High-efficiency catalysis macroscopic quantity preparation method for graphene oxide or compound thereof reduced and peeled based on microwaves

A technology of graphene and composites, which is applied in the field of high-efficiency catalytic macro-preparation, can solve the problems that have not been reported, long time of microwave irradiation of graphite oxide, unsatisfactory peeling effect, etc., and achieve good peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take ordinary graphite powder and apply the improved Hummers method, that is, take a small amount (about 300 mesh) and add 0.5-5 g of sodium nitrate powder and 30-120 ml of concentrated sulfuric acid, and slowly add 1-9 g of potassium permanganate in a cold water bath. Stir and react in a water bath between 40~45 °C for 1~4 h, then add a small amount of water, continue to react for 10~50 min, then add a large amount of water above 100 ml, react for 5~20 min, add an appropriate amount of hydrogen peroxide until the solution turns golden yellow.

[0037] After the solution was left to settle, discard the supernatant, add an appropriate amount of 5% to 20% hydrochloric acid, divide it into centrifuge tubes and centrifuge at a high speed (10000~15000 r / min), discard the supernatant, and then centrifuge and wash with water until neutral. , collect the product after washing with water, add an appropriate amount of deionized water for ultrasonic dispersion, and then centrifuge...

Embodiment 2

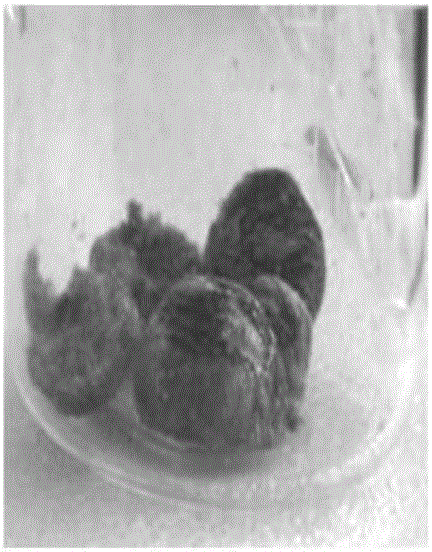

[0040] Obtain the freeze-dried GO product according to the method in the above-mentioned Example 1, put it into a beaker, sprinkle a trace amount (3.11 mg) of flake graphite powder (200 mesh) on its surface, and put it into a microwave oven for microwave irradiation (500~1000 W), under the catalysis of graphite flakes, the reaction started about 2 s after turning on the microwave, accompanied by a strong plasma arc, the reaction was completed in about 9 s, and a large number of microwave-assisted reduction and exfoliation graphene flocs (MEGO) were obtained. Raman and high-resolution transmission electron microscope characterization results prove that the product is high-quality graphene.

Embodiment 3

[0042]Obtain the freeze-dried GO product according to the method in the above-mentioned Example 1, put it into a beaker, sprinkle a trace amount (1.27mg) of flake graphite powder (325 mesh) on its surface, and put it into a microwave oven for microwave irradiation (500~1000 W), under the catalysis of flake graphite, the reaction starts instantly after turning on the microwave (the time interval is less than 1 s), accompanied by a strong plasma arc, the reaction is completed in about 6 s, and the microwave-assisted reduction and exfoliation of graphene flocs (MEGO) is obtained , but the amount is relatively small compared with the previous example, because the smaller the particle size, the stronger the ability to induce plasma, and the resulting local high-energy environment leads to the loss of part of the generated graphene due to the reaction with oxygen. Raman and high-resolution transmission electron microscope characterization results prove that the product is high-qualit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com