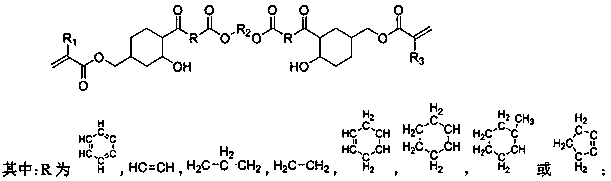

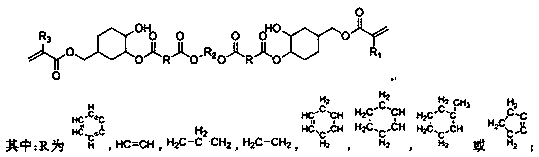

A kind of epoxy acrylic resin of two functionalities and its preparation method and application

A technology of epoxy acrylic acid and epoxy acrylate, which is applied in the application, household appliances, polyether adhesive and other directions, can solve the problems of poor light resistance and yellowing resistance, limited application scope, monotonous performance, etc., and achieves light resistance. The effect of good aging and yellowing resistance, fast curing speed and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In parts by weight, add 45 parts of polyethylene glycol, 15 parts of maleic anhydride, and 0.1 part of organotin catalyst into the reaction vessel, heat to 100°C, stir and react for 5 hours, and measure the acid value until before heating When the total acid value is 1 / 2±3%, cool down to room temperature, put 19 parts of 3,4-epoxycyclohexyl methyl methacrylate, 0.1 part of hydroquinone, and 0.1 part of triphenylphosphine into the reaction vessel , heated to 110°C until the measured acid value is less than 5mgKOH / g, the transparent colorless or light yellow liquid resin that is cooled and discharged is difunctional epoxy acrylic resin A.

[0035] The viscosity, curing speed and weather resistance of the prepared difunctional epoxy acrylic resin are shown in Table 1.

Embodiment 2

[0037] In parts by weight, add 40 parts of polycaprolactone diol, 20 parts of succinic anhydride, and 0.2 parts of an organic bismuth catalyst into the reaction vessel, heat to 90°C, stir and react for 6 hours, and measure the acid value until before heating When the total acid value is 1 / 2±3%, cool down to room temperature, put 20 parts of 3,4-epoxycyclohexyl methacrylate, 0.2 parts of hydroquinone, and 0.2 parts of triphenylphosphine into the reaction vessel, Heating to 120°C until the measured acid value is less than 5mgKOH / g, the transparent colorless or light yellow liquid resin discharged after cooling down is difunctional epoxy acrylic resin B.

[0038] The viscosity, curing speed and weather resistance of the prepared difunctional epoxy acrylic resin are shown in Table 1.

Embodiment 3

[0040] In parts by weight, add 50 parts of hydroxyl-terminated polybutadiene, 10 parts of glutaric anhydride, and 0.1 part of organotin catalyst into the reaction vessel, heat to 110°C, stir for 4 hours, and measure the acid value until before heating When the total acid value is 1 / 2±3%, cool down to room temperature, put 10 parts of 3,4-epoxycyclohexyl methacrylate, 0.1 part of hydroquinone, and 0.1 part of tetrabutylammonium bromide into the reaction vessel , heated to 100°C until the measured acid value is less than 5mgKOH / g, the transparent colorless or light yellow liquid resin discharged after cooling down is difunctional epoxy acrylic resin C.

[0041] The viscosity, curing speed and weather resistance of the prepared difunctional epoxy acrylic resin are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com