Fatty acid soap deinking agent and preparing method and application thereof

A technology of fatty acid soap and deinking agent, applied in the application of chemicals in paper products, pulping and papermaking fields, can solve the problems of high waste paper consumption, cumbersome compounding process optimization, large fiber loss, etc., to achieve good whiteness and Yield, good ink release, good bleachability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

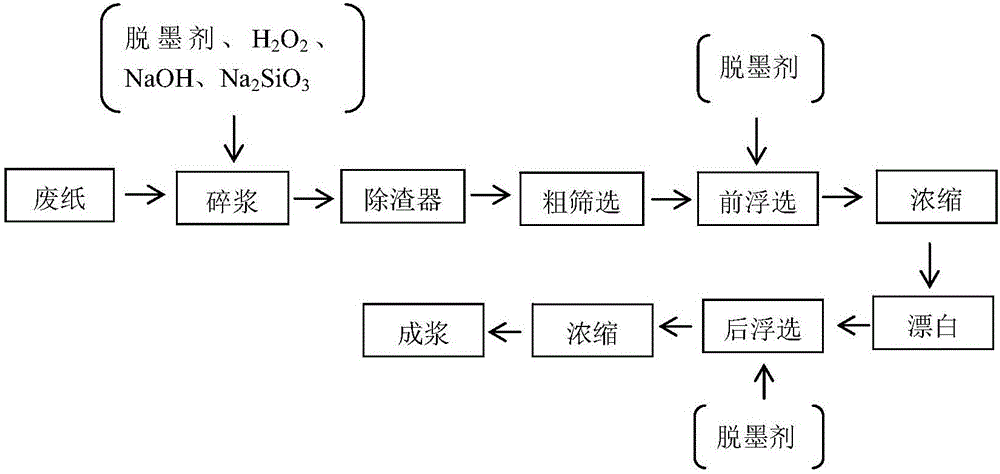

[0026] For the actual production line, VOITH’s ECO horizontal flotation cell is selected, and the raw material waste paper used is 100% #8 American waste paper, so the appropriate amount of foam is matched with #8 waste paper to produce high-quality deinking slurry, and fatty acid soap is selected Deinking agents are used in deinking systems. In each embodiment, the fatty acid soap deinking agent prepared by combining the fatty acid soap carbon chains with various greases is applied to the deinking of #8 waste paper.

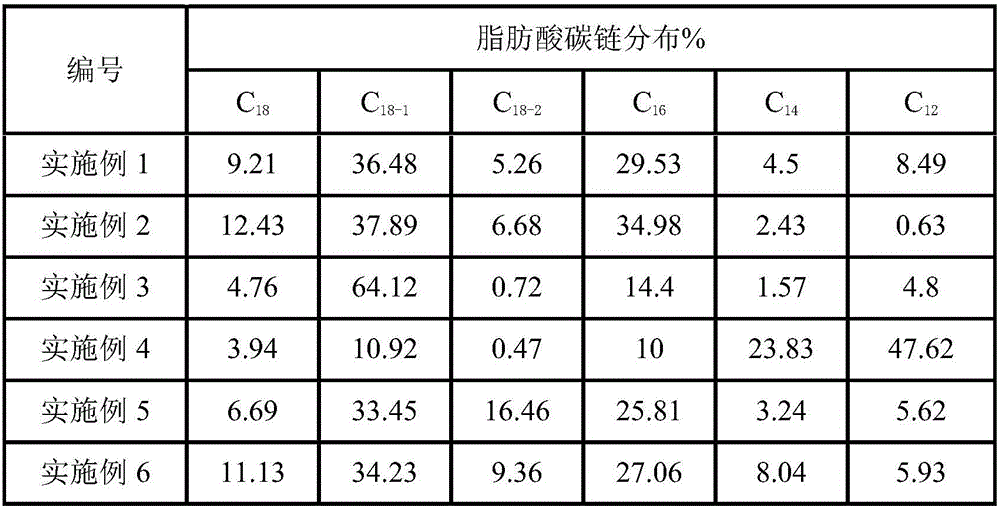

[0027] (1) Fatty acid soap carbon chain ratio:

[0028]

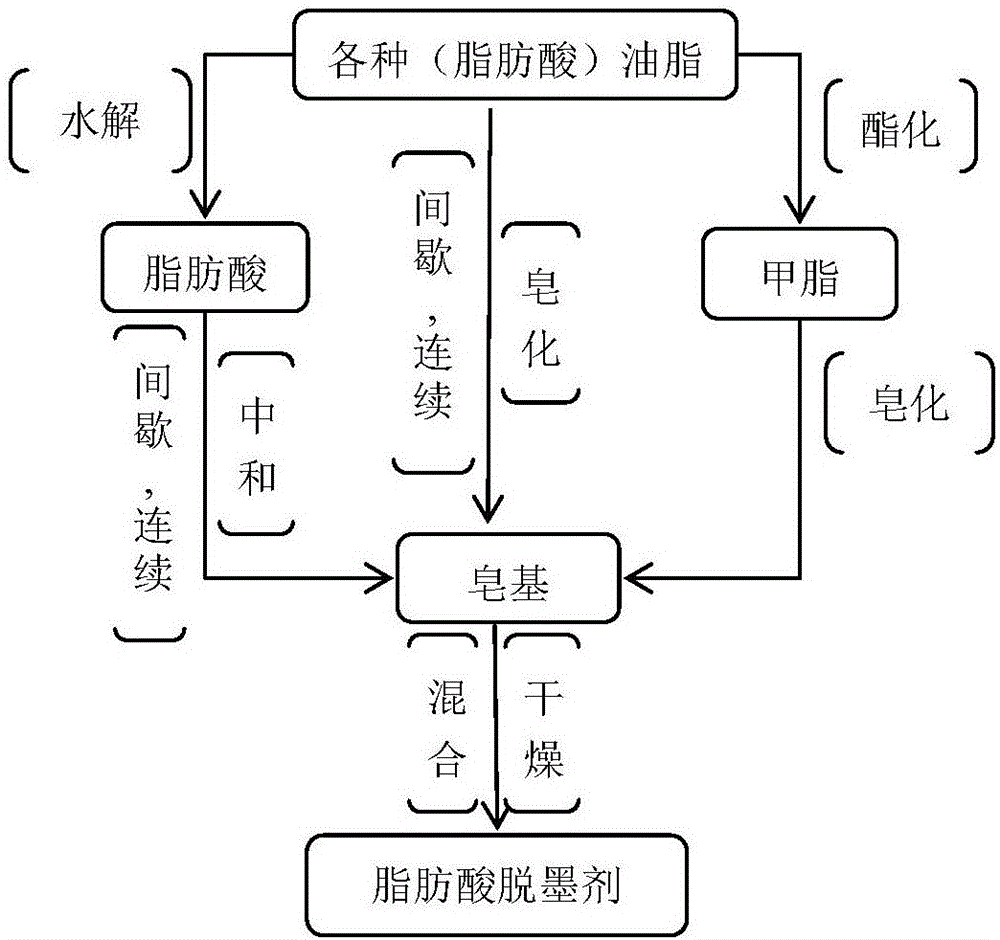

[0029] (2) the preparation method of above-mentioned fatty acid soap deinking agent:

[0030] Select natural oils (palmitic acid, tallow, mutton oil, lard, castor oil, coconut oil), analyze the carbon chain distribution of each oil, and then calculate the required amount of each oil according to the carbon chain demand of fatty acids after mixing. Each type of oil is matched according to the carbon c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com