Oxygen-based high-efficiency clean bleaching pulp preparation method and device thereof

A pulp and high-efficiency technology, used in pulp bleaching, cellulose pulp post-processing, papermaking, etc., can solve problems such as non-bleaching, and achieve uniform bleaching effect, obvious mass transfer efficiency, and efficient mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

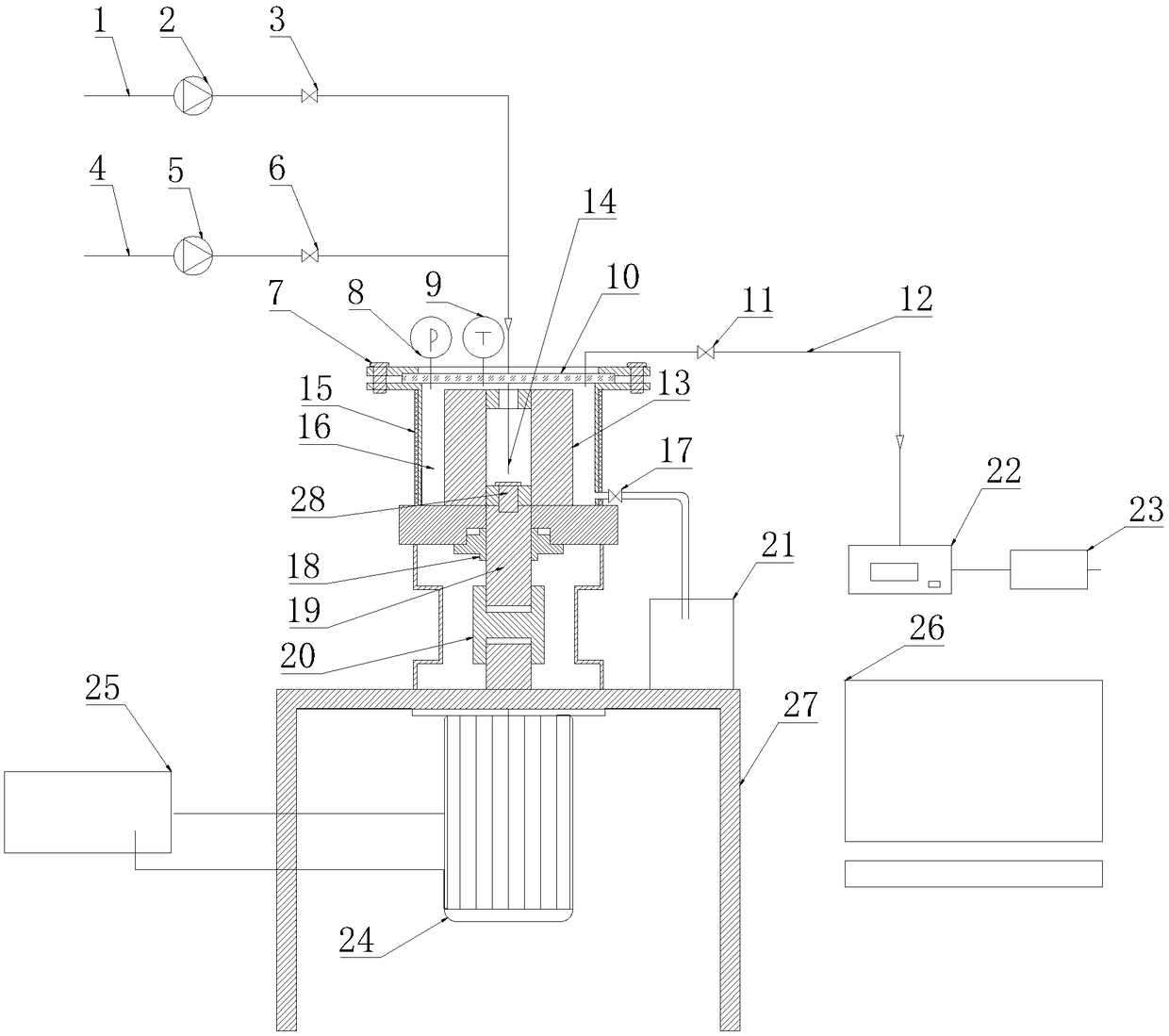

Method used

Image

Examples

Embodiment 1

[0081] Oxygen delignified pulp preparation:

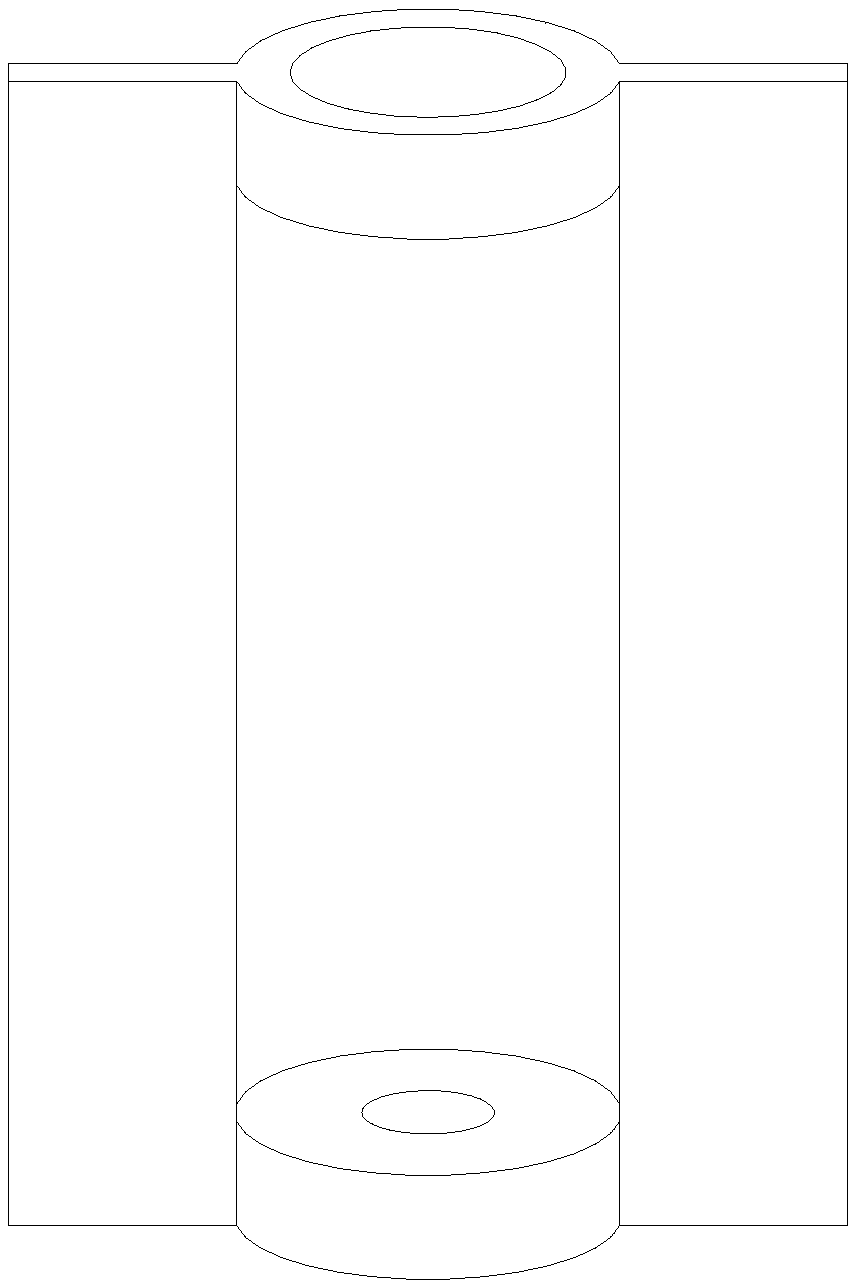

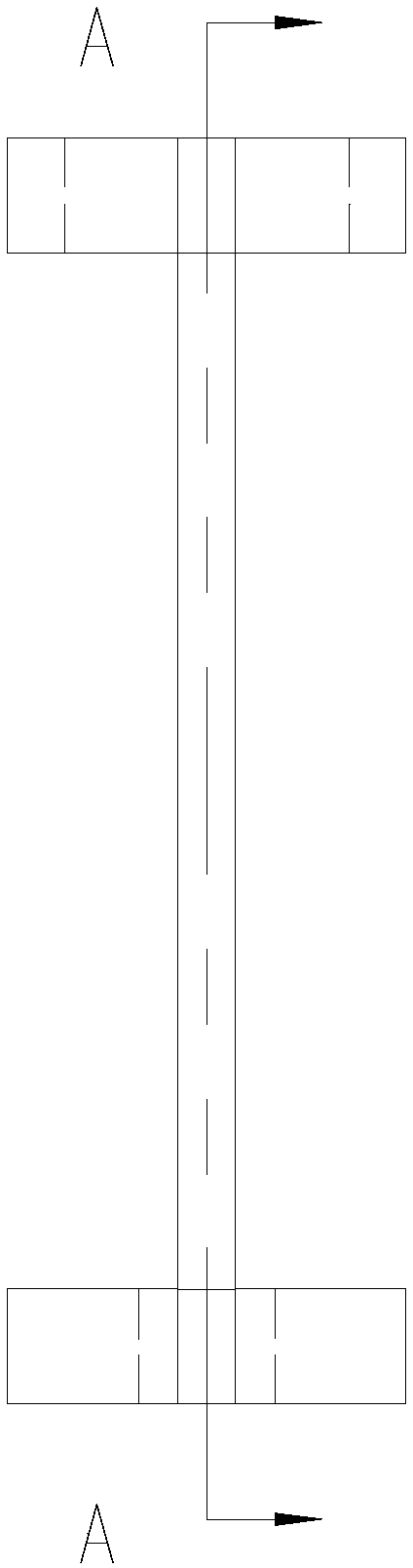

[0082] (1) Pot loading: remove the cover body 10, select and install the corresponding hollow mixing rotor 13 according to the pulp consistency characteristics of the pulp to be bleached; choose the hollow mixing rotor 13 with linear blades for low consistency and medium consistency bleaching, and choose the hollow mixing rotor 13 for high consistency bleaching Hollow mixing rotor 13 with helical blades; add an appropriate amount of dry slurry, install cover 10, insert aeration tube 14 into the center of hollow mixing rotor 13, and use end cover bolts 7 to tighten cover 10 and mixing reaction chamber 16 solid seal.

[0083] (2) Adjust the slurry concentration: turn on the liquid medicine pump 2, pump a corresponding volume of dilution water through the liquid inlet pipe 1 and the aeration pipe 14, turn on the frequency converter 25, and use a medium and low speed of 800-1500r / min to mix and adjust the concentration , adjust the pu...

Embodiment 2

[0102] Oxygen delignified pulp preparation:

[0103] (1) Pot loading: remove the cover body 10, select and install the corresponding mixing rotor 13 according to the pulp consistency characteristics of the pulp to be bleached, choose a linear hollow rotor for low-consistency and medium-consistency bleaching, and select a spiral hollow rotor for high-consistency bleaching; Add an appropriate amount of dry slurry, install the cover body 10, insert the aeration tube 14 into the center of the rotor 13, and use the end cover bolts 7 to fasten and seal the cover body 10 and the mixing reaction chamber 16.

[0104] (2) Adjust slurry concentration: turn on liquid medicine pump 2, pump a corresponding volume of dilution water through liquid inlet pipe 1 and aeration pipe 14, turn on frequency converter 25, use a medium speed of 1500r / min, mix and adjust the concentration, and adjust the mixing The slurry to be bleached in the reaction chamber 16 is 14% in medium concentration or 30% in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com