Pulping continuous cooking method and device

A cooking device and pulping technology, which is applied in the direction of digesters, textiles, papermaking, papermaking, etc., can solve the problems of inability to carry out large-scale continuous production, short circuit of cooking liquid, difficult replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

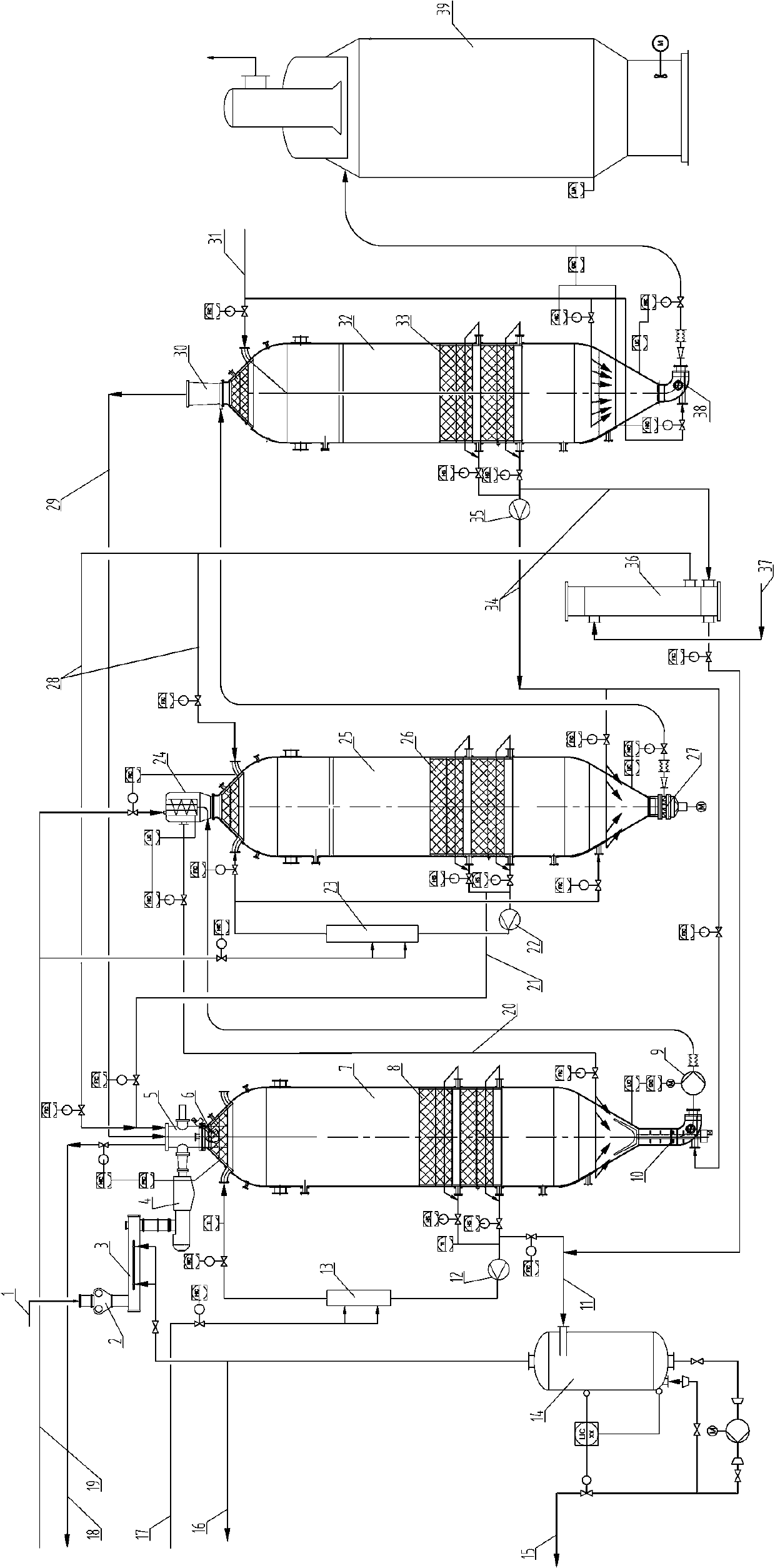

[0053] Depend on Figure 1 ~ Figure 3 It can be seen that a continuous cooking method for pulping comprises the following steps:

[0054] (1) Extrusion: The fiber raw material 1 prepared by dry method or wet method is continuously added to the feeder 4 through the meter 2 and the preheating screw feeder 3 for extrusion treatment, so that its volume can be reduced or extruded Part of the moisture content of the fiber raw material 1;

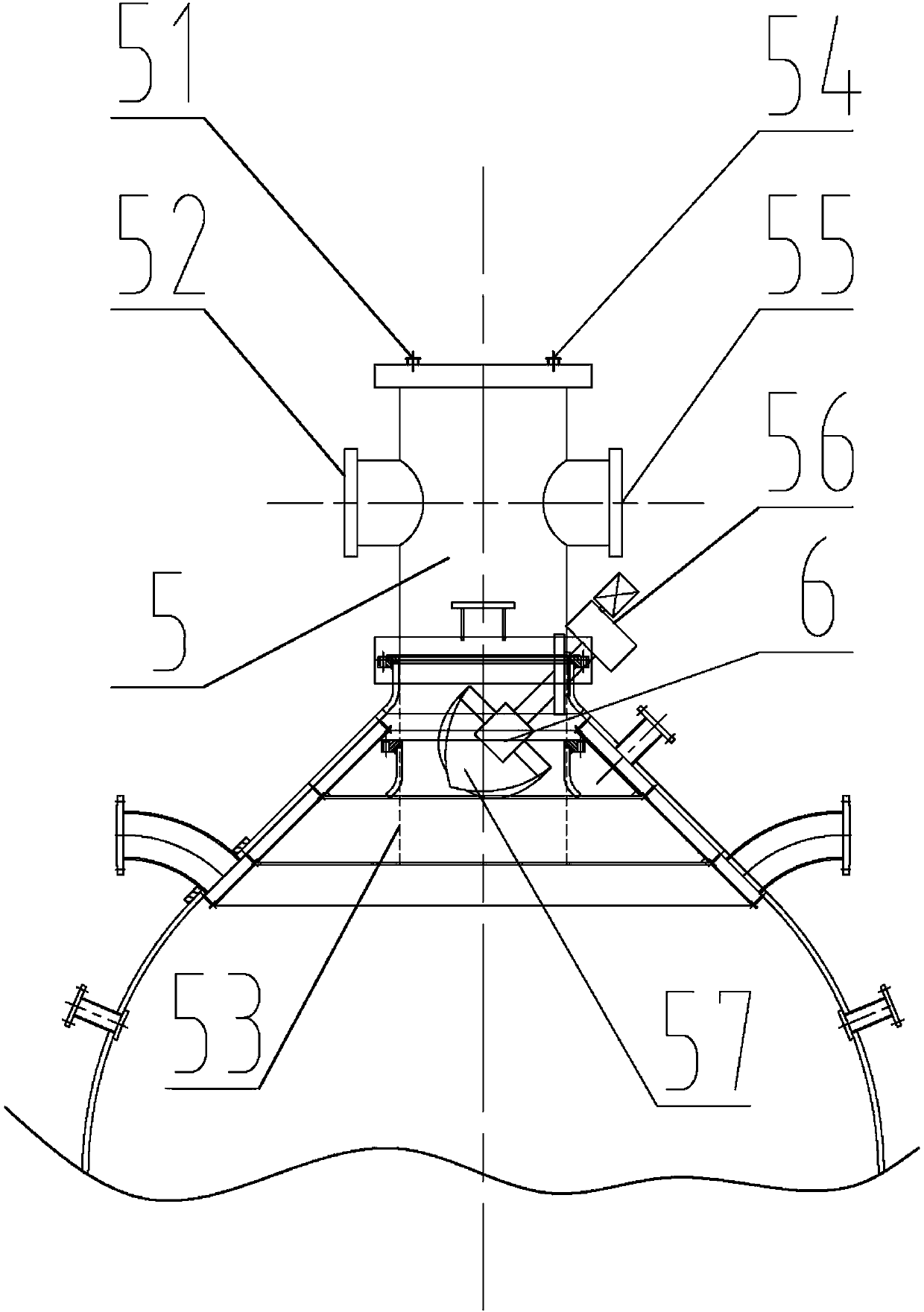

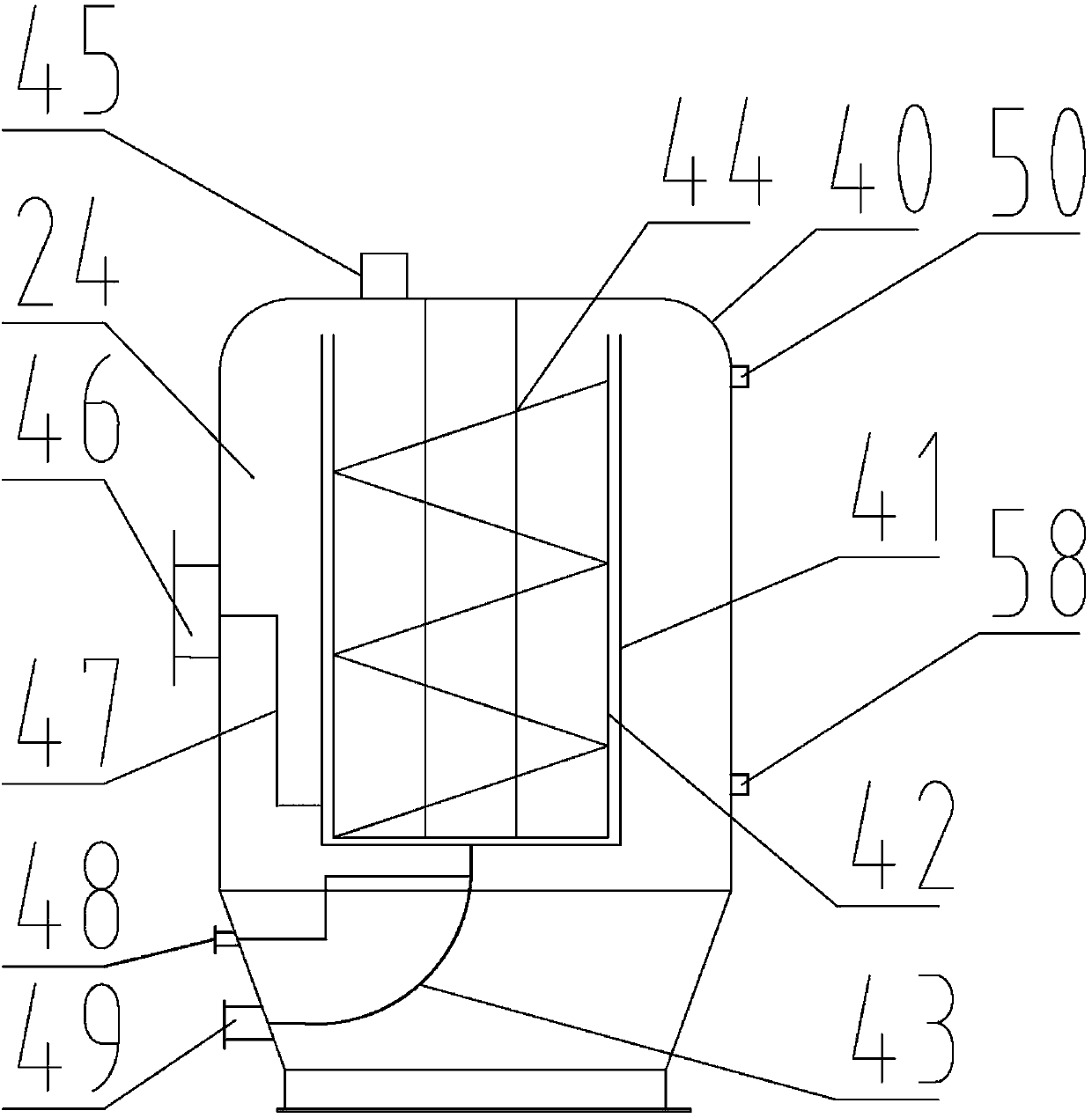

[0055] (2) Prepreg cooking: Push the extruded fiber raw material 1 to the T-shaped tube 5 at the feed inlet of the pretreatment pot 7, and at the same time add the (high temperature) gas discharged from the cooking pot 25 in the subsequent step to the top of the T-shaped tube 5 . Reflux the black liquor 21, part of the cooking liquid 28 that has been heated up after the heat exchange has been completed and flow out from the heat exchanger 36, to improve the yield and viscosity of the slurry in the pretreatment pot 7, and introduce it into the sub...

Embodiment 2

[0092] In the step (2) described in the present embodiment, the cooking liquid 28 added from the top of the T-shaped pipe 5 of the pretreatment pot 7 is 120° C. The pressure of the steam 29 is 0.3 MPa; the pre-cooking treatment is to cook the fiber raw material 1 at a temperature of 120° C. for 50 minutes.

[0093] In the step (4) described in this embodiment, the cooking liquid 28 added into the cooking pot 25 is 165°C; during the second stage of cooking in the cooking pot 25, the cooking temperature is 155°C, and the cooking pressure is 155°C. is 0.6MPa, and the cooking time is 45 minutes.

[0094] The rest are the same as embodiment 1.

Embodiment 3

[0096] In the step (2) described in this embodiment, the cooking liquid 28 added from the top of the T-shaped pipe 5 of the pretreatment pot 7 is 125° C., and the flash vapor produced in the flash separator 30 of the replacement washing pot 32 The pressure of the steam 29 is 0.35 MPa; the pre-cooking treatment is to cook the fiber raw material 1 at a temperature of 125° C. for 30 minutes.

[0097] In the step (4) described in this embodiment, the cooking liquid 28 added into the cooking pot 25 is 160°C; during the second stage of cooking in the cooking pot 25, the cooking temperature is 160°C, and the cooking pressure is 160°C. is 0.65MPa, and the cooking time is 35 minutes.

[0098] The rest are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com