Strain for high-temperature composting of sludge and application thereof

A composting and bacterial agent technology, applied in the field of microbial fermentation technology and environmental protection, can solve the problems of high power consumption, reduced treatment efficiency, and more odor, and achieves high temperature for a long time, complete degradation of organic matter, ammonia gas, etc. Odor reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

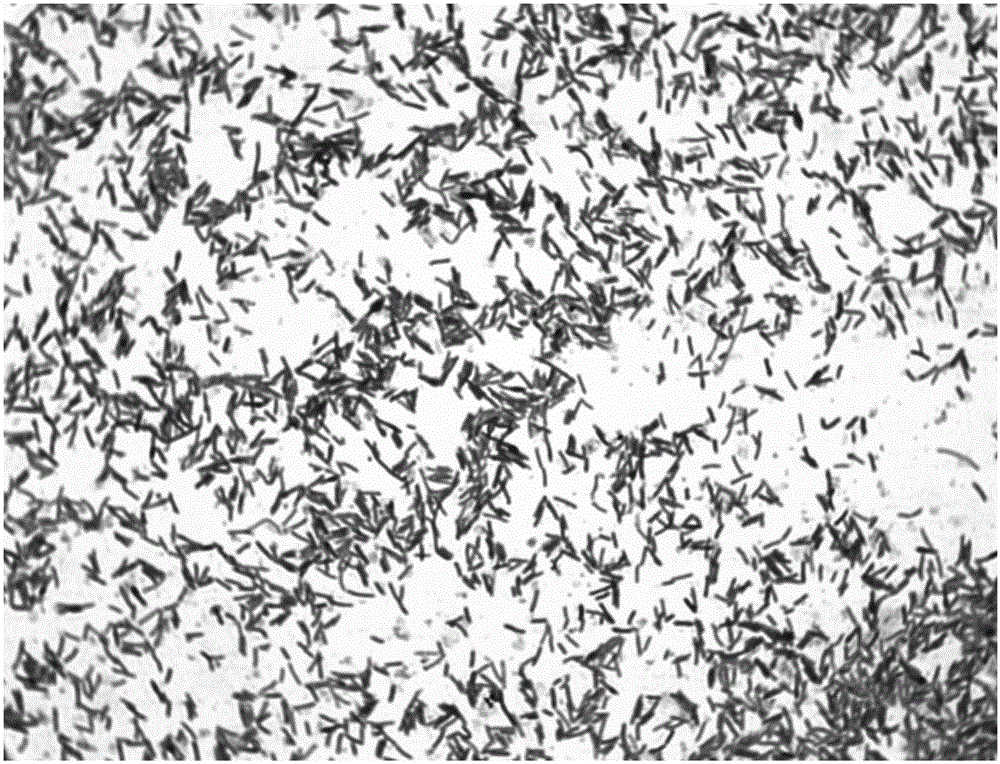

[0035] The isolation and identification of embodiment 1 thermospheroid urea bacillus D1

[0036] 1) Sampling: Sampling 50g of the heap that has reached a high temperature of 50-70°C for more than 2 days, put it into a sterile Erlenmeyer flask, add 250ml of sterilized water, and shake for 30 minutes.

[0037] 2) Separation: In a sterile operating bench, the above-mentioned samples are coated on a flat plate by the extinction dilution method, put into a culture bag, and put into an incubator together.

[0038] Cultivation: place in a constant temperature incubator at 50-65°C for 12-48 hours;

[0039] Solid culture plate formula: according to the mass percentage of water, imported yeast powder 0.5-1%, sucrose 2%, industrial peptone 2%, sodium chloride 1%, agar 2.0-2.5%, distilled water, sterilized at 121 degrees Celsius for 30 minutes.

[0040]3) Purification: the cultured bacterial strains were separated by streaking on the above-mentioned solid culture plate until the pure cul...

Embodiment 2

[0049] The preparation of embodiment 2 compost inoculants

[0050] 1) Activation culture: activating and culturing the strain of Bacillus thermosphaeroidus D1 with the preservation number CGMCC No. 12329 at 60-80°C for 12-48 hours;

[0051] 2) Seed solution preparation: inoculate the activated strains into the culture solution, seal the bottle mouth, shake and cultivate at 65-80°C for 1-3 days, and the oscillation frequency is 160-200rpm;

[0052] 3) Preparation of fermented bacteria liquid: adding the seed liquid obtained in step 2) into the sterilized culture liquid at a volume ratio of 3%-10%, and the fermentation time is 48-72 hours. During the fermentation, the gas:liquid ratio of ventilation is 1:0.5 in 0-24 hours, 1:1 in 24-72 hours, the tank pressure of the fermenter is 0.08-0.1Mpa, and the stirring rate is 180-200rpm ;

[0053] 4) Preparation of compost inoculant: uniformly mix fermented bacteria liquid and sugar, add adsorption material, mix evenly with compost mat...

Embodiment 3

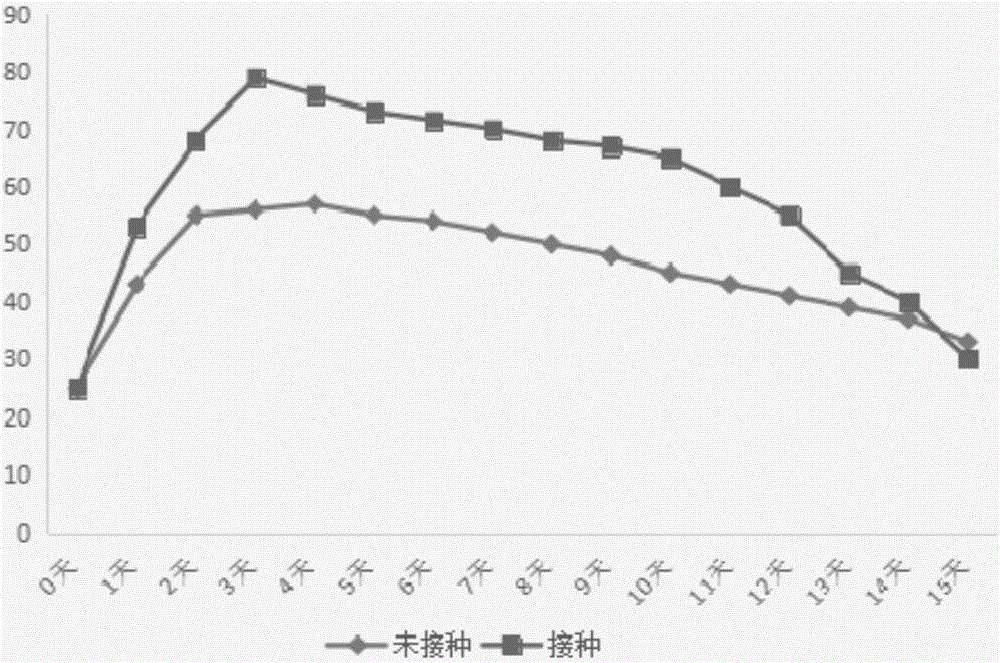

[0058] Application and effect of embodiment 3 compost inoculants of the present invention

[0059] 1. Sludge composting effect

[0060] The application effect of the compost inoculant prepared in Example 2 of the present invention will be described below with the composting treatment of municipal sludge. Take municipal sludge and straw powder at a weight ratio of 1:0.5 and mix them evenly, then add the compost inoculant prepared in Example 2 at 0.5% of the total material, and carry out stacking and fermentation, which is inoculation treatment. Another control was set up without inoculation of compost inoculants for the test. Among them, for conventional treatment, turn over every 5 days or when the temperature exceeds 75°C; for inoculation treatment, turn over every 4-6 days. Determine the maturity of the compost through the temperature change and oxygen consumption rate of the compost, and monitor the odor emission during the composting process.

[0061] The number of days...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com