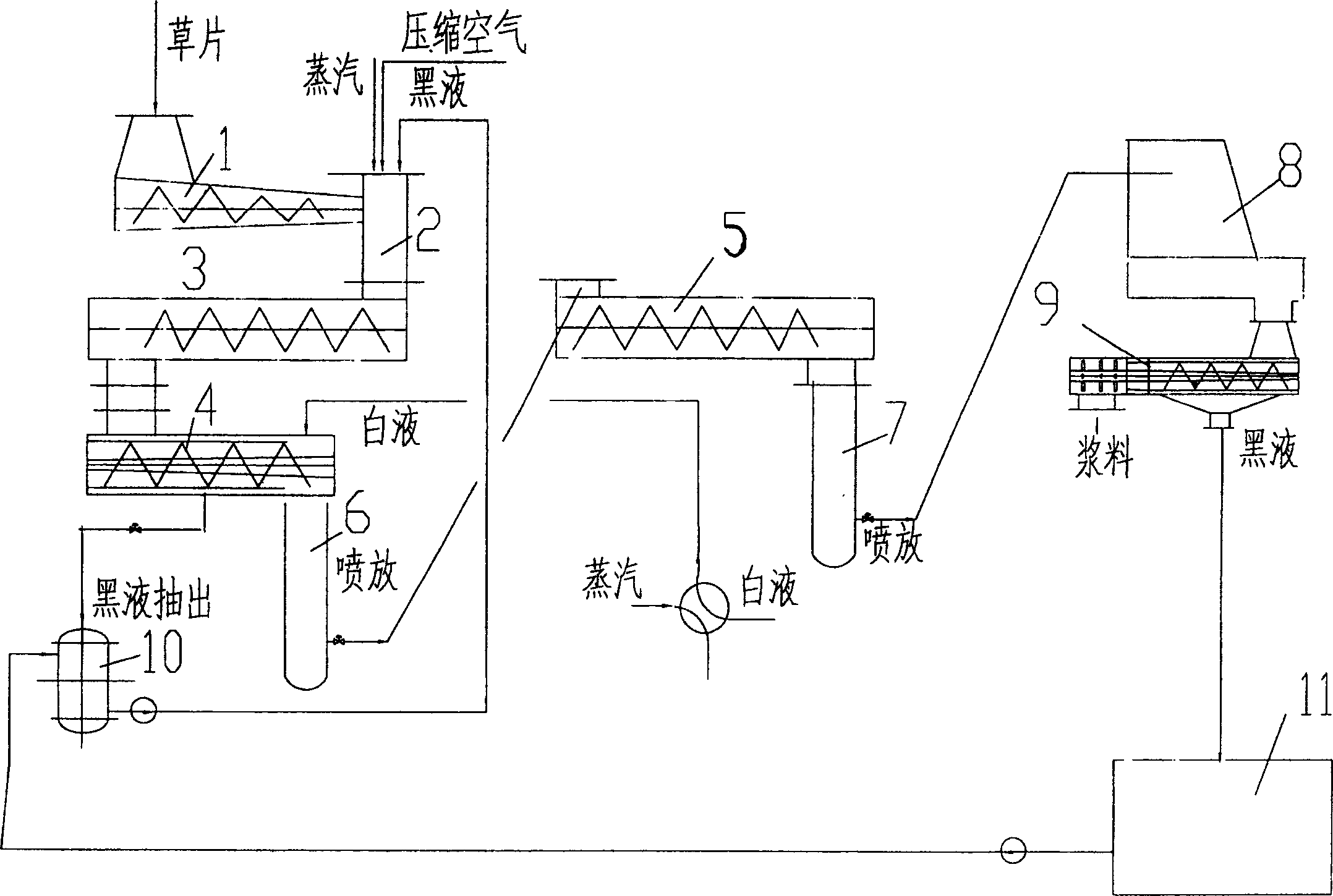

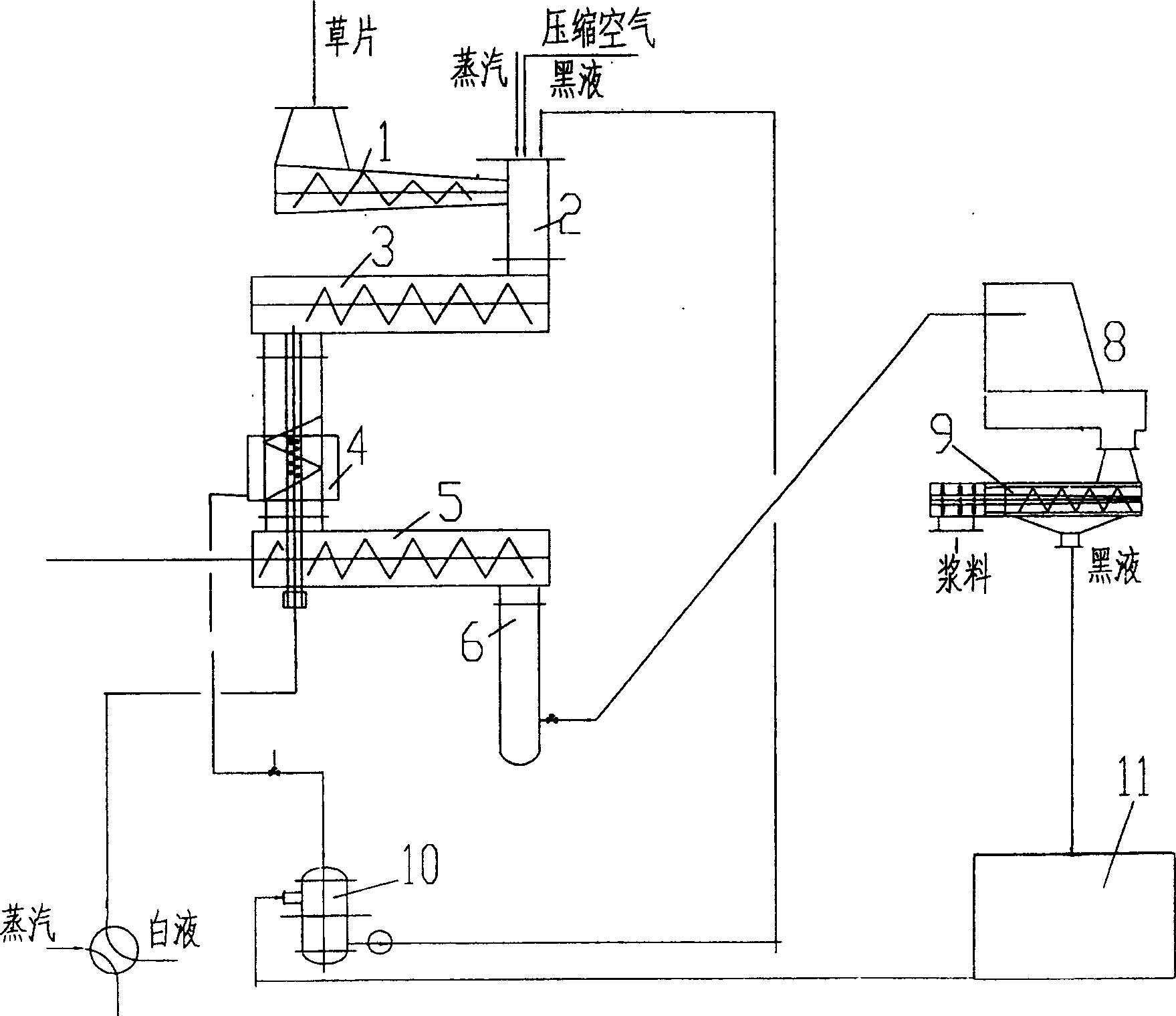

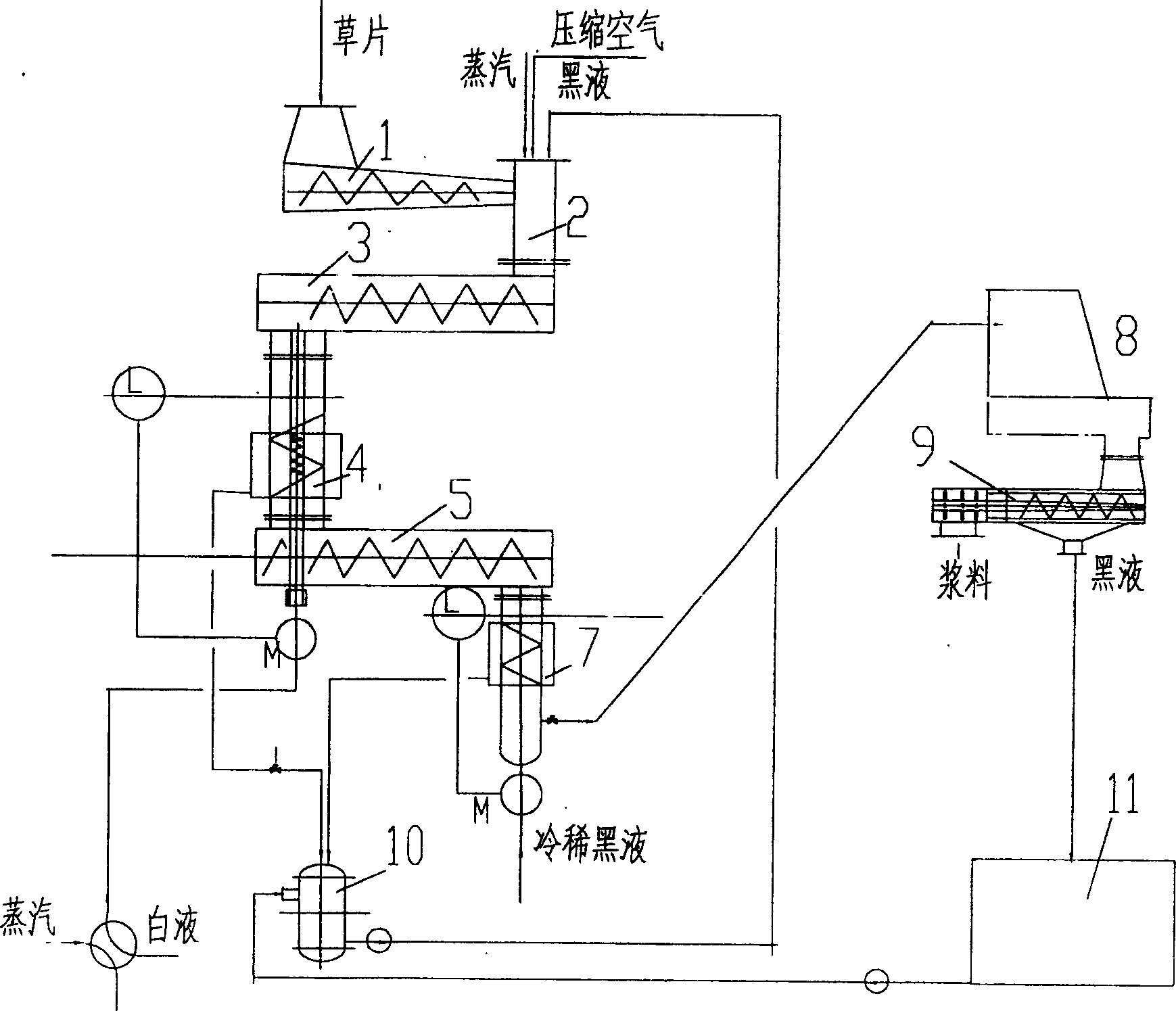

Non-wood fibre displacement, continuous boiling method and apparatus therefor

A non-wood fiber and screw device technology, which is applied in continuous pulping process, non-woody plant/crop pulp, etc., can solve the problems of inability to carry out large-scale continuous production, high labor intensity, large equipment volume, etc., and achieve improvement Hardness and bleachability, quality improvement, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] From the process of delignification of non-wood fiber alkaline pulping, its delignification speed is faster than that of wood chips, 60%-70% of lignin can be dissolved before the temperature rises to 100°C, and 90% of lignin is heated to 160°C previously dissolved. During the cooking process, the alkali is mainly consumed in the reaction with the acidic components in the raw materials and the subsequent reaction of the leachate in the early stage. The alkali consumption of these two parts accounts for 52.8% and 31% of the actual alkali consumption respectively, and the alkali consumption in the later cooking only accounts for the total. 16.2% of alkali consumption. Among the alkali consumption consumed in the subsequent reaction of the eluate in the early stage, 72% was consumed in the subsequent degradation of carbohydrates, and 28% was consumed in the subsequent degradation of lignin. According to the dissolution of lignin and the law of alkali consumption in the non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com