Method for preparing food-grade rosin xylose ester through catalytic esterification- separation coupling

A technology of rosin wood and food grade is applied in the field of catalytic esterification-separation coupling preparation of food grade rosin xylose ester, which can solve the problems of high production cost, pollution of rosin ester, low profit, etc., and achieves the improvement of speed and chemical equilibrium conversion rate. , to avoid pollution, to eliminate the effect of feedback inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

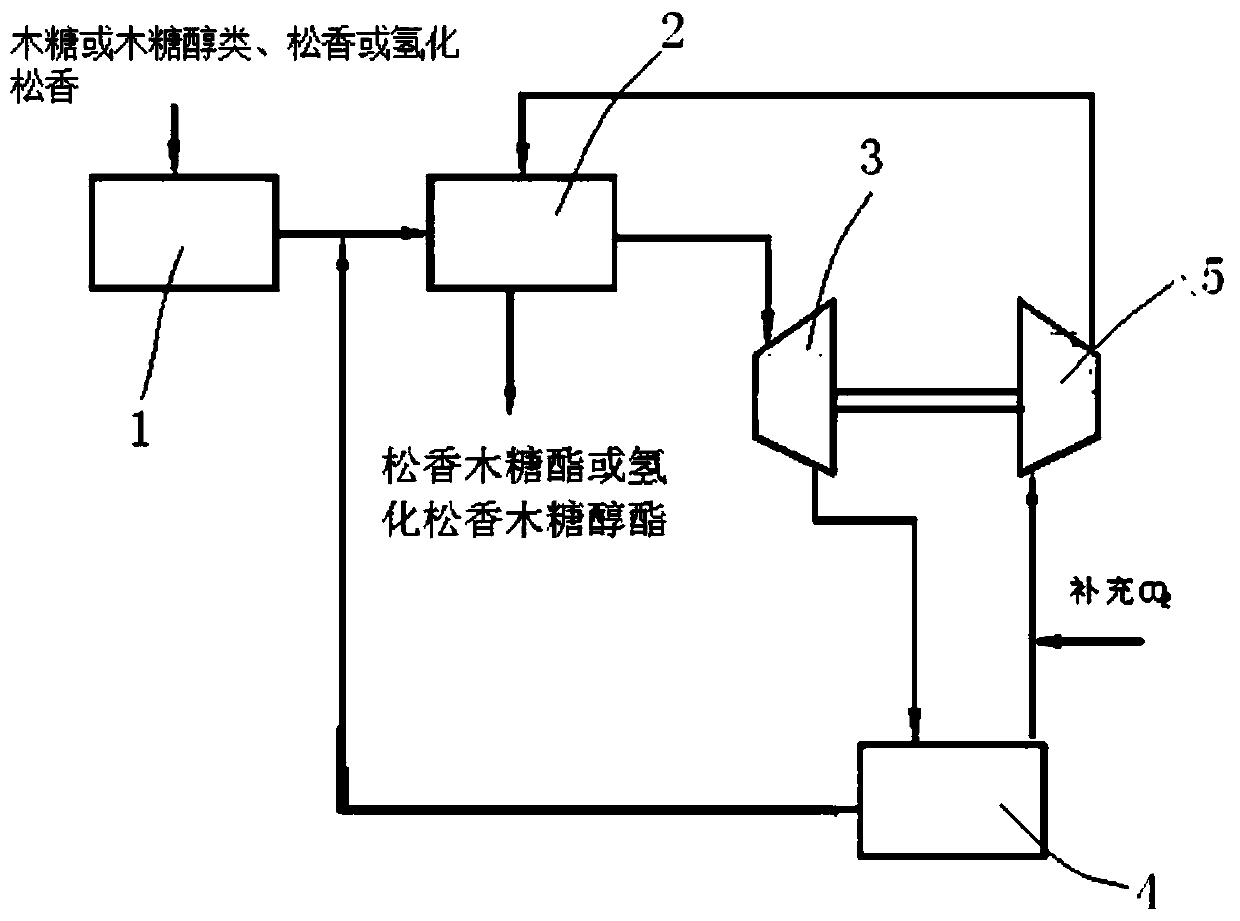

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing food-grade rosin xylose ester through catalytic esterification-separation coupling, the operation steps are as follows:

[0028] (1) Mix food-grade xylose and rosin at a molar ratio of 1:1, add to a melting kettle, then add ethanol with 50% xylose and rosin quality, heat, dissolve at 85°C, and form a mixed material;

[0029] (2) into CO 2 Press the mixed material obtained in step (1) into the esterification reactor, then raise the temperature to 125°C, and continuously feed CO 2 To the pressure in the esterification reactor is 2.0MPa;

[0030] (3) then open the esterification reactor gas outlet valve, make the water vapor, ethanol vapor, CO produced in the esterification process in step (2) 2 The mixed gas phase material flows out continuously, and the outflow volume is ≤1000m 3 / h, pressure ≤ 4.0MPa, enter the condensing cooler, after expansion and decompression ≤ 0.05MPa, cooling ≤ 50 ℃, water vapor and ethanol vapor are condensed into liquid...

Embodiment 2

[0034] A method for preparing food-grade hydrogenated rosin xylitol ester through catalytic esterification-separation coupling, the operation steps are as follows:

[0035] (1) Mix xylitol and hydrogenated rosin at a molar ratio of 2:1, add to a melting kettle, then add xylitol and turpentine with 30% mass of hydrogenated rosin, heat, dissolve at 85° C., and form a mixed material;

[0036] (2) into CO 2 Press the mixed material obtained in step (1) into the esterification reactor, then raise the temperature to 200°C, and continuously feed CO 2 To the pressure in the esterification reactor is 3.0MPa;

[0037] (3) open the esterification reactor air outlet valve then, make the water vapor, turpentine steam, CO produced in the esterification process in step (2) 2 The mixed gas phase material flows out continuously, and the outflow volume is ≤1000m 3 / h, pressure ≤ 4.0MPa, enter the condensing cooler, after expansion and depressurization ≤ 0.05MPa, cooling ≤ 50 ℃, water vapor a...

Embodiment 3

[0041] A method for preparing food-grade rosin xylose ester through catalytic esterification-separation coupling, the operation steps are as follows:

[0042] (1) Mix food-grade xylose and rosin at a molar ratio of 1:1, add to a melting kettle, then add ethanol with 20% xylose and rosin quality, heat, dissolve at 85°C, and form a mixed material;

[0043] (2) into CO 2 Press the mixed material obtained in step (1) into the esterification reactor, then raise the temperature to 325°C, and continuously feed CO 2 To the pressure in the esterification reactor is 4.0MPa;

[0044] (3) then open the esterification reactor gas outlet valve, make the water vapor, ethanol vapor, CO produced in the esterification process in step (2) 2 The mixed gas phase material flows out continuously, and the outflow volume is ≤1000m 3 / h, pressure ≤ 4.0MPa, enter the condensing cooler, after expansion and decompression ≤ 0.05MPa, cooling ≤ 50 ℃, water vapor and ethanol vapor are condensed into liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com