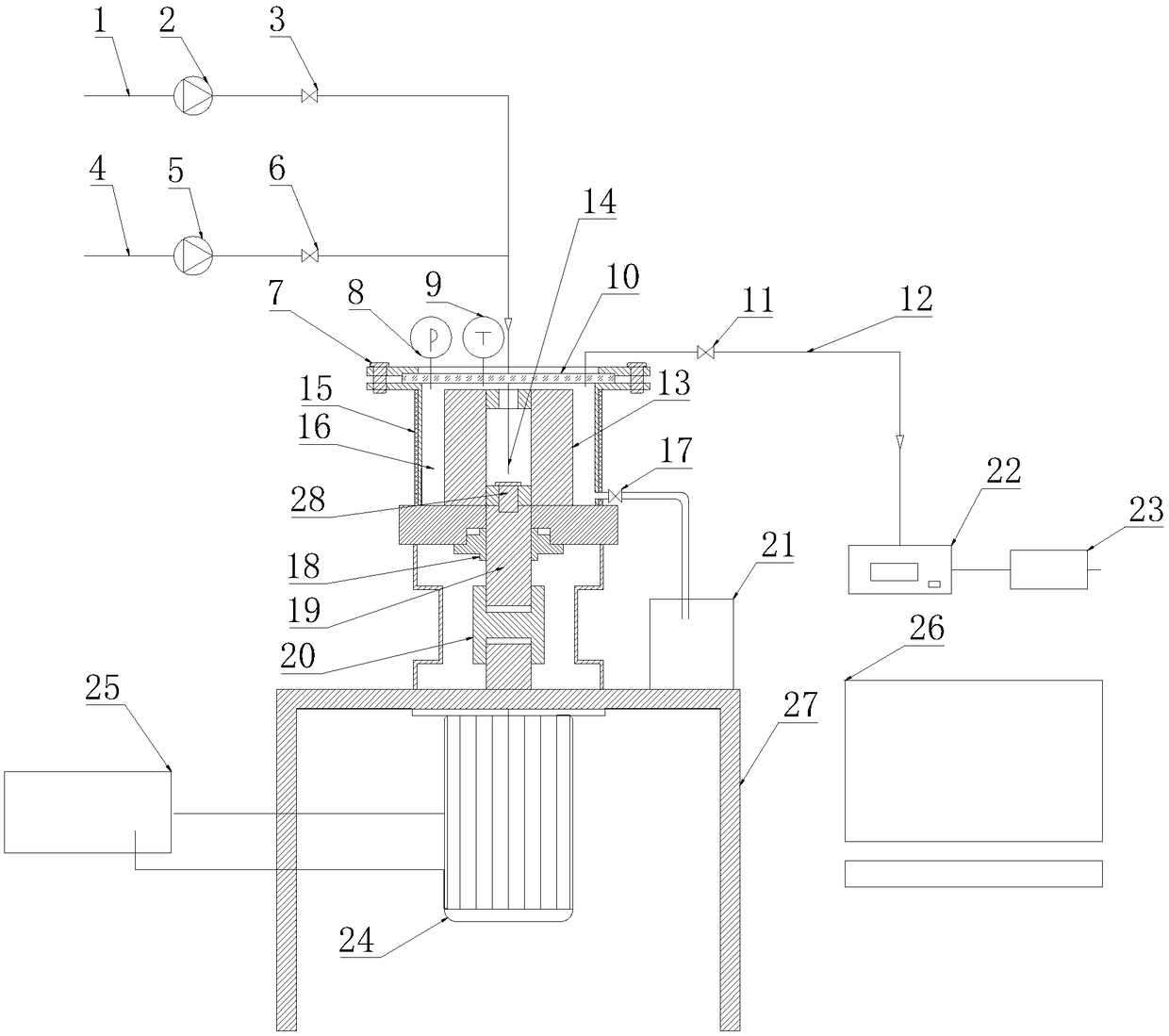

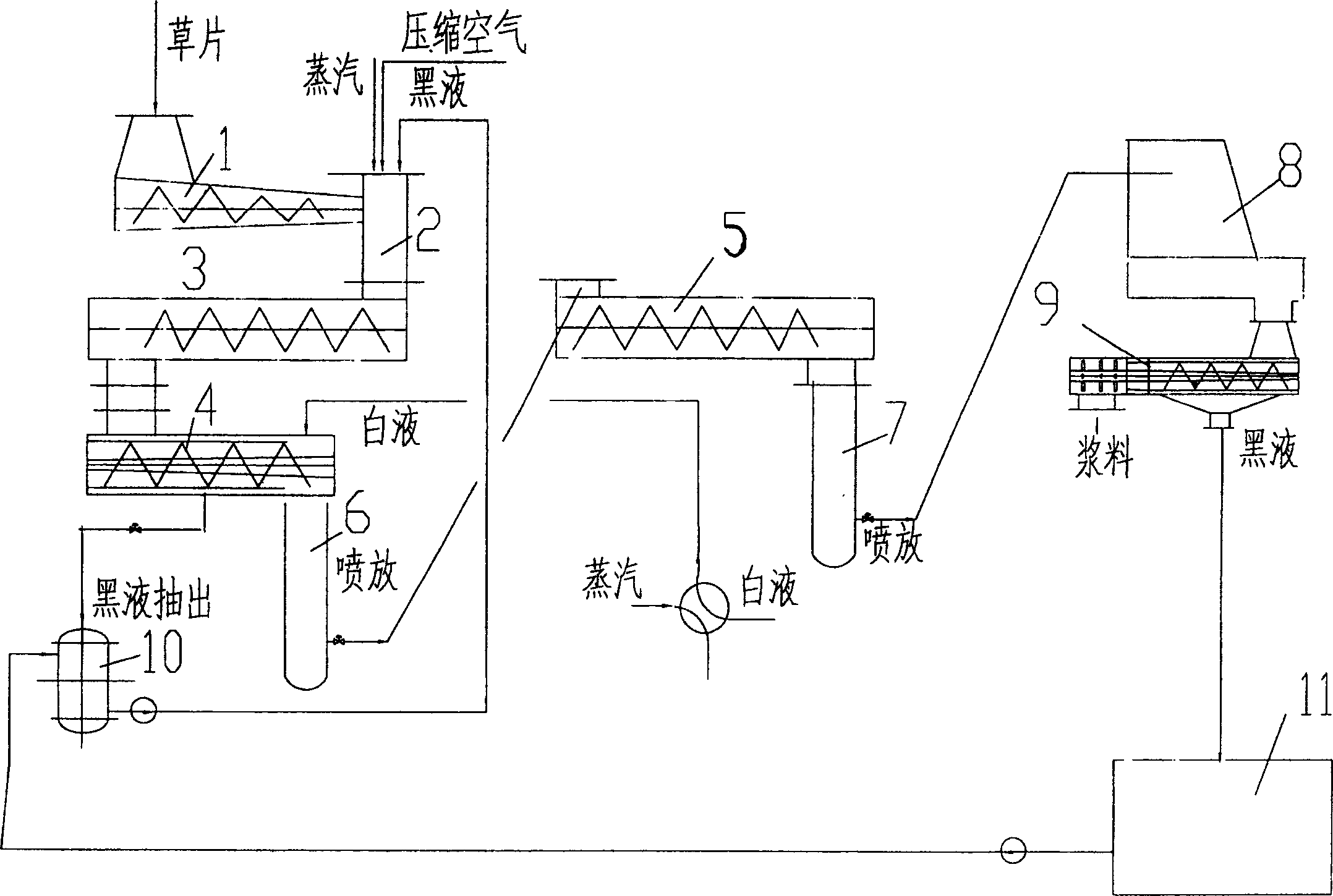

Pulping continuous cooking method and device

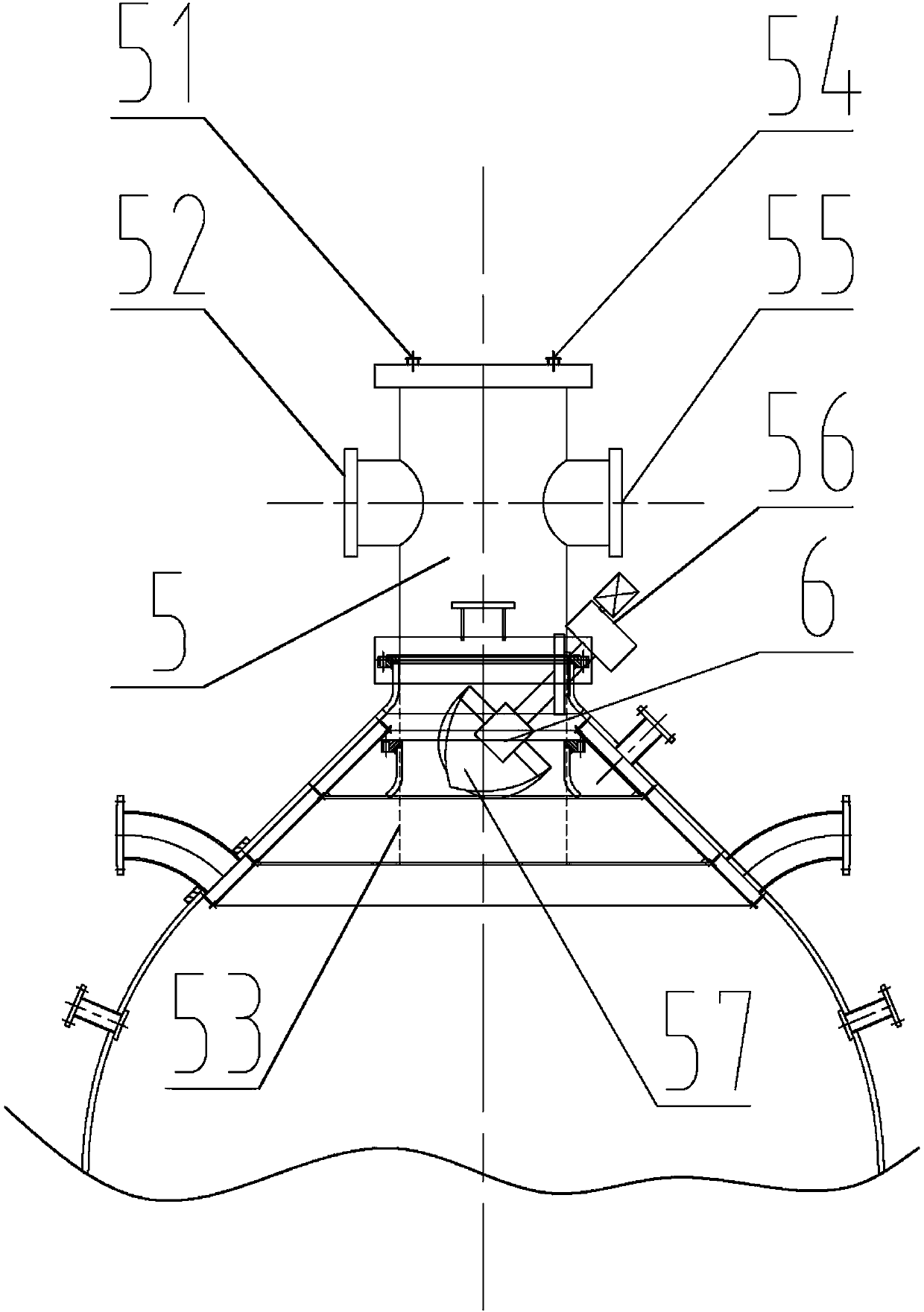

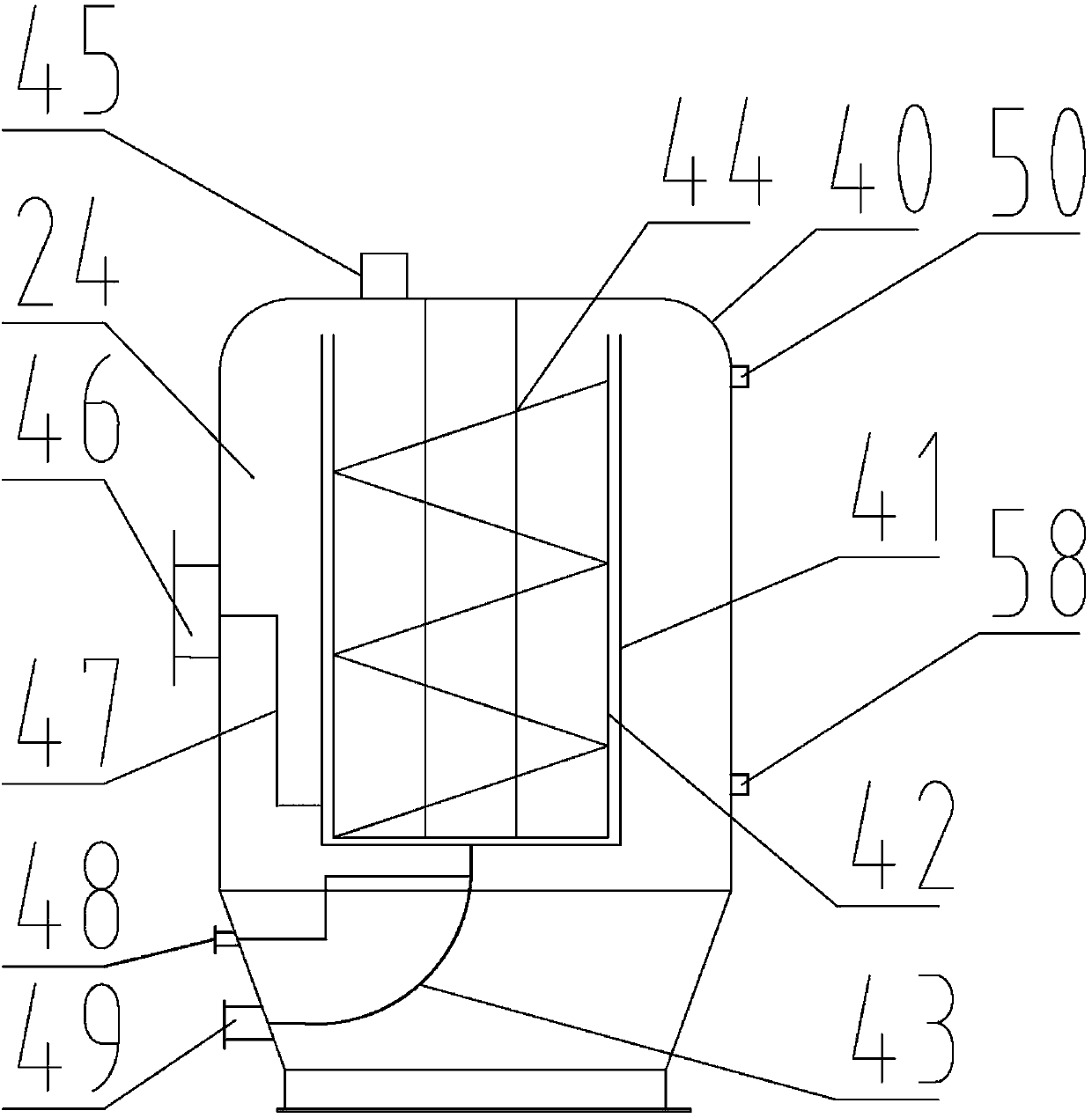

ActiveCN111350092AQuality improvementIncrease concentrationDigestersPaper material treatmentBlack liquorWood fibre

The invention discloses a pulping continuous cooking method applicable to non-wood fiber raw materials. The pulping continuous cooking method comprises the steps of extrusion, presoaking cooking, liquid extraction, concentration, hot spraying and the like. A feeder of a pulping continuous cooking device is connected with a pretreatment pot through a T-shaped pipe, a presoaking cooking sieve plateis arranged in the pot, connected with a flash tank and connected back with the pretreatment pot through a pretreatment pot circulating pump and a first heater, and a bottom dilution discharging pipeis connected with a cooking pot through a discharging pump. A cooking filter sieve plate in the pot is connected with the T-shaped pipe and is connected back to the cooking pot through the cooking potcirculating pump and a second heater, and a hot spraying device is connected with a replacement washing pot; a replacement sieve plate in the replacement washing pot is connected with the flash tankand the T-shaped pipe through a heat exchanger, and is connected with the cooking pot and the dilution discharge pipe through an infusion pump; the replacement washing pot is connected to a spraying pot through a cold spraying device. The pulping continuous cooking device is compact in structure, improves cooking uniformity and paper pulp quality, improves pulping hardness and bleachability, recycles black liquor, reduces alkali consumption, is low in energy consumption, achieves zero emission of waste gas, saves energy and protects the environment. And upgrading and reconstruction of traditional equipment are met.

Owner:王桂林

Method of preparing semi-chemical pulp with broadleaf wood slab

ActiveCN108221470AHigh strengthTake advantage ofPulp beating methodsPaper/cardboardBlack liquorAlcohol

The invention belongs to the technical field of pulping and papermaking and particularly relates to a method of preparing semi-chemical pulp with broadleaf wood slab. In the method, the broadleaf woodslab is used as a raw material and is pre-treated with alcohol; then through two-stage defibrination, washing and sieving, high-performance semi-chemical pulp is produced. In the method, the broadleaf wood slab, as the raw material, has abundant sources and is low in cost. With the alcohol as a main solvent for treating the broadleaf wood slab, alkali use amount is reduced, and cost of treating pulping black liquor is saved.

Owner:QILU UNIV OF TECH

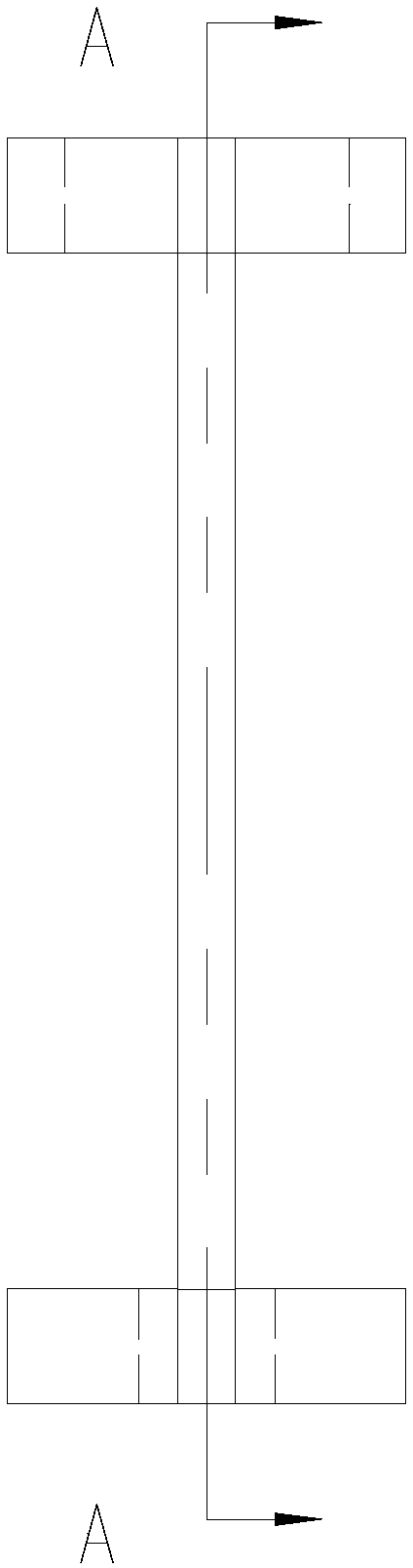

Oxygen-based high-efficiency clean bleaching pulp preparation method and device thereof

ActiveCN109267413AEnhanced mass transferConsistent mass transferPulp bleachingHigh concentrationChemical reaction

The invention discloses an oxygen-based high-efficiency clean bleaching pulp preparation method and a device thereof. A hollow hybrid rotor in the device is connected to the shaft end of a high-speedvariable frequency motor spindle located at the bottom of a mixing reaction chamber by bolts. Blades of the hollow hybrid rotor are a plurality of linear or spiral blades distributed symmetrically ina hollow structure. The method is widely used in oxygen bleaching or ozone bleaching of chemical pulp of any raw material. All use oxygen-containing bleaching agents. Final products decomposed from the chemical reaction are oxygen and water, and the residual of harmful substances in the bleached pulp is eliminated. The bleached pulp is high in whiteness, more uniform and not prone to return to yellow. A variable frequency motor drives the hollow rotor to conduct high speed mixing through the spindle and a mechanical seal, so that medium- and high-concentration pulp and an oxygen-based gaseousbleaching agent in the mixed reaction chamber are more efficient in mass transfer. The mixed contact is more uniform and sufficient. The device is reasonable in structure, can accurately control consumption of liquid, oxygen and ozone and simple and efficient in the bleached pulp preparation process.

Owner:SOUTH CHINA UNIV OF TECH

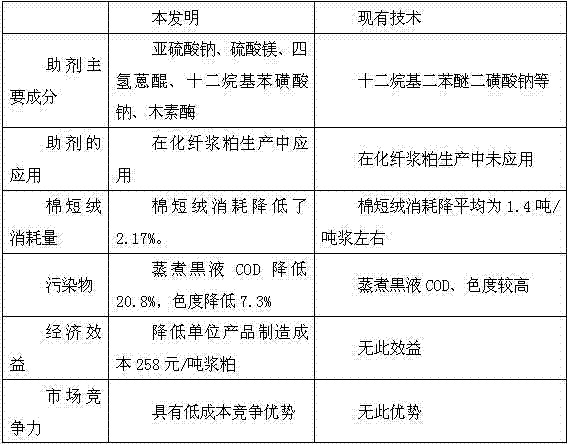

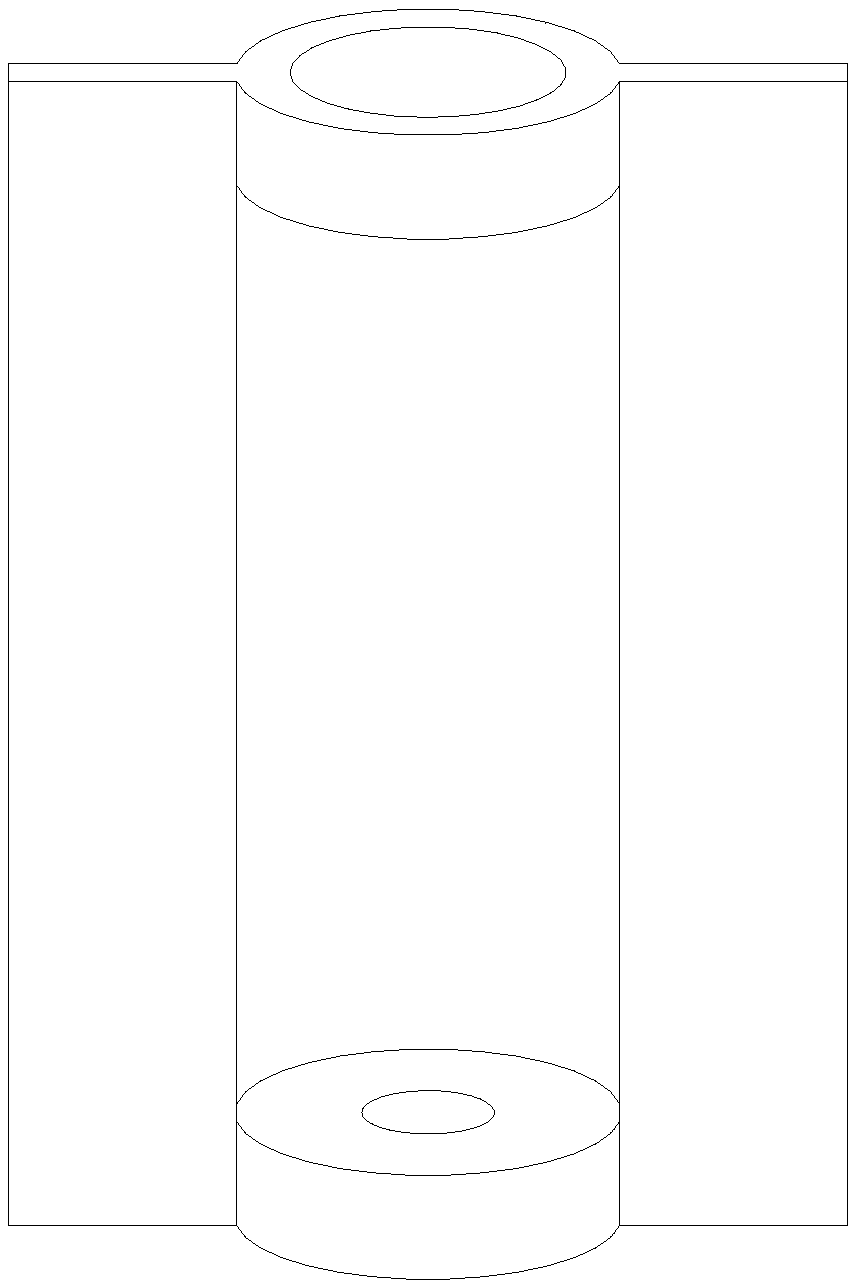

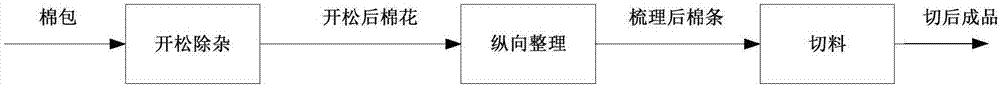

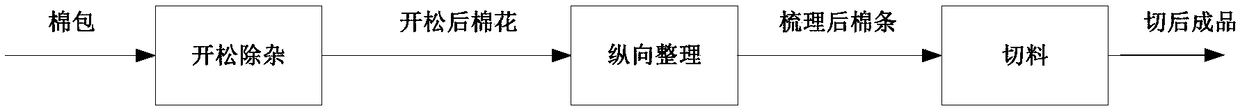

Dry-cut cotton fiber bio-enzyme pulping process

ActiveCN106988136AImprove bleachabilityImprove uniformityPulp bleachingFinely-divided material pretreatmentPectinaseCotton fibre

The invention provides a dry-cut cotton fiber bio-enzyme pulping process. The process includes the following steps that dry-cut cotton fibers are pretreated with pectinase to obtain pulp; the pretreated pulp is subjected to cook bleaching through an alkaline hydrogen peroxide method. According to the dry-cut cotton fiber bio-enzyme pulping process, firstly, the cotton fibers are firstly pretreated with bio-enzymes to remove pectin and other impurities affecting following production, and then the pretreated pulp is subjected to cook bleaching through the alkaline hydrogen peroxide method. According to the dry-cut cotton fiber bio-enzyme pulping process, production can be completed under low-temperature and normal-pressure conditions, and the use amount of chemical medicine can be greatly reduced; meanwhile alkaline hydrogen peroxide bleaching operation is also carried out under the normal-pressure condition. The pulp prepared through the dry-cut cotton fiber bio-enzyme pulping process completely meets the production requirements of banknote paper pulping.

Owner:BAODING BANKNOTE PAPER CO LTD +1

Paper pulp biomass-based enzyme pretreatment bleaching method

The invention discloses a paper pulp biomass-based enzyme pretreatment bleaching method. The method comprises the following steps: paper pulp is delivered into a reaction kettle, and a biomass-based enzyme solution is added for treating; the paper pulp processed after biomass-based enzyme treatment is delivered into a bleaching tower, and an oxidative chemical is added at the same time; a reaction is carried out for a period of time, such that first-stage bleached paper pulp is obtained. According to the invention, after the first-stage bleached paper pulp is obtained, the first-stage bleached paper pulp can be subjected to first-stage mild extraction; a pulp material obtained after extraction is delivered into a second-stage reaction kettle; under a condition in which a pH value is 5-10, the biomass-based enzyme solution is added for carrying out secondary treatment; the pulp material obtained after secondary treatment is delivered into a second-stage bleaching tower and is subjected to hydrogen peroxide bleaching, such that second-stage bleached paper pulp is obtained. The above operation steps can be repeated according to needs. With the method provided by the invention, addition of a bleaching agent and other agents can be reduced, such that costs can be reduced. Paper pulp physical performance can be improved, and bleaching waste water pollution load can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

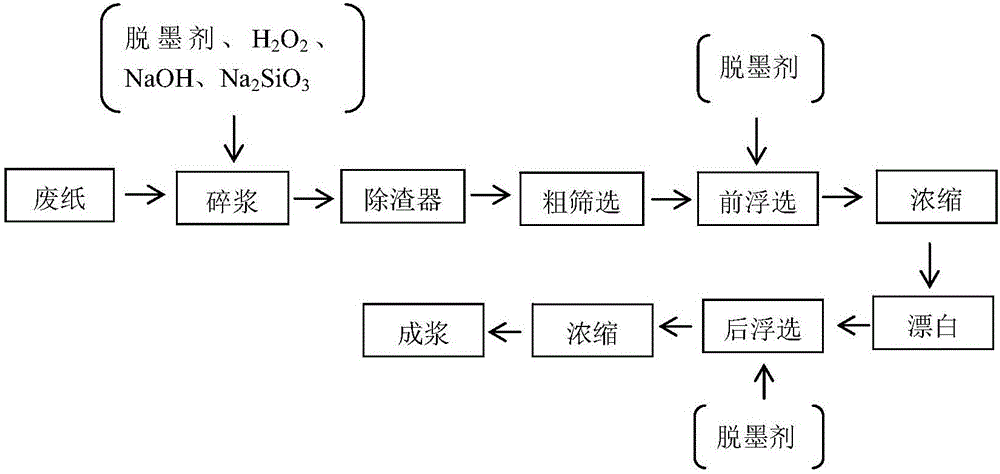

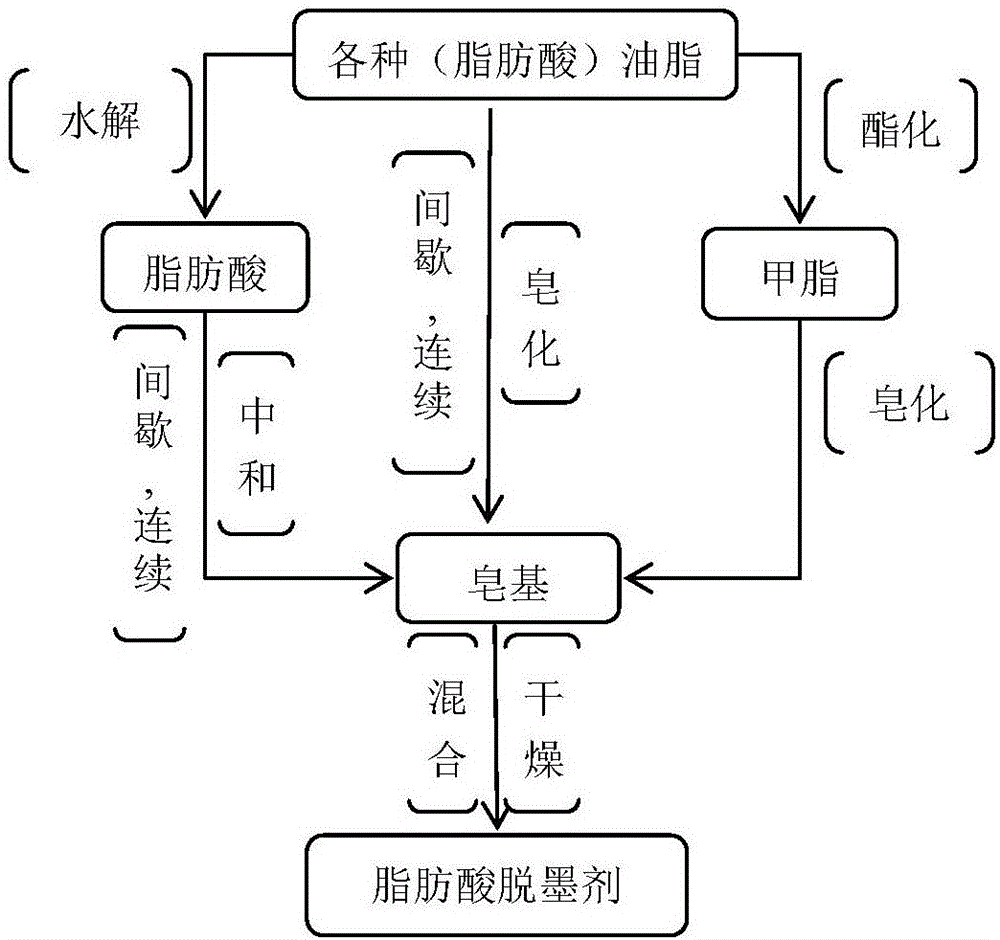

Fatty acid soap deinking agent and preparing method and application thereof

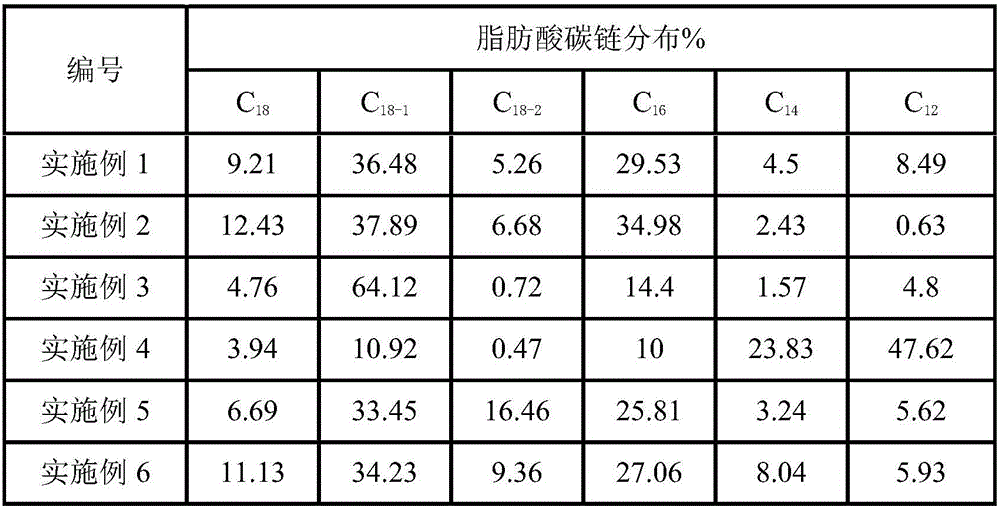

ActiveCN106087510AEfficient strippingHelp to emergePaper recyclingWaste paper working-upDeinkingMyristic acid

The invention discloses a fatty acid soap deinking agent and a preparing method and application thereof. The deinking agent is formed by mixing and saponification of various fatty acids. The fatty acids include, by weight, 30-40% of oleic acid, 5-10% of linoleic acid, 9-15% of stearic acid, 25-35% of palmitic acid, 4.5-10% of myristic acid and 4.8-8.5% of lauric acid. The deinking agent can be applied to preparation of deinked stock by means of #8 United States waste paper. The fatty acid soap deinking agent is prepared through fatty acid compounding by means of natural oil, a surfactant does not need to be added additionally, and ink detachment and ink emersion can be well achieved; meanwhile, the stock has high bleachability, so that final whiteness and yield of the stock are high.

Owner:广州造纸股份有限公司

Enzymatic straw material pulping process

InactiveCN1190555CGood effectQuality assuranceChemical/chemomechanical pulpNon-woody plant/crop pulpLignin peroxidaseXylanase Y

The enzymatic straw material pulping process includes three stages of mechanical pre-treatment, enzyme treatment and chemical pulping or chemical-mechanical pulping. After being pretreated mechanically in a pulp grinder, the straw material is treated with hemicellulase liquid or mixed enzyme liquid comprising hemicellulase and lignin peroxidase at pH 3.5-6.5 and 40-60 deg.c for 1-10 hr. In chemical pulping, the material is presoaked with waste pulp-making liquor before extruding out wastes liquor and digested; and in chemical-mechanical pulping, the material is first treated with EDTA, NaOH and H2O2 at 40-80 deg.c for 30-120 min and then ground to form the pulp. The present invention is used in papermaking enterprises with straw as material and has the advantages of low pollution load, high, paper pulp quality, easy-to-process waste liquor, etc.

Owner:SHANDONG UNIV

Low-foam easy-to-rinse laundry detergent containing enzyme preparation and preparation method thereof

InactiveCN112300870AImprove bleachabilityMeet the needs of low foam and easy rinsingInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPreservativeHydroxide potassium

The invention belongs to the technical field of washing products, and particularly relates to a low-foam easy-to-rinse laundry detergent containing an enzyme preparation and a preparation method thereof. The low-foam easy-to-rinse laundry detergent comprises the following components in parts by mass: 8 to 23 percent of LAS, 5 to 12 percent of methyl cocoate ethoxylate, 0.1 to 2 percent of saturated fatty acid, 0.5 to 1.5 percent of an enzyme preparation, 1 to 5 percent of an enzyme preparation stabilizer, 0.1 to 2 percent of a thickener, 0.1 to 2 percent of potassium hydroxide, 0.1 to 0.3 percent of a preservative, 0.1 to 1 percent of a chelating agent, 0.1 to 0.3 percent of a pH regulator and 60 to 75 percent of deionized water. The low-foam performance is achieved by adding the saturatedfatty acid, meanwhile, the methyl cocoate ethoxylate and the saturated fatty acid salt are compounded, the bleaching ability of the laundry detergent is remarkably improved, and the prepared laundrydetergent is high in detergency, has good detergency for various stains and has a certain stain re-precipitation resisting effect.

Owner:广州清淞泉生物科技有限公司

Deinking Technique for news bogus paper through enzyme

A waste new print zyme deinking technology includes crushing the pulp, deinking, suspension selection, washing, bleaching among which, deinking agent, laccase, amboceptor are added into the pulped with waste newsprints and waster to be inlet with oxygen and the pulp concentration is controlled at 3%-18%, temperature 20-70deg.C pulping, keeping warmth.

Owner:QILU UNIV OF TECH

Pretreatment process for cleaning and bleaching chemical mechanical pulp

ActiveCN102154886BImprove bleachabilitySolve the problem of easy yellowingPulp bleachingChemical/chemomechanical pulpActive agentWastewater

The invention relates to a cleaning and bleaching technology suitable for chemical mechanical pulp, particularly alkaline peroxide mechanical pulp (APMP). The process is mainly characterized in that: the APMP is pretreated by adopting compound biological enzyme before H2O2 bleaching, and diffusion of the enzyme in the pulp and role exertion of a laccase / mediator system are improved by using good compatibility of biological surfactant and enzyme preparation, so that the bleaching efficiency of the chemical mechanical pulp is improved, the final bleaching degree of the produced pulp is improved, the whiteness stability of the pulp is good, and the pulp can meet the requirements of paper products with high additional values. Meanwhile, the wastewater pollution load produced by bleaching the pulp is effectively reduced by biological enzyme pretreatment.

Owner:SHANDONG TAIYANGZHIYE +1

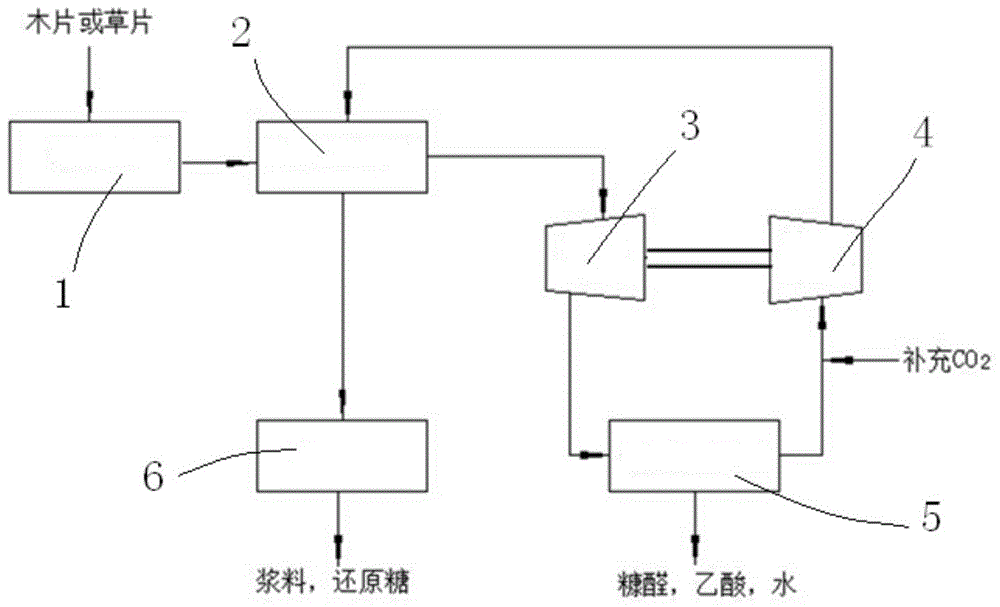

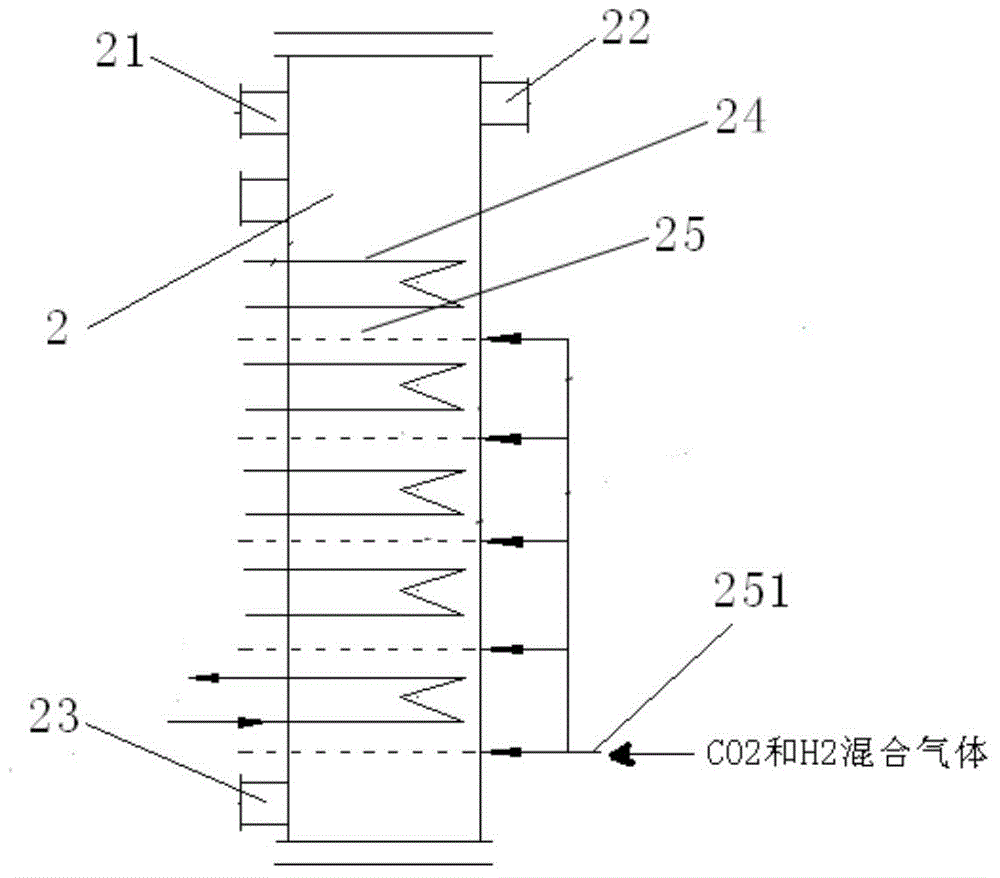

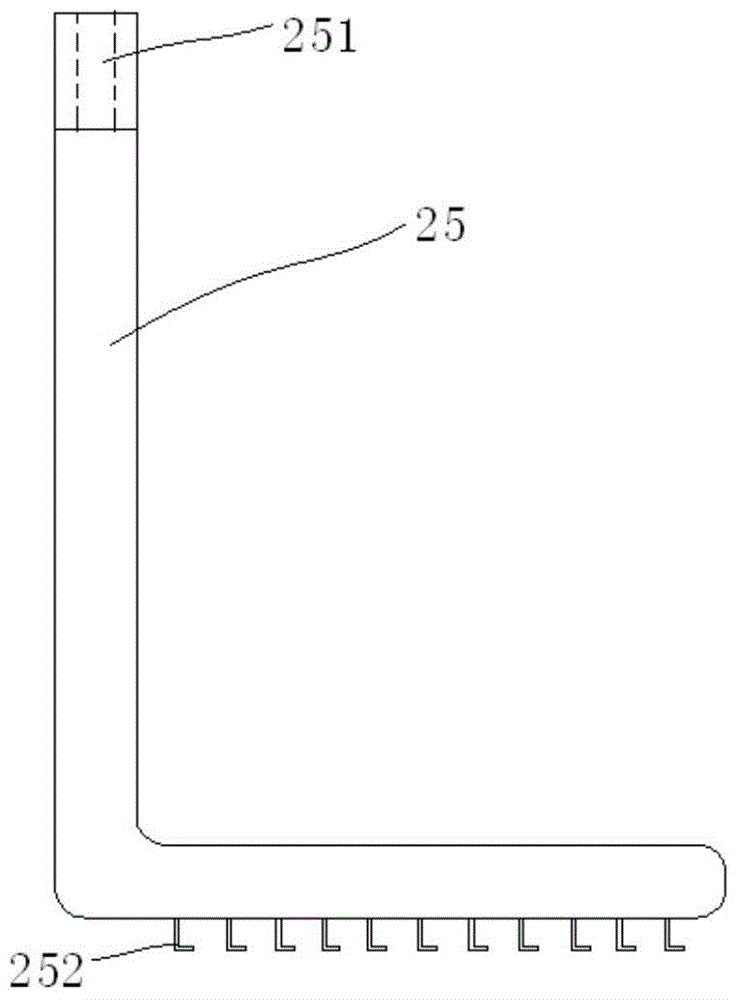

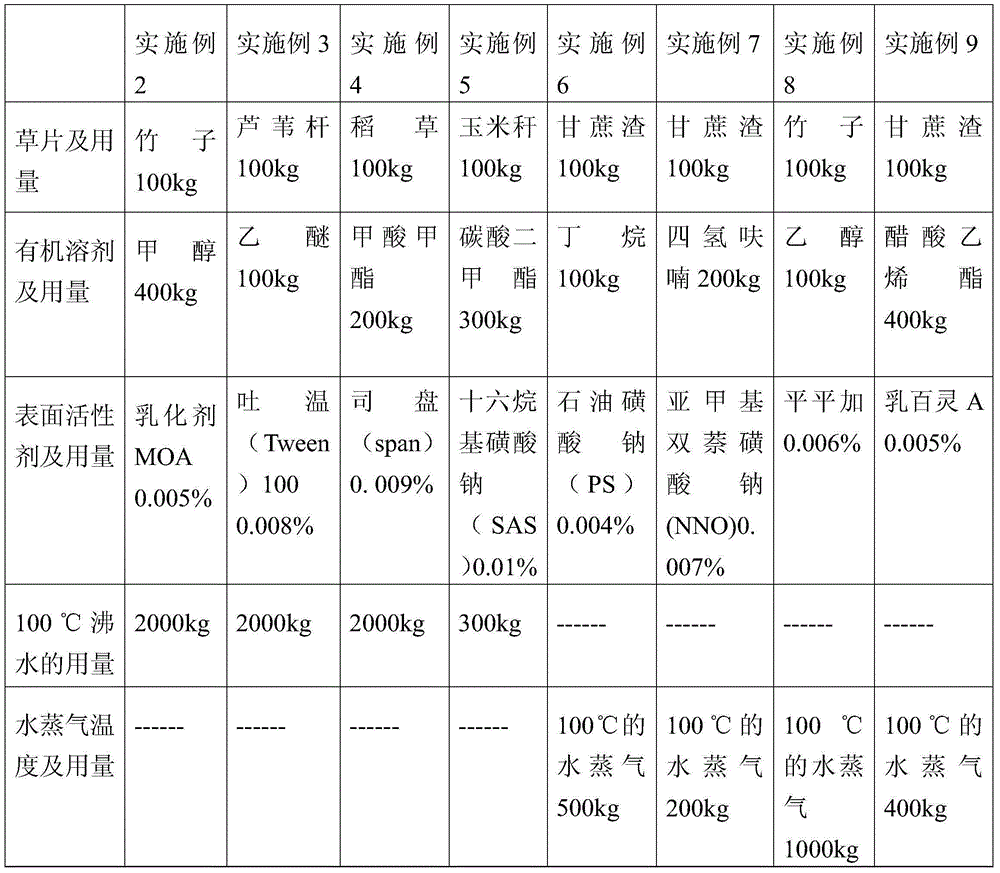

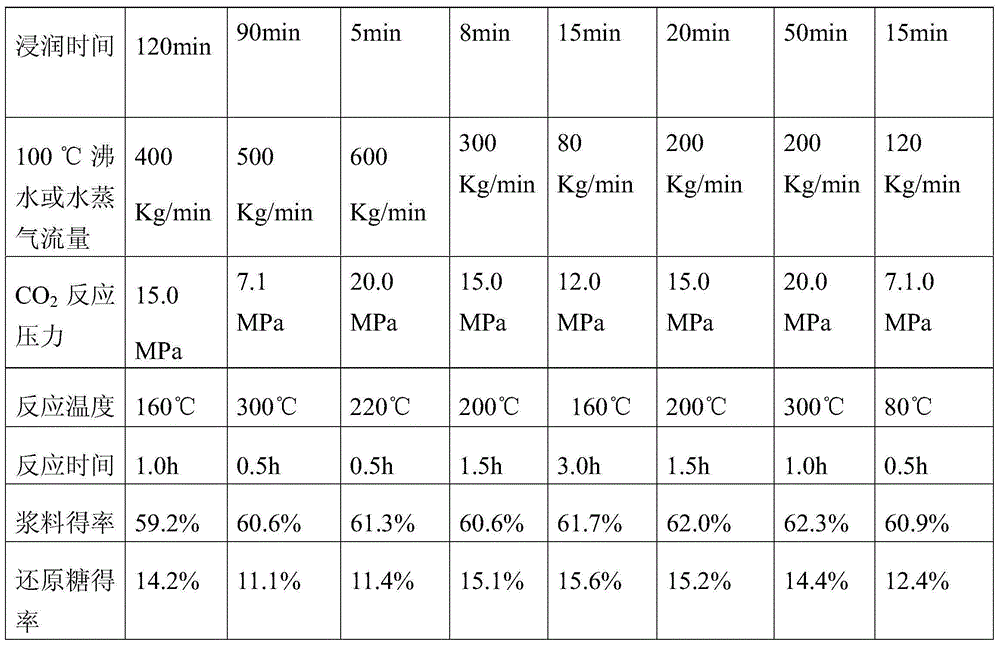

Method and device for hydrolyzing pulping

ActiveCN104674585AEmission reductionNo emissionsDigestersPulping with acid salts/anhydridesBlack liquorSulfate

The invention discloses a method for hydrolyzing pulping. The method comprises the following steps: (1) preparing raw materials, namely, mixing water and wood chips or grass chips in mass ratio of 2:1-200:1, and then preheating; (2) caryring out hydrolyzing reaction, namely, feeding a mixture obtained in step (1) into a reactor, charging CO2 into the reactor, wherein the temperature in the reactor is 80 to 500 DEG C and the pressure is 3 to 50MPa; enabling the charged CO2 to enter a supercritical state or a subcritical state under the conditions that the temperature in the reactor is 80 to 500 DEG C and the reaction pressure is 0.5 to 50.0MPa; (3) discharging the mixed reacted gas from the reactor; and (4) reacting for 1 to 6 hours, discharging pressure-reduced materials from the reactor, and reacting to obtain pulp and reducing sugar. According to the method, supercritical / subcritical CO2 is dissolved in water to be used as protonic acid to replace caustic soda or sulphate or sulfite to pulp by the chemical method, so that the emission amount of heavy-polluted wastewater can be reduced; in addition, the pulping method is free of black liquor or waste gas emission, so that the pulping method is an environmentally-friendly pulping method.

Owner:GUANGXI UNIV

Methods to decrease scaling in digester systems

ActiveUS7241363B2Reduce problem sizeLower energy requirementsPulp liquor regenerationDigestersCalcium concentrationChemistry

One aspect of this invention relates to a method and digester for reducing the deposition of calcium-based scale in a wood chip digester including extraction from the digester of first and second quantities of cooking liquor having respective first and second calcium concentrations, treating the extracted cooking liquors to produce a cooking liquor having a calcium concentration less that the calcium concentration of the either of the first and second extracted cooking liquors, and, reintroducing the treated cooking liquor to the digester. Another aspect of this invention relates to a method and digester in which through put through the digester is increased by the continuous addition of process liquor into the digester preferably at an upper region of the digester.

Owner:INT PAPER CO

Process for enzyme treating before pulping by plant fibre raw material

InactiveCN100365198CAvoid degradationHigh strengthFinely-divided material pretreatmentLiquid ratioPlant fibre

The invention relates to an enzyme processing method before plant fiber raw material pulping. It belongs to paper making field. The includes the following steps: mixing plant fiber raw material and biological enzyme; the biological enzyme contains 0.5-50LAMU laccase, 0.1-5% mediator, and / or 0.5 -50IU xylanase per gram raw material; adding water to make raw material liquid ratio be 1: 4.5-5.5; mechanical grinding the processed enzyme; adding water to make liquid ration be 1:5.5-9.5; and injecting oxygen for 0.5-8h. The processed material can be used to do traditional chemical or mechanical pulp. This can greatly improve paper pulp strength and whiteness.

Owner:QILU UNIV OF TECH

Non-wood fibre displacement, continuous boiling method and apparatus therefor

InactiveCN1252349CQuality improvementHigh hardnessContinuous pulping processNon-woody plant/crop pulpBlack liquorWood fibre

Owner:王广维

Method of producing pulp by instant vaporization expansion-infiltration in straw sheets

ActiveCN105200834AEliminate Feedback InhibitionIncreased reaction rate and equilibrium conversionPulping with organic solventsNon-woody plant/crop pulpBoiling pointCell membrane

The invention discloses a method of producing pulp by instant vaporization expansion-infiltration in straw sheets. The method includes the steps of adding straw sheets as a raw material into an organic solvent having a boiling point lower than 100 DEG C, according to a straw sheet to organic solvent weight ratio: 1:1 to 1:4 so as to infiltrate the straw sheets for 5-120 min, adding the straw sheets into 100 DEG C boiling water or vapor having a temperature higher than the boiling point of the organic solvent, according to a straw sheet to water weight ratio: 1:1 to 1:20, and producing pulp by boiling under supercritical CO2. cell membranes are caused to expand and break by instant vaporization of the organic solvent among fiber cells of the straw sheets, so that the speed of the removal of intercellular lignin from the straw sheets by boiling is increased by 1 to 5 times, and the usage of the organic solvent is decreased by 2 to 10 times.

Owner:GUANGXI UNIV

A kind of biomass-based enzyme pretreatment bleaching method of pulp

The invention discloses a biomass-based enzyme pretreatment bleaching method for pulp. The method comprises the following steps: feeding the pulp into a reaction kettle and adding a biomass-based enzyme solution for treatment; then sending the pulp treated with the biomass-based enzyme into a bleaching tower, adding oxidizing chemicals at the same time, and obtaining a bleached pulp. After obtaining a section of bleached pulp in the present invention, a section of bleached pulp can also be subjected to a section of gentle extraction; then the extracted slurry is sent to a secondary reaction kettle, and under the condition of a pH value of 5-10, biomass-based The enzyme solution is subjected to a secondary treatment; the pulp after the secondary treatment is passed into a second-stage bleaching tower for hydrogen peroxide bleaching to obtain a second-stage bleached pulp, and the above operation steps can be repeated as required. The invention can reduce the addition of bleaching agents and other chemicals, thereby reducing costs, not only improving the physical properties of the pulp, but also reducing the pollution load of bleaching wastewater.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing chemical fiber pulp

InactiveCN102174756BAvoid emulsificationPrevent removalCellulose material pulpingSpinningPulp and paper industry

Owner:YIBIN GRACE GROUP CO LTD

A kind of dry-cut cotton fiber biological enzyme pulping process

ActiveCN106988136BImprove bleachabilityImprove uniformityPulp bleachingFinely-divided material pretreatmentPectinaseCotton fibre

Owner:BAODING BANKNOTE PAPER CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com