Paper pulp biomass-based enzyme pretreatment bleaching method

A biomass and pretreatment technology, applied in pulp bleaching and other directions, can solve the problem that the effect of xylanase is not very ideal, and achieve good bleachability, improve whiteness, and reduce wastewater pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

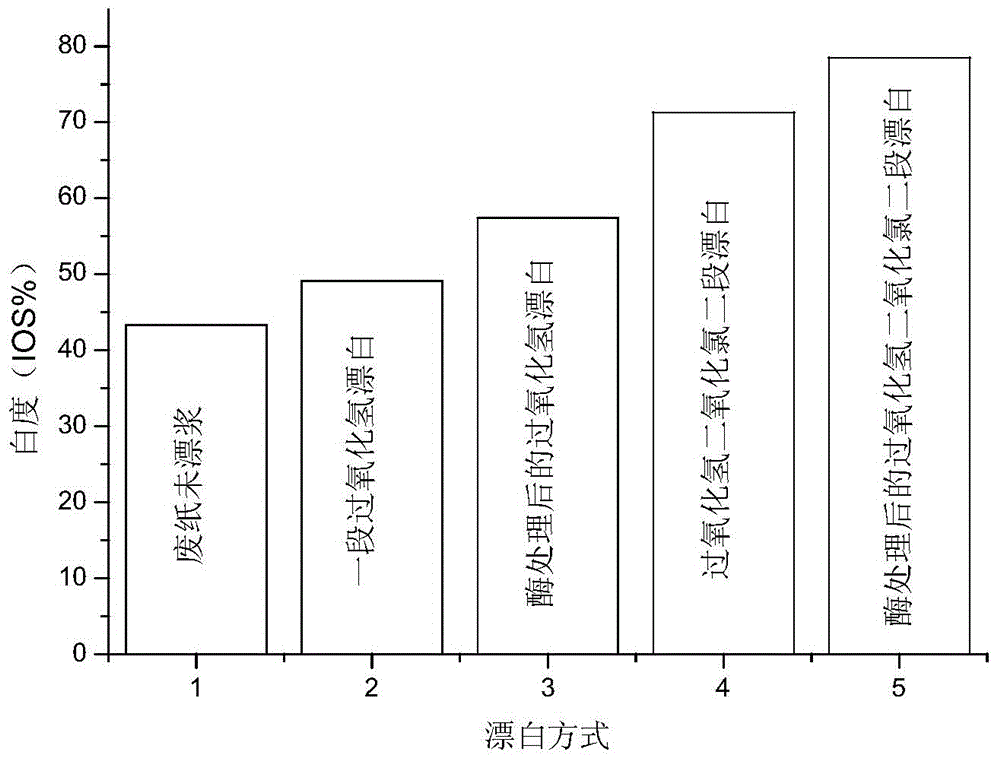

[0032] A biomass-based enzyme pretreatment bleaching method for pulp, comprising the following steps:

[0033] (1) Send unbleached waste paper pulp (43.3% whiteness) into the reaction kettle, add water to adjust to medium concentration (15wt%), stir evenly, add biomass-based enzyme solution to treat waste paper pulp (the amount of biomass-based enzyme is 200mL / t absolute dry pulp, the treatment temperature is 50°C, and the treatment time is 2h), then control the temperature until the pulp temperature reaches the required temperature of 70°C for bleaching, send the waste paper pulp treated with biomass-based enzymes into the bleaching tower, and add ClO at the same time 2 Mix evenly for reaction (ClO 2 The dosage is 10kg / t dry pulp) The reaction time is 2h, and the reaction temperature is 70-100°C to obtain a section of bleached pulp;

[0034] (2) Put the bleached pulp obtained in step (1) into a warm water extractor for a mild and weak base extraction, wherein the pH of the ...

Embodiment 2

[0045] Example 2: The specific steps are as described in Example 1, except that the amount of biomass-based enzyme used in the two-stage pretreatment process is 100mL / t, the treatment time is 1h, and the treatment temperature is 40°C. Whiteness is 72.2% ISO.

Embodiment 3

[0046] Example 3: The specific steps are as described in Example 1, except that the amount of biomass-based enzyme used in the two-stage pretreatment process is 300mL / t, the treatment time is 3h, and the treatment temperature is 60°C. The obtained bleached pulp 1-3 Whiteness is 79.7% ISO.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com