Patents

Literature

59results about How to "Improve enzyme production capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

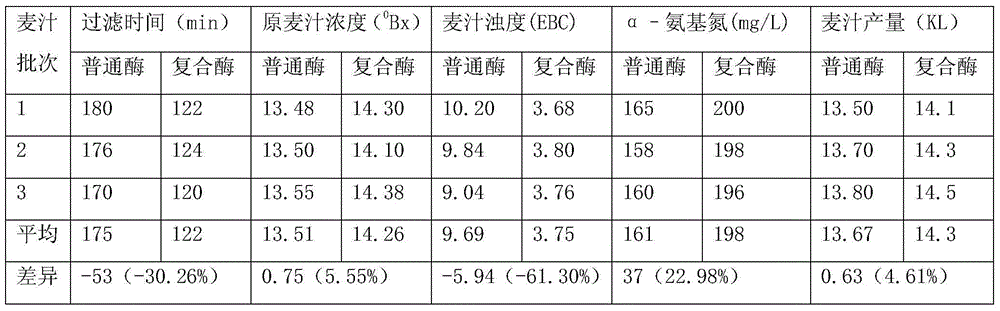

Fungal alpha-amylase-containing beer complex enzyme and preparation method thereof

ActiveCN104651335AEnsure food safetyIncrease profitOxidoreductasesGlycosylasesAntioxidantAlpha-amylase

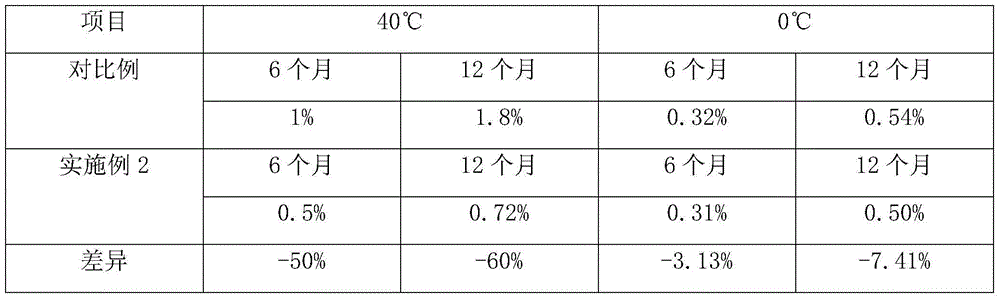

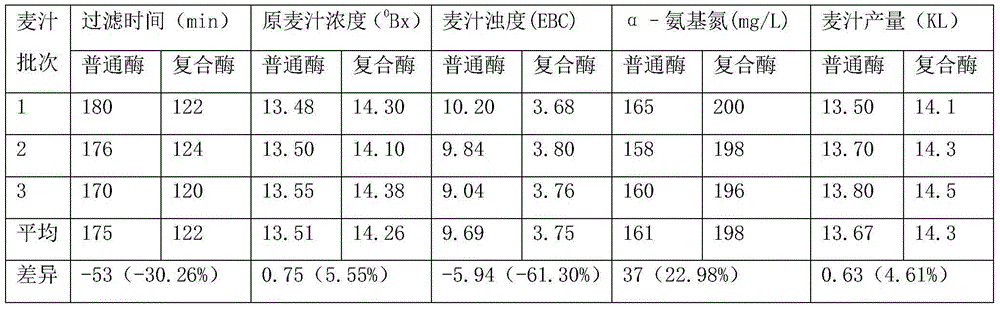

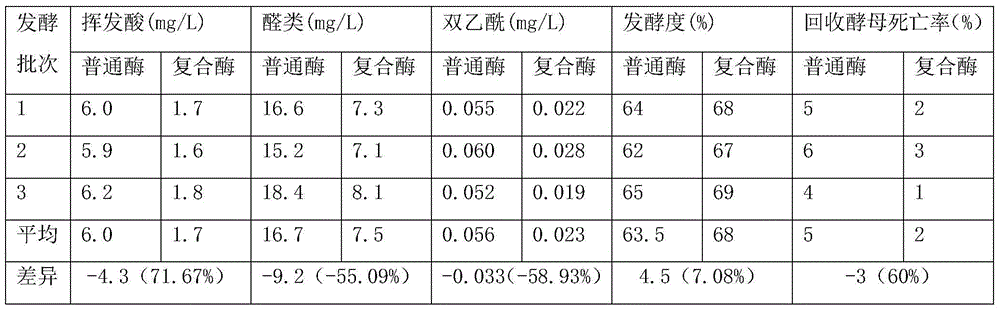

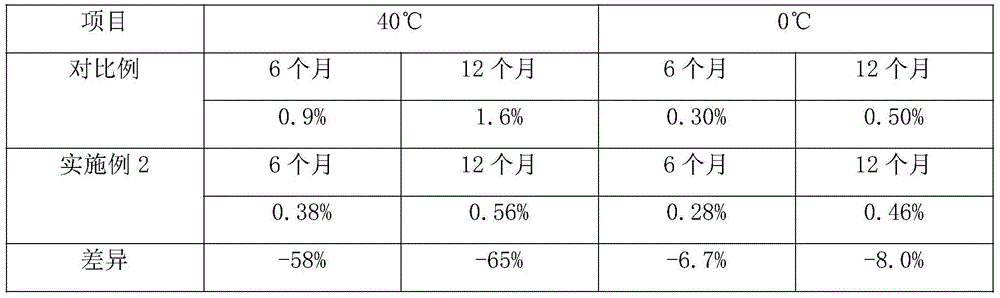

The invention discloses a fungal alpha-amylase-containing beer complex enzyme and a preparation method thereof, belonging to the field of enzyme preparation processing. The high-activity fungal alpha-amylase and other food grade enzyme preparations, plant extracts, antioxidants, protective agents, activating agents and the like can be scientifically compounded by taking concentrated maltase and concentrated malt juice powder as main raw materials; the prepared beer complex enzyme is complete in proteases, high in enzyme activity, difficult to deactivate, mellow in malt aroma, and capable of providing abundant nitrogen source for malt juice, wherein the activity of fungal alpha-amylase in fermenting liquor during the preparation of fungal alpha-amylase is 17000-21000 U / mL. The complex enzyme can be stored for 12 months under the conditions of 0DEG C and 40DEG C, the single enzyme activity loss in the complex enzyme are respectively 0.50% and 0.72%, the enzyme deactivation caused by environment change, and inappropriate operation methods during packaging, storage, transportation, use and the like can be effectively prevented, especially the enzyme deactivation caused by high temperature can be prevented.

Owner:湖南新鸿鹰生物工程有限公司

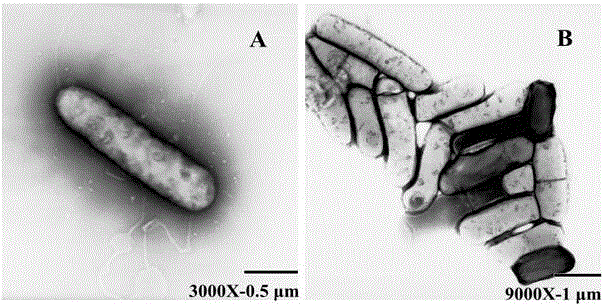

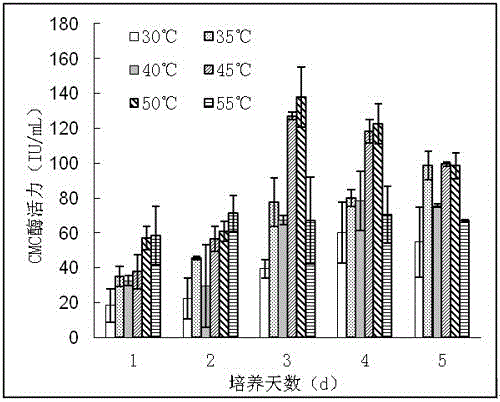

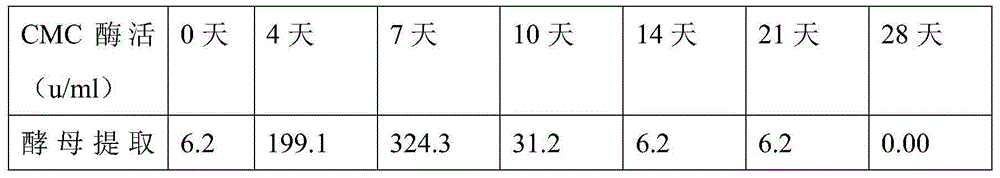

High-temperature-resistant cellulase producing bacterium and application thereof

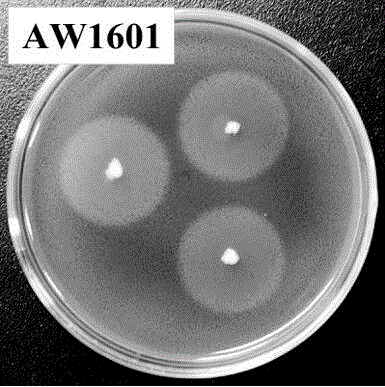

InactiveCN106434417AImprove enzyme production capacityShorten the production cycleBio-organic fraction processingBacteriaFiber compositionCompost

The invention relates to a high-temperature-resistant cellulase producing bacterium and application thereof, and belongs to the technical field of microbiological screening and application. The strain is separated from a mixture of cow dung and straw in an earthworm farm, identified as bacillus subtilis, named as AW1601 and preserved in the China General Microbiological Culture Collection Center on June 24, 2016, and the number is CGMCC No.12650. The strain has the high cellulase producing capacity at the high culture temperature of 50 DEG C to 55 DEG C, the fermentation cycle is short in liquid and solid environments, the degrading degree of straw substrates is high, the problems that a cellulase preparation is high in cost, a high temperature composting strain is low in activity, and the fiber composition degrading rate of the substrates is low when an edible fungus culture medium or coarse fodder is prepared are well solved, and the strain can serve as a novel cellulase producing bacterium and be widely used for recycling agricultural biomass solid waste.

Owner:AOWEI TIANJIN ENVIRONMENTAL PROTECTION TECH

Microorganism formulation for eliminating nutrilit-resistance function and preparation method

InactiveCN101371682AElimination of anti-nutritional factor effectsImprove immunityAnimal feeding stuffBiotechnologyNutrition

The invention relates to a microorganism preparation used for eliminating the effect of anti-nutritional factors and is characterized by consisting of the following materials by weight percentage: 28 to 35 percent of bacillus subtilis, 45 to 53 percent of lactobacillus plantarum and 12 to 27 percent of yeast of brewer; a preparation method of the microorganism preparation comprises the following steps: the production of the strain is produced by combining the ray induction and production performance test, the production strain with high yield and large enzyme production are screened, the production technique adopts the technology of liquid single culture and solid composite culture, product accelerators are added into the culture medium so as to lead the product to be rich in active metabolites such as beneficial living bacterium, enzyme, peptide, polysaccharide and amino acids, and the like; after the feed material and complete feed are added with the microorganism preparation, the effect of anti-nutritional factors to the nutrient components in the feed can be eliminated greatly, the palatability of the feed is improved, feed intake is improved, stress resistance and immunity of the cultured animals is enhanced, group uniformity is improved, the growing speed and feed utilization can be improved and the culture cost can be reduced.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

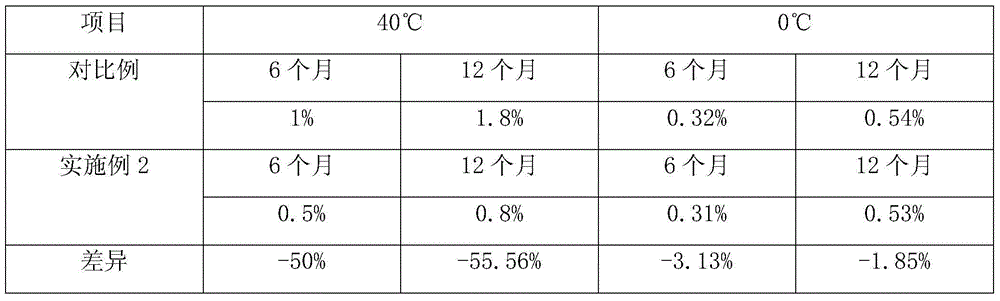

Beer compound enzyme containing acid protease and preparation method of beer compound enzyme containing acid protease

InactiveCN105316299AEnsure food safetyIncrease profitHydrolasesOxidoreductasesFood gradeProteinase activity

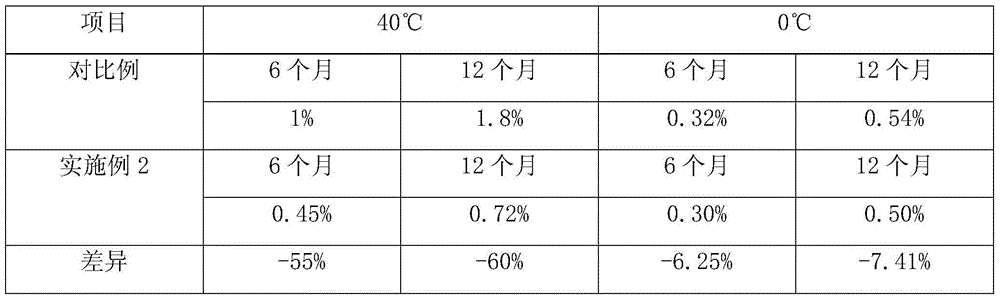

The invention discloses a beer compound enzyme containing acid protease and a preparation method of the beer compound enzyme containing the acid protease and belongs to the field of enzyme preparation processing. The beer compound enzyme complete in protease system, high in enzyme activity, less prone to inactivation, strong in malt fragrance and capable of providing a rich nitrogen source for wort is mainly prepared from a concentrated malt enzyme and concentrated wort powder by scientifically compounding food-grade enzyme preparations such as the high-activity acid protease, plant extracts, antioxidants, protective agents, activating agents and the like, wherein the enzyme activity of the acid protease in fermentation liquor in an fermentation liquor preparation process is 18000-20000U / mL. When the beer compound enzyme is stored at the temperatures of 0 DEG C and 40 DEG C for 12 months, enzyme inactivation rates of single enzyme in the beer compound enzyme are 0.53% and 0.8% respectively, so that enzyme inactivation caused by environment changes and improper operation methods during packaging, storage, transportation, use and the like can be prevented effectively, and especially, enzyme inactivation caused by high temperature can be prevented.

Owner:湖南新鸿鹰生物工程有限公司

Method for preparing galacto-oligosaccharide

ActiveCN102676614ASimple production processEasy to operateMicroorganism based processesOn/in organic carrierLactoseGalactooligosaccharide

The invention discloses a method for preparing galacto-oligosaccharide. The method comprises the following steps: (1) reacting glutaraldehyde with a macroporous weak basic styrene resin for 16 to 24 hours with stirring at the temperature of between 15 and 35DEG C to activate the resin; (2) reacting liquid beta-galactosidase with the activated macroporous weak basic styrene resin obtained in the step (1) for 16 to 24 hours with stirring at the temperature of between 15 and 35DEG C to obtain cured beta-galactosidase; and (3) adding the cured beta-galactosidase into a lactose solution, and reacting for 24 to 36 hours with stirring at the temperature of between 48 and 52DEG C. By the method for producing the galacto-oligosaccharide, the filter pressure can be kept stable in a syrup filtering process, the yield of the galacto-oligosaccharide is improved, the energy consumption is reduced and the industrial production requirement can be met.

Owner:量子高科(广东)生物有限公司

Cellulase producing bacteria and application thereof

ActiveCN105039195ANeutral excellentAlkaline cellulaseBacteriaMicroorganism based processesNeutral phCellulase

The invention discloses a cellulase producing bacteria classified and named bacillus megatherium. The bacteria strain is preserved in China Center for Type Culture Collection (CCTCC) at May 21, 2015 and is assigned the accession number of CCTCC M2015320. The bacteria strain is used for preparing high-activity cellulase under a neutral pH and is significantly better than an acidic cellulase in the field of water-washing enzyme application. In the invention, sodium carboxymethylcellulose is employed as a carbon source, which is excellent than a fiber raw material in the aspects of transportation, material feeding and disinfection and the like. With urea as a soluble nitrogen source, the cellulase producing bacteria is low in cost and is convenient to prepare and use. According to the invention, the cellulase is high in activity, is wide in application range and good in stability to pH, and is short in production period.

Owner:INST OF AQUATIC LIFE ACAD SINICA +1

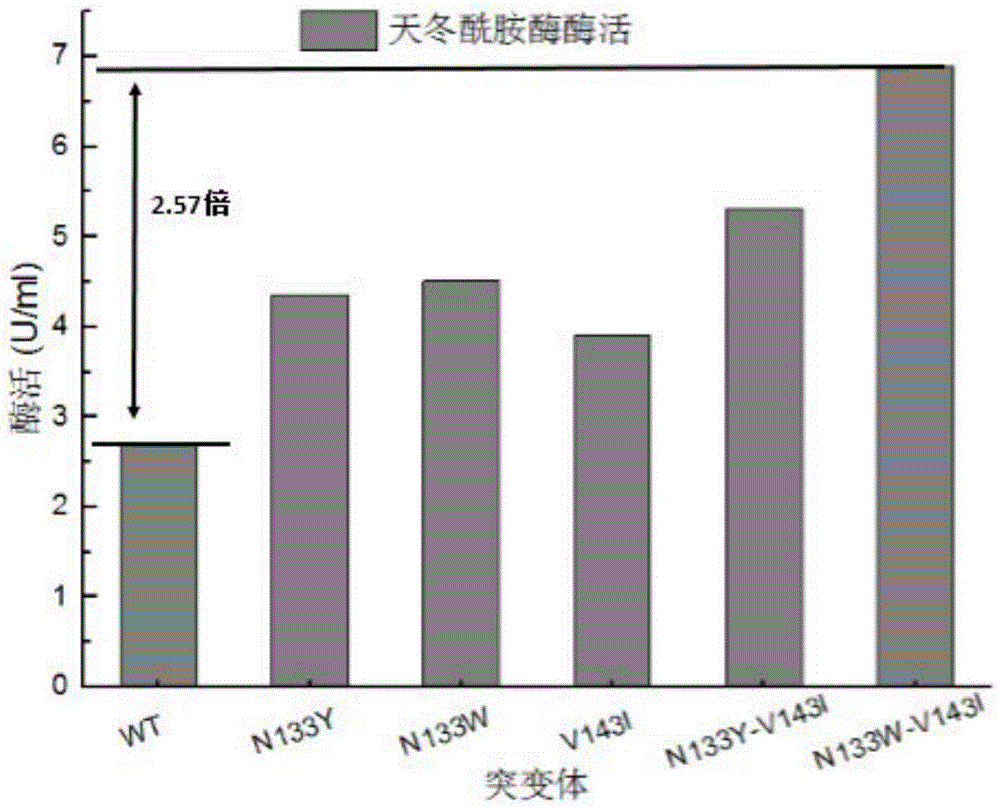

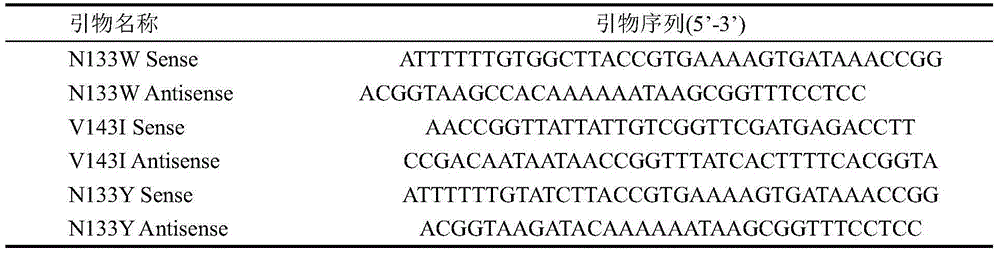

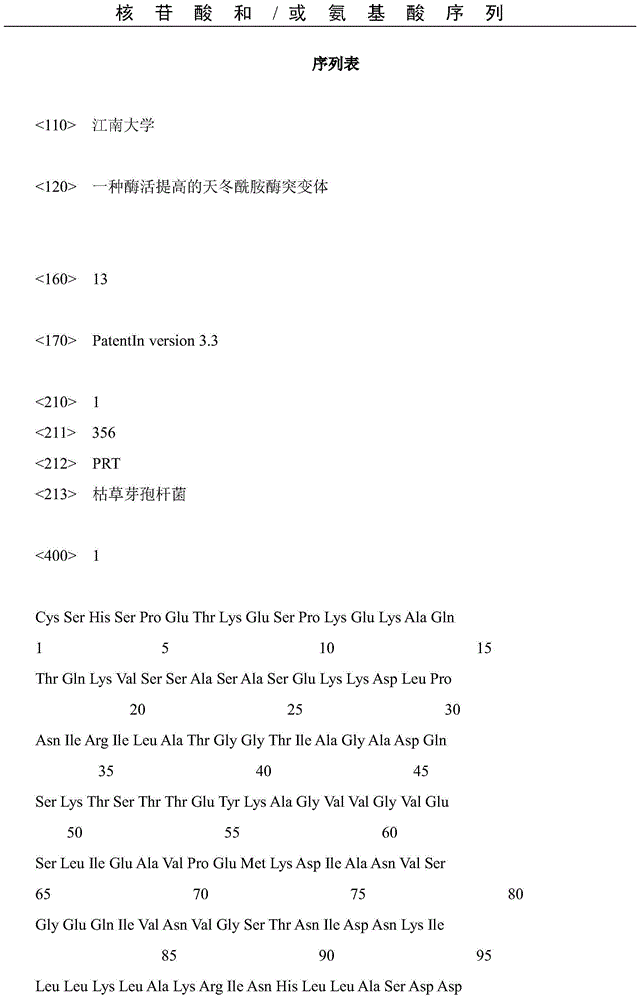

Asparaginase mutant with enhanced enzyme activity

The invention discloses an asparaginase mutant with enhanced enzyme activity, and belongs to the field of enzyme engineering. According to the asparaginase mutant, hydrophilic amino acid asparaginate and valine which are contained in an asparaginase molecule are mutated into tyrosine, tryptophan and isoleucine which have high hydrophobicity in a site-specific mutagenesis mode, so that the hydrophobicity inside the asparaginase molecule is changed, the enzyme activity, which is expressed by a strain, of asparaginase is remarkably improved, and the enzyme activity of the asparaginase is enhanced by 2.57 times. The improved strain is remarkably enhanced in enzyme producing capacity, more suitable for industrial application, reduced in production cost and improved in production efficiency.

Owner:JIANGNAN UNIV

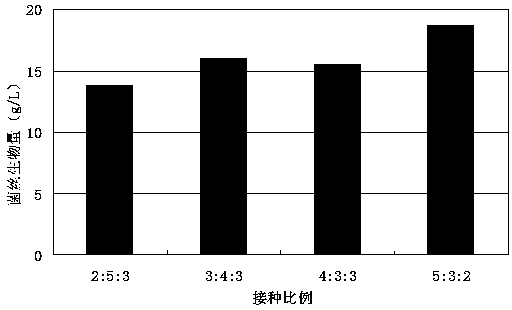

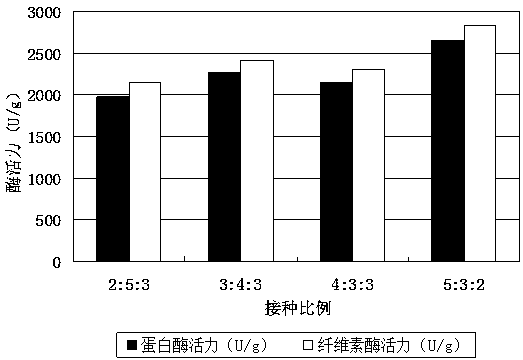

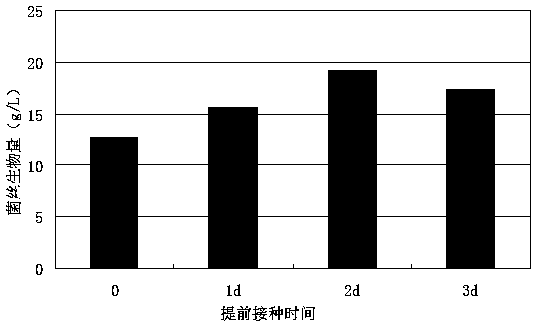

Method for mixed fermentation of biological feed by using pomace and distiller's grains as raw materials

InactiveCN109497265AHigh nutritional valueImprove qualityFood processingAnimal feeding stuffNutritive valuesBiotechnology

The invention provides a method for mixed fermentation of a biological feed by using pomace and distiller's grains as raw materials, and belongs to the field of industrial by-product reuse. The methodcomprises the steps of preparing seed liquid, preparing mixed fermentation broth, stimulating the mixed fermentation broth and preparing a biological feed. According to the method, edible fungus agaricus bisporus is adopted to undergo mixed fermentation with mold and saccharomycetes for the first time, and under suitable culture conditions, the funguses are mutually beneficial and symbiotic to jointly complete the metabolic activities, thereby greatly improving the fermentation efficiency and the raw material conversion rate, remarkably improving the nutritive value of the fermented feed. According to the method, a liquid solid state fermentation mode is adopted, and the advantages of the two modes are combined to comprehensively utilize the pomace and the distiller's grains, so as to provide a direction for the large-scale production of the biological feed.

Owner:江苏春之雨生物科技发展有限公司

Acid protease and preparation method thereof

InactiveCN101638647AHigh enzyme productionImprove performanceHydrolasesPeptide/protein ingredientsMicroorganismYeast

The invention provides acid protease which is derived from microorganism sources and a preparation method thereof. The acid protease is characterized in that a. enzymology characteristics: the optimumpH is 2.5-3.5, the stable pH is 2.5-6.0, the optimum temperature is 40-50 DEG C, and the temperature stability ranges from 30 DEG C to 50 DEG C; b. with A. niger as an enzyme producing strain and wheat bran as main materials, the acid protease is prepared by solid fermentation process; the fermenting and enzyme producing capabilities are more than or equal to 47000u / g (based on dry yeast), the yield of liquid enzyme is more than or equal to 85% and that of solid enzyme is more than or equal to 80%, which all reach the food grade hygienic standards. The acid protease takes grain processing by-products as main raw materials and has high fermentation enzyme activity, high enzyme extraction purification yield and low production cost. The acid protease is suitable for serving as the preparation raw material or the additive of the products in such industries as tanning, medicine, brewing and feed.

Owner:SHANDONG LONGKETE ENZYME PREPARATION

B.subtilis spores strain and application thereof

ActiveCN103266074AImprove enzyme production capacityIncrease production capacityBacteriaAnimal feeding stuffSporeAgricultural science

The invention aims at providing b.subtilis spores and application of the b.subtilis spores to livestock and poultry breeding. The b.subtilis spores is screened from a fresh fecal sample of a healthy piglet, has strong capacity in producing amylase, protease and cellulase, can be applied to a livestock feed as a feed additive, can effectively improve the production performance of breading an animal, and is wide in application prospect.

Owner:山东蔚蓝生物科技有限公司 +1

High-yield heat resistant type neutral phytase bacterial strain as well as fermentation culture medium and enzyme production method thereof

InactiveCN102424803AImprove heat resistanceSlight facilitationBacteriaHydrolasesBiotechnologyMicroorganism

The invention discloses a high-yield heat resistant type neutral phytase bacterial strain. The classification naming of the bacterial strain is Bacillusnealsonii, the preservation number is China General Microbiological Center Culture Collection Center (CGMCC) No.5396, the preservation date is October 28th, 2011, and the preservation unit is CGMCC. The phytoenzyme produced by the bacterial strain has better high-temperature heat resistance, 41 percent of activity is also reserved after 30min under warm bath at 80 DEG C, under the condition of 90 DEG C, 73 percent of activity is also reserved after 10min, and 21 percent of activity is reserved after 30min. The invention also provides a bacterial strain culture medium and a method for producing heat resistant type neutral phytase by the bacterial strain.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Complex microbial inoculant for straw compost maturity and european corn borer prevention, as well as preparation and application of complex microbial inoculant

InactiveCN103540552AAccelerate the rate of decayIncrease profitBiocideFungiBiotechnologyBacillus licheniformis

The invention discloses a complex microbial inoculant for straw compost maturity and european corn borer prevention, as well as preparation and application of the complex microbial inoculant. The complex microbial inoculant comprises a mixed strain and an additive, wherein the mixed strain comprises trichoderma harzianum, bacillus licheniformis and beauveria bassiana, and is prepared by the following steps: inoculating three bacterial strain test tube slant culture media subjected to purification and rejuvenation to corresponding fluid nutrient media respectively, performing fermentation to obtain liquid strains, inoculating the three fermented fluid strains into a solid culture medium, culturing for 48-72h at the temperature being 28-30 DEG C, dying, and crushing; the additive comprises glucose, superphosphate and humic acid; the mixed strain and the additive are mixed according to a mass ratio being (2.0-8.0):1.0 so as to obtain the complex microbial inoculant. The mixed strain and the additive are mixed so as to play a relatively good synergy role; the complex microbial inoculant has the capabilities of increasing the speed of straw compost maturity, killing european corn borer larvae and pupae, reducing the incidence of european corn borer, reducing the harm, improving granhle soil structures, increasing the fertilizer utilization rate and playing a yield increasing role.

Owner:辽宁省微生物科学研究院

Method for extracting xylooligosaccharide from wheat bran

InactiveCN104894189AHigh purityImprove enzyme production capacityFermentationLow cholesterol levelsBifidobacterium

The invention discloses a method for extracting xylooligosaccharide from wheat bran. The method is used for preparing xylooligosaccharide with efficacies of promoting bifidobacterium reproduction, preventing constipation, reducing cholesterol, protecting the liver and the like by using byproduct of agricultural and sideline product processing, i.e., bran as a raw material and by using microbial fermentation and biological enzymolysis technologies, the quality of the obtained xylooligosaccharide product satisfies the industrial standard requirement of xylooligosaccharide, the high-efficiency utilization of the bran is realized, the use value of the bran is improved and the popularization prospect is better. The method for extracting xylooligosaccharide from wheat bran has the advantages that firstly the yield of xylooligosaccharide is improved through a combined preparation process of compound microbial solid fermentation and ultrasonic assisted enzymolysis; secondly the purity of the xylooligosaccharide product is obviously improved through the ultrasonic assisted enzymolysis for removing protein and starch and enzymolysis of phytase and mannase; and thirdly the capability of xylooligosaccharide fermentation and enzymolysis is improved through multi-bacteria mixed fermentation; fourthly the production process is simple, the energy consumption is low, no environmental pollution is caused, the investment is small and the mass production is facilitated.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

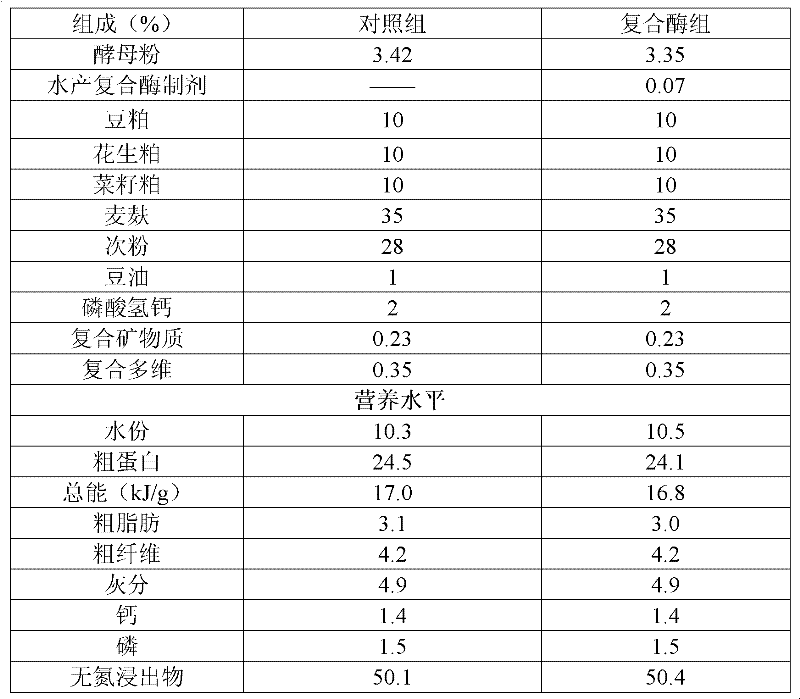

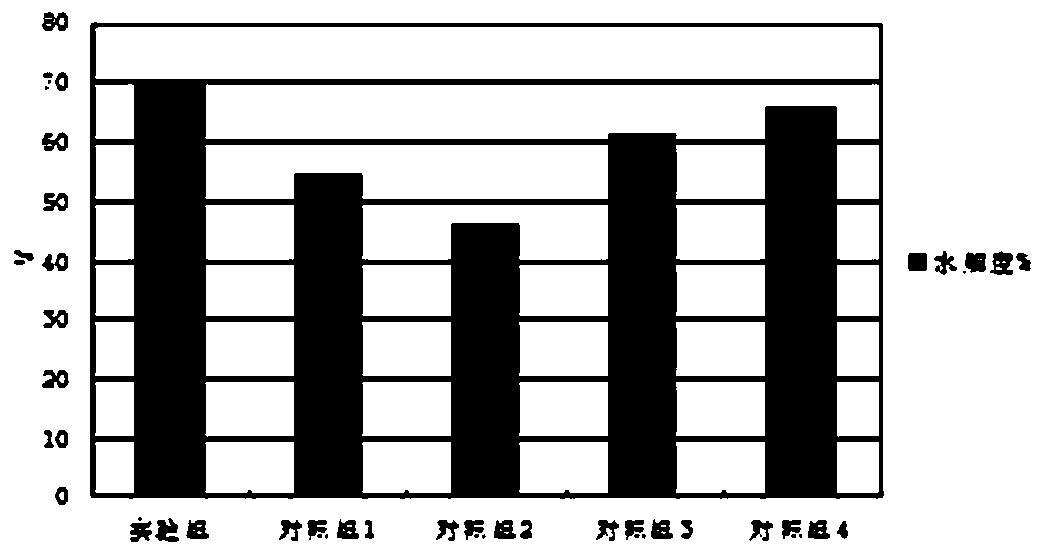

Complex enzyme preparation for aquatic animal and preparation process thereof

InactiveCN102396652AIncrease production capacityReduction factorAnimal feeding stuffCelluloseNeutral protease

The invention relates to a complex enzyme preparation for aquatic animals and a preparation process thereof. The complex enzyme preparation comprises 5,000-7,000u / g of neutral protease activity, 2,000-3,000u / g of mannose activity, 3,000-4,000u / g of xylanase activity and 2,000-3,000u / g of cellulose activity. A mixed fermentation technology of two high-temperature resistant high-yield strains is adopted in the preparation process. The preparation process of the invention is simple and controllable and is easier for operation, and the obtained product has strengthened enzyme producing capability and strengthened high-temperature resistant characteristics of the produced enzyme and can completely tolerate tempering temperature during the production of aquatic feed and maintain higher activity; and the invention can reduce and eliminate chime viscosity improvement and cellulose barrier effect caused by antinutritional factors and supplement the deficiency of endogenous digestive protease, is good for the digestive absorption of high protein aquatic materials, lowers nutrition content in the excrement of the aquatic animals, reduces pollution to a water body, improves water quality and the animal production performance and reduces the bait coefficient and the breeding cost.

Owner:宝鸡市星星协力生物有限公司

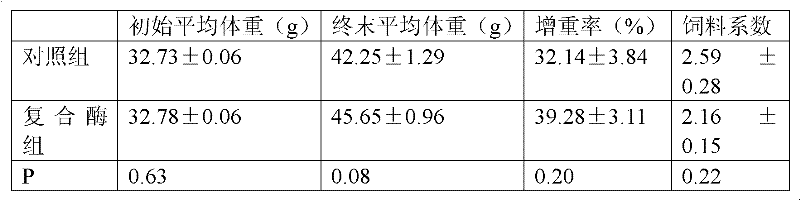

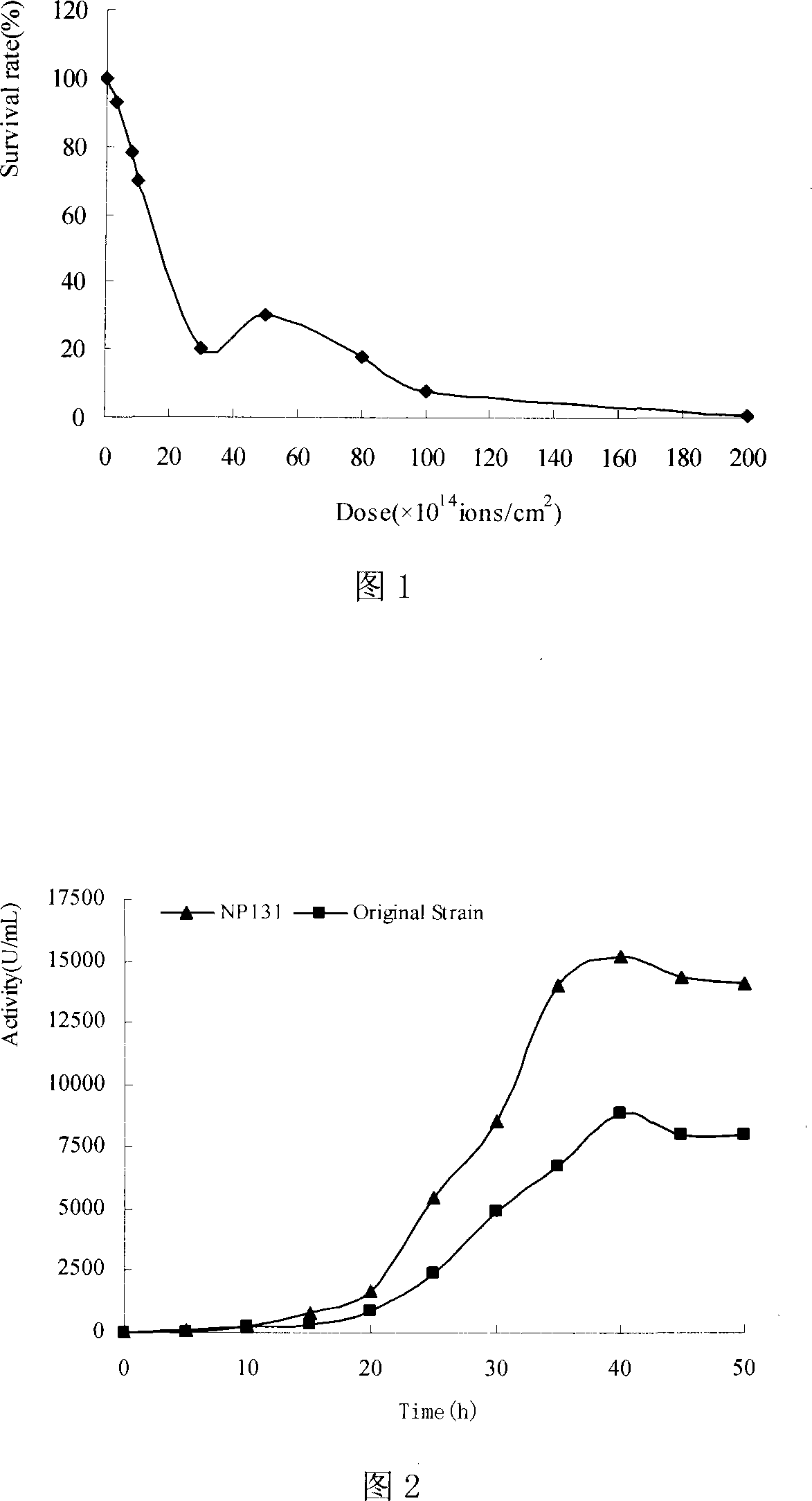

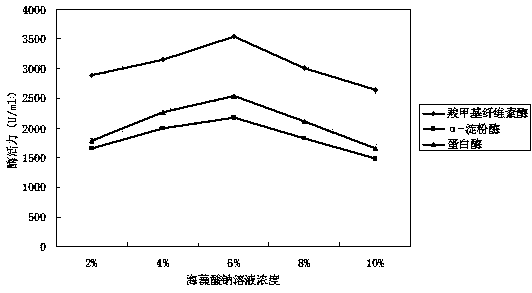

Method for mutagenesis breeding neuter protease high yield bacterial strain by hypophrenia N+ion injection technology

InactiveCN101182513AImprove enzyme production capacityReduce manufacturing costBacteriaMutant preparationNeutral proteinaseBacterial strain

The invention relates to an inducing and breeding method of high yield neutral proteinase strain by using low energy N <+> ion injection technology. The steps are that (1) the initial strain is screened; (2) the N <+> ion is injected for the induced mutation; (3) the high yield strain is screened; (4) the N <+> ion is injected for the induced mutation; (5) the high yield neutral proteinase strain is determined. The invention uses the N <+> ion injection technology for the induced mutation of Bacillus Subtilis AS1.398 of neutral proteinase; after the injection of different dosage of N <+> ion, the survival rate of the strain takes a typical saddle shape dose-effect curve; a high yield mutant strain with good genetic stability can be screened at the best injection dosage of 50*10 <14> ions / cm <2>; the shaking flask activity of the neutral proteinase is about 8230U / mL, which is improved by 81.3 percent. The ion injection technology can be applied into the mutation and selection of high yield neutral proteinase strain; the invention has a higher mutation rate and a wider mutation spectrum for the microorganism; the invention has good mutation effects, which is an ideal breeding method for the microorganism.

Owner:TIANJIN UNIV OF SCI & TECH

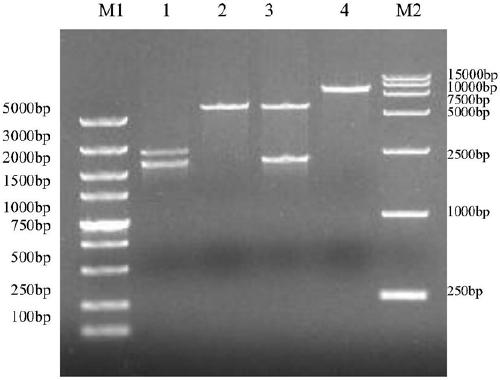

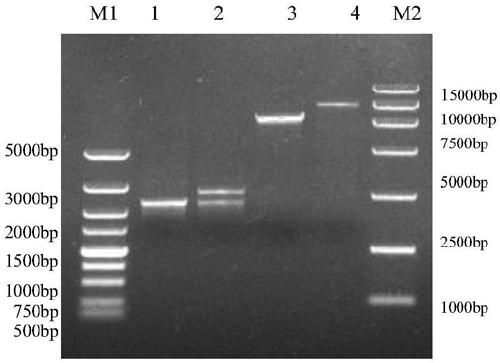

Method for fermenting production of feed enzyme preparation by immobilized cell technology

ActiveCN109554302AStrong enzyme production abilityEnzyme richFungiBacteriaTrichoderma koningiiParticle stability

The invention discloses a method for fermenting production of a feed enzyme preparation by an immobilized cell technology, wherein the method comprises the following steps: S1, activation and enlargedculture of strains; S2, preparation of immobilized cells; S3, electrification culture of the immobilized cells; S4, fermentation enzyme-production culture; S5, separation and purification of an enzyme preparation; and S6, recycling. The immobilized cell technology is used for immobilizing aspergillus niger, trichoderma koningii, bacillus subtilis and bacillus natto together in carrier granules, and mixed fermentation is carried out to produce the feed enzyme preparation; with mutually beneficial symbiosis among the strains, the variety of produced enzymes is abundant. Compared with a method of single fermentation to produce various enzymes and then compounding, the method can simplify the production process, shorten the production cycle and greatly improve the production efficiency. The prepared immobilized cell particles have the advantages of good stability and easy separation and recovery, can be recycled for enzyme production, greatly reduce production costs, and have good application prospects in the field of feed enzyme preparation production.

Owner:佳纬生物技术有限公司 +1

Saccharomyces cerevisiae S8-H with high yield of xylanase and application

ActiveCN108949602AImprove palatabilityImprove enzyme production capacityFungiMicroorganism based processesReticulum cellXylanase

The invention relates to a saccharomyces cerevisiae strain S8-H with high yield of xylanase. The saccharomyces cerevisiae strain S8-H has the beneficial effects that the xylanase xynB genes from aspergillus niger CICC2462 are used for constructing expression boxes, utilizing a rDNA integration method to construct and obtain 8 copied xylanase gene strains, the expression quantity of the xylanase is325U / mL, 8 copied-xylanase engineered saccharomyces cerevisiaes with over-expressed HACl are obtained by transforming pYES6-PGK-HACl fragments to the strain, the expression quantity of the xylanase reaches 381U / mL, and by over-expressed HACl, the expression level of endoplasmic reticulum protein folding associated genes is improved; simultaneously, the invention provides a model for secretory expression of multiple copied exogenous genes by the saccharomyces cerevisiae, and the model can be utilized for constructing and expressing other genes; the saccharomyces cerevisiae strain with high yield of the xylanase can be advantageously applied in straw degration and the feed manufacturing process.

Owner:JILIN AGRICULTURAL UNIV

Compound ethanol enzyme with acid proteases and method for preparing compound ethanol enzyme

InactiveCN105524772AHigh utilization rate of raw materialsEnsure food safetyBiofuelsAlcoholic beverage preparationNutrientChemistry

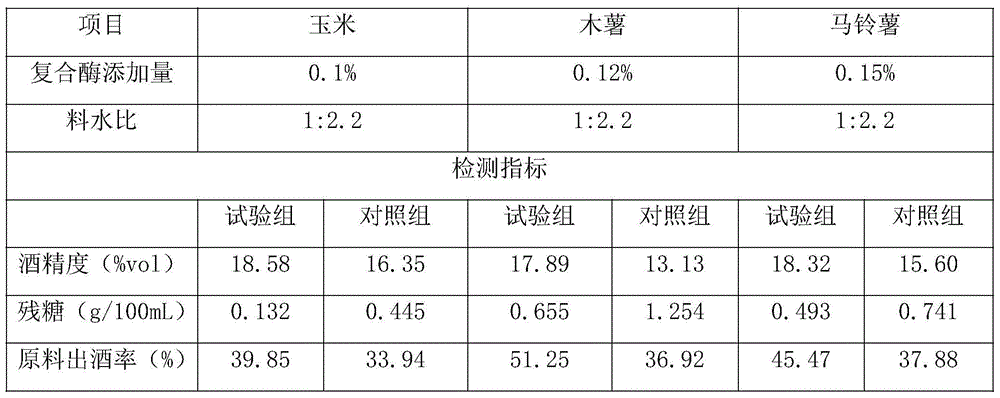

The invention discloses a compound ethanol enzyme with acid proteases and a method for preparing the compound ethanol enzyme. The compound ethanol enzyme and the method have the advantages that the high-activity acid proteases and plant extract with abundant plant-based enzymes and nutrient substances are particularly compounded on the basis of scientific compound food-grade enzyme preparations, so that the compound ethanol enzyme is provided with complete enzyme systems; activators, protective agents and antioxidants are further added into the high-activity acid proteases and the plant extract, the enzyme activity can be completely released by the aid of the activators and can be stabilized by the aid of the protective agents and the antioxidants, and hops extract and novasil which are used for inhibiting bacteria contamination and promoting saccharification of leaven and quick proliferation and fermentation of saccharomyces cerevisiae are further scientifically compounded; starch, proteins, fat, cellulose, hemi-cellulose, pectin and the like in unprocessed grain can be sufficiently and effectively hydrolyzed, accordingly, the raw material utilization rate and the liquor yields can be effectively increased, and the alcohol contents can be increased by 13.63%, 36.25% and 17.44% respectively as compared with commercially available special compound ethanol enzymes; the liquor yields of raw materials can be respectively increased by 17.41%, 38.81% and 20.04%, and the ethanol production cost can be obviously reduced.

Owner:湖南新鸿鹰生物工程有限公司

Baijiu-brewing compound enzyme containing acid protease and preparation method of Baijiu-brewing compound enzyme containing acid protease

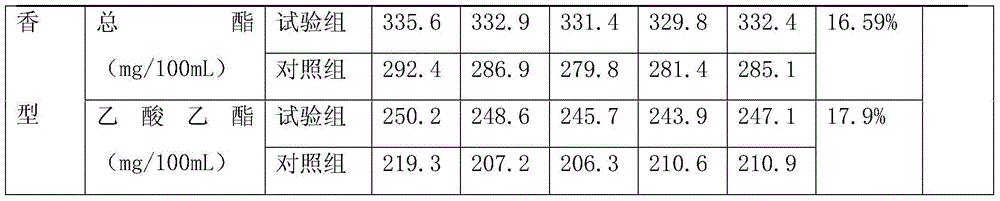

InactiveCN105524901AEnsure food safetyIncrease profitHydrolasesAlcoholic beverage preparationAntioxidantEnzyme system

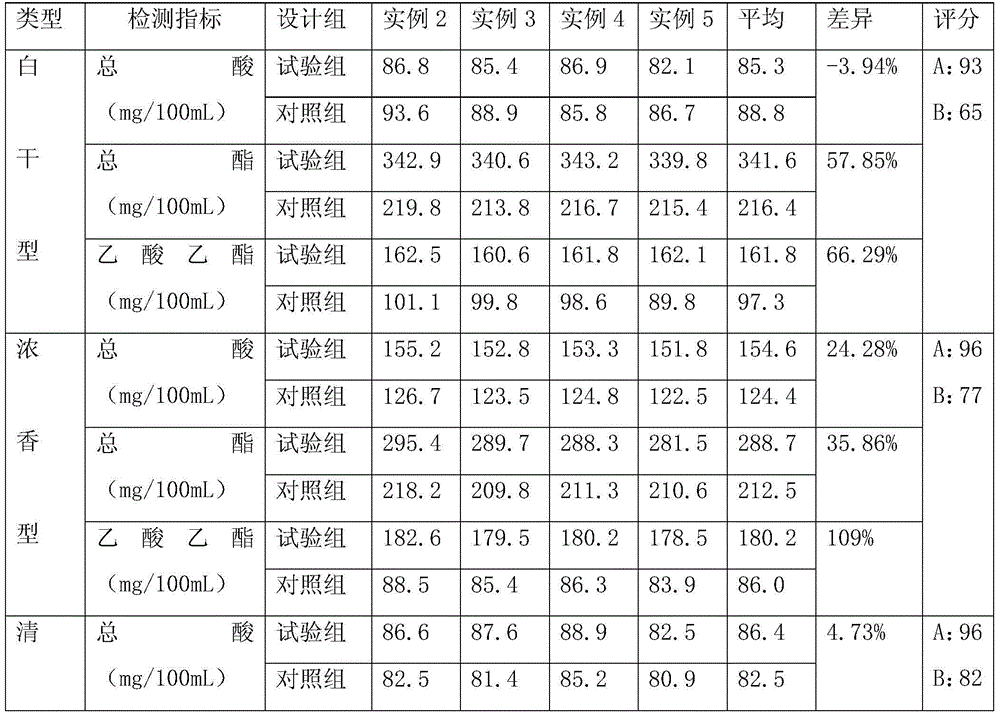

The invention discloses a Baijiu-brewing compound enzyme containing acid protease and a preparation method of the Baijiu-brewing compound enzyme containing the acid protease and belongs to the technical field of compound enzyme preparation. The Baijiu-brewing compound enzyme containing the acid protease and the preparation method have the advantages that on the basis of scientific compounding of food-grade enzyme preparations, high-activity acid protease and plant extracts containing plant enzymes and nutrient substances are compounded specially to enable an enzyme system of the compound enzyme to be more complete; activating agents enabling enzyme activity to be completely released and protective agents and antioxidants enabling enzyme activity to be more stable are added, and esterified red yeast and aroma-producing active dry yeast which make Baijiu more sufficient in aroma are compounded scientifically, so that starch, protein, fat, cellulose, hemicellulose, pectin and the like in grain can be hydrolyzed sufficiently and effectively, Baijiu yield can be increased by 24% to 29% remarkably, total ester content can be increased from 16.59% to 57.85%, and ethyl acetate content can be increased from 17.9% to 109%; taste of various types of Baijiu can be improved remarkably, and the compound enzyme can be suitable for brewing various types of Baijiu and addition of different Baijiu brewing methods.

Owner:湖南新鸿鹰生物工程有限公司

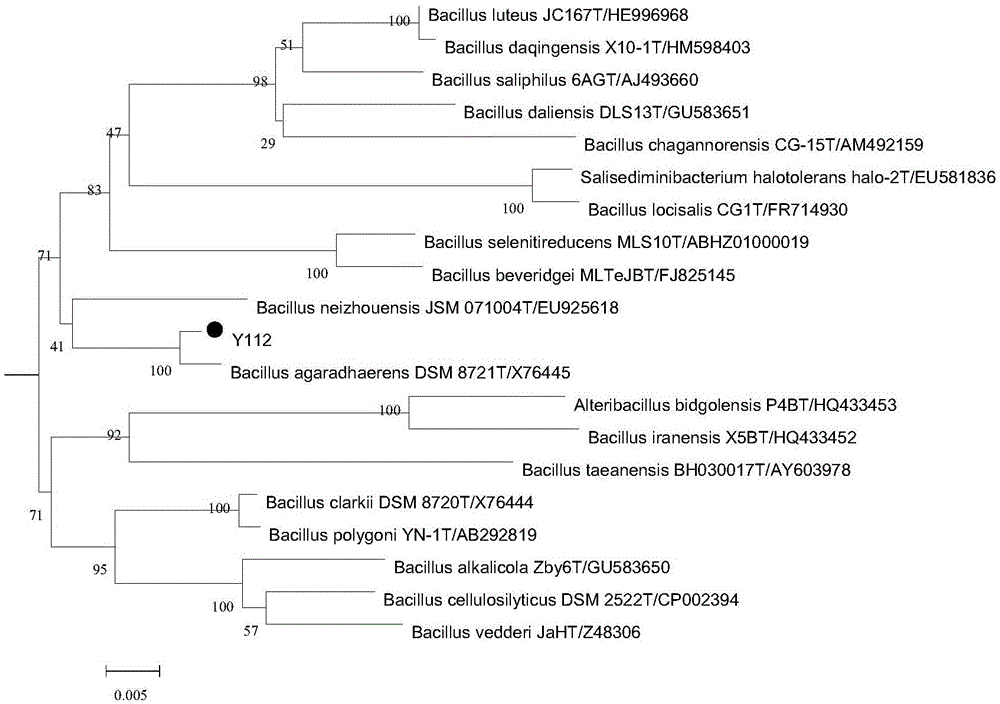

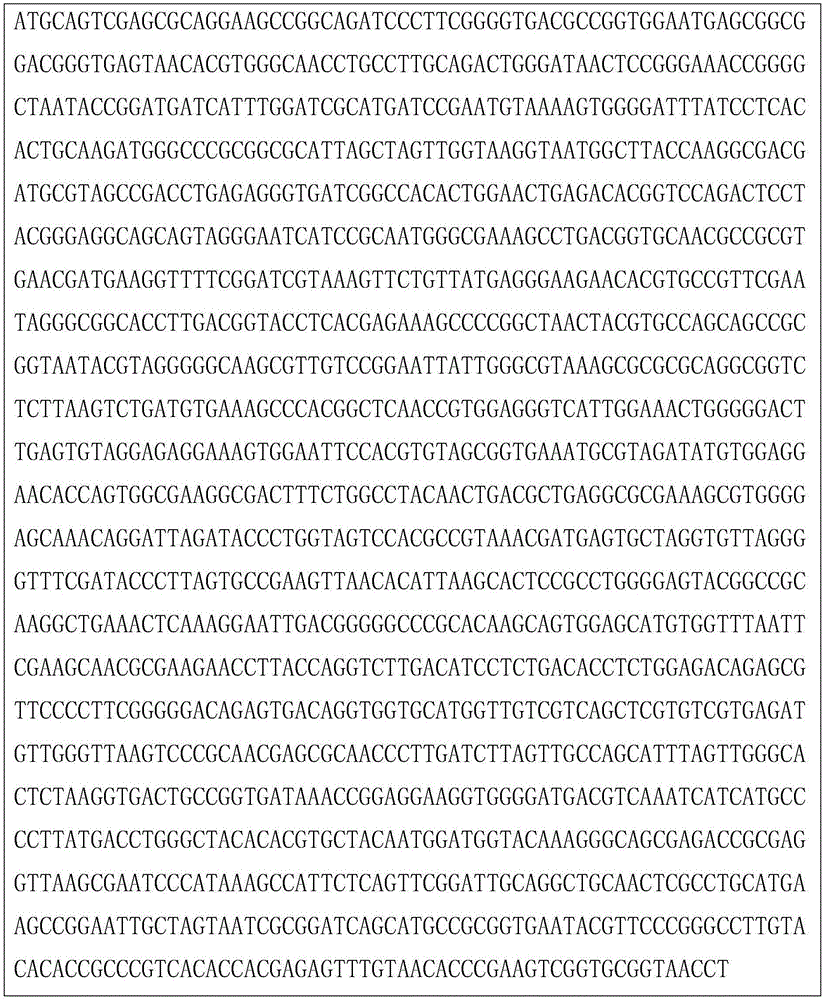

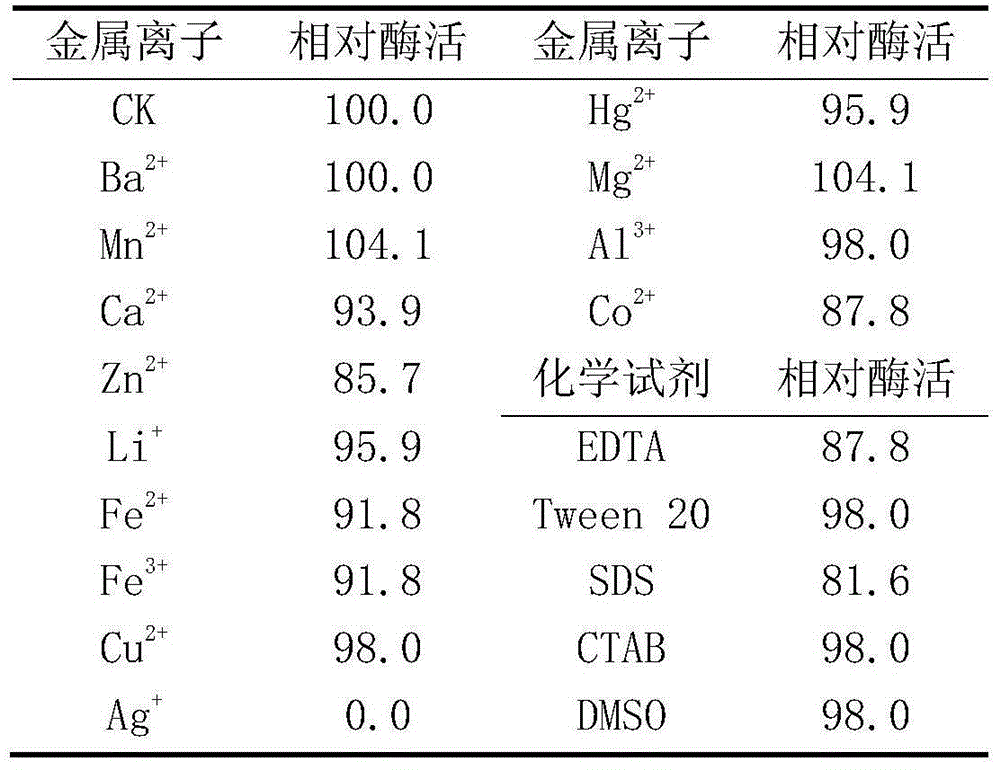

Marine microorganism strain Y112 and alpha-cyclodextrin glycosyltransferase produced by strain

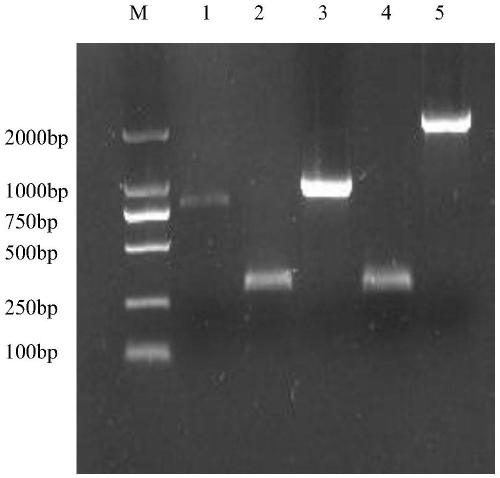

ActiveCN105154352AImprove stabilityImprove enzyme production capacityBacteriaTransferasesSequence analysisMicrobiology

The invention relates to a marine microorganism strain Y112 for producing alpha-cyclodextrin glycosyltransferase and enzyme produced by the strain. Upon 16SrDNA sequence analysis and in coordination with physiological and biochemical characteristics, the strain belongs to bacillus; and through sequencing, 16SrDNA sequence is about 1420bp long, and base composition is as shown in Figure 1. The marine microorganism strain is extensively applicable to medicine, food, chemical industry, cosmetics, industry, agriculture, analytical chemistry and like aspects.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

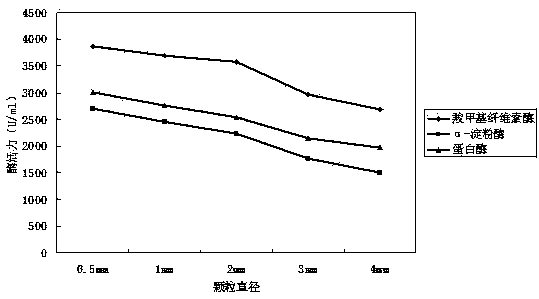

Method for producing alginate lyase through fermentation by using marine bacteria

InactiveCN110195051AEasy to separateEasy to purifyBacteriaMicroorganism based processesMicroorganismAlginate lyase

The invention discloses a method for producing alginate lyase through fermentation by using marine bacteria, which relates to the technical field of sea microbial fermentation. The method adopts the marine bacterium Flavobacterium mizutaii as a starting strain, and obtains a crude enzyme solution of alginate lyase by the steps of preparing the seed liquid, expanding the seed liquid for culture, fermenting for enzyme production culture, and extracting the fermentation liquid. The method aims at enzyme production rule of Flavobacterium mizutaii for optimizing the fermentation conditions and a fermentation medium, and improves the enzyme production ability of the aquatic Flavobacterium mizutaii by a carbon source feeding strategy and a method of adding various enzyme-inducing substances, andprovides important technical parameter guidance for the large-scale production of the alginate lyase in the future.

Owner:张学花

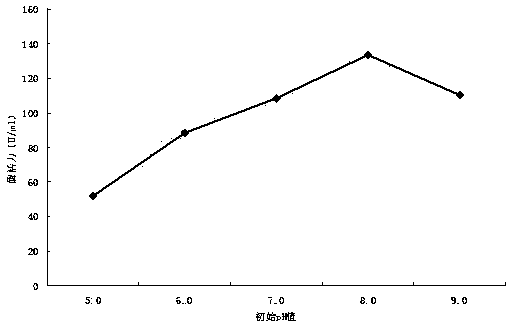

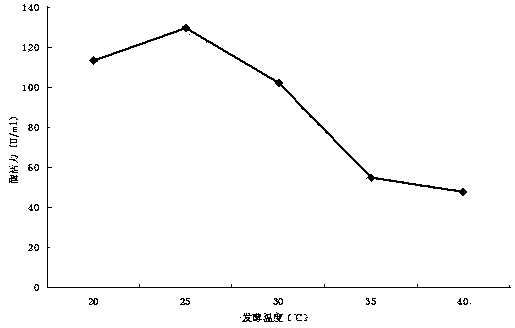

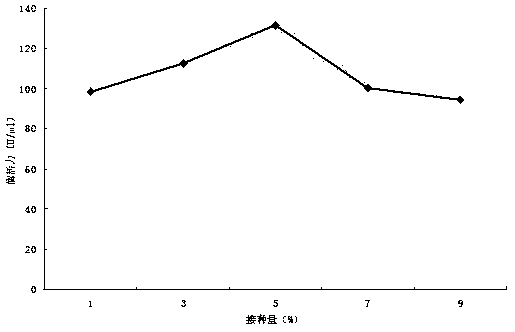

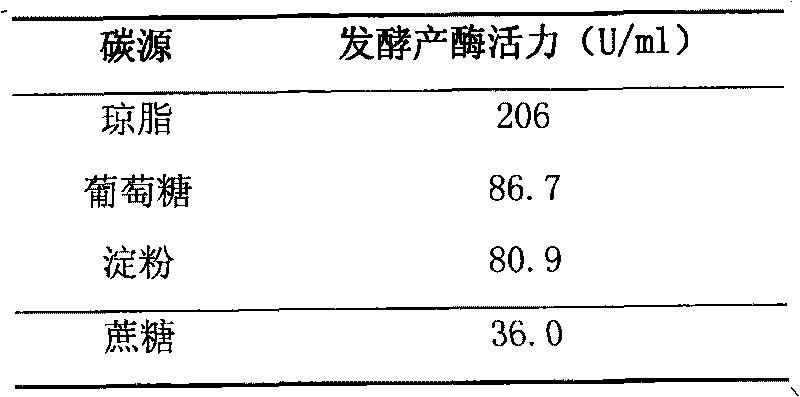

High-yield fermentation production process of Beta-agarase

InactiveCN101717760AIncrease enzyme activityStable traitsMutant preparationMicroorganism based processesPurification methodsMicrobiology

The invention relates to a process condition for producing agarase by fermenting mutant breeding strains of vibrio which is a producing strain of Beta-agarase, and provides a fermentation culture process and an optional culture condition for breeding high-yield strain by mutagenesis. The invention determines the components of a slop culture medium, a seed culture medium, a fermentation culture medium and culture conditions, and the fermentation enzyme capability is more than 180U / ml; a conventional separation and purification method can be adopted to prepare the high-activity Beta-agarase. Therefore, the invention provides a production process of agarase, which has industrialized conversion prospects.

Owner:四川金稞生物科技有限公司

Preparation method of composite zymoprotein

InactiveCN101507469AExcellent strainStrong generation stabilityAnimal feeding stuffAccessory food factorsNutritive valuesZymogen

The invention relates to a method for preparing a complex enzyme protein, which is characterized by comprising the following steps: preparing an aerobic fermentation medium, preparing an anaerobic fermentation medium, sterilizing the mediums, activating bacterial strains, performing amplification cultivation and inoculation, preparing an aerobic fermentation condition, preparing an anaerobic fermentation condition, drying at a low temperature, mixing the mixture, and packaging. The method has the advantages that: 1, the strains are excellent and the passage stability is strong; 2, each strain plays a synergetic role in the process of fermentation, the growth and the metabolism of each strain is thriving, and the enzyme productivity is strong; 3, aerobic zymogens and anaerobic zymogens perform fermentations separately so that each strain gives play to the best enzyme producing performance; and 4, proteins which are difficult to absorb by animals in raw materials are converted into thalli single cell proteins which are easy to absorb so that the nutritive value of products is improved.

Owner:江西普润药业有限公司

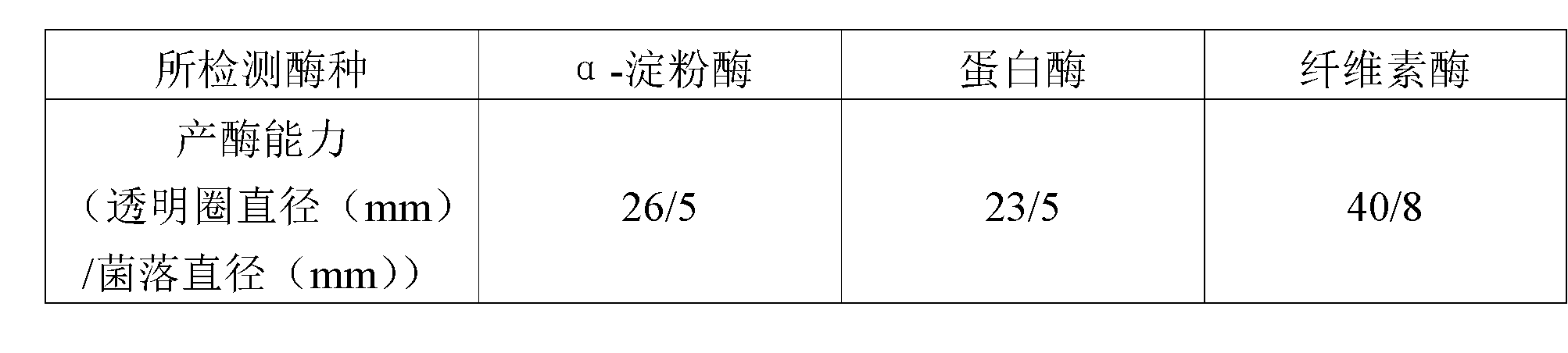

Screening method of composite microbial system for producing organic fertilizer

InactiveCN105315024AImprove enzyme production capacityImprove compatibilityOrganic fertilisersProduction effectScreening method

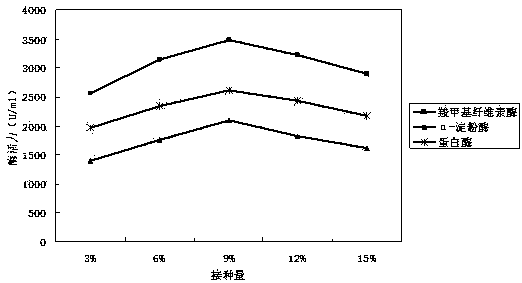

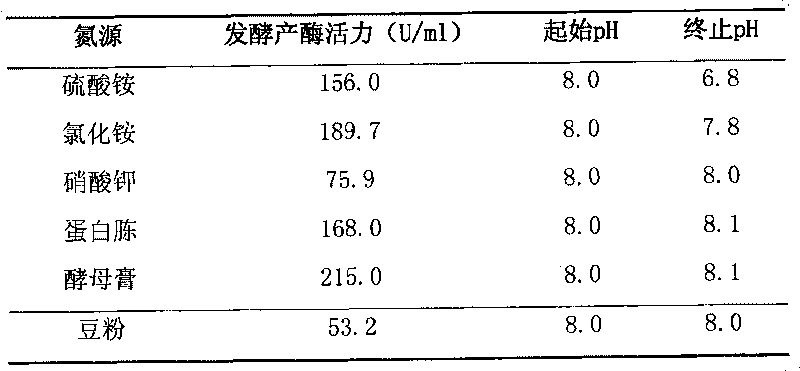

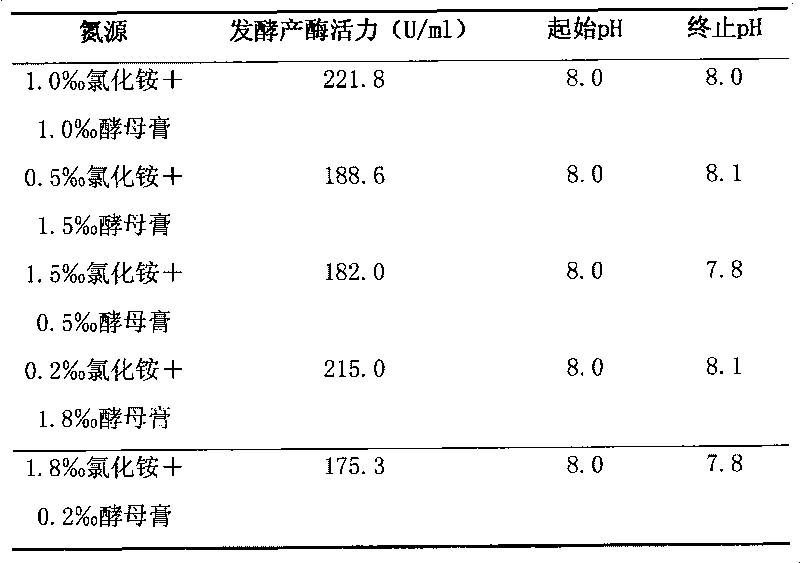

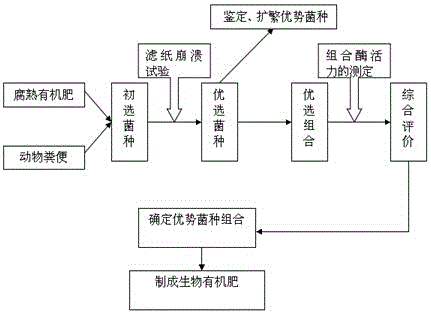

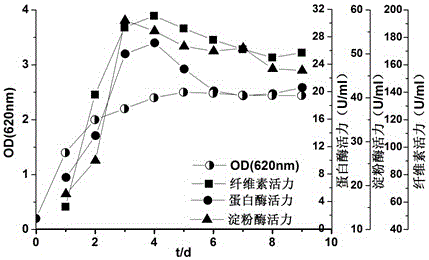

The invention discloses a screening method of a composite microbial system for producing organic fertilizer. According to the method, samples are firstly collected from organic fertilizer which is completely decomposed or animal manure, then strains are separated from the samples through different culture media, dominant strains good in enzyme production effect are screened out through a filter paper collapse test and a transparent ring test and then are identified, purified and subjected to enrichment culture, the antagonism test is performed on the basis that the dominant strains are obtained, and the optimally-combined composite microbial system for producing organic fertilizer is obtained by analyzing the combination activity of bacterial strains. The composite microbial system for producing organic fertilizer is good in compatibility, the enzyme production capacity is obviously higher than that of single bacterial strains, and the activity of cellulase, protease and amylase of the composite microbial system for producing organic fertilizer reaches 193.5, 25.3 and 55.7 (U / ml) respectively. Thus, the obtained composite microbial system can effectively degrade straw, animal manure and other agricultural waste so that the organic fertilizer can be obtained, the environment can become clean, biological organic fertilizer can be processed, and sustainable development of agriculture is achieved.

Owner:董玲玲

Alkaline-lipase-producing Aspergillus niger mutant strain

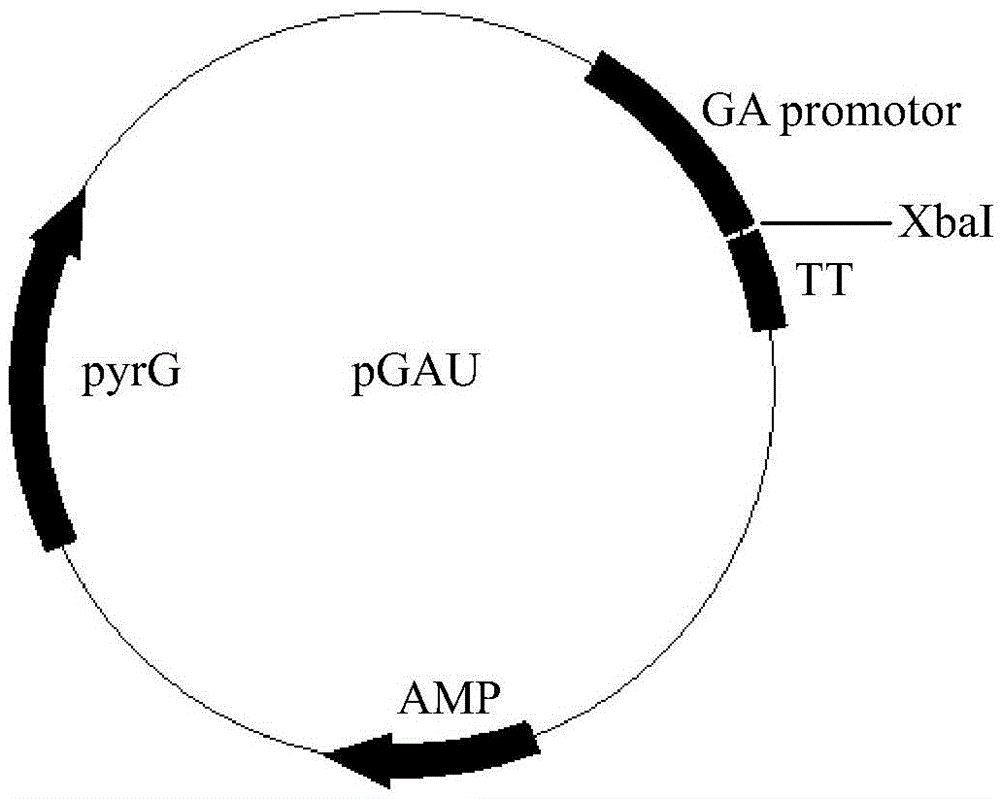

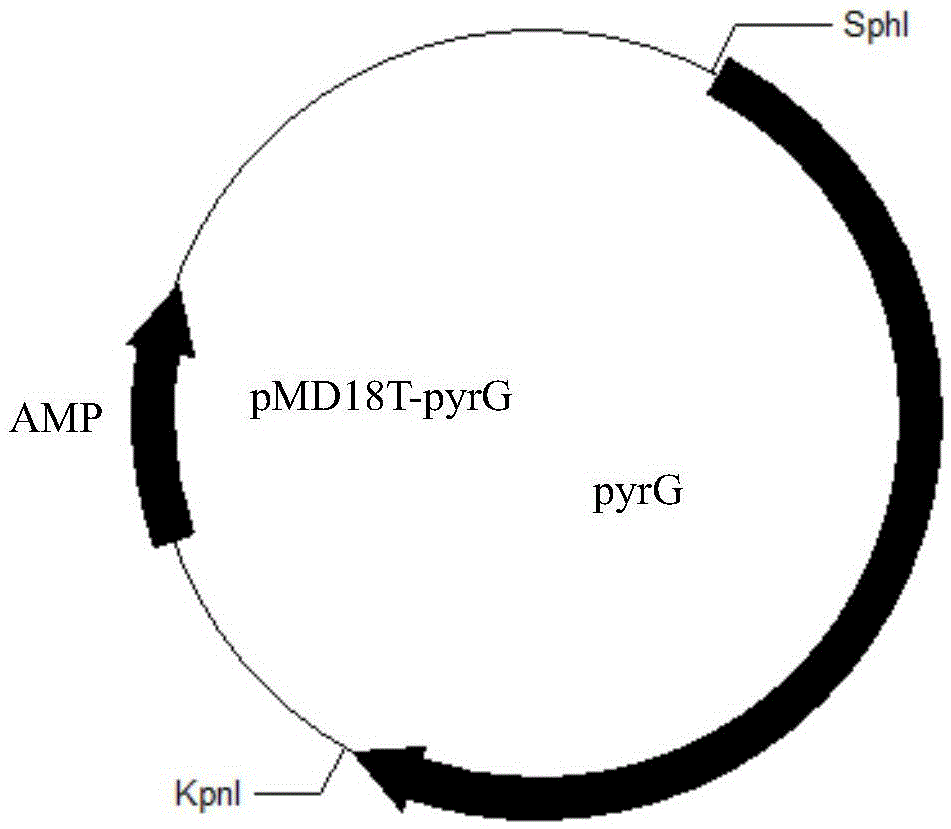

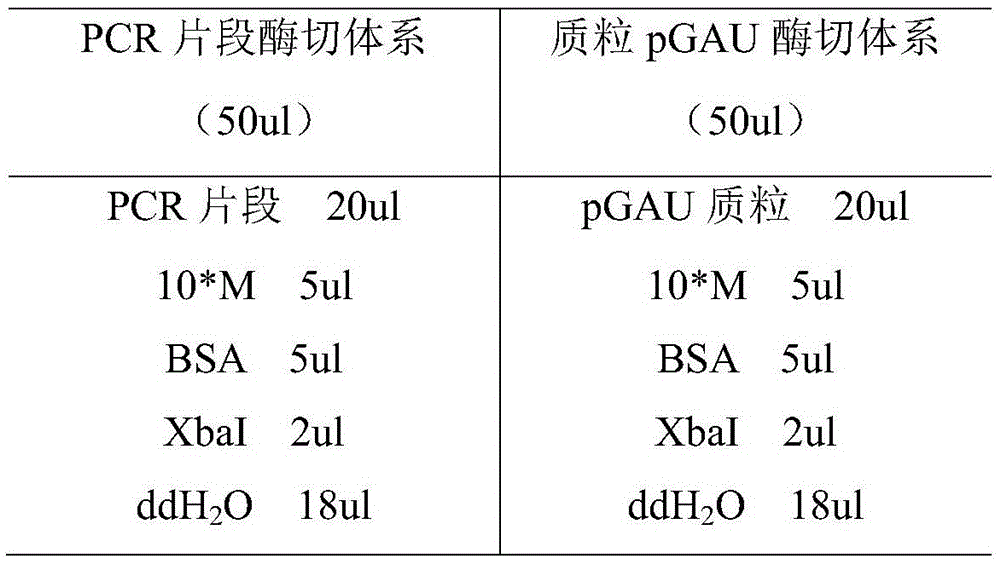

The invention aims to provides an alkaline-lipase-producing Aspergillus niger mutant strain which is prepared by the following steps: transforming an alkaline lipase gene into an Aspergillus niger host strain to construct an Aspergillus niger engineering strain capable of efficiently expressing alkaline lipase; and knocking out the amylase gene of the host strain by gene knock-out means, and screening to obtain the mutant strain with obviously enhanced alkaline lipase yield. The collection number of the mutant Aspergillus niger strain is CCTCC NO:M2015761. The alkaline lipase activity of the mutant strain Aspergillus niger Su-12 reaches 15766 u / ml, and the protein expression level is 5.4 g / L, which are respectively enhanced by 56.3% and 18.9% as compared with the strain before mutation, thereby being beneficial to wide application of the enzyme.

Owner:QINGDAO VLAND BIOTECH GRP

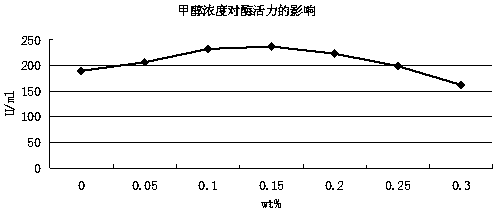

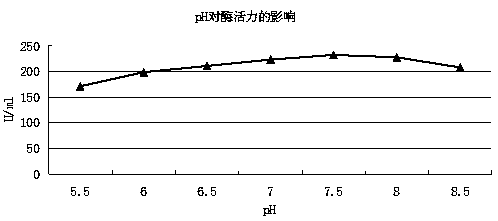

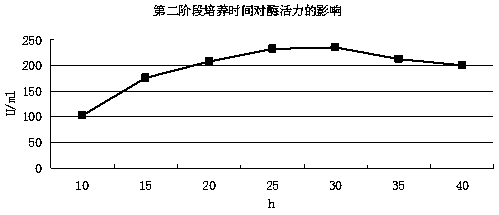

Method for preparing glucose oxidase from microbial fermentation

ActiveCN108384766APromote proliferationImprove enzyme production capacityFungiBacteriaMicroorganismAspergillus niger

The invention belongs to the technical field of microbial fermentation, and discloses a method for preparing glucose oxidase from microbial fermentation. The method comprises the steps of first-stagecultivation and second-stage cultivation; according to the first-stage cultivation, an Aspergillus niger seed solution is cultivated for 30-40 h, and then, a Lactobacillus casei seed solution is inoculated for continuous cultivation for 20-30 h. The method is high in fermentation enzyme production activity and short in fermentation time.

Owner:宁波天皓生物科技有限公司

Bacillus subtilis strain usable as probiotic preparation and fermentation process thereof

InactiveCN105861355AImprove enzyme production capacityIncrease production capacityBacteriaMicroorganism based processesGlucose polymersD-Glucose

The invention discloses a Bacillus subtilis strain usable as a probiotic preparation and a fermentation process thereof. The fermentation process comprises the following steps: step 1, inoculating an inclined medium with the Bacillus subtilis strain and carrying out culture for 3 days in a thermotank with a temperature of 37 DEG C, wherein the obtained substance is used as a seed culture; and step 2, inoculating a glucose nutritional broth with the seed culture, carrying out culture at 37 DEG C for 24 h, mixing the obtained solution with light calcium carbonate according to a ratio of 1: 3, drying the obtained mixture and then crushing the mixture. Compared with the prior art, the invention has the following beneficial effects: the Bacillus subtilis strain BB has high enzyme production capability, is applicable as a feed additive to feeds for livestock and poultry, can improve production performance of bred animals and has wide application prospects.

Owner:孟丽辉

Process for preparation of organic fertilizer with amino acid fermentation tail liquor

InactiveCN109970495AStrong oxidation abilityImprove enzyme production capacityFungiMagnesium fertilisersAmino acid fermentationOrganic fertiliser

Belonging to the field of amino acid fermentation tail liquor treatment, the invention discloses a process for preparation of an organic fertilizer with amino acid fermentation tail liquor. The methodincludes the steps of: 1) preparation of thallus powder, 2) preparation of a seed solution, step 3) preparation of an enzymolysis liquid and 4) preparation of an organic fertilizer. The process provided by the invention is simple and feasible, utilizes amino acid fermentation tail liquor to prepare the organic fertilizer with high fertilizer efficiency, and the application prospect is broad.

Owner:许传高

Ecological fermented feed and preparation technology thereof

PendingCN107594149AReplenish evenlyGrow fastFood processingAnimal feeding stuffAnimal sciencePotato starch

The invention relates to an ecological fermented feed and a preparation technology thereof. The ecological fermented feed consists of the following raw materials in parts by weight: 10-50 parts of grass meal, 20-60 parts of corn sugar dregs, 10-50 parts of bran, 5-45 parts of cottonseed meal, 10-50 parts of potato starch dregs, 5-30 parts of molasses, 0.01-10 parts of ruminant multiple vitamins, 0.1-20 parts of ruminant multiple minerals, 0.1-10 parts of activation bacterial liquid and 5-60 parts of sodium humate. The feed prepared by the preparation technology disclosed by the invention can supply collocation of a concentrated feed and a coarse feed and nutrient substances of protein, energy, vitamins, minerals and the like required for growth of cattle and sheep in a balanced manner, sothat animals of mutton sheep, cows and the like can grow quickly and are good in meat quality in winter and spring, and the ecological fermented feed has the advantages of being low in cost and easy to store; and besides, the pressure of a grassland can be relieved, ecological damage is reduced, dust storm is prevented and controlled, environment is further protected, and the ecological fermentedfeed has important significance in sustainable development of animal husbandry in China.

Owner:INNER MONGOLIA KAIJIA BIOTECH

High activity, high-purity and high temperature resistant Alpha-amylase production process

InactiveCN101182501AOvercoming high carbon-nitrogen ratioOvercome Dissolved Oxygen DifferenceElectrical/wave energy microorganism treatmentEnzymesFiltrationUltrafiltration

The invention provides a production process that bacteria strain (12 hours)to a first-class seed tank (28 hours)to big tank (about 100 hours, 12000u / ml draw off enzyme activity)to post treatment of flocculation (70 degree)-pressure filtration-cycle initial filtration-ultra-filtration to fine filtration (10 hours) to final product treatment (elevated temperature 80 degree) to precipitation (48 hours) to alpha-amylase production process with high activity, high purity and high temperature resistance. The XF-19 strain is selected; a secondary fermentation process, the addition of feeding material into the basic material, continuous feeding of ammonia and the application of cooked soybean meal as nitrogen source are applied during the production process; the cycle initial filtration and fine filtration are added in the post treatment process, which solves the shortcomings of old production process such as weak enzyme production ability per unit, decreasing pH value during auto-metabolism of the enzyme seed, little enzyme activity, poor temperature resistance, easy precipitation and high total bacteria count etc. The invention can reduce the production cost, great economic benefits and big popularization and application value.

Owner:津市市新型发酵有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com