Organic fermentation fertilizer and preparation method thereof

A fermented fertilizer and organic technology, applied in the field of organic fermented fertilizer and its preparation, can solve the problems of high heavy metal content, poor comprehensive fertilizer efficiency, low nutrient content, etc., and achieve the effects of high organic matter content, inhibition of proliferation, and high nutrient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

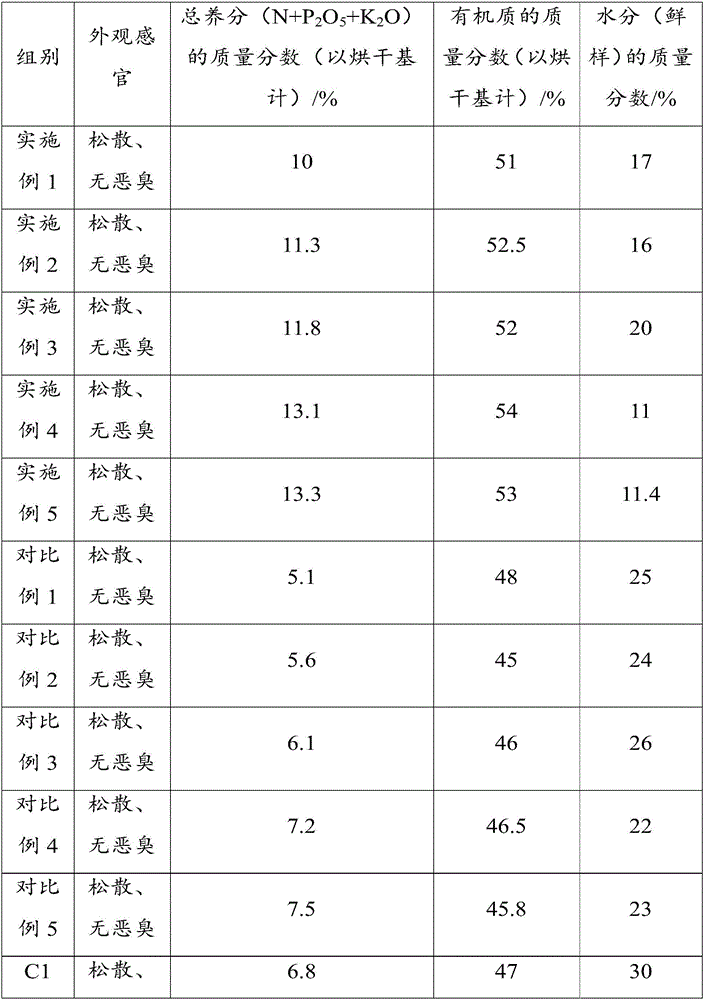

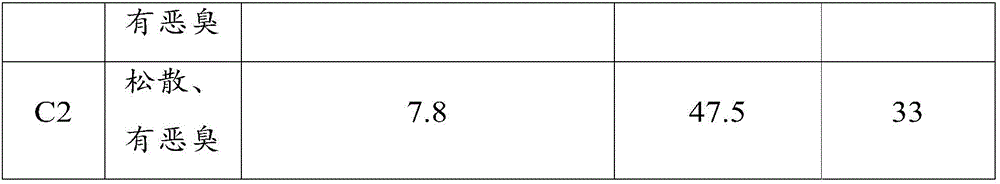

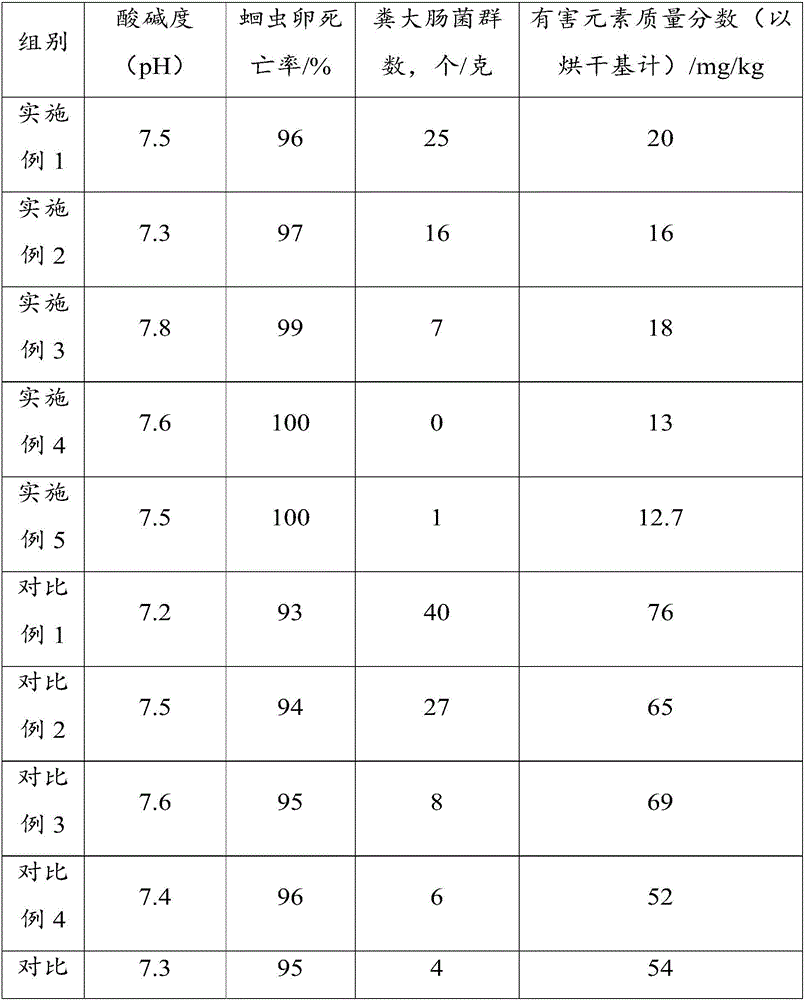

Examples

preparation example Construction

[0035] The invention provides a kind of preparation method of organic fermented fertilizer, comprises the following steps:

[0036] (1) Aerobic fermentation: mix poultry manure with aerobic bacteria, and ferment at 60-80°C for 8-15 days to form primary fermented fertilizer;

[0037] (2) Facultative anaerobic fermentation: mix primary fermentation fertilizer with facultative anaerobic bacteria, and ferment at 50-60°C for 10-20 days to form secondary fermentation fertilizer;

[0038] (3) Anaerobic fermentation: the secondary fermented fertilizer is mixed with anaerobic bacteria, and fermented at a temperature not higher than 45° C. for more than 3 months to form the organic fermented fertilizer.

[0039] The fermentation method of traditional organic fertilizer adopts a single aerobic fermentation or anaerobic fermentation, and the organic fertilizer obtained is relatively smelly, has heavy peculiar smell, low nutrient content, and contains a large number of parasites; the prepa...

Embodiment 1

[0075] A preparation method of organic fermented fertilizer, comprising the following steps:

[0076] (1) Aerobic fermentation: mix chicken manure with bacillus, and ferment at 60°C for 8 days to form a primary fermented fertilizer;

[0077] (2) Facultative anaerobic fermentation: the primary fermentation fertilizer is mixed with EM bacteria, and fermented at 50°C for 20 days to form a secondary fermentation fertilizer;

[0078] (3) Anaerobic fermentation: the secondary fermentation fertilizer is mixed with spore-type lactic acid bacteria, and fermented at a temperature of 45° C. for 3 months to form the organic fermentation fertilizer.

Embodiment 2

[0080] A preparation method of organic fermented fertilizer, comprising the following steps:

[0081] (1) Aerobic fermentation: Cow dung is mixed with Bacillus and Trichoderma, and fermented at 80°C for 15 days to form a primary fermented fertilizer;

[0082] (2) Facultative anaerobic fermentation: the primary fermentation fertilizer is mixed with Bacillus megaterium and EM bacteria, and fermented at 60°C for 13 days to form a secondary fermentation fertilizer;

[0083] (3) Anaerobic fermentation: the secondary fermentation fertilizer is mixed with spore-type lactic acid bacteria, and fermented at a temperature of 40° C. for 3.5 months to form the organic fermentation fertilizer;

[0084] In parts by weight, cow dung, aerobic bacteria, facultative anaerobic bacteria and anaerobic bacteria are 90 parts, 1 part, 1 part and 1 part in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com