Method and device for extracting fumaric acid in fermentation broth in continuous counter current manner by means of amine extractants and application of fermentation technology combined with method

A technology of fumaric acid and fermented liquid, which is applied in the field of bioengineering, can solve the problems of unextracted fumaric acid, etc., and achieve the effect of large extraction and separation factor, easy automatic control and scale-up, and beneficial to normal growth and metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

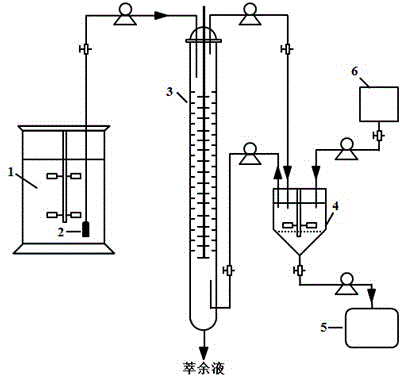

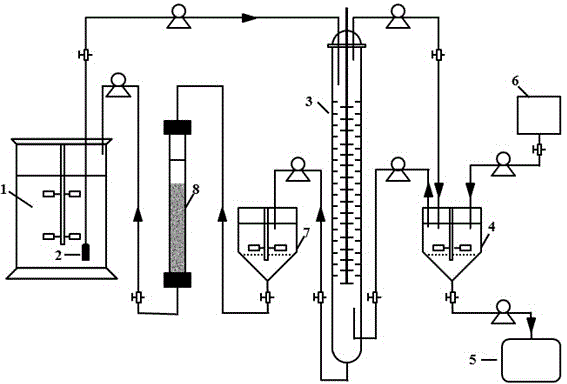

Image

Examples

Embodiment 1

[0041] Example 1: Continuous countercurrent extraction of fumaric acid in the fermentation broth by amine extractant was used to continuously prepare fumaric acid in coupled fermentation technology.

[0042] (1) Preparation of spore suspension: Rhizopus oryzae ( Rhizopus oryzae ) ME-F13 was inoculated on PDA slant medium (take 200g of fresh peeled potatoes, cut into small pieces, add 1000mL of water, heat and boil for 30min, filter with gauze and make up water loss to 1000mL, get 20% potato extract, add 20g of sucrose , agar 22g, melted and subpackaged, sterilized at 121°C for 20min), the slope was placed in a constant temperature incubator at 35°C for 6 days, after the spores matured, the spores were washed with sterile water under sterile conditions Filtered with a layer of gauze, collected into a conical flask equipped with glass beads, placed in a shaker at 25°C and 150r / min for 30min, and the spore concentration was controlled at 10 7 A / mL spare;

[0043] (2) Fermented...

Embodiment 2

[0047]Example 2: Continuous countercurrent extraction of fumaric acid in fermentation broth by amine extractant Continuous preparation of fumaric acid in coupled fermentation technology.

[0048] (1) Prepare spore liquid and fermented seeds according to the method in Example 1.

[0049] (2) Fermentation culture: 3L of fermentation medium (glucose 80g / L, urea 0.1g / L, KH 2 PO 4 0.4g / L, MgSO 4 ·7H 2 O 0.5g / L, ZnSO 4 ·7H 2 O 0.0176g / L, FeSO 4 ·7H 2 O 0.000498g / L), sterilized at 115°C for 30min, after the tank was cooled to room temperature, fermented seeds were added, the inoculation amount was 8% (v / v), the fermenter was placed at a temperature of 33°C, an air flow of 1.2 vvm, and a rotation speed of The fermentation culture was carried out under the operating condition of 300 rpm, and the pH was adjusted to 5.0 by 3.0 mol / L sodium carbonate. After 36 hours of fermentation, the growth of Rhizopus oryzae entered the late stage of logarithmic growth. The concentrations of ...

Embodiment 3

[0052] Example 3: Continuous countercurrent extraction of fumaric acid in the fermentation broth by amine extractant coupled fermentation technology for continuous preparation of fumaric acid.

[0053] (1) Prepare spore liquid and fermented seeds according to the method in Example 1.

[0054] (2) Fermentation culture: 5L of fermentation medium (glucose 100g / L, urea 0.1g / L, KH 2 PO 4 0.5g / L, MgSO 4 ·7H 2 O 0.5g / L, ZnSO 4 ·7H 2 O 0.0176g / L, FeSO 4 ·7H 2 O 0.000498g / L), sterilized at 115°C for 30min, after the tank was cooled to room temperature, fermented seeds were added, the inoculation amount was 15% (v / v) the fermenter was placed at a temperature of 38°C, an air flow of 0.5 vvm, and a rotation speed of The fermentation culture was carried out under the operating condition of 600 rpm, and the pH was adjusted to 6.0 by 1.0 mol / L sodium hydroxide. After 20 hours of fermentation, the growth of Rhizopus oryzae entered the mid-logarithmic growth phase. The concentrations ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com