Method and device for hydrogenation modified rosin and c9/c5 petroleum resin in transcritical reaction system

A reaction system and petroleum resin technology, applied in the field of rosin deep processing, can solve the problems of limited application scope, deterioration of thermal stability and oxidation stability of resin, reduction of compatibility between resin and application objects, etc., to improve thermal efficiency, Conducive to manufacturing, reducing the effect of heat-to-work conversion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

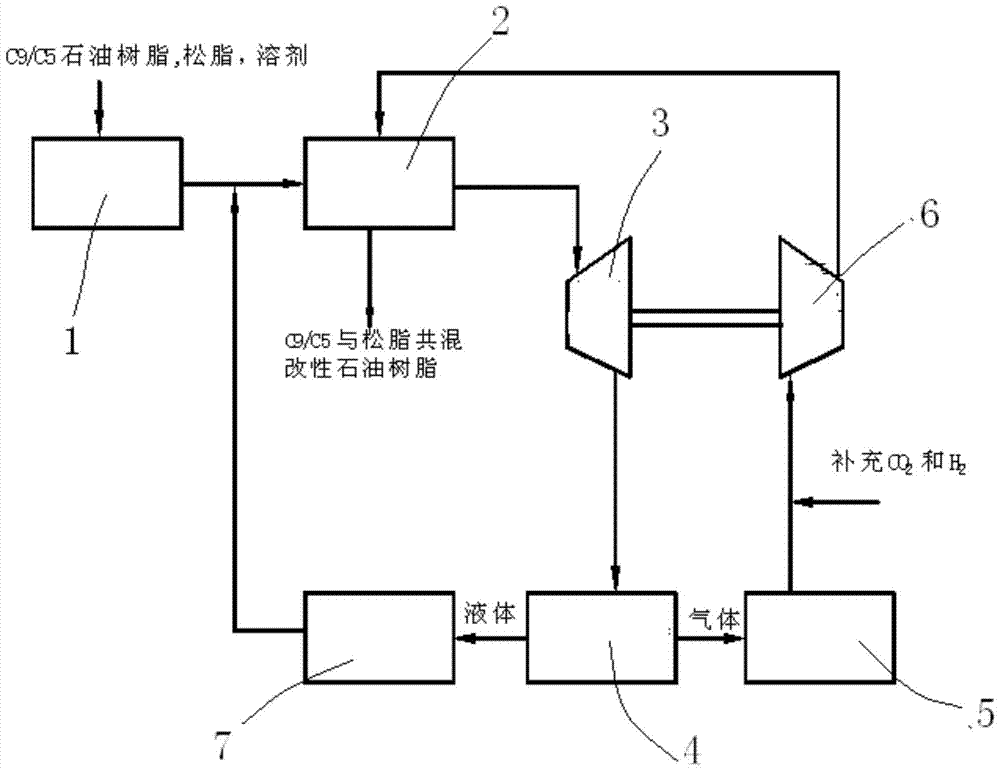

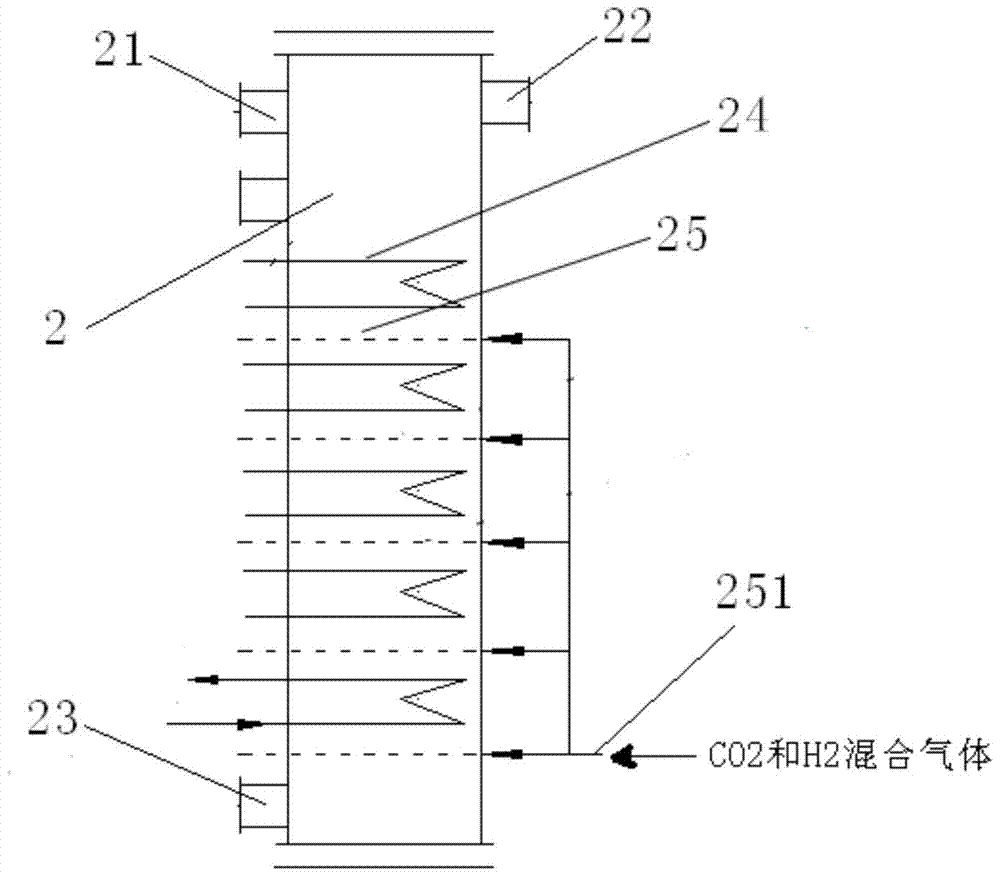

[0040] Such as Figure 1-4 As shown, the device for hydrogenation of modified rosin and C9 / C5 petroleum resin in the transcritical reaction system includes: dissolution kettle 1, hydrogenation reactor 2, expander 3, gas-liquid separator 4, absorption tower 5, permeation Flat compressor 6, solvent pump 7.

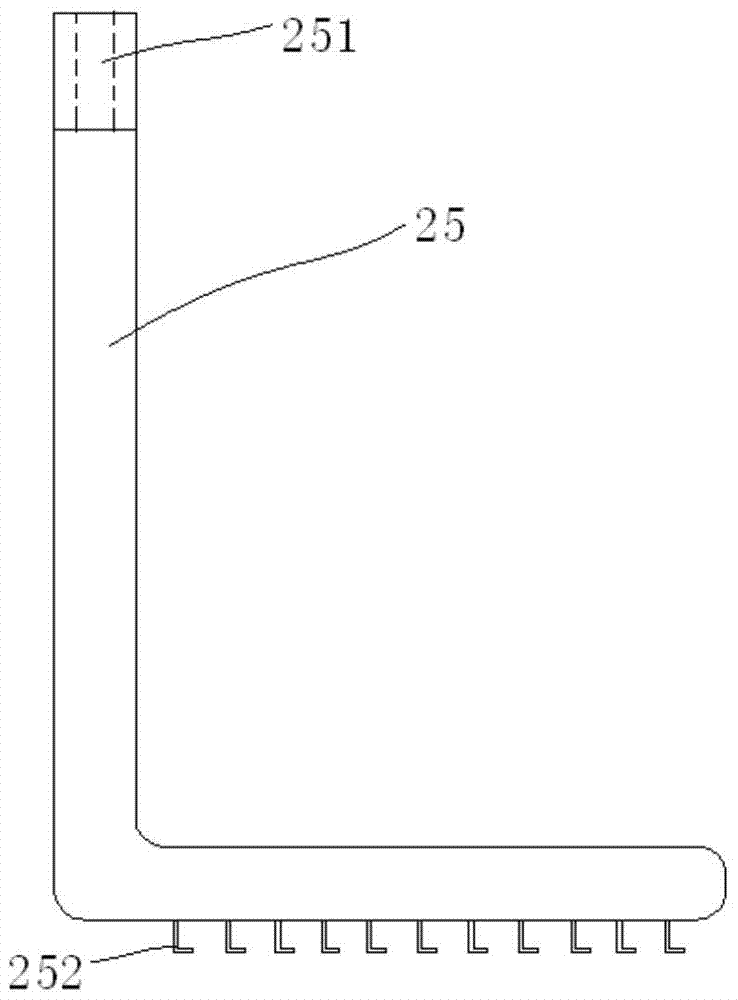

[0041] The discharge port of the dissolution tank 1 is connected with the feed port of the hydrogenation reactor 2, and the dissolution tank 1 is used for dissolving raw materials required for production. The hydrogenation reactor 2 is cylindrical. The upper part of the hydrogenation reactor is provided with a feed inlet 21, a gas outlet 22, and the bottom is provided with a discharge outlet 23. The hydrogenation reactor 2 includes a heating pipe 24, which is a heating coil. It is arranged inside the hydrogenation reactor; the gas distributor 25 includes an air inlet 251 and a plurality of nozzles 252 for exhaust; the expander 3 is connected to the gas outlet of the hydroge...

Embodiment 2

[0050] The reaction unit that uses is identical with embodiment 1, a kind of transcritical reaction system hydrogenation modified turpentine and C9 / C5 petroleum resin method, comprises the following steps:

[0051] (1) Prepare raw materials, use turpentine and C9 / C5 petroleum resin as raw materials, mix its hydrogenated turpentine and modified bentonite loaded nickel, add turpentine, C9 / C5 petroleum resin and solvent in a mass ratio of 1:3:1, The amount of nickel loaded on the modified bentonite is 10% of the total mass of turpentine and C9 / C5, put it into the dissolution kettle 1, and heat to dissolve;

[0052] (2) Hydrogenation reaction, put the mixture prepared in step (1) into the hydrogenation reactor 2, then heat the temperature up to 150°C, and fill the hydrogenation reactor with a molar ratio of H 2 :CO 2 = 1:1 mixed gas until the pressure is 10.0MPa, continue to heat up to 250°C;

[0053] (3) Maintain the pressure in the hydrogenation reactor 2 to be 10.0MPa, open t...

Embodiment 3

[0056] The reaction unit that uses is identical with embodiment 1, a kind of transcritical reaction system hydrogenation modified turpentine and C9 / C5 petroleum resin method, comprises the following steps:

[0057] (1) Prepare raw materials, take turpentine and C9 / C5 petroleum resin as raw materials, mix its hydrogenated turpentine and modified bentonite loaded nickel, add turpentine, C9 / C5 petroleum resin and solvent in a mass ratio of 10:10:1, The amount of nickel loaded on the modified bentonite is 30% of the total mass of turpentine and C9 / C5, put into the dissolution kettle 1, and heat to dissolve;

[0058] (2) Hydrogenation reaction, put the mixture prepared in step (1) into the hydrogenation reactor 2, then heat the temperature up to 150°C, and fill the hydrogenation reactor with a molar ratio of H 2 :CO 2 = 20:1 mixed gas until the pressure is 7.0MPa, continue to heat up to 250°C;

[0059] (3) Maintain the pressure in the hydrogenation reactor 2 at 7.0MPa, open the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com