Method for producing cellulase by mixed fermentation of aspergillus oryzae and fusarium chlamydosporum

A technology of Fusarium chlamydoides and cellulase, applied in the field of mixed fermentation of Aspergillus oryzae and Fusarium chlamydoides to produce cellulase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

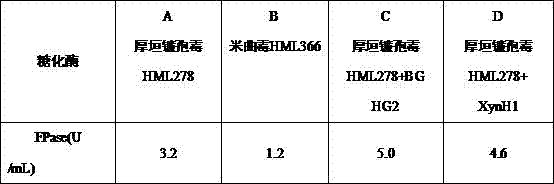

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following examples.

[0018] (1) Strain storage:

[0019] Aspergillus oryzae HML366 and Fusarium chlamydogum HML278 were stored on PDA slant at 4°C;

[0020] (2) Method for purifying β-glucosidase BG HG2 from Aspergillus oryzae HML366

[0021] Include the following steps: S1. add the Aspergillus oryzae HML366 obtained by screening to 10 mL physiological saline to make spore liquid, take 10 7 The spores were transferred to bagasse solid medium for solid-state fermentation. Bagasse solid medium: 6 g bagasse, 4 g bran, 30 mL Mandels nutrient solution, cultured at 30°C for 4 days; the culture was added with 200 mL sterile ddH 2 O, extract in a constant temperature water bath at 40°C for 1~3h, filter with four layers of gauze, centrifuge at 6000 r / min for 10min to obtain a crude enzyme solution, collect the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com