Material preparation process for preparing dissolving pulp by modifying bleached bamboo-wood composite pulp

A technology of bamboo pulp and dissolving pulp, which is applied in post-treatment modification of cellulose pulp, separation of raw materials, pretreatment with alkaline compounds, etc., can solve problems such as discomfort, high cost, and low quality of dissolving pulp, and achieve cost reduction, The effect of low cost and easy material preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

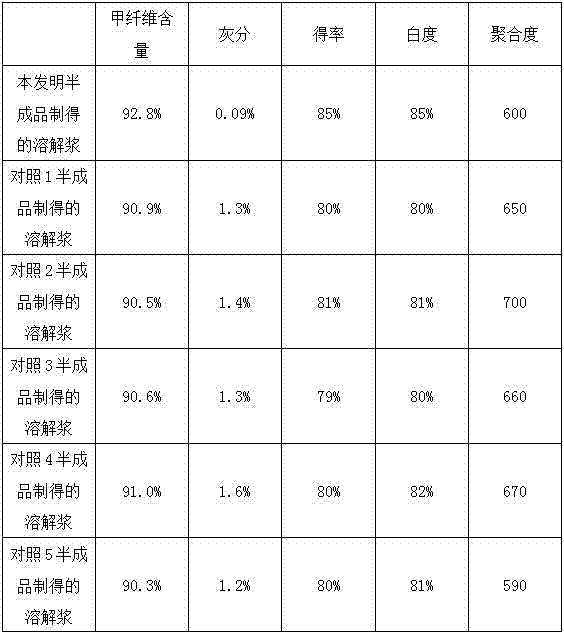

Examples

Embodiment 1

[0053] A material preparation process for preparing dissolving pulp by modifying bleached bamboo-wood composite pulp, comprising the following process steps:

[0054] A. Raw material preparation

[0055] According to the ratio of the total weight of bleached bamboo pulp and bleached wood pulp to the volume of the digester: 100kg: 1m 3 Prepare raw materials, select bleached bamboo pulp and bleached wood pulp;

[0056] B. Scatter and slice

[0057] Dispersing bleached bamboo pulp and bleached wood pulp into pulp boards and cutting bleached bamboo pulp boards and bleached wood pulp boards into small pieces;

[0058] C. Dipping

[0059] The dispersed and sliced bleached bamboo pulp and bleached wood pulp are mixed with sodium hydroxide solution to obtain a mixture of bleached bamboo pulp, bleached wood pulp and sodium hydroxide solution, that is, pulp porridge, and the control liquid ratio is 1:3. The solid weight of sodium hydroxide in the sodium hydroxide solution is 17% o...

Embodiment 2

[0062] A material preparation process for preparing dissolving pulp by modifying bleached bamboo-wood composite pulp, comprising the following process steps:

[0063] A. Raw material preparation

[0064] According to the ratio of the total weight of bleached bamboo pulp and bleached wood pulp to the volume of the digester is 250kg: 1m 3 Prepare raw materials, select bleached bamboo pulp and bleached wood pulp;

[0065] B. Scatter and slice

[0066] Dispersing bleached bamboo pulp and bleached wood pulp into pulp boards and cutting bleached bamboo pulp boards and bleached wood pulp boards into small pieces;

[0067] C. Dipping

[0068] The bleached bamboo pulp and bleached wood pulp dispersed and sliced are mixed with sodium hydroxide solution to obtain a mixture of bleached bamboo pulp, bleached wood pulp and sodium hydroxide solution, namely pulp porridge. The control liquid ratio is 1:4, The solid weight of sodium hydroxide in the sodium hydroxide solution is 22% of th...

Embodiment 3

[0071] A material preparation process for preparing dissolving pulp by modifying bleached bamboo-wood composite pulp, comprising the following process steps:

[0072] A. Raw material preparation

[0073] According to the ratio of the total weight of bleached bamboo pulp and bleached wood pulp to the volume of the digester is 175kg: 1m 3 Prepare raw materials, select bleached bamboo pulp and bleached wood pulp;

[0074] B. Scatter and slice

[0075] Dispersing bleached bamboo pulp and bleached wood pulp into pulp boards and cutting bleached bamboo pulp boards and bleached wood pulp boards into small pieces;

[0076] C. Dipping

[0077] Mix bleached bamboo pulp and bleached wood pulp with sodium hydroxide solution after dispersing and slicing to obtain a mixture of bleached bamboo pulp, bleached wood pulp and sodium hydroxide solution, that is, pulp porridge. The control liquid ratio is 1:3.5, The solid weight of sodium hydroxide in the sodium hydroxide solution is 19.5% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com