Material preparation process suitable for utilizing unbleached wood pulp to prepare dissolving pulp in modified mode

A technology of dissolving pulp and natural color, which is applied in post-treatment modification of cellulose pulp, pretreatment with alkaline compounds, fine split raw material pretreatment, etc. It can solve the problems of high cost, low quality of semi-finished and final finished dissolving pulp, etc. , to achieve the effect of low cost, easy control of ash content and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

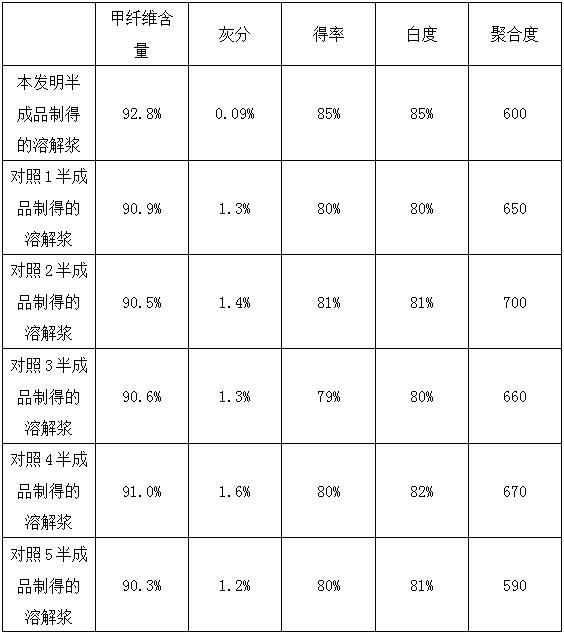

Examples

Embodiment 1

[0057] A material preparation process suitable for preparing dissolving pulp by modifying natural color unbleached wood pulp, comprising the following process steps:

[0058] A. Raw material preparation

[0059] According to the ratio of the weight of natural unbleached wood pulp to the volume of the digester: 100kg: 1m 3 Prepare raw materials, select natural color unbleached wood pulp;

[0060] B. Dispersion and pulping

[0061] Disperse unbleached unbleached wood pulp into pulp boards, then mix unbleached unbleached wood pulp with water and perform pulping treatment to obtain a mixture of unbleached unbleached wood pulp and water, which is pulp porridge, and then press and deliquify in the next step Processing, the concentration of the gruel obtained through the crushing treatment is 3%;

[0062] C. Squeeze and remove liquid

[0063] Squeeze and deliquify the dispersed and crushed porridge until the dryness of the porridge is 20%;

[0064] D. Dipping

[0065] Mix the d...

Embodiment 2

[0068] A material preparation process suitable for preparing dissolving pulp by modifying natural color unbleached wood pulp, comprising the following process steps:

[0069] A. Raw material preparation

[0070] According to the ratio of natural unbleached wood pulp weight to digester volume: 250kg: 1m 3 Prepare raw materials, select natural color unbleached wood pulp;

[0071] B. Dispersion and pulping

[0072] Disperse unbleached unbleached wood pulp into pulp boards, then mix unbleached unbleached wood pulp with water and perform pulping treatment to obtain a mixture of unbleached unbleached wood pulp and water, which is pulp porridge, and then press and deliquify in the next step Processing, the concentration of the gruel obtained through the crushing treatment is 5%;

[0073] C. Squeeze and remove liquid

[0074] The pulp porridge that has been dispersed and crushed is subjected to dehydration by pressing until the dryness of the porridge is 35%;

[0075] D. Dipping ...

Embodiment 3

[0079] A material preparation process suitable for preparing dissolving pulp by modifying natural color unbleached wood pulp, comprising the following process steps:

[0080] A. Raw material preparation

[0081] According to the ratio of the weight of natural unbleached wood pulp to the volume of the digester is 175kg: 1m 3 Prepare raw materials, select natural color unbleached wood pulp;

[0082] B. Dispersion and pulping

[0083] Disperse unbleached unbleached wood pulp into pulp boards, then mix unbleached unbleached wood pulp with water and perform pulping treatment to obtain a mixture of unbleached unbleached wood pulp and water, which is pulp porridge, and then press and deliquify in the next step Processing, the concentration of the gruel obtained through the crushing treatment is 4%;

[0084] C. Squeeze and remove liquid

[0085] The pulp porridge that has been dispersed and crushed is subjected to dehydration by pressing until the dryness of the porridge is 27.5%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com