Pretreatment process for cleaning and bleaching chemical mechanical pulp

A chemical mechanical and pretreatment technology, applied in the direction of chemical/chemical mechanical pulp, pulp bleaching, etc., can solve the problems of high cost, poor fiber affinity, and limited use range, so as to reduce the dosage, improve the biochemical property, and solve the problem of easy return yellow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

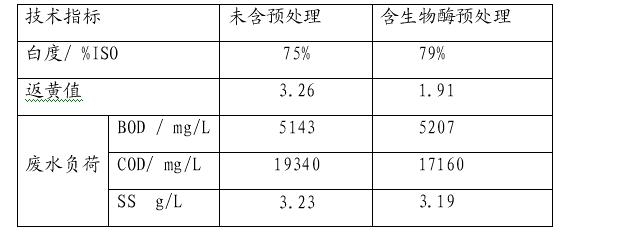

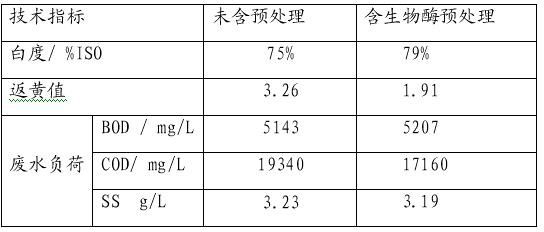

Examples

Embodiment 1

[0022] (1) A certain amount of solid enzyme preparations: laccase, hemicellulase, and cellulase are used in a certain proportion, and the enzyme activity is 10:20:1, of which the enzyme activity of laccase is 30000IU per ton of pulp, wood poly Carbohydrate enzyme activity is 60000U, cellulase activity is 3000U, add to the material tank;

[0023] (2) Then add clean water to the material tank, the pH value is 6, and add the mediator HBT 2-(2'-hydroxyphenyl)benzotriazole, the dosage is 5‰ of the ton slurry, and non-ionic surfactant TX-10 octylphenol polyoxyethylene ether, the dosage is 2.5‰ per ton of pulp, stir evenly in the material tank, the rotation speed during stirring is 65r / min, and the enzyme solution with a concentration of 20% is prepared;

[0024] (3) After stirring for 3 minutes, input the enzyme liquid into the finished product tank, and store at 50°C;

[0025] (4) Add 2% dilute sulfuric acid, adjust the pH value of the slurry in the upflow tower to 4.0, the temper...

Embodiment 2

[0029] (1) A certain amount of solid enzyme preparations: laccase, hemicellulase, and cellulase are used in a certain ratio, and the enzyme activity is 10:20:2, of which the enzyme activity of laccase is 30000IU per ton of pulp, wood poly Carbohydrate enzyme activity is 60000U, cellulase activity is 6000U, add to the material tank;

[0030] (2) Then add clean water to the material tank, the pH value is 7, and add the mediator HBT 2-(2'-hydroxyphenyl) benzotriazole, the dosage is 4‰ per ton of pulp, and non-ionic surfactant TX-10 octylphenol polyoxyethylene ether, the dosage is according to 3‰ per ton of pulp, stir evenly in the material tank, the rotating speed is 85r / min during stirring, and the enzyme solution with a concentration of 10% is prepared;

[0031] (3) After stirring for 3 minutes, input the enzyme solution into the finished product tank, and store at 45°C;

[0032] (4) Add dilute sulfuric acid to adjust the pH value of the slurry in the upflow tower to 5.0, the ...

Embodiment 3

[0036] (1) A certain amount of solid enzyme preparations: laccase, hemicellulase, and cellulase are used in a certain proportion, and the enzyme activity is 10:20:1, of which the enzyme activity of laccase is 30000IU per ton of pulp, wood poly Carbohydrate enzyme activity is 60000U, cellulase activity is 3000U, add to the material tank;

[0037] (2) Then add clear water to the material tank, the pH value is 6.5, and add the mediator HBT 2-(2'-hydroxyphenyl) benzotriazole, the dosage is 6‰ per ton slurry, and non-ionic surfactant TX-10 (octylphenol polyoxyethylene ether), consumption is according to 2 ‰ of ton slurry, stirs evenly in feed tank, and rotating speed is 90r / min during stirring, and the enzyme liquid that makes concentration is 25%;

[0038] (3) After stirring for 3 minutes, input the enzyme solution into the finished product tank, and store at 35°C;

[0039] (4) Add 2% dilute sulfuric acid to adjust the pH value of the slurry in the upflow tower to 4.5, the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com