Method of producing pulp by instant vaporization expansion-infiltration in straw sheets

A technology of instantaneous vaporization and straw flakes, which is applied to pulping with organic solvents, pulping of cellulose raw materials, and non-woody plant/crop pulp, etc. and other problems, to achieve the effect of improving the reaction rate and equilibrium conversion rate, eliminating feedback inhibition and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh grass slices: bagasse 100kg; organic solvent 100kg. The added sugarcane bagasse mass 0.004% surfactant Pingpingjia, 100kg of boiling water at 100°C, put Pingpingjia in boiling water and mix it for later use. Add the grass slices bagasse into the cooking pot, then add the above-mentioned weighed ethanol and mix and infiltrate the bagasse evenly. The soaking time is 10 minutes, and then add the above-mentioned 100°C boiling water with surfactant added, and the boiling water flow rate is 100kg / min. The ethanol that penetrates into the sugarcane fiber cells instantly vaporizes and expands to destroy the cell membrane, and then passes CO into the cooking pot 2 , control reaction pressure 7.1MPa, reaction temperature 80 ℃, reaction time 0.5h, using organic solvent ethanol, surfactant Pingpingjia and supercritical CO 2 Carry out self-catalytic de-lignification between fiber cells of grass slices. During the reaction, ethanol forms steam and the water vapor generated du...

Embodiment 2

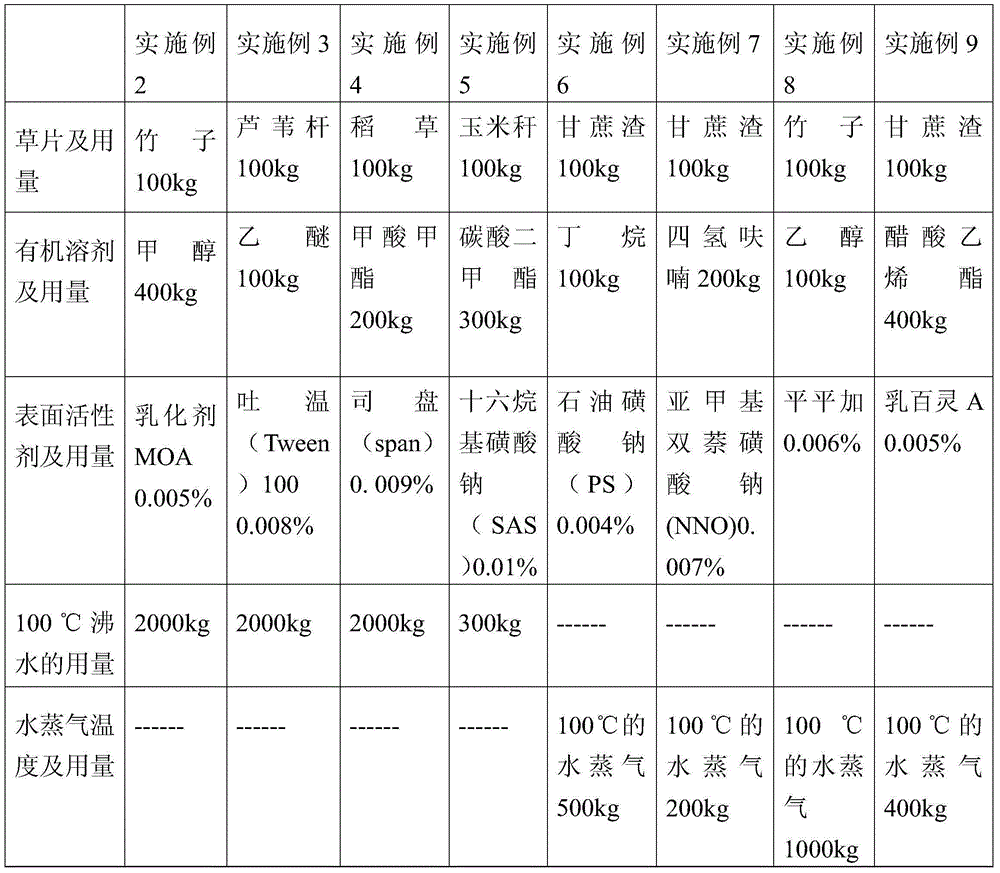

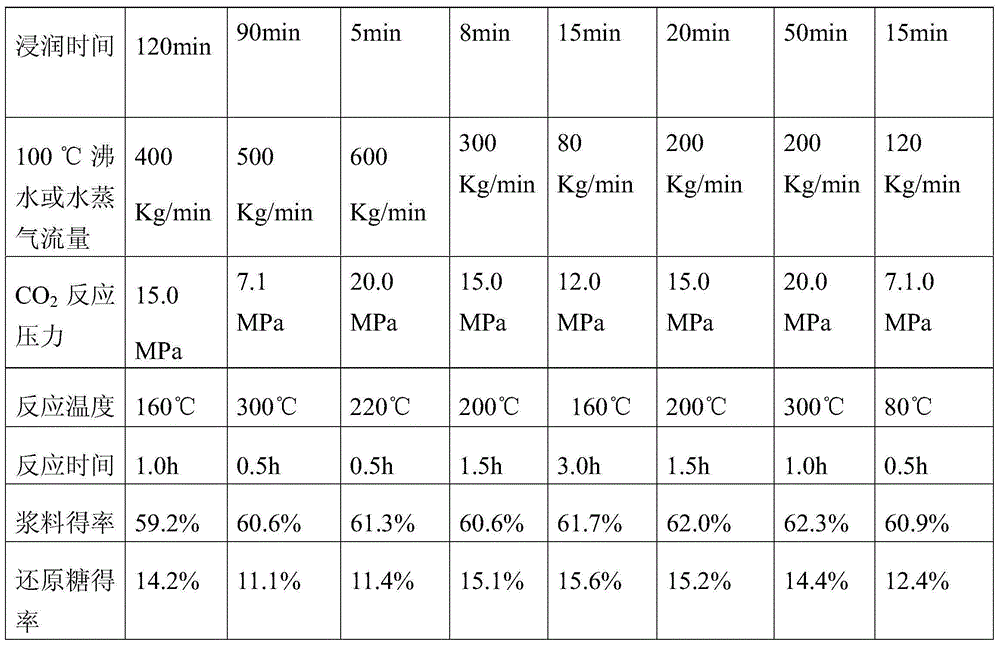

[0035] The method steps of Example 1 were repeated with the components and process parameters specified in Table 1 below.

Embodiment 3

[0037] The method steps of Example 1 were repeated with the components and process parameters specified in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com