Carbon material dispersing agent, preparation method thereof and water-borne dispersion body of stable carbon material containing dispersing agent

A dispersant, carbon material technology, applied in nano-carbon, graphite, graphene and other directions, can solve the problems of difficult to realize industrial production, dangerous ionic liquids, high toxicity of organic solvents, etc., and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0093] 1. An amphiphilic hyperbranched polymer, said polymer has a skeleton structure containing an amine group and a monocyclic, polycyclic ring that is covalently bonded to said skeleton structure and non-covalently associated with a graphene structure , fused ring or heterocyclic aryl.

[0094] 2. The amphiphilic hyperbranched polymer according to embodiment 1, wherein the amphiphilic hyperbranched polymer has a weight average molecular weight in the range of 2000-30000 g / mol.

[0095] 3. The amphiphilic hyperbranched polymer according to embodiment 1, wherein the degree of branching of the amphiphilic hyperbranched polymer is in the range of 0.21-0.62.

[0096] 4. The amphiphilic hyperbranched polymer according to embodiment 1, wherein the monocyclic, polycyclic, condensed ring or heterocyclic aryl groups include substituted or unsubstituted groups derived from: benzene, naphthalene, Pyrene, anthracene, pentacene, benzo[a]pyrene, benzophenone, thioxanthone, pyridine, pero...

Synthetic example 1

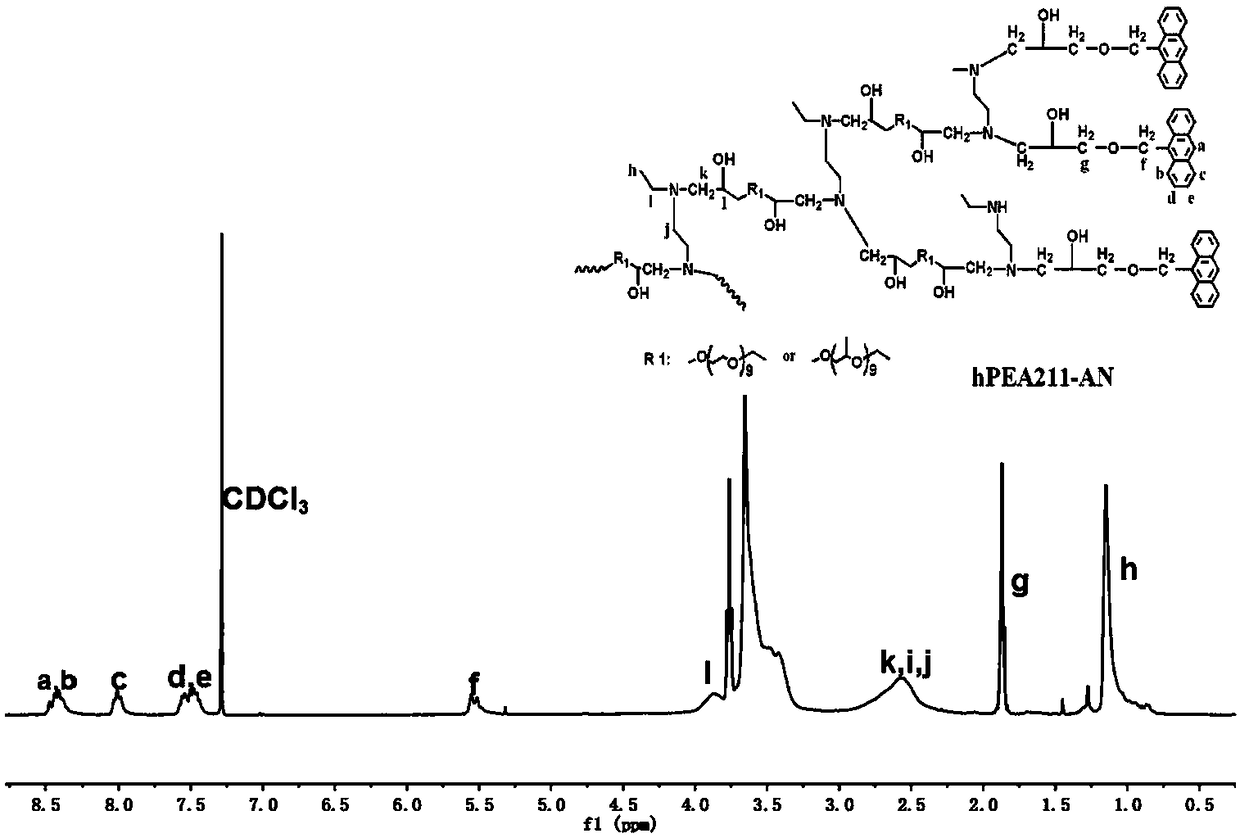

[0119] Synthesis Example 1: Synthesis of Hyperbranched Polymer

[0120] Polyethylene glycol diglycidyl ether (PEG-DE, Mn=500 g / mol), polypropylene glycol diglycidyl ether (PPG-DE, Mn=640 g / mol), and N- Ethylethylenediamine (NEED) and N,N'-diethylethylenediamine were dissolved in ethanol, under nitrogen protection, stirred at room temperature for 48h, heated to 80°C, and continued to reflux for 24h. After the reaction was completed, it was cooled to room temperature, and the ethanol was removed by distillation under reduced pressure to obtain a light yellow viscous solid product, namely polymer 1-5, with a yield of about 90%.

[0121] Table 1

[0122]

[0123] It can be seen from the results in Table 1 that the ring-opening reaction of polyglycidyl ethers and polyfunctional amines such as trifunctional amines can form hyperbranched polymers, and the presence of difunctional amines can be used to adjust the branching degree of polymers. The hyperbranched polymers 1-4 obta...

Embodiment 1

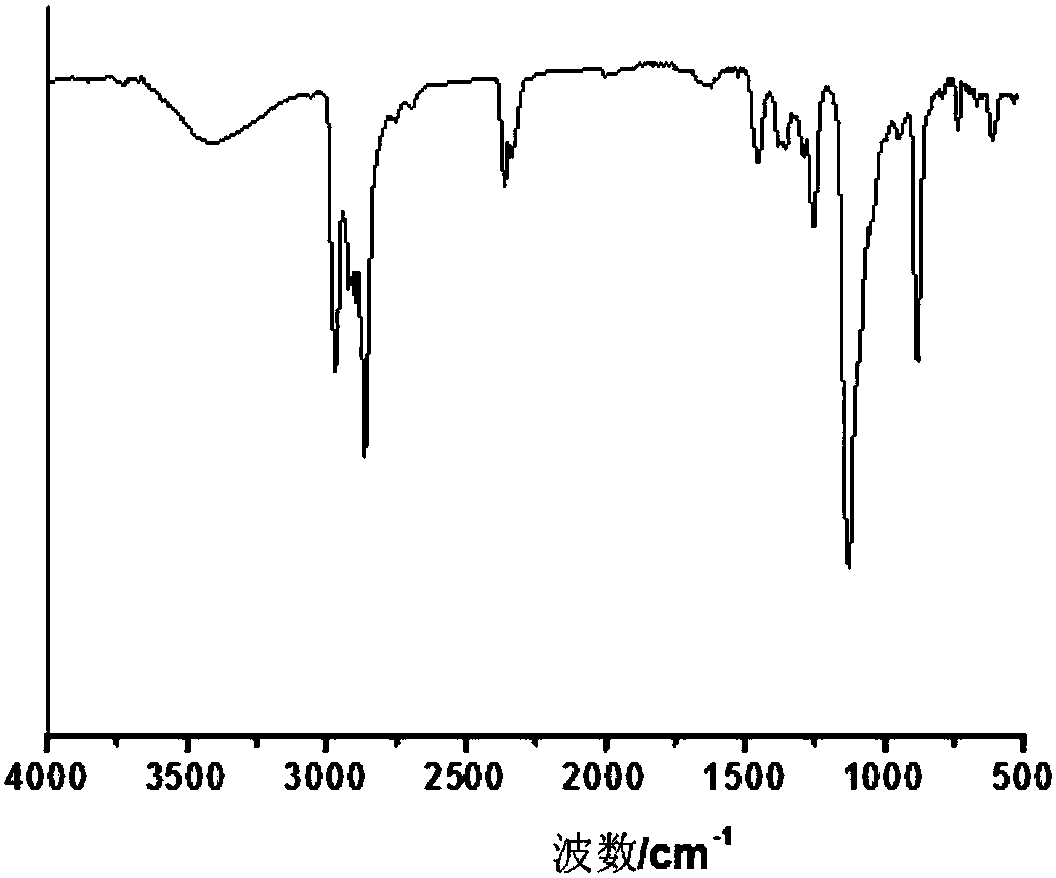

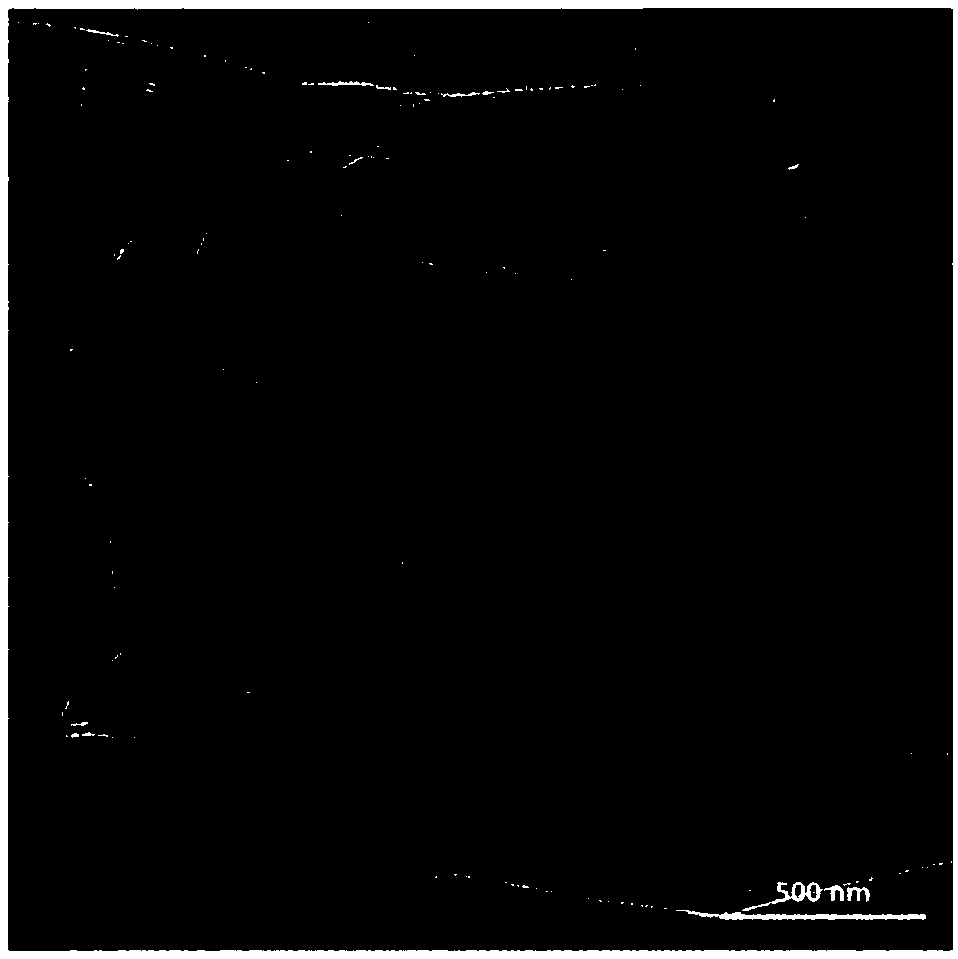

[0124] Embodiment 1: Synthesize a dispersant with 9-anthracene methanol as a non-covalent bonding component with graphene, and use this component Powder Preparation of Graphene Aqueous Dispersion

[0125] (1) Preparation of hyperbranched polymer backbone. Polyethylene glycol diglycidyl ether (PEG-DE, Mn=500g / mol, 10.52g), polypropylene glycol diglycidyl ether (PPG-DE, Mn=640g / mol, 12.8g), and N-ethyl Ethylenediamine (NEED, 3.52g) was dissolved in ethanol, under the protection of nitrogen, stirred at room temperature for 48h, heated to 80°C, and continued to reflux for 24h. After the reaction was completed, it was cooled to room temperature, and the ethanol was removed by distillation under reduced pressure to obtain a light yellow viscous solid product, Hyperbranched Polymer-1, with a yield of about 90%.

[0126] (2) Synthesis of monocyclic, polycyclic, condensed ring or heterocyclic compounds containing functional groups. Dissolve 9-anthracenemethanol (4.17g, 0.02mol) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com