Preparation method of aluminium dihydrogen phosphate paint for silicon steel

A technology of aluminum dihydrogen phosphate and coatings, which is applied to chemical instruments and methods, coatings, phosphorus compounds, etc., can solve the problems of many impurities, achieve the effects of less impurities, improve insulation and adhesion, and reduce cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

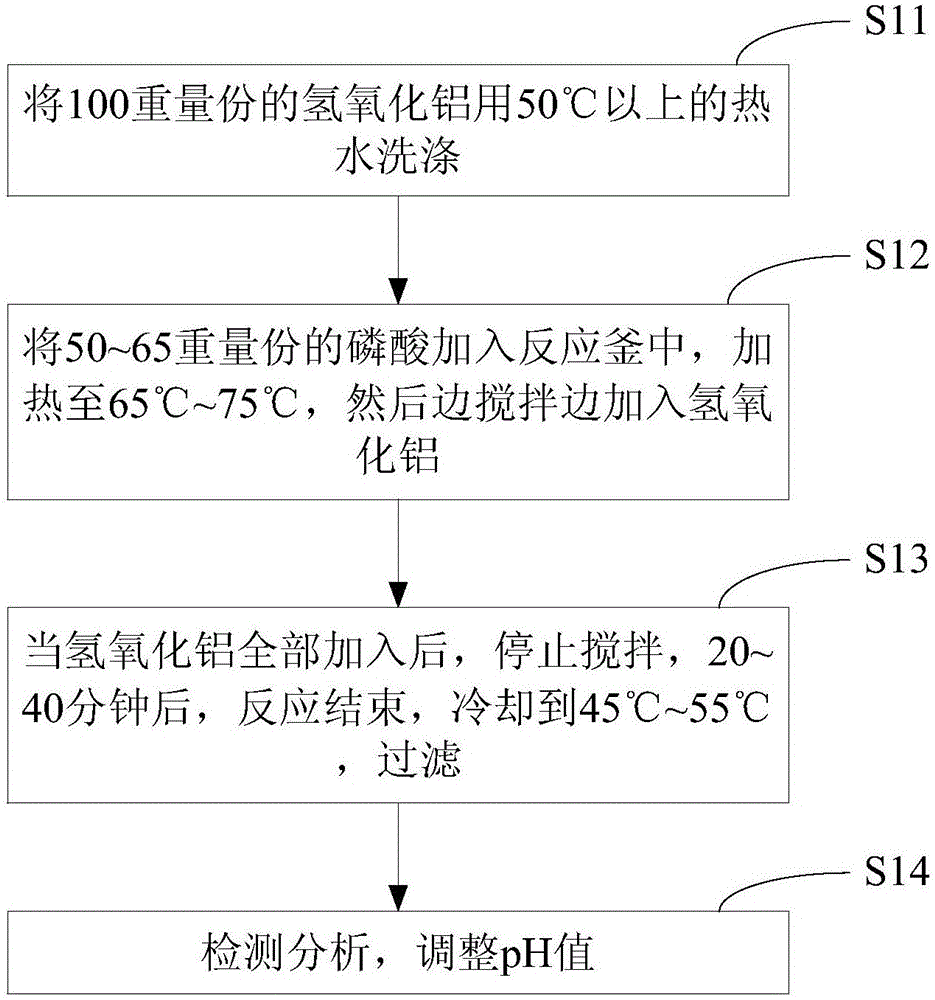

[0013] see figure 1 , figure 1 It is a flow chart of the preparation method of the aluminum dihydrogen phosphate coating for silicon steel in the first embodiment of the present invention. The invention provides a method for preparing an aluminum dihydrogen phosphate coating for silicon steel. The preparation method for the aluminum dihydrogen phosphate coating for silicon steel comprises steps:

[0014] In step S11, 100 parts by weight of aluminum hydroxide is washed with hot water above 50°C. The optimum temperature of hot water is 60°C-70°C, and the weight is the same as that of aluminum hydroxide. When washing, the washing degree should reach the pH value of the washing water to reach 7-8. On the one hand, this step is to wash off the residual sodium hydroxide in the aluminum hydroxide to avoid the reaction of Na+ ions and phosphoric acid; on the other hand, it is to activate the aluminum hydroxide, which is beneficial to the reaction of aluminum hydroxide and phosphori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com