Patents

Literature

31results about How to "Eliminate Feedback Inhibition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of alcohol from mixed bacterial population degradable fermented bastose substance

InactiveCN1896254AReduce degradationShorten the fermentation cycleBiofuelsMicroorganism based processesAlcohol productionCellulose degradation

Production of alcohol from mixed microbial pool degradable and fermented lignocellulose substance is carried out by crushing lignocellulose substance, soaking with H2SO4, bursting by steam, solid-liquid separating, adding nutritive liquid into solid-phase substance, sterilizing, adding distiller's yeast and cellulose degrading microbe into saccharifying fermentative substrate, degradation saccharifying-fermenting synchronously, distilling and rectifying to obtain final product. It is simple, has short saccharifying and fermenting period, higher raw material utilization rate and more alcohol yield and no feedback inhibition function.

Owner:HARBIN INST OF TECH

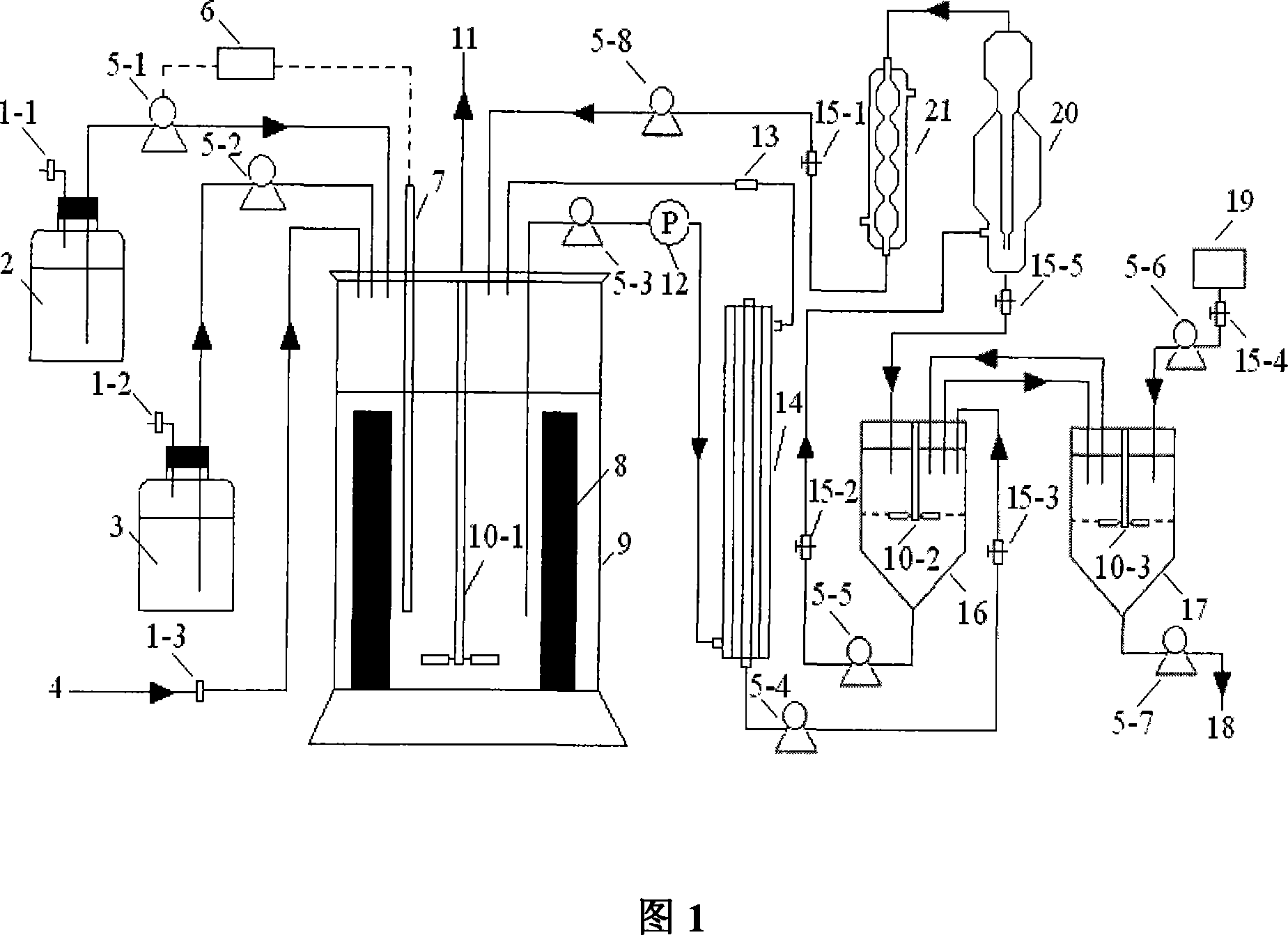

Device and technique for producing propanoic acid by coupling of fibrous bed bioreactor with extraction separation

InactiveCN101182455AEfficient fermentationImprove adsorption capacityBioreactor/fermenter combinationsBiological substance pretreatmentsHigh densityPropanoic acid

The invention discloses a fibrous bed reactor and the equipment and process for extracting separation and coupling production of propionic acid. The invention utilizes an immobilized fibrous bed reactor unit, a membrane separation unit, an extraction and anti-extraction unit and an elution and condensation unit to realize the efficient production of propionic acid. The device has strong feasibility, simple operation, easy realization of automation, immobilized materials, long using life of the membrane and the matching equipment, convenient maintenance and good application prospect. Through extracting separation and coupling production technology, the separation of propionic acid is realized. The invention radically eliminates the feedback inhibition of propionic acid, implements the high density fermentation of propionibacterium and greatly improves the production efficiency of propionic acid through the fermentation method. The extracted water phase is returned to the reactor for recycle after elution and condensation by an elution device, which eliminates the harm of extractant for propionibacterium from the root.

Owner:NANJING UNIV OF TECH

Microbial zymogene prepn and feed and alcohol producing process with zymogene prepn

The present invention has the technology scheme of adopting microbial zymogene preparation containing neurospora and saccharomycete. The fermentation process with the microbial zymogene preparation of the present invention to produce feed or alcohol is to add the microbial zymogene preparation components simultaneously or gradually and to process the obtained material for producing feed or alcohol. The present invention has the beneficial effect that the coupled and synergistic fermentation with the microbial zymogene preparation can eliminate the feedback suppression and saccharide or ethanol product suppression in the fermentation, raise the protein content, soften material, generate spirit fragrance, improve the taste of feed and raise production efficiency and product quality.

Owner:NANJING NORMAL UNIVERSITY

Method for preparing compound biological adsorbent by solid-state fermentation of herb residue

InactiveCN101564680AReduce pollutionSolve the problem of food competitionOther chemical processesMicroorganism based processesBiotechnologySporeling

The invention discloses a method for producing compound biological adsorbent by utilizing herb residues through a synchronous saccharification-solid-state fermentation technology. The invention is realized by the following steps: firstly, the herb residues are pretreated by the following concrete steps of: drying, grinding, screening and chemical treating the herb residues; secondly, the pretreated herb residues, wheat bran and nitrogen sources are uniformly mixed according to a certain proportion, a pH value is regulated, and Trichoderma Koningii Oud or white rot fungus spore suspension liquid is inoculated to prepare cellulase through the solid state fermentation after high-pressure steam sterilization treatment; and thirdly, the cellulase, the pretreated herb residues and the wheat bran are uniformly mixed according to a certain proportion, a pH value is regulated, candida utilis or candida tropicalis spore suspension liquid is inoculated to carry out synchronous saccharification-solid state fermentation, and a mixture of a fermentation product and raw material residues is the compound biological adsorbent.

Owner:CHENGDU UNIV OF INFORMATION TECH

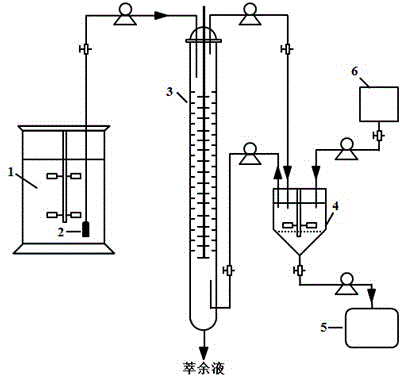

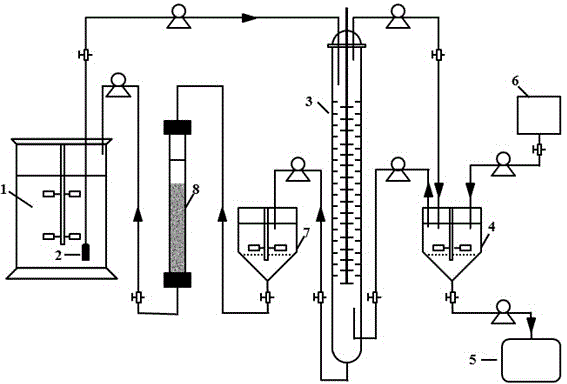

Method and device for extracting fumaric acid in fermentation broth in continuous counter current manner by means of amine extractants and application of fermentation technology combined with method

InactiveCN102875359AEfficient fermentationEliminate Feedback InhibitionMicroorganism based processesLiquid solutions solvent extractionChemistryRhizopus oryzae

The invention provides a method for extracting fumaric acid in fermentation broth in a continuous counter current manner by means of amine extractants. The method includes that filtered fermentation broth flow is added into an extracting tower to perform liquid-liquid extraction in the continuous counter current manner, the fermentation broth is used as heavy phase, the extraction system is used as light phase, extracts left the extraction tower is subjected to reextraction to generate fumaric acid or fumaric acid salt by reextraction, and the extraction system after reextraction returns the extraction tower and is used circularly; meanwhile, the extract can successively pass a primary organic solvent collection tank and a secondary organic solvent collection tank for secondary treatment, and finally the extracts flowing out returns the fermentation for reusing. The invention further provides a device for extracting fumaric acid in fermentation broth in a continuous counter current manner by means of amine extractants and application of a fermentation technology combined with the continuous counter-current extraction technology in continuous preparation of the fumaric acid. By the method, suppression to products in the process of fermentation of the fumaric acid can be effectively eliminated, and meanwhile, toxicity of the extracts to rhizopus oryzae can be avoided, and fermentation production level of the fumaric acid can be improved.

Owner:NANJING UNIV OF TECH

Method for extracting xylooligosaccharide from wheat bran

InactiveCN104894189AHigh purityImprove enzyme production capacityFermentationLow cholesterol levelsBifidobacterium

The invention discloses a method for extracting xylooligosaccharide from wheat bran. The method is used for preparing xylooligosaccharide with efficacies of promoting bifidobacterium reproduction, preventing constipation, reducing cholesterol, protecting the liver and the like by using byproduct of agricultural and sideline product processing, i.e., bran as a raw material and by using microbial fermentation and biological enzymolysis technologies, the quality of the obtained xylooligosaccharide product satisfies the industrial standard requirement of xylooligosaccharide, the high-efficiency utilization of the bran is realized, the use value of the bran is improved and the popularization prospect is better. The method for extracting xylooligosaccharide from wheat bran has the advantages that firstly the yield of xylooligosaccharide is improved through a combined preparation process of compound microbial solid fermentation and ultrasonic assisted enzymolysis; secondly the purity of the xylooligosaccharide product is obviously improved through the ultrasonic assisted enzymolysis for removing protein and starch and enzymolysis of phytase and mannase; and thirdly the capability of xylooligosaccharide fermentation and enzymolysis is improved through multi-bacteria mixed fermentation; fourthly the production process is simple, the energy consumption is low, no environmental pollution is caused, the investment is small and the mass production is facilitated.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Novel process for preparing polysaccharide by high-valued comprehensive utilization of wheat bran

InactiveCN106191163AHigh yieldHigh purityMicroorganism based processesFermentationPhytaseCholesterol

The invention discloses a novel process for preparing polysaccharide by high-valued comprehensive utilization of wheat bran. The novel process is characterized in that a byproduct bran generated by agricultural and sideline product processing is used as a raw material to prepare xylooligosaccharide with the efficacy of promoting proliferation of bifidobacterium, preventing constipation, reducing cholesterol, protecting liver and the like by using microbial fermentation and biological enzymolysis technologies; the quality of an obtained xylooligosaccharide product reaches standard requirements of a xylooligosaccharide industry, high-efficiency utilization of the bran is realized, and the utilization value of the bran is improved; the novel process has a better popularization prospect. The novel process disclosed by the invention has the advantages that firstly, the yield of the xylooligosaccharide is improved by a preparation process of cooperating ultrasonic assisted enzymolysis for three times with microbial fermentation; secondly, the purity of the xylooligosaccharide product is remarkably improved by performing ultrasonic assisted enzymolysis to remove protein and starch, and performing enzymolysis on phytase and mannase; thirdly, the capability of fermenting and performing enzymolysis on xylan is improved by multi-bacterium mixed fermentation; fourthly, a production process is simple, low in energy consumption, free of environmental pollution, low in investment and easy for scale production.

Owner:BINZHOU ZHONGYU FOOD

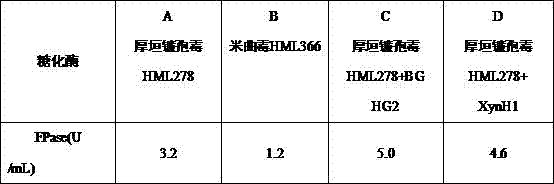

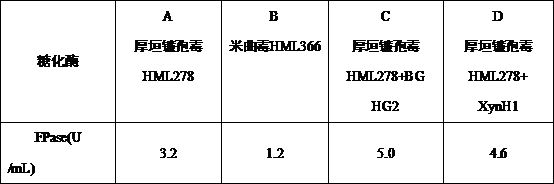

Method for producing cellulase by mixed fermentation of aspergillus oryzae and fusarium chlamydosporum

InactiveCN107460180AEliminate Feedback InhibitionHigh activityMicroorganism based processesFermentationAlgluceraseMixed culture

The invention discloses a method for producing cellulase by mixed fermentation of aspergillus oryzae and fusarium chlamydosporum. The method comprises the following steps: inoculating the fusarium chlamydosporum and the aspergillus oryzae on a bagasse solid culture medium and performing mixed culture fermentation, wherein the culture temperature is 20-50 DEG C, and pH value is 4.0-10.0; finishing fermentation culture after the maximum cellulose yield is reached. The method disclosed by the invention has the benefits that through the mixed culture of the aspergillus oryzae and the fusarium chlamydosporum, high-transglycoside activity belta-glucosidase produced by the aspergillus oryzae can synthesize gentiobiose, and the gentiobiose can stimulate the synthesis of the cellulase from the fusarium chlamydosporum; through the mixed culture of the aspergillus oryzae and the fusarium chlamydosporum, the composition of a cellulase system is optimized, so that the overall enzyme activity of the cellulase system can be significantly improved.

Owner:HECHI UNIV

Liquid phase hydrogen desulfurization-separation and coupling refining method for petroleum refining coarse oil

ActiveCN104312624ALess investmentAvoid generatingTreatment with hydrotreatment processesRefining with aqueous alkaline solutionsPtru catalystFluid phase

The invention discloses a liquid phase hydrogen desulfurization-separation and coupling refining method for petroleum refining coarse oil. The method comprises the following steps: (1) mixing coarse oil and hydrogen and entering into a hydrogenation reactor, and carrying out hydrogen desulfurization under the effect of a hydrogen desulfurization refining catalyst, wherein the use level of the hydrogen desulfurization refining catalyst is 1.0-10% by mass of the coarse oil, the hydrogen desulfurization refining catalyst is a metal supported catalyst, and a carrier is a heavy oil catalytic cracking waste accelerant; and (2) carrying out gas-liquid separation on the reaction product, wherein a gas phase substance flow is continuously extracted and washed and neutralized by alkali liquor; a liquid phase substance flow is extracted to obtain the refined oil. The method disclosed by the invention can be used for treating high-sulfur and high-nitrogen petroleum refining coarse oil so as to carry out hydrogen desulfurization-separation and coupling refining on the coarse oil under a relatively mild temperature and pressure operating condition, so that the equipment investment and operating expenses are greatly lowered.

Owner:GUANGXI UNIV

Method for preparing feed protein from alcohol waste liquid and crop straws

InactiveCN106721054AElimination of repressionEliminate Feedback InhibitionFood processingAnimal feeding stuffLiquid wasteResource utilization

The invention discloses a method for preparing a feed protein from alcohol waste liquid and crop straws, aiming at phenomena that the utilization rate of crops straw feed is not high and alcohol waste liquid pollution is caused, so as to meet straw comprehensive utilization requirements, requirements of animal husbandry feed proteins and objective requirements of alcohol waste liquid harmless treatment and utilization. The method disclosed by the invention mainly comprises the following three steps: ammonifying, carrying out compound enzymatic hydrolysis and carrying out multi-strain three-step solid-state fermentation. The method disclosed by the invention has the advantages of promoting growth and development, improving the feed utilization rate, improving the intestinal micro-ecology, preventing diseases and the like; recycling high-value utilization of the crops straws and harmless treatment and resource utilization of the alcohol waste liquid are realized; healthy, green and scientific development of a feed processing industry is facilitated, and the method has a wide application prospect.

Owner:新昌县拜瑞珂生物技术有限公司

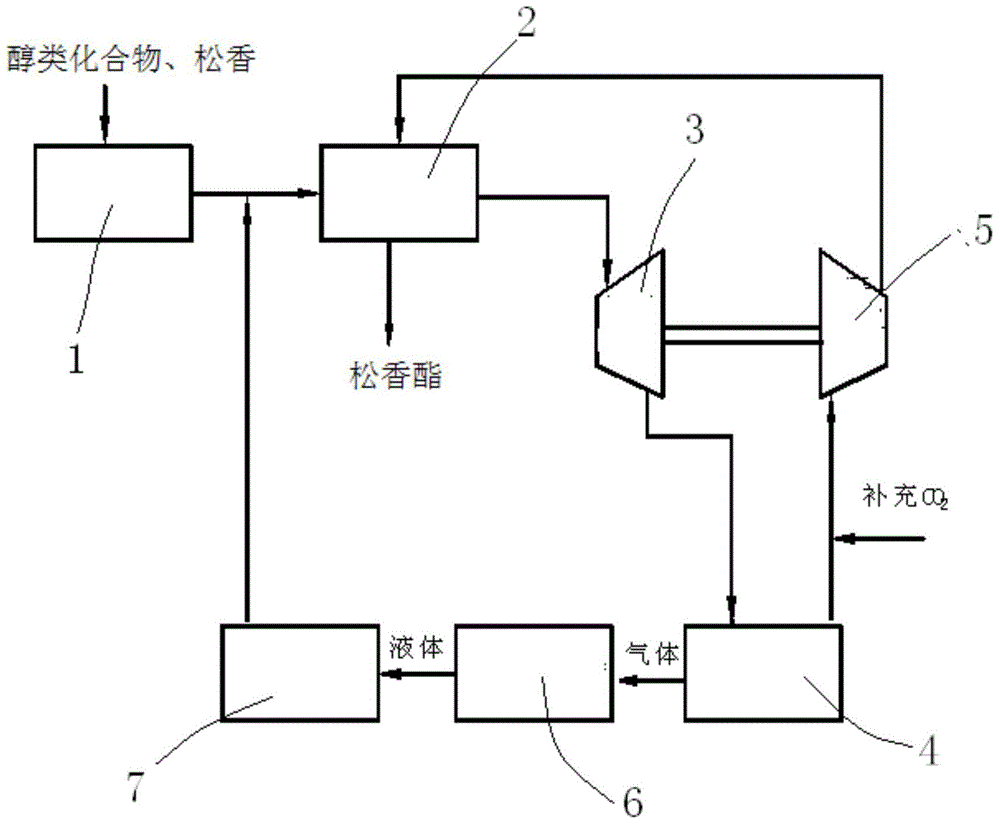

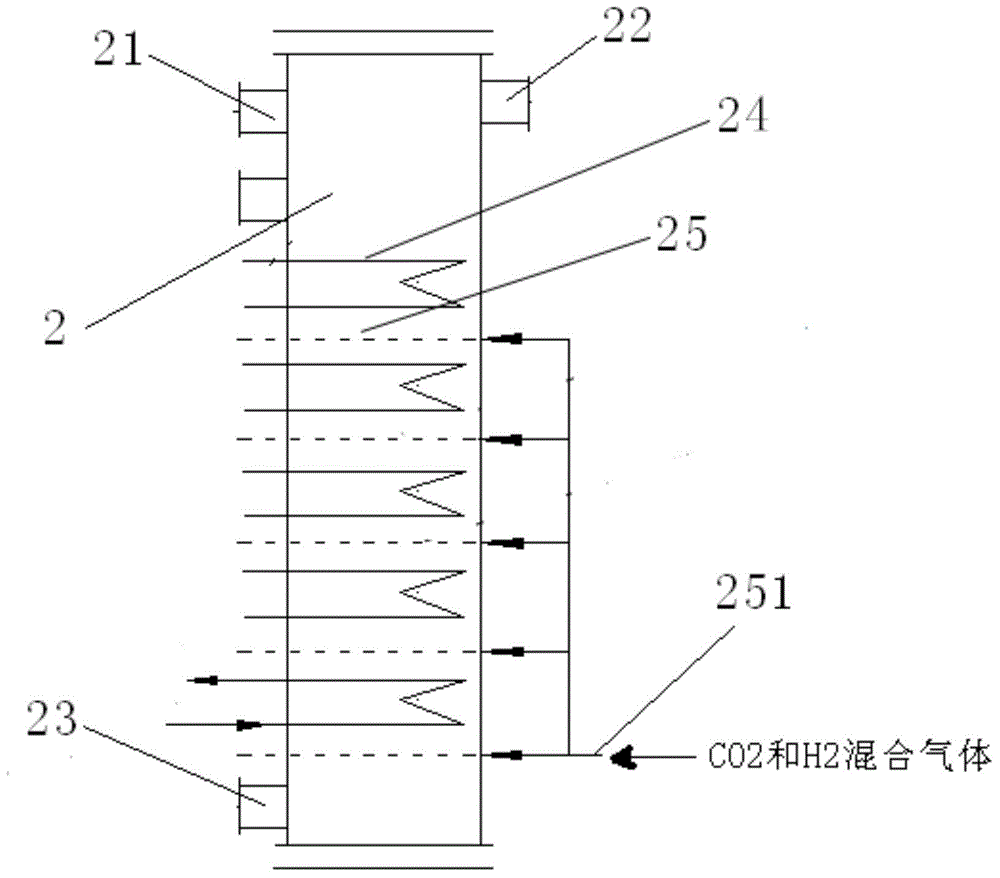

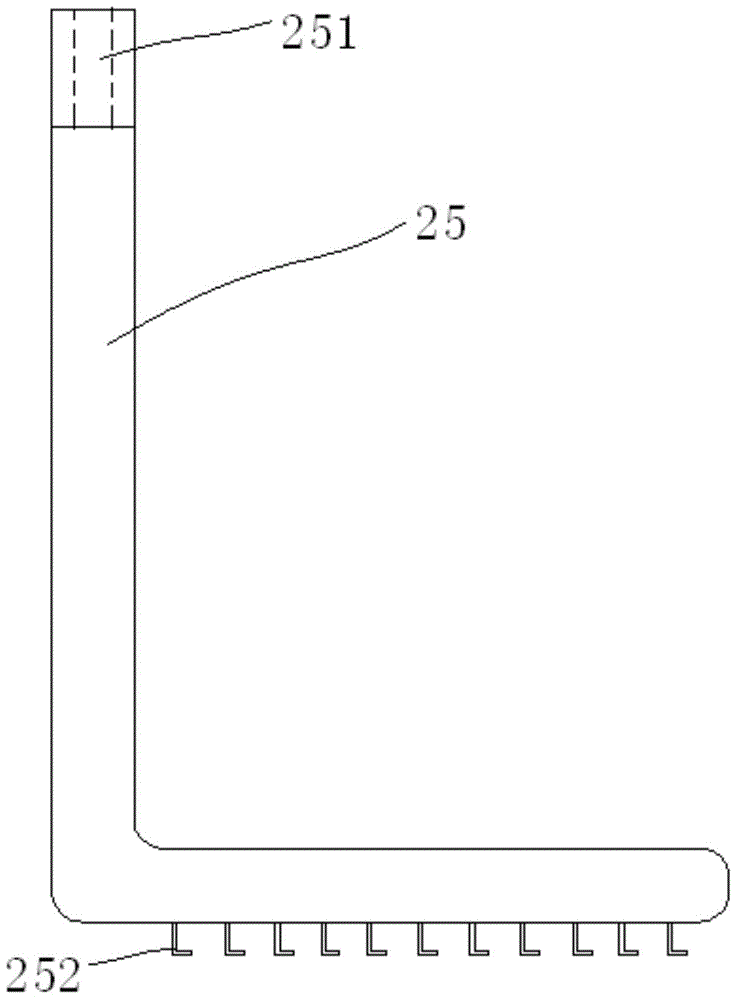

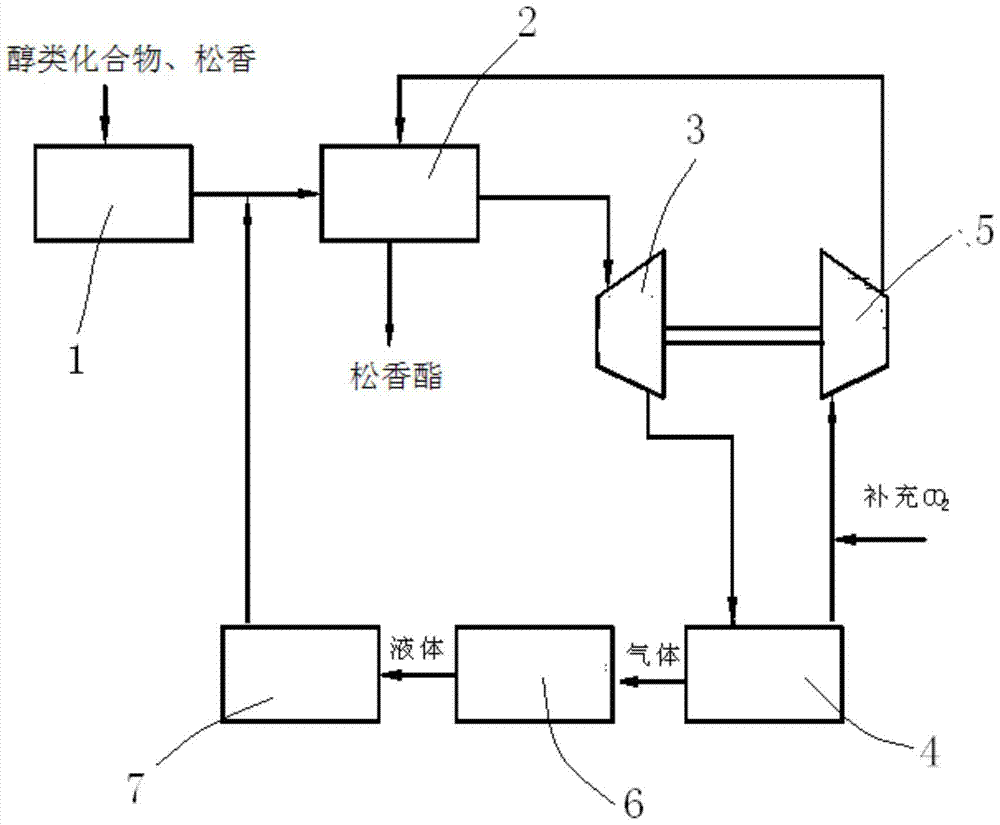

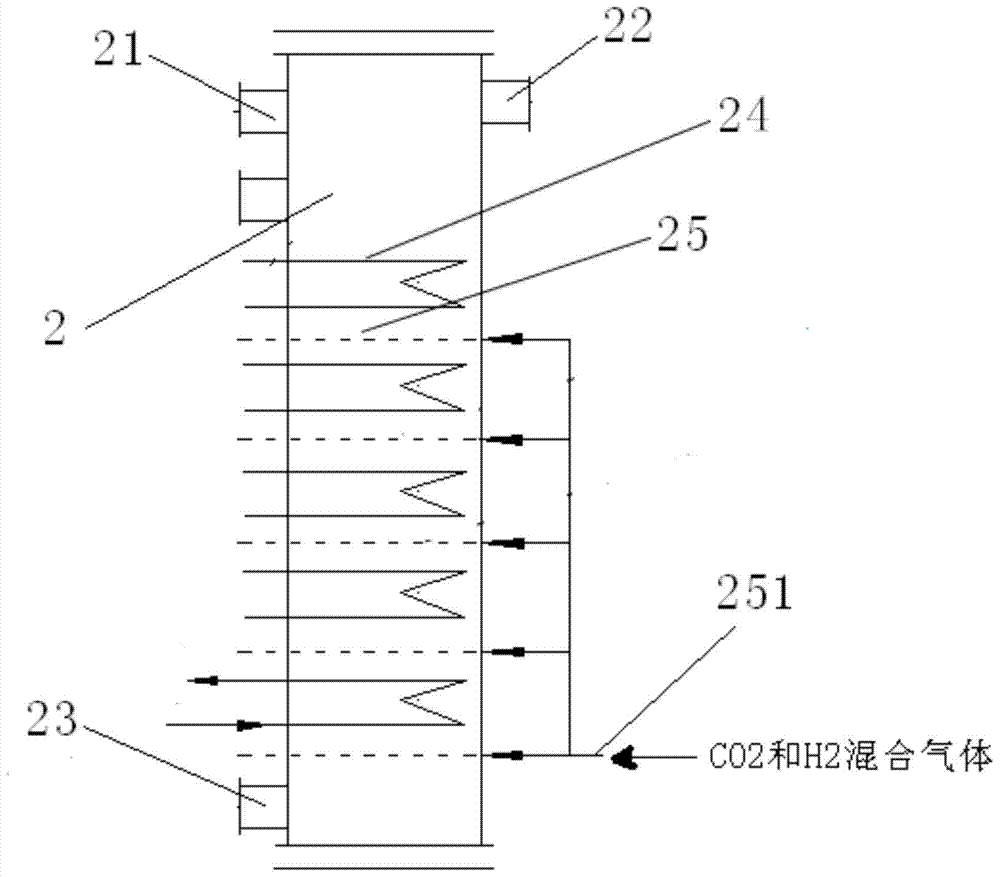

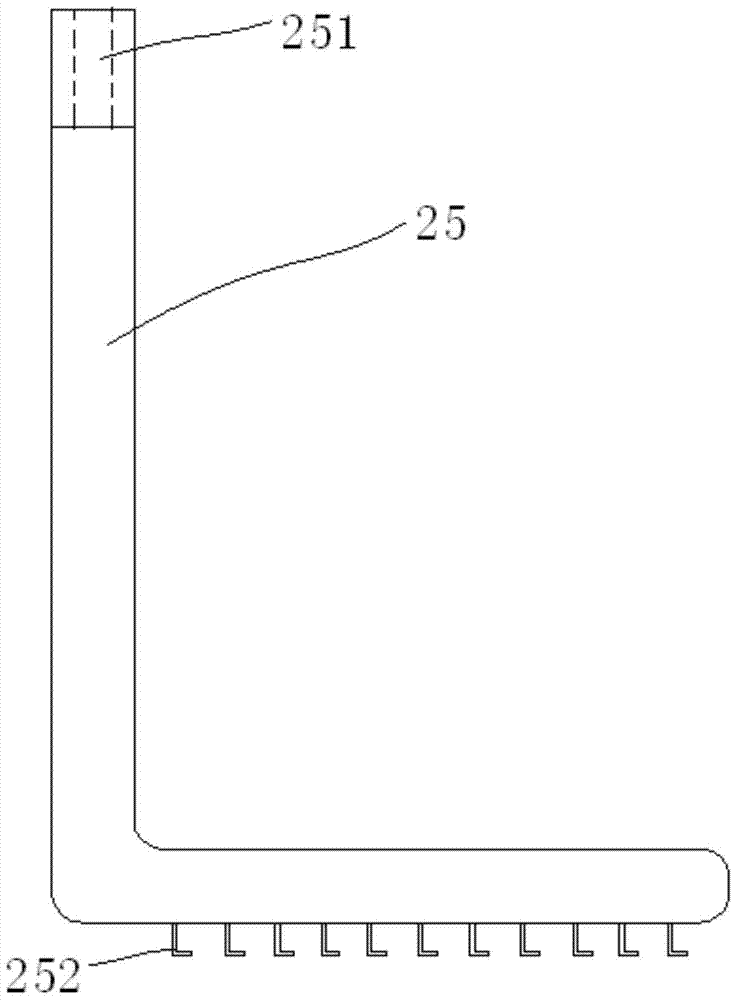

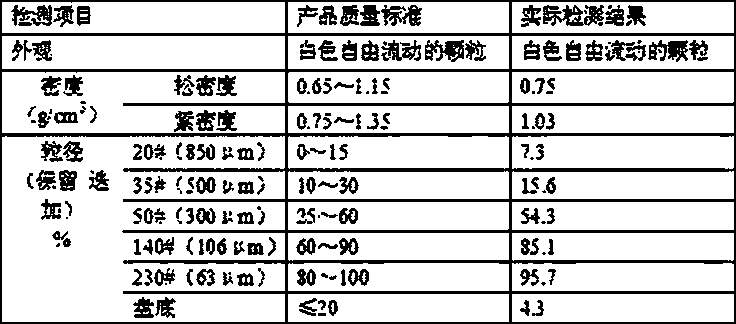

Method and device for preparing rosin ester by coupling catalytic esterification and separation

ActiveCN104694014AEliminate chemical balanceBreak chemical balanceChemical/physical/physico-chemical stationary reactorsNatural resin chemical modificationAlcoholVapor–liquid separator

The invention relates to a method for preparing rosin ester by coupling catalytic esterification and separation, which comprises the following operation steps: (1) mixing an alcohol compound, a rosin and a solvent, and dissolving; (2) putting the dissolved substance in the step (1) into an esterification reactor, and introducing 0.01-10.0-MPa CO2 to perform esterification reaction at 150-300 DEG C; (3) recovering the gas phase in the esterification reaction process, sending the gas phase into a gas-liquid separator through an expander, and returning the separated CO2 and newly supplemented CO2 into the esterification reactor through a turbine compressor; and (4) after reacting in the esterification reactor for 1.0-8.0 hours, relieving the pressure, and taking the obtained product out of the esterification reactor. The invention aims to provide a preparation method which has the advantages of lower cost and high rosin ester quality.

Owner:GUANGXI UNIV

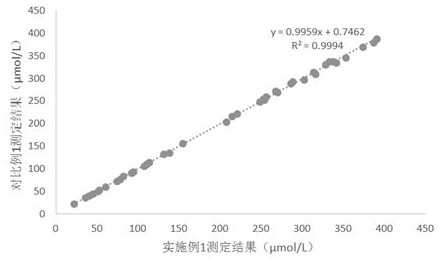

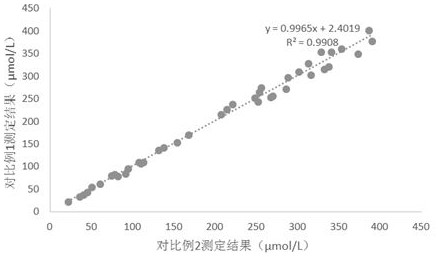

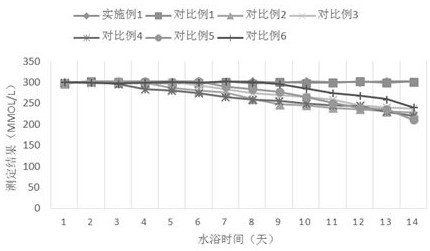

1, 5-sorbitan determination kit, preparation method and application thereof

InactiveCN112255219AEliminate Feedback InhibitionSolve the energy supply problem of the elimination processMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsMethylanilinePhosphate

The invention provides a 1, 5-sorbitan determination kit, a preparation method and an application thereof. The kit contains a reagent R1 and a reagent R2, wherein the reagent R1 contains the followingcomponents: a buffer solution, adenosine disodium triphosphate, hexokinase, glucose-6-phosphate dehydrogenase, nicotinamide adenine dinucleotide, phosphoenolpyruvate monopotassium salt, 4-amino antipyrine (4-AA), pyruvate kinase, peroxidase, lactic dehydrogenase, ascorbic acid oxidase, magnesium chloride, potassium chloride, an enzyme stabilizer and a preservative; and the reagent R2 is preparedfrom the following components in concentration: the buffer solution, pyranose oxidase, N-ethyl-N-(2-hydroxy-3-sulfopropyl)-3-methylaniline sodium salt, a surfactant and the preservative. The kit is aliquid kit with strong stability, high accuracy, high sensitivity and a stable glucose elimination capability, can be suitable for a full-automatic biochemical analyzer, and is simple and convenient to operate.

Owner:中拓生物有限公司 +2

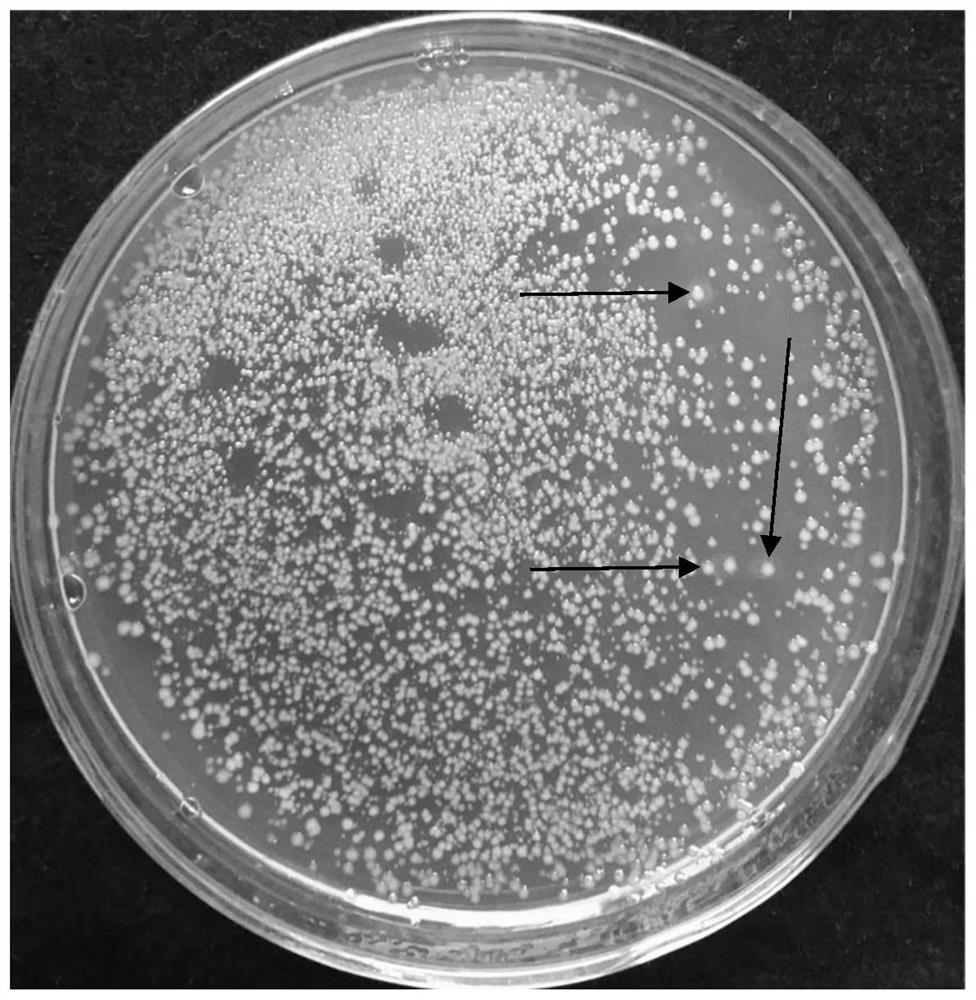

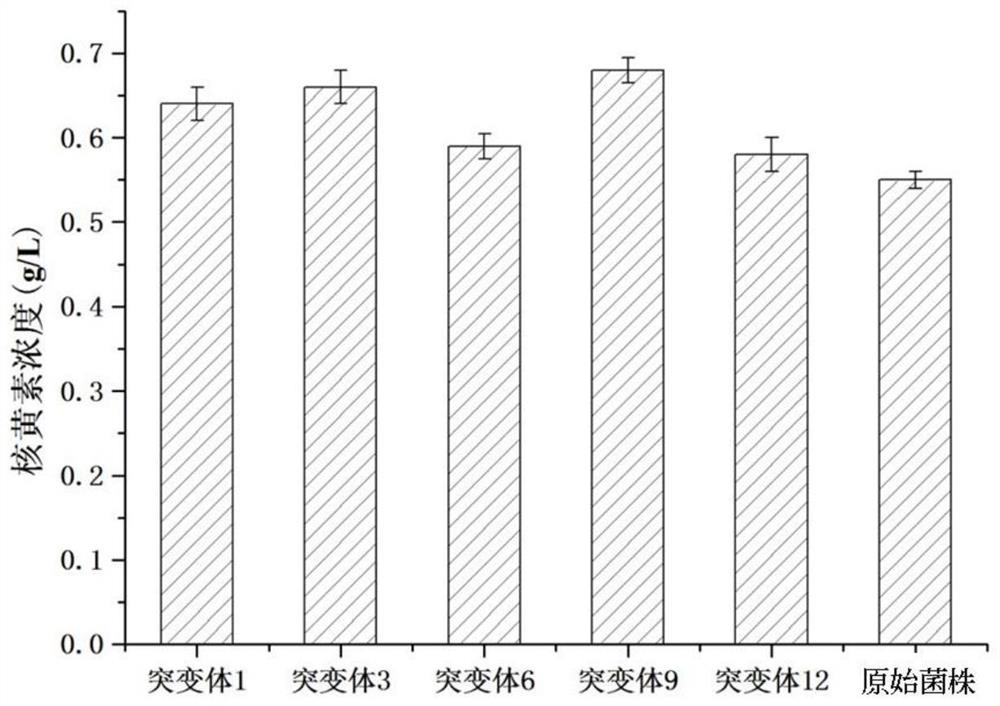

Method for improving riboflavin production capacity of escherichia coli engineering bacteria by DNA shuffling

PendingCN114181963ALow toxicityEliminate Feedback InhibitionTransferasesMicroorganism based processesEscherichia coliRiboflavin biosynthesis

The invention provides a method for improving riboflavin production capacity of escherichia coli engineering bacteria by using DNA shuffling, and relates to the field of genetic engineering, and the method comprises the following steps: constructing riboflavin-producing escherichia coli engineering bacteria containing 26 genes; carrying out DNA rearrangement and directional screening on the T7RNA polymerase gene expression unit, and extracting to obtain a first batch of positive plasmids; carrying out DNA rearrangement and directional screening on a riboflavin biosynthesis and transport system, and extracting to obtain a second batch of positive plasmids; carrying out DNA rearrangement and directional screening on the Escherichia coli sigma factor gene, and extracting to obtain a third batch of positive plasmids; introducing the third batch of plasmids into different chassis cells to obtain recombinant strains; and selecting the positive strain with the highest riboflavin yield. The toxicity problem of T7RNAP to an escherichia coli host in the construction process of the riboflavin-producing escherichia coli engineering bacteria, the feedback inhibition problem of a product and the moderate and coordinated expression problem of a constructed riboflavin biosynthetic gene are effectively eliminated. The efficiency and the yield of biosynthesis of riboflavin by the escherichia coli engineering strain are further improved.

Owner:SHANGHAI ACAD OF AGRI SCI

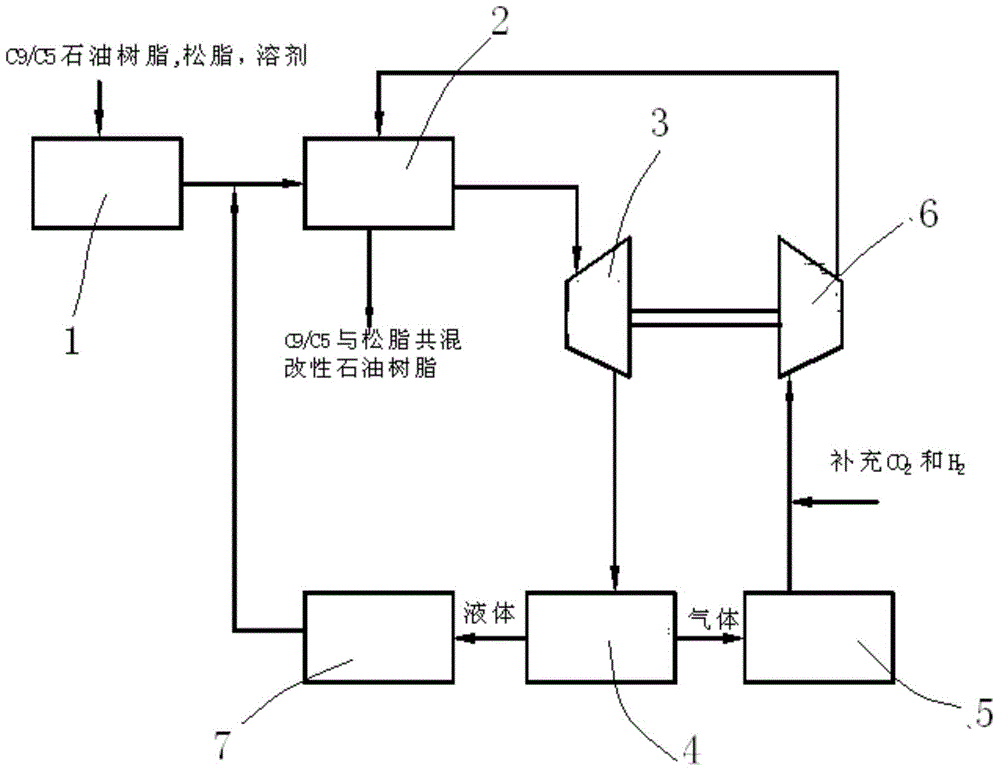

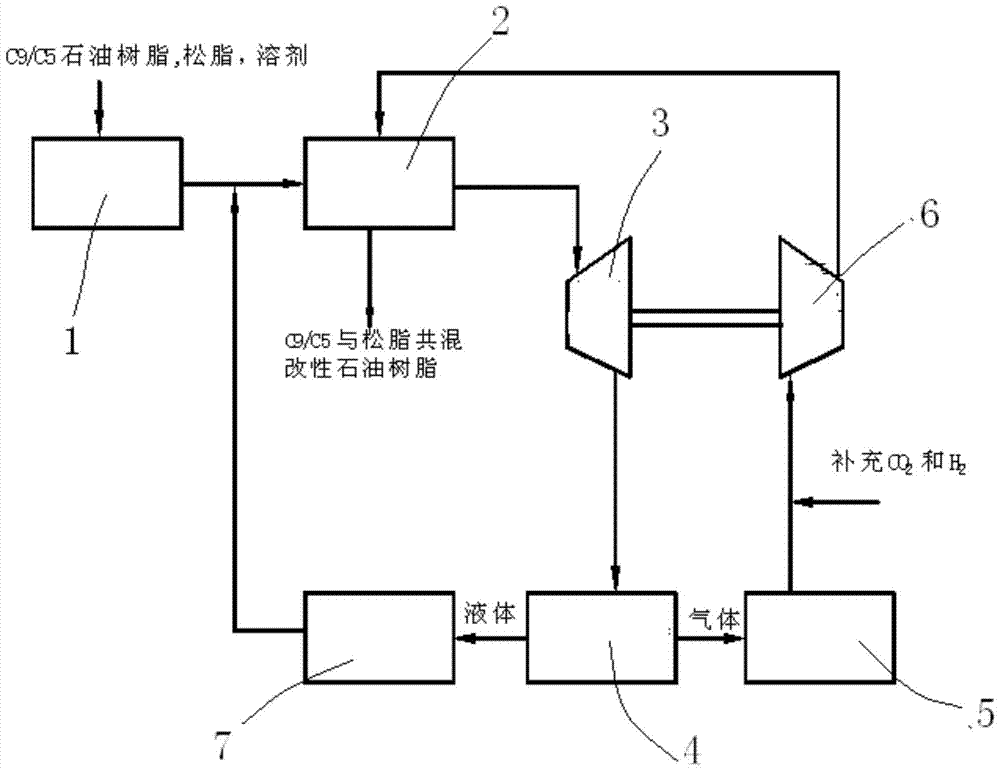

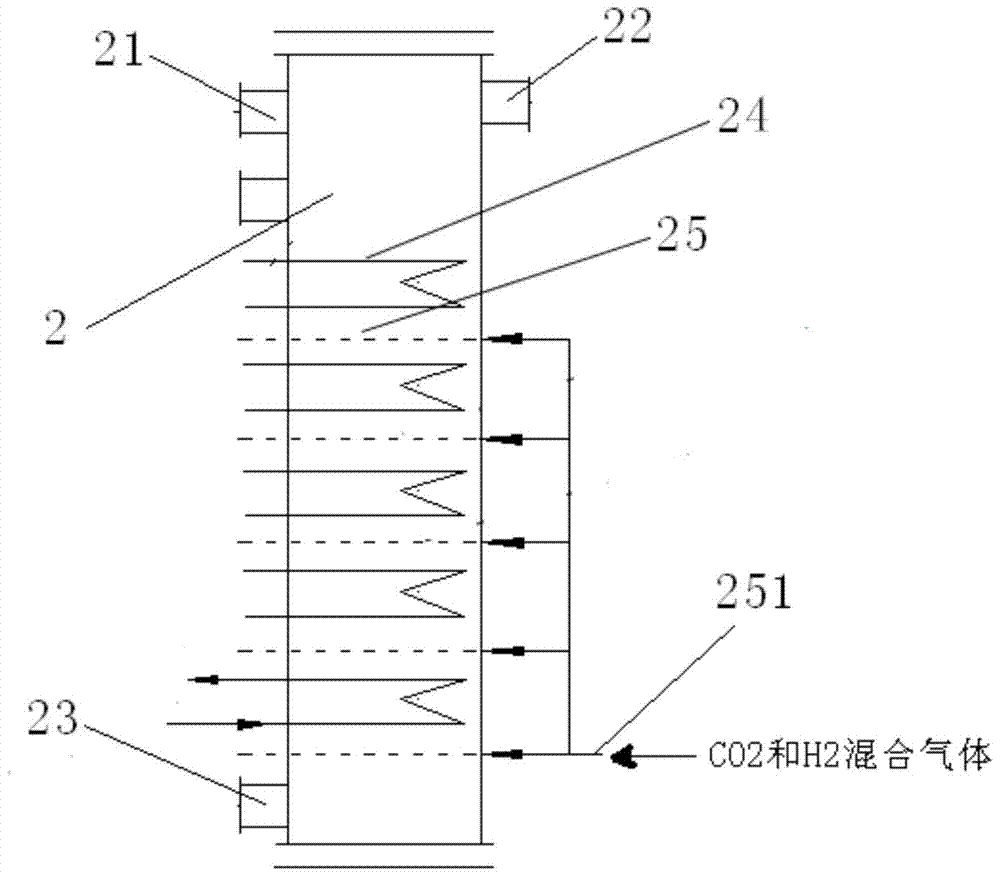

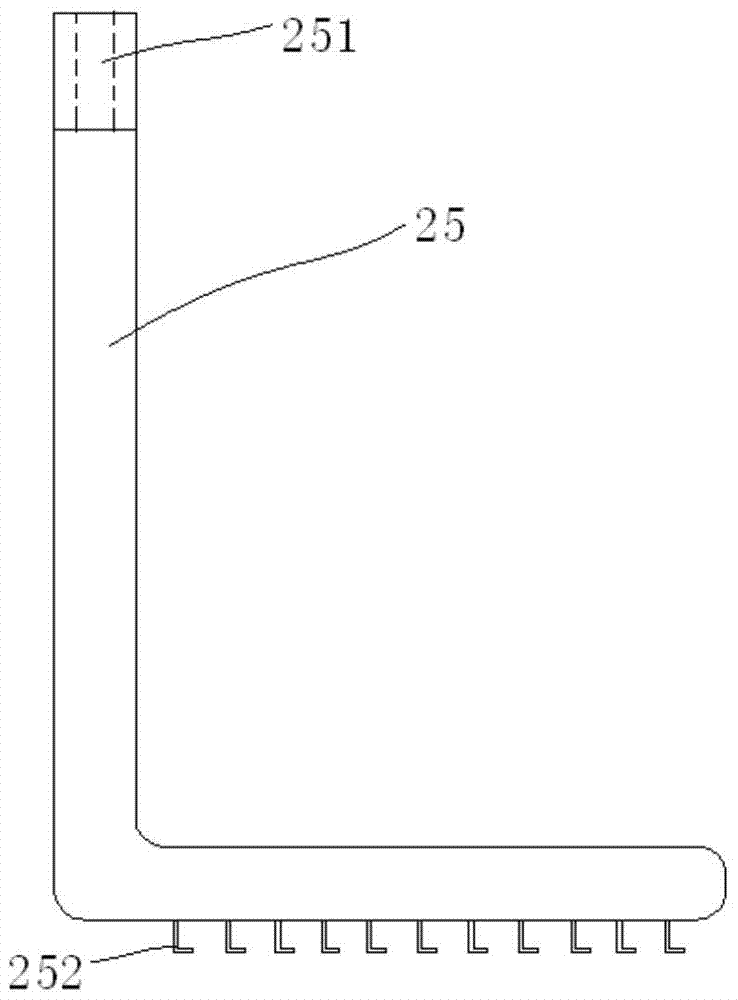

Turpentine-C9/C5 petroleum resin blend hydrogenation modification method and device

ActiveCN104693359AImprove heating efficiencyReduce heat conversion processNatural resin chemical modificationChemical/physical processesHydrogenation reactionTurpentine

The invention discloses a turpentine-C9 / C5 petroleum resin blend hydrogenation modification method which comprises the following steps: (1) raw material preparation: mixing raw materials turpentine and C9 / C5 petroleum resin with a solvent and a catalyst, and dissolving by heating; (2) hydrogenation reaction: putting the mixture prepared in the step (1) into a hydrogenation reactor, charging a gas mixture of H2 and CO2 in a mole ratio of 1:1-20:1, and carrying out hydrogenation reaction at 150-400 DEG C under the pressure of 3.0-35.0 MPa; (3) taking out the reacted gas mixture in the hydrogenation reactor, passing the gas through an expander which is connected with a turbine compressor, supplementing the CO2-H2 gas mixture into the turbine compressor, and introducing the gas mixture into the hydrogenation reactor; and (4) after carrying out hydrogenation-desulfurization reaction for 1-10 hours, relieving the pressure, and discharging the blend hydrogenation modified turpentine-C9 / C5 petroleum resin product out of the hydrogenation reactor. The method enhances the hydrogenation-desulfurization reaction speed and equilibrium conversion rate, and implements coupling of the hydrogenation reaction and desulfurization separation.

Owner:GUANGXI UNIV

Production of alcohol from mixed bacterial population degradable fermented bastose substance

InactiveCN1896254BReduce degradationShorten the fermentation cycleBiofuelsMicroorganism based processesAlcohol productionCellulose degradation

The present invention discloses a method for producing alcohol from mixed microbial pool degradable and fermented lignocellulose substance, relating to a method for producing alcohol by degradation of fermented lignocellulose substance, and solves the problems of high cost and long production cycle in production of alcohol by using the lignocellulose substance in the prior art. The method comprises the following steps: 1) crushing lignocellulose substance, soaking with H2SO4, and bursting by steam; 2) solid-liquid separating, adding nutritive liquid into solid-phase substance, and sterilizing; 3) adding distiller's yeast and cellulose degrading microbe into saccharifying fermentative substrate; 4) degradation saccharifying-fermenting synchronously, distilling and rectifying to obtain final product. The method for producing alcohol from mixed microbial pool degradable and fermented lignocellulose substance provided by the present invention has the advantages that: degradation and saccharification-fermentation are synchronously occurred, thus the degradation and saccharification-fermentation period is shortened by 40% while the productive technology is simplified and the use ratio of equipment is improved. Moreover, the feedback inhibition function to cellulose hydrolysis of monose is eliminated and both the raw material utilization rate and alcohol yield are improved.

Owner:HARBIN INST OF TECH

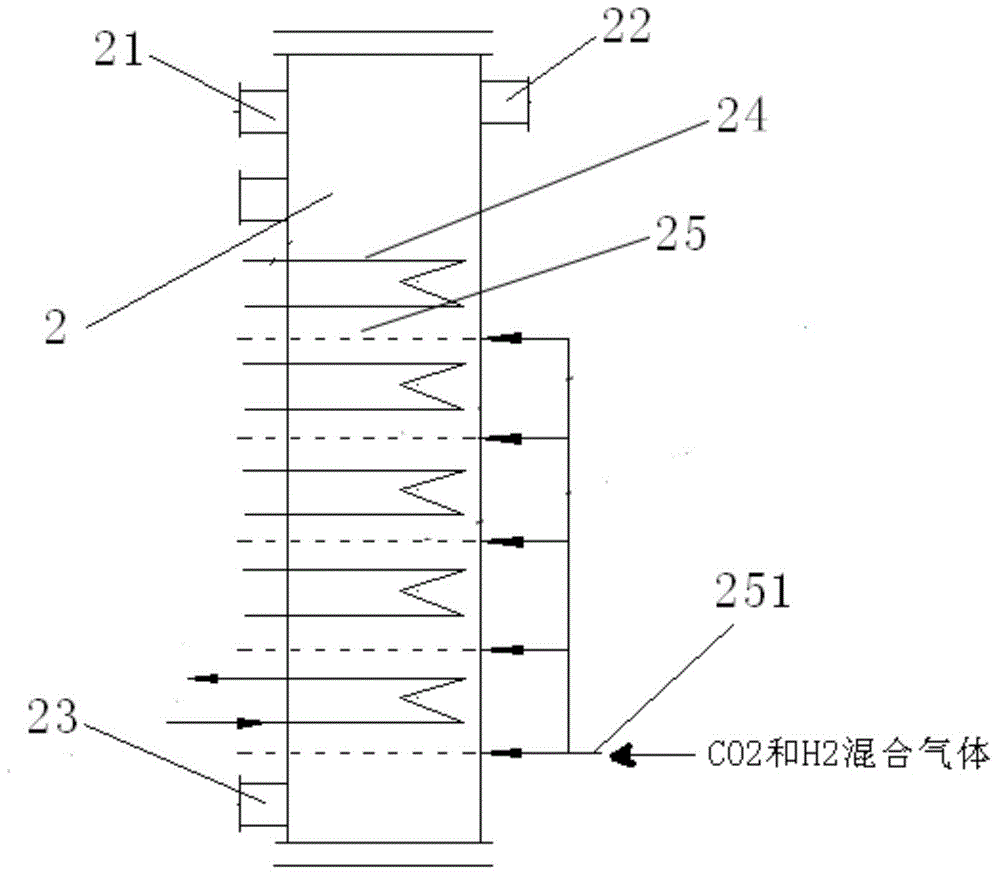

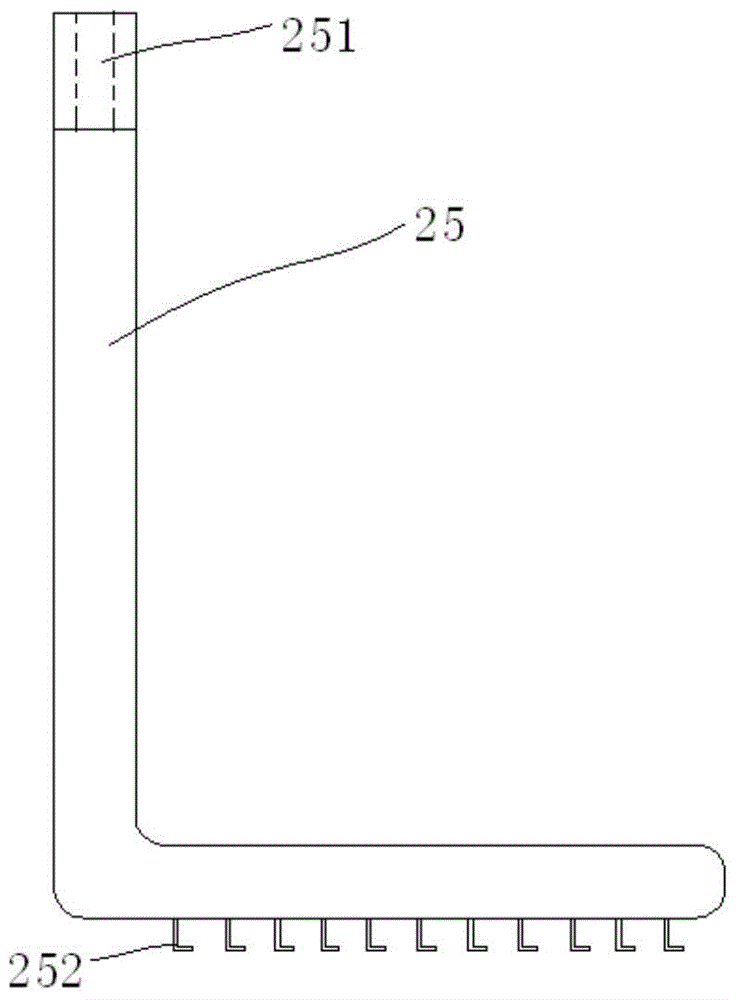

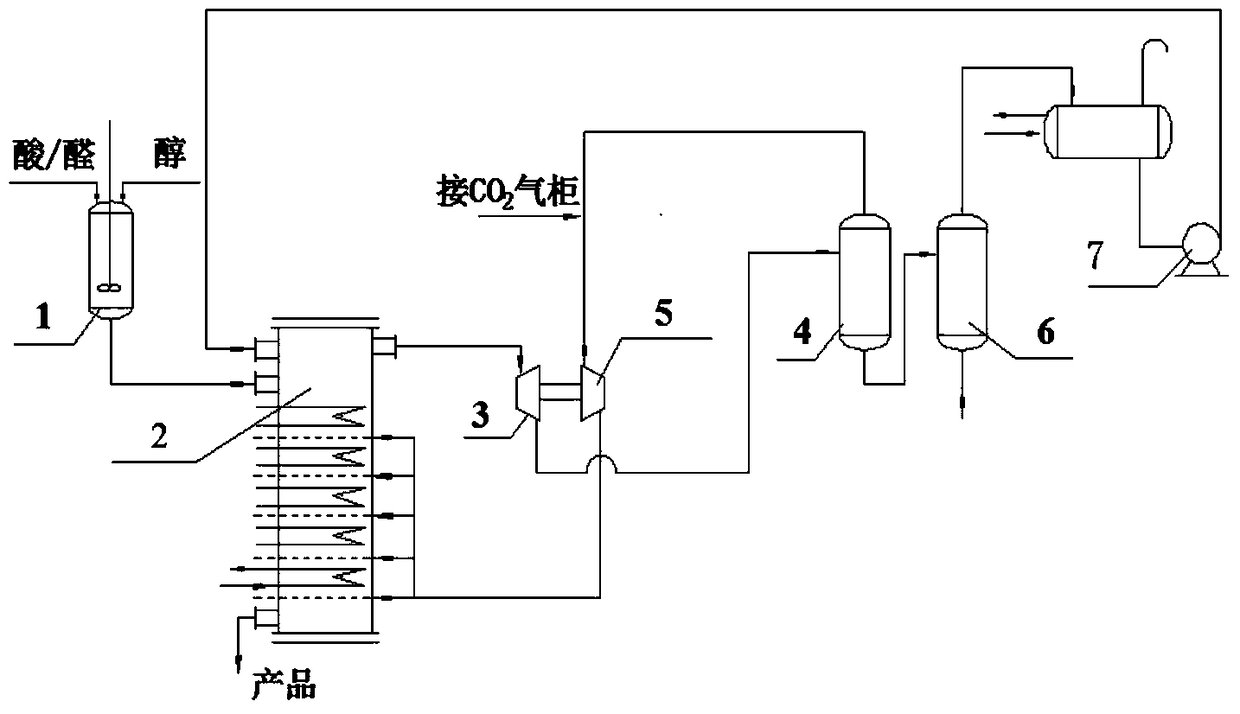

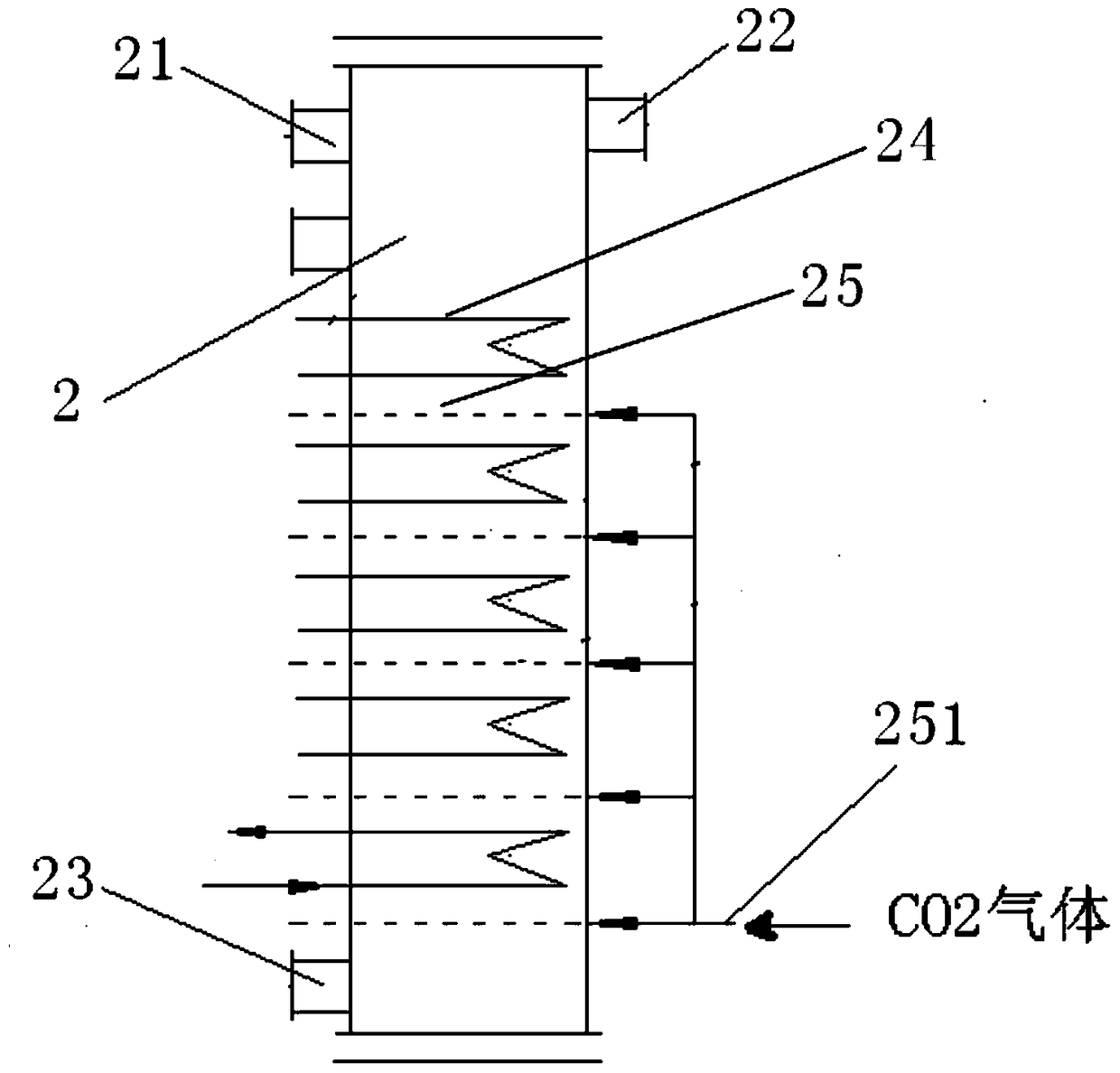

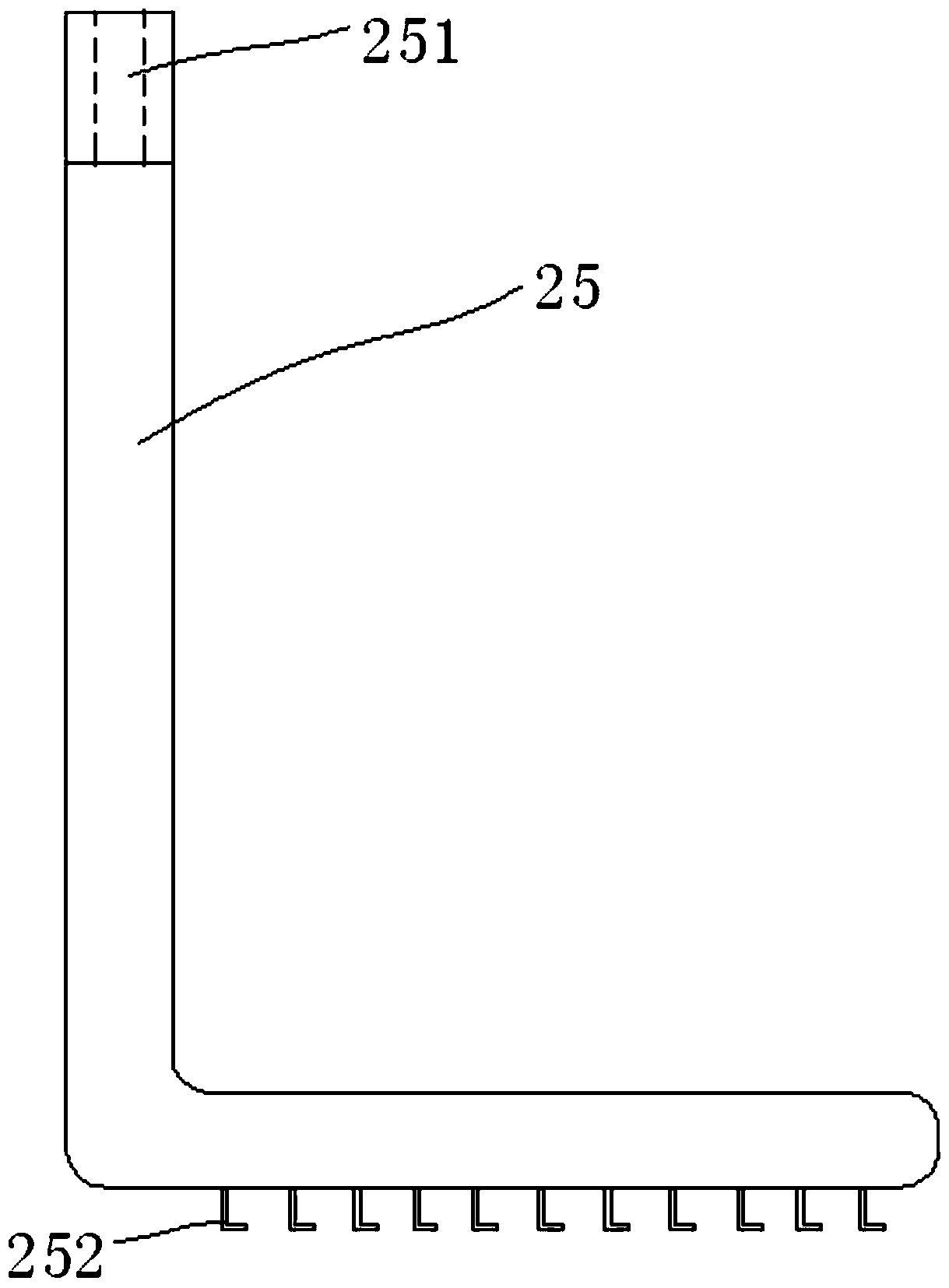

Transcritical CO2 catalytic esterification/condensation-separation coupling reaction method and equipment

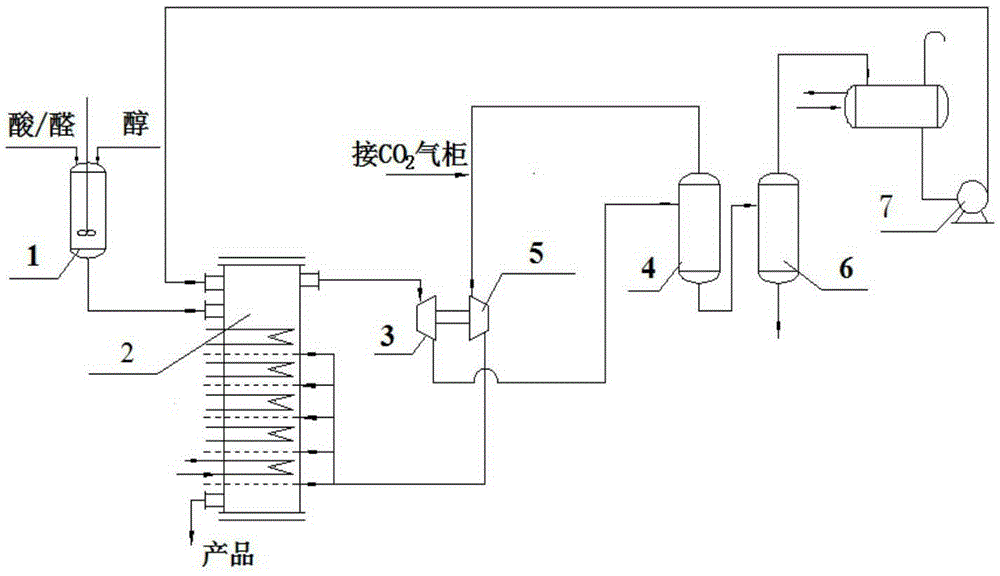

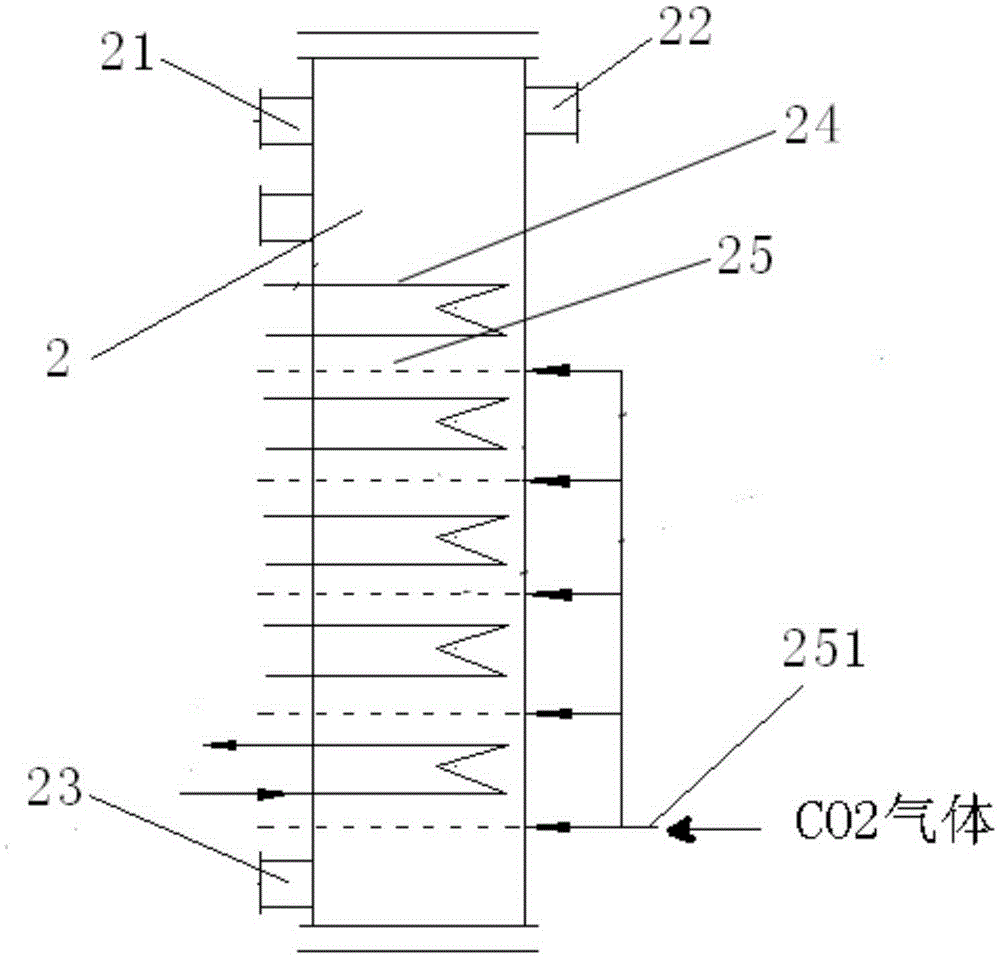

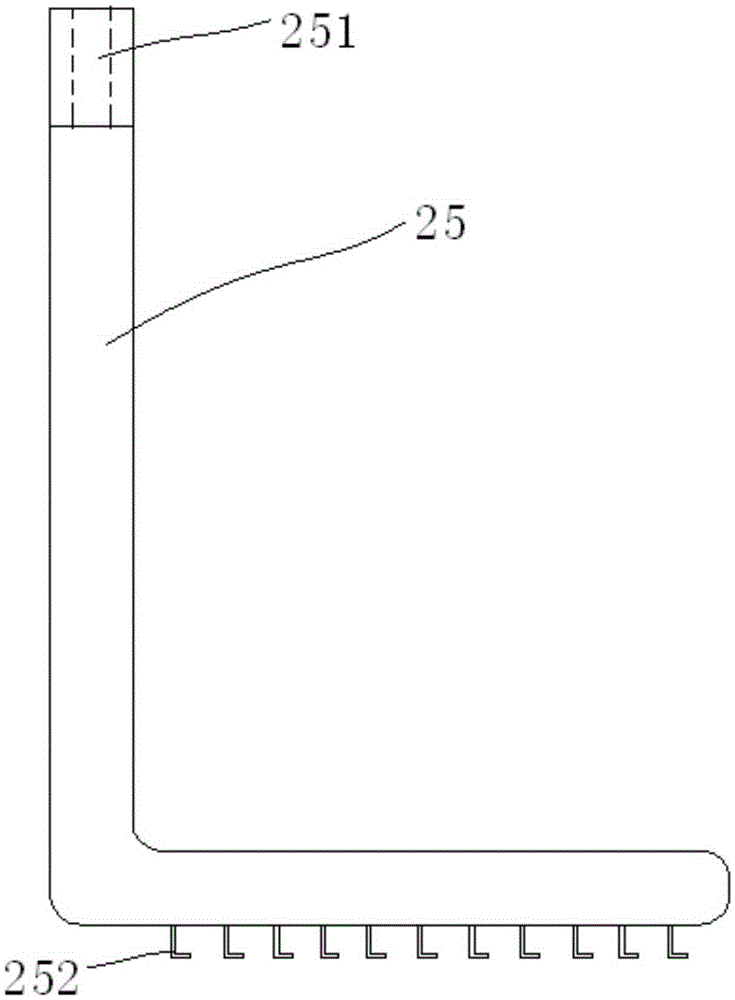

ActiveCN105237318AAvoid pollutionImprove reaction speedOrganic compound preparationCarboxylic acid esters preparationVapor–liquid separatorAlcohol

The invention discloses a transcritical CO2 catalytic esterification / condensation-separation coupling reaction method. The method comprises the following steps: mixing alcohol compounds, acid / aldehyde compounds, and a solvent, dissolving, transferring the solution to a reactor, introducing CO2 into the reactor to carry out reactions; collecting the byproducts in gas phase, converting the gas phase by an expansion machine from a supercritical state into a subcritical state, then introducing the gas phase into a gas-liquid separator, pressurizing the separated CO2 and supplemented CO2 by a turbo-compressor, then introducing the pressurized CO2 into the reactor, carrying out reactions for 0.5 to 10 hours, reducing the pressure in the reactor, and taking out reaction products from the reactor. The equipment used by the provided method comprises an esterification / condensation reactor, which comprises a plurality of heating pipes and a gas distributor. The expansion machine and the turbo-compressor are integrated into one machine, and the turbo-compressor is driven by the recovered expansion work of the reaction system. The provided transcritical CO2 catalytic esterification / condensation-separation coupling reaction method and equipment have the advantages that the technology is convenient, the quality of esters / condensed carbonyl product is high, and the conversion rate is high.

Owner:GUANGXI UNIV

Liquid-phase hydrodesulfurization reaction-separation coupled refining method for crude oil in petroleum refining

ActiveCN104312624BLess investmentAvoid generatingTreatment with hydrotreatment processesRefining with aqueous alkaline solutionsPtru catalystHydrodesulfurization

The invention discloses a liquid-phase hydrogenation desulfurization reaction-separation coupled refining method for crude oil products in petroleum refining, which comprises the following steps: (1) mixing the crude oil products and hydrogen into a hydrogenation reactor, and refining them in hydrodesulfurization The hydrodesulfurization reaction is carried out under the action of the catalyst; the dosage of the hydrodesulfurization refining catalyst is 1.0%-10% of the crude oil quality, the hydrodesulfurization refining catalyst is a metal-supported catalyst, and the carrier is heavy oil catalytic cracking waste catalyst; (2) The gas-liquid separation of the above reaction products is carried out, and the gas phase stream is continuously extracted, washed and neutralized with lye; the liquid phase stream is extracted, which is a refined oil product. The invention can process crude oil refined from high-sulfur and high-nitrogen petroleum, and carry out hydrogenation desulfurization reaction-separation coupled refining of crude oil under relatively mild temperature and pressure operating conditions, greatly reducing equipment investment and operating costs.

Owner:GUANGXI UNIV

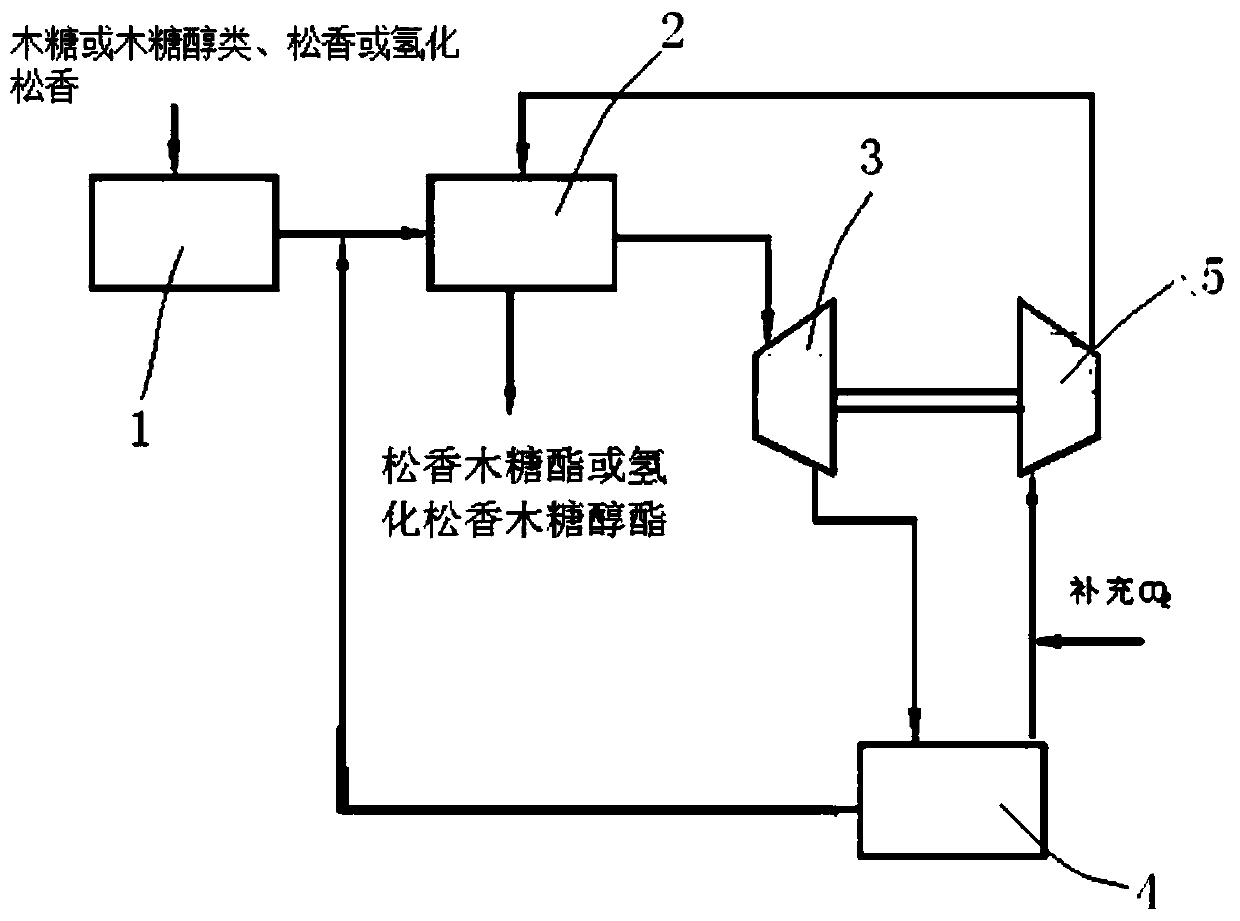

Method for preparing food-grade rosin xylose ester through catalytic esterification- separation coupling

PendingCN110143990AAvoid pollutionEliminate Feedback InhibitionEsterified saccharide compoundsSugar derivativesSolventXylose

The invention discloses a method for preparing food-grade rosin xylose ester through catalytic esterification-separation coupling. The method comprises the operation steps of (1) mixing xylose or xylitol, with rosin or hydrogenated rosin and a green solvent to obtain a mixture, and enabling the mixture to dissolve; (2) inflating CO2, and performing an esterification reaction; (3) continuously taking out a gas phase, and performing condensing and separation; (4) after the esterification reaction is performed for 2.0-16.0h, taking out reaction products from an esterification reaction reactor; and (5) performing constant-pressure distillation and underpressure distillation on the reaction products, and removing the green solvent to obtain the food-grade rosin xylose ester. The rosin or the hydrogenated rosin, and the xylose or the xylitol are used as the raw materials for preparing the food-grade rosin xylose ester, because the xylose or the xylitol is a natural healthy sweetening agent,and when the food-grade rosin xylose ester is used as a food additive, the sweetening agent does not need to be added additionally. The product produced by the method is safe and reliable, the green solvent is recycled, and the method is a green method and cleaning production process for preparing the food-grade rosin xylose ester from the rosin or the hydrogenated rosin through catalyzing.

Owner:GUANGXI UNIV

Preparation method of red date enzyme

PendingCN110338400AImprove immunityTo promote metabolismFood sciencePectinaseLactobacillus rhamnosus

The invention discloses a preparation method of a red date enzyme, adopting enzymolysis-coupling fermentation production technology. The preparation method comprises the following steps: (1) pulp preparation: cleaning selected red dates and carrying out pulp preparation to obtain red date pulp; (2) enzymolysis: adjusting the red date pulp to a pH value of 5.0-6.5 and a temperature of 25-50 DEG C,adding a complex enzyme at least consisting of rhamnosan degrading enzyme, pectinase, dextranase and galactosidase, and carrying out enzymolysis for 1-3 hours; (3) coupling fermentation: preparing lactobacillus rhamnosus into bacterial suspension of 10<4>-10<8> CFU / mL by using sterile normal saline; when the enzymolysis lasts for 1-3 hours, inoculating the lactobacillus rhamnosus aseptically, stirring the mixture, carrying out static culture for 12-48 hours, and stopping fermentation when the pH value is 3.5-4.5; and (4) post-treatment: carrying out solid-liquid separation on the enzyme fermented in the step (3) to obtain liquid red date enzyme. The method disclosed by the invention adopts the enzymolysis-coupling fermentation production technology, thus improving the utilization rates ofred date components and the yields of the enzyme and prebiotics.

Owner:MARINE BIOMEDICAL RES INST OF QINGDAO CO LTD

transcritical co 2 Catalytic esterification-separation coupling method and device for preparing rosin ester

ActiveCN104694014BAvoid pollutionImprove reaction speedChemical/physical/physico-chemical stationary reactorsNatural resin chemical modificationVapor–liquid separatorAlcohol

The invention relates to a method for preparing rosin ester by coupling catalytic esterification and separation, which comprises the following operation steps: (1) mixing an alcohol compound, a rosin and a solvent, and dissolving; (2) putting the dissolved substance in the step (1) into an esterification reactor, and introducing 0.01-10.0-MPa CO2 to perform esterification reaction at 150-300 DEG C; (3) recovering the gas phase in the esterification reaction process, sending the gas phase into a gas-liquid separator through an expander, and returning the separated CO2 and newly supplemented CO2 into the esterification reactor through a turbine compressor; and (4) after reacting in the esterification reactor for 1.0-8.0 hours, relieving the pressure, and taking the obtained product out of the esterification reactor. The invention aims to provide a preparation method which has the advantages of lower cost and high rosin ester quality.

Owner:GUANGXI UNIV

Method for producing fuel ethanol from paper mill sludge

InactiveCN103627733AReduce pollutionEliminate Feedback InhibitionSludge processingFermentationCentrifugationRoom temperature

The invention discloses a method for producing fuel ethanol from paper mill sludge. The method comprises the following steps of 1, crushing paper mill sludge, neutralizing the crushed paper mill sludge by an acid and carrying out drying, 2, preparing a fermentation medium containing 5g / L of peptone, 3g / L of yeast powder and 3g / L of wort, 3, filling 50-60ml of the fermentation medium prepared from a phosphate buffer salt having a pH value of 5.0 into a 250mL of an erlenmeyer flask, adding 5-6g of the treated paper mill sludge into the erlenmeyer flask, carrying out high-pressure steam disinfection at a temperature of 121 DEG C for 20min, carrying out cooling to a room temperature, adding 20-25FPU / g of cellulase and 5-6% of a seed yeast into the fermentation medium, plugging the bottle opening by a microaerobic rubber plug, and carrying out constant-temperature synchronous saccharification fermentation at a shaking table rate of 100-150r / min at a temperature of 36DEG C, wherein in the fermentation, a nonionic surfactant can be used, and 4, carrying out centrifugation at a rotation rate of 4000-5000r / min. The method utilizes the synchronous saccharification fermentation process to produce fuel ethanol from paper mill sludge, changes wastes into valuables and reduces paper mill sludge-caused environmental pollution.

Owner:QINGDAO JIENENG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

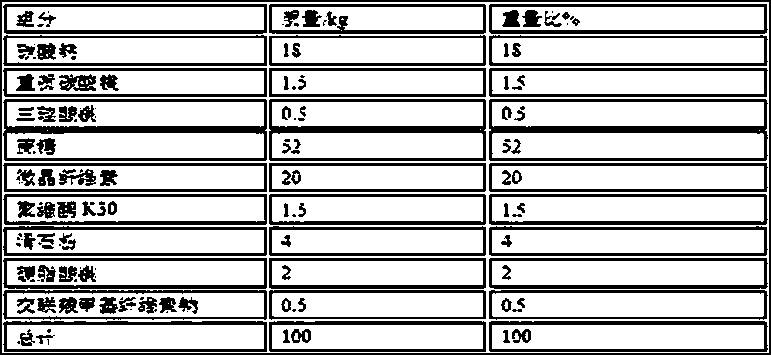

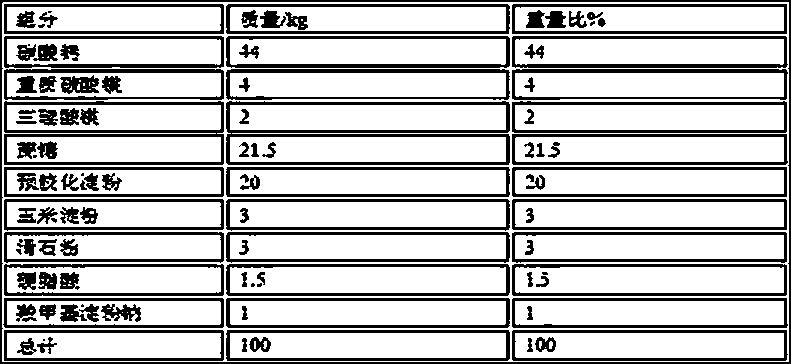

Medicine for treating hyperacidity and preparation method thereof

InactiveCN104069126ARaise the pHEliminate Feedback InhibitionMetabolism disorderDigestive systemFormularyPharmaceutical drug

The invention discloses a medicine for treating hyperacidity and a preparation method thereof. The formula of the medicine comprises the following components in percentage by weight: 20-80wt% of main medicines including calcium carbonate, heavy magnesium carbonate and magnesium trisilicate, and the balance of accessories including a filler, a binder, a disintegrant and a lubricant. The medicine is mild and lasting in action, but has no direct inhibition effect on gastric acid secretion; the medicine for treating hyperacidity is suitable for the adults and also suitable for children to take.

Owner:浙江康乐药业股份有限公司

Microbial zymogene prepn and feed and alcohol producing process with zymogene prepn

The invention discloses a microbial fermentation agent and a method for producing feed or ethanol using the fermentation agent. The technical solution adopted by the present invention to solve the technical problem is: a microbial fermentation inoculant containing Neurospora and yeast. The method of producing feed or ethanol by fermentation with the microbial fermentation agent of the present invention is to add the components of the fermentation agent to the raw materials simultaneously or step by step for fermentation, and the obtained materials are processed to produce feed or ethanol. The beneficial effects of the present invention are: using the microbial fermentation agent of the present invention for coupled collaborative fermentation, it can effectively eliminate feedback inhibition and product inhibition of sugar or ethanol during the fermentation process, increase the protein content of feed, soften materials, and produce wine aroma. , improve the palatability of feed, improve production efficiency and product quality.

Owner:NANJING NORMAL UNIVERSITY

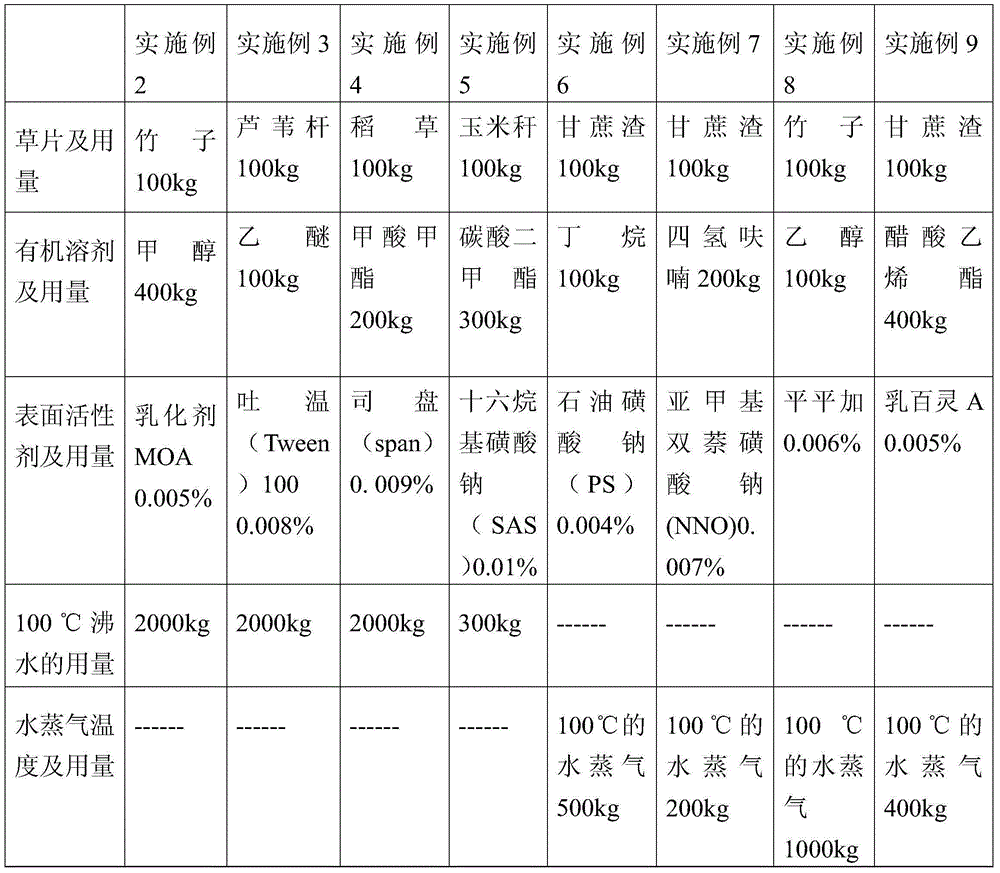

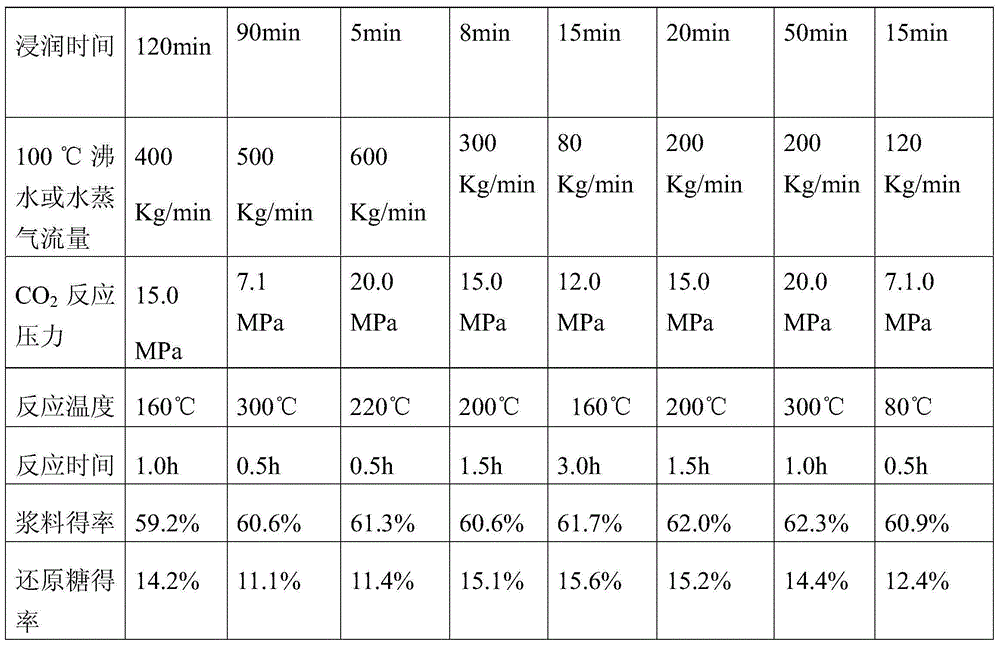

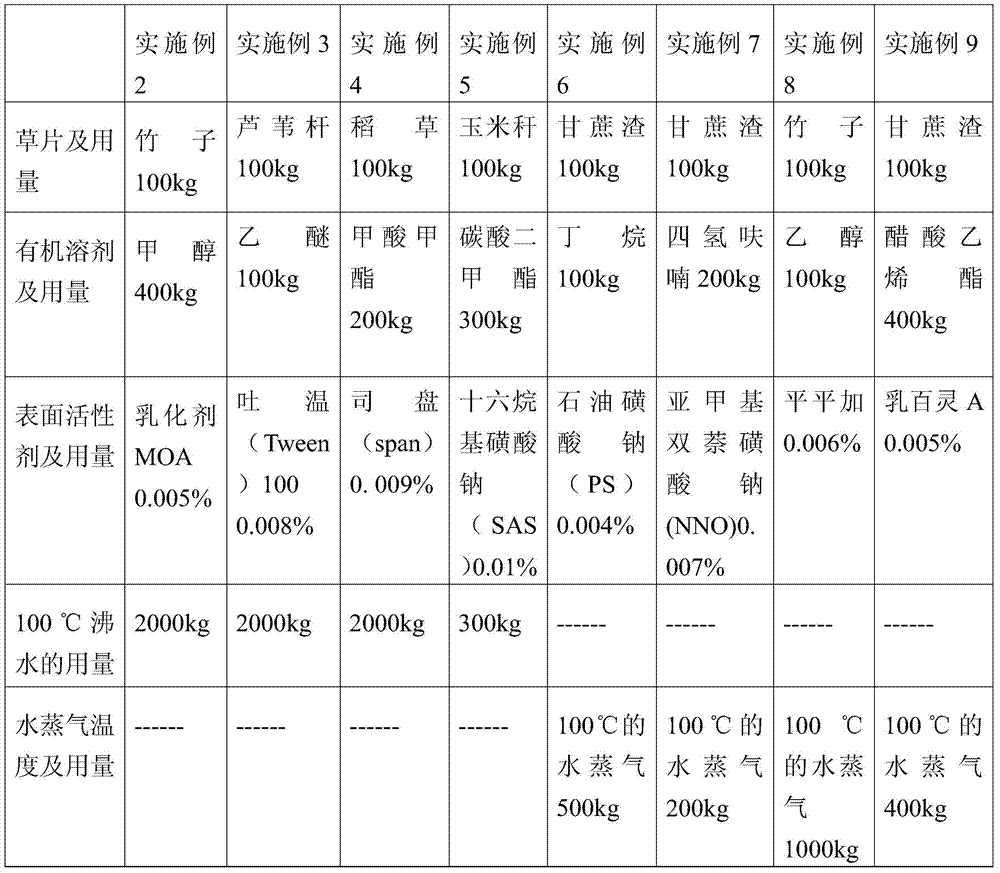

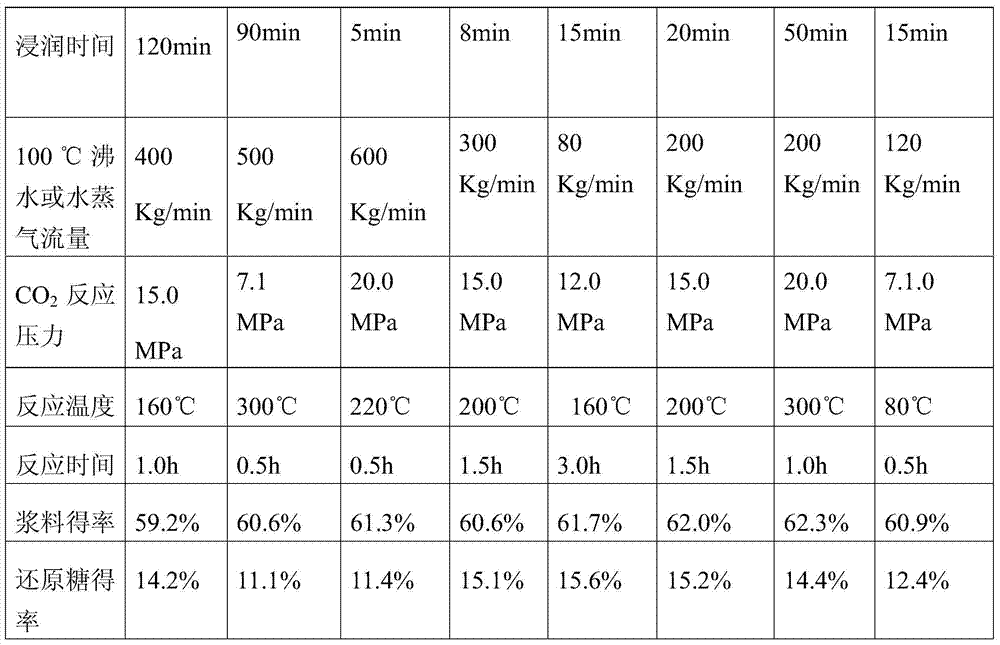

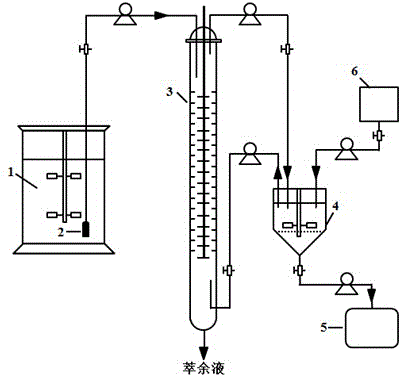

Method of producing pulp by instant vaporization expansion-infiltration in straw sheets

ActiveCN105200834AEliminate Feedback InhibitionIncreased reaction rate and equilibrium conversionPulping with organic solventsNon-woody plant/crop pulpBoiling pointCell membrane

The invention discloses a method of producing pulp by instant vaporization expansion-infiltration in straw sheets. The method includes the steps of adding straw sheets as a raw material into an organic solvent having a boiling point lower than 100 DEG C, according to a straw sheet to organic solvent weight ratio: 1:1 to 1:4 so as to infiltrate the straw sheets for 5-120 min, adding the straw sheets into 100 DEG C boiling water or vapor having a temperature higher than the boiling point of the organic solvent, according to a straw sheet to water weight ratio: 1:1 to 1:20, and producing pulp by boiling under supercritical CO2. cell membranes are caused to expand and break by instant vaporization of the organic solvent among fiber cells of the straw sheets, so that the speed of the removal of intercellular lignin from the straw sheets by boiling is increased by 1 to 5 times, and the usage of the organic solvent is decreased by 2 to 10 times.

Owner:GUANGXI UNIV

Method and device for hydrogenation modified rosin and c9/c5 petroleum resin in transcritical reaction system

ActiveCN104693359BEliminate Feedback InhibitionHigh speedNatural resin chemical modificationChemical/physical processesHydrogenation reactionPetroleum resin

The invention discloses a turpentine-C9 / C5 petroleum resin blend hydrogenation modification method which comprises the following steps: (1) raw material preparation: mixing raw materials turpentine and C9 / C5 petroleum resin with a solvent and a catalyst, and dissolving by heating; (2) hydrogenation reaction: putting the mixture prepared in the step (1) into a hydrogenation reactor, charging a gas mixture of H2 and CO2 in a mole ratio of 1:1-20:1, and carrying out hydrogenation reaction at 150-400 DEG C under the pressure of 3.0-35.0 MPa; (3) taking out the reacted gas mixture in the hydrogenation reactor, passing the gas through an expander which is connected with a turbine compressor, supplementing the CO2-H2 gas mixture into the turbine compressor, and introducing the gas mixture into the hydrogenation reactor; and (4) after carrying out hydrogenation-desulfurization reaction for 1-10 hours, relieving the pressure, and discharging the blend hydrogenation modified turpentine-C9 / C5 petroleum resin product out of the hydrogenation reactor. The method enhances the hydrogenation-desulfurization reaction speed and equilibrium conversion rate, and implements coupling of the hydrogenation reaction and desulfurization separation.

Owner:GUANGXI UNIV

A method for producing cellulase by mixed fermentation of aspergillus oryzae and fusarium chlamydoides

InactiveCN107460180BEliminate Feedback InhibitionHigh activityMicroorganism based processesFermentationBiotechnologyAspergillus oryzae

The invention discloses a method for producing cellulase by mixed fermentation of aspergillus oryzae and fusarium chlamydosporum. The method comprises the following steps: inoculating the fusarium chlamydosporum and the aspergillus oryzae on a bagasse solid culture medium and performing mixed culture fermentation, wherein the culture temperature is 20-50 DEG C, and pH value is 4.0-10.0; finishing fermentation culture after the maximum cellulose yield is reached. The method disclosed by the invention has the benefits that through the mixed culture of the aspergillus oryzae and the fusarium chlamydosporum, high-transglycoside activity belta-glucosidase produced by the aspergillus oryzae can synthesize gentiobiose, and the gentiobiose can stimulate the synthesis of the cellulase from the fusarium chlamydosporum; through the mixed culture of the aspergillus oryzae and the fusarium chlamydosporum, the composition of a cellulase system is optimized, so that the overall enzyme activity of the cellulase system can be significantly improved.

Owner:HECHI UNIV

Instantaneous vaporization and expansion of grass slices - osmotic pulping method

ActiveCN105200834BReduce dosageEmission reductionPulping with organic solventsNon-woody plant/crop pulpOrganic solventWater vapor

The invention discloses a method for instantaneous vaporization and expansion inside grass slices-infiltration pulping. Soak the grass slices with an organic solvent for 5 to 120 minutes, then add boiling water at 100°C or water vapor whose temperature is higher than the boiling point of the organic solvent according to the mass ratio of the grass slices to water 1:1 to 1:20, and then under the condition of supercritical CO2 Under cooking pulping. The method of the invention causes the cell membrane to expand and rupture through the instant vaporization of the organic solvent between the fiber cells of the grass slice, so that the rate of removing intercellular lignin by cooking the grass slice is accelerated by 1-5 times, and the consumption of the organic solvent is reduced by 2-10 times.

Owner:GUANGXI UNIV

Method and device for extracting fumaric acid in fermentation broth in continuous counter current manner by means of amine extractants and application of fermentation technology combined with method

InactiveCN102875359BEfficient fermentationEliminate Feedback InhibitionMicroorganism based processesLiquid solutions solvent extractionBiotechnologyOrganic solvent

The invention provides a method for extracting fumaric acid in fermentation broth in a continuous counter current manner by means of amine extractants. The method includes that filtered fermentation broth flow is added into an extracting tower to perform liquid-liquid extraction in the continuous counter current manner, the fermentation broth is used as heavy phase, the extraction system is used as light phase, extracts left the extraction tower is subjected to reextraction to generate fumaric acid or fumaric acid salt by reextraction, and the extraction system after reextraction returns the extraction tower and is used circularly; meanwhile, the extract can successively pass a primary organic solvent collection tank and a secondary organic solvent collection tank for secondary treatment, and finally the extracts flowing out returns the fermentation for reusing. The invention further provides a device for extracting fumaric acid in fermentation broth in a continuous counter current manner by means of amine extractants and application of a fermentation technology combined with the continuous counter-current extraction technology in continuous preparation of the fumaric acid. By the method, suppression to products in the process of fermentation of the fumaric acid can be effectively eliminated, and meanwhile, toxicity of the extracts to rhizopus oryzae can be avoided, and fermentation production level of the fumaric acid can be improved.

Owner:NANJING TECH UNIV

Transcritical CO2-catalyzed esterification/condensation-separation coupled reaction method and its equipment

ActiveCN105237318BAvoid pollutionImprove reaction speedOrganic compound preparationCarboxylic acid esters preparationAlcoholVapor–liquid separator

The invention discloses a transcritical CO2 catalytic esterification / condensation-separation coupling reaction method. The method comprises the following steps: mixing alcohol compounds, acid / aldehyde compounds, and a solvent, dissolving, transferring the solution to a reactor, introducing CO2 into the reactor to carry out reactions; collecting the byproducts in gas phase, converting the gas phase by an expansion machine from a supercritical state into a subcritical state, then introducing the gas phase into a gas-liquid separator, pressurizing the separated CO2 and supplemented CO2 by a turbo-compressor, then introducing the pressurized CO2 into the reactor, carrying out reactions for 0.5 to 10 hours, reducing the pressure in the reactor, and taking out reaction products from the reactor. The equipment used by the provided method comprises an esterification / condensation reactor, which comprises a plurality of heating pipes and a gas distributor. The expansion machine and the turbo-compressor are integrated into one machine, and the turbo-compressor is driven by the recovered expansion work of the reaction system. The provided transcritical CO2 catalytic esterification / condensation-separation coupling reaction method and equipment have the advantages that the technology is convenient, the quality of esters / condensed carbonyl product is high, and the conversion rate is high.

Owner:GUANGXI UNIV

A method for preparing feed protein by using alcohol waste liquid and crop stalks

ActiveCN104256057BRich in compositionHigh protein contentFood processingAnimal feeding stuffBiotechnologyCellulose

Aiming at the current situation that crop straws are not highly utilized as feed and the pollution of alcohol waste liquid is serious, the present invention discloses a method for preparing feed protein by using alcohol waste liquid and crop straws, so as to meet the comprehensive utilization of straws, animal husbandry feed protein demand, alcohol Objective requirements for harmless treatment and utilization of waste liquid. The invention adopts the process of "ammonification + compound enzymolysis + multi-strain three-step solid-state fermentation" to obtain a feed protein product with high degradation degree of cellulose and xylan and high content of feed protein. The product is rich in probiotics, vitamins, Nutrients such as enzymes, amino acids, short peptides, and high-quality protein have the advantages of promoting growth and development, improving feed utilization, enhancing immunity, improving intestinal microecology, and preventing diseases; the invention realizes high resource utilization of crop straw Value utilization and harmless treatment and resource utilization of alcohol waste liquid have broad application prospects.

Owner:黑龙江成福食品集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com