High-yield fermentation production process of Beta-agarase

A kind of agarase and process technology, applied in the direction of enzymes, enzymes, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

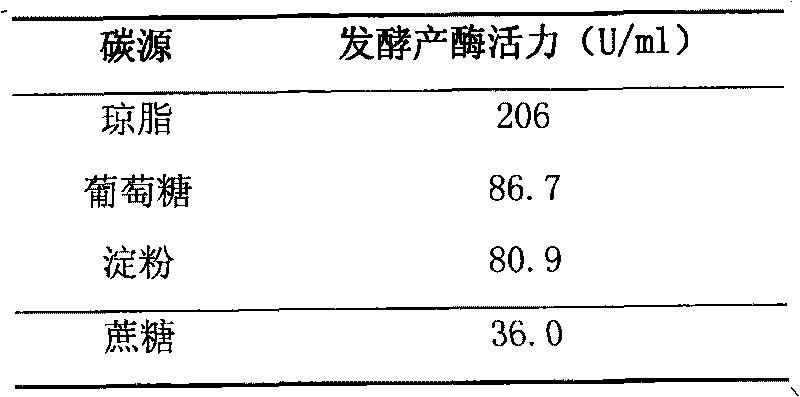

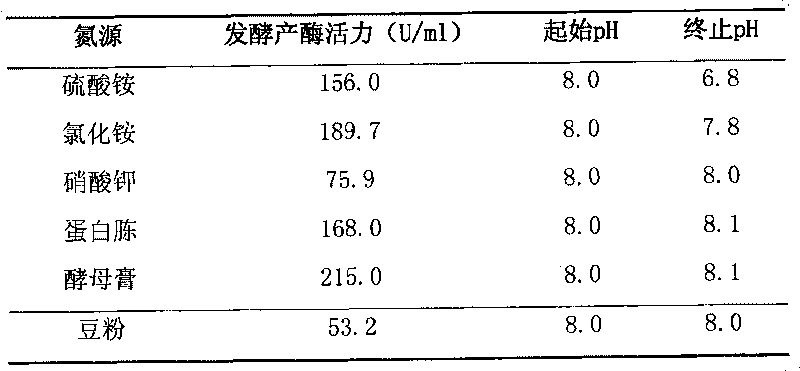

Examples

Embodiment 1

[0034] The screening of embodiment 1 agarase producing bacterial strain

[0035] The seawater collected from the ocean is dispersed in the culture medium dish that contains 1.5% agar, and the composition of culture medium is: peptone 5g, yeast extract 1g, ferric phosphate 0.1g, agar 15g, NaCl 20g, add water and be diluted to 1000ml. After culturing at 25°C, a transparent circle was formed around the agarase-producing colony, and the culture medium was concave in the shape of a kettle bottom. This feature was used as the basis for the initial screening of strains.

[0036] The strains screened were observed under a microscope, and the bacteria were curved and arc-shaped, with a single flagella; the experimental examination was Gram-negative bacteria, oxidase positive, catalase positive, 0 / 129 test positive, using glucose to produce acid. Gas production, according to the above characteristics, it was initially identified as Vibrio (Vibrio). The bacteria grow on the plate, can s...

Embodiment 2

[0038] Embodiment 2 Mutagenesis of agarase producing strain

[0039]First turn on the ultraviolet lamp (30W) in the inoculation room to preheat for 10 minutes, take 5ml of the prepared bacterial suspension and transfer it into a sterile petri dish with a diameter of 90mm, put a sterile magnetic stirring bar, and place it on a magnetic stirrer at a distance of 254nm from the wavelength. Open the lid of the dish at 30cm under the ultraviolet lamp and irradiate while stirring, and the doses are 15min respectively. After incubating the irradiated bacterial solution for 4 h, take 1 ml of the bacterial suspension with different irradiation time, and carry out 10 -1 、10 -2 、10 -3 、10 -4 、10 -5 、10 -6 and 10 -7 Gradient dilution, take 10 -3 、10 -5 , and 10 -7 Spread 1ml of each concentration dilution on the separation plate, spread on the plate for primary screening, select colonies with fast growth and large transparent circles and transfer them to slant medium, culture at 2...

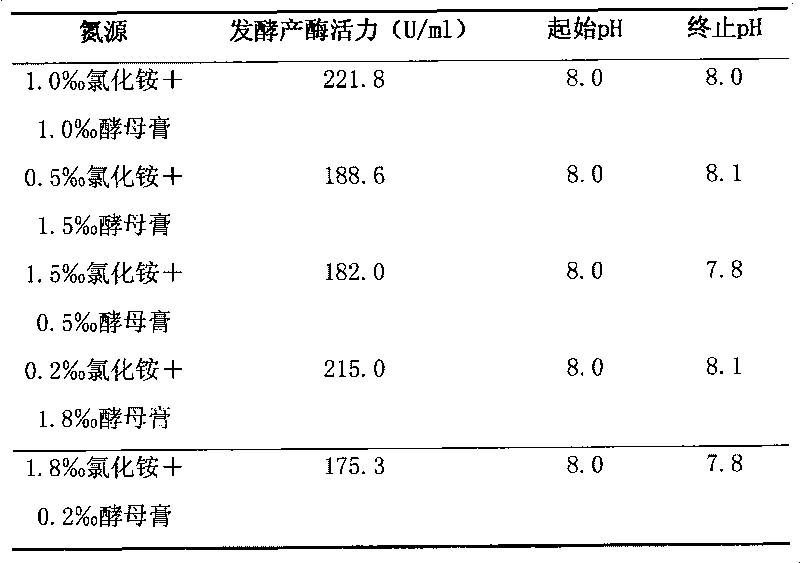

Embodiment 3

[0041] Seed culture and 5L fermenter cultivation of embodiment 3 mutant high-yield bacterial strains

[0042] 1. Seed culture

[0043] The composition of the seed medium: agar 2.0‰, yeast extract 0.3%, NH 4 Cl 1.0‰, K 2 HPO 4 0.1%, NaCl 1.0%, pH 8.0.

[0044] Temperature 25°C;

[0045] Shaker speed 150rpm;

[0046] Capacity 30ml / 250ml.

[0047] 2. Fermentation culture

[0048] The strains cultivated from the seeds were inoculated in a 5L fermenter for fermentation culture, the inoculation amount of the strains was 8%, and the amount of the fermentation medium was 2L.

[0049] The composition of the fermentation medium is: agar 2.0‰, yeast extract 0.1%, NH 4 Cl 1.0‰, K 2 HPO 4 0.12%, NaCl 1.0%, pH 8.0.

[0050] Fermentation temperature 25°C;

[0051] The initial pH value of fermentation is 8.0;

[0052] Fermentation stirring speed 150rpm;

[0053] The fermentation and cultivation time was 24h.

[0054] 3. Using a conventional method to separate and enrich the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com