Fiberglass pultrusion grille continuous production line

A glass fiber and production line technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of working environment impact, work efficiency reduction, fiber arrangement disorder, etc., and achieve uniform propulsion force distribution, high precision of propulsion direction, Ensure the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

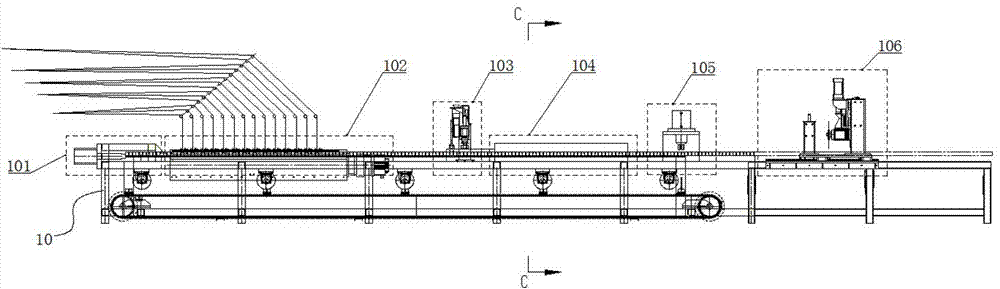

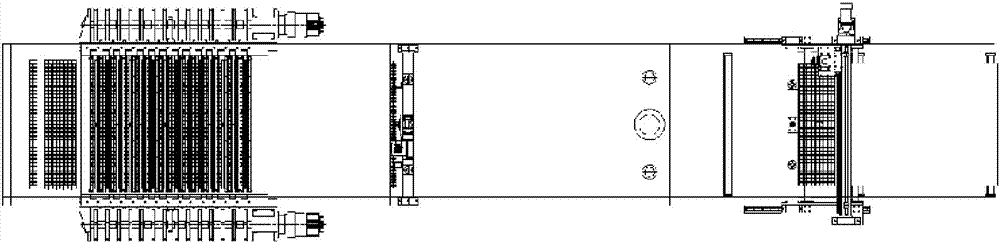

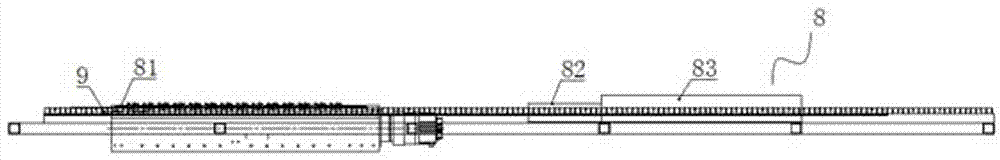

[0053] Such as figure 1 , 2 As shown, it includes frame, core mold pushing mechanism 1, automatic laying mechanism 2, resin mixture injection mechanism 3, heating and curing mechanism 4, core mold demoulding mechanism 5, grid cutting mechanism 7 and fixed mold 8 and several moving parts. The grid mold that mandrel 9 forms. The details are as follows:

[0054] Frame 10, the upper layer of the frame 10 is divided into a mandrel pushing station 101, an automatic yarn laying station 102, an injection station 103, a curing station 104, and a demoulding and ejecting station from front to back along its horizontal extension direction. position 105 and grid cutting station 106, the upper layer of the frame 10 has a mandrel movement guide channel that runs through the automatic yarn laying station, injection station, curing station, demoulding and ejection station in sequence, and the mandrel movement guide The channel may be formed by a pair of rails 109 arranged in parallel.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com