Modified acrylate polyurethane water-based paint for woodware and preparation method thereof

An acrylic polyurethane and acrylate technology, which is used in polyurea/polyurethane coatings, biocide-containing paints, antifouling/underwater coatings, etc., to accelerate grafting and crosslinking, reduce discoloration, and enhance the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

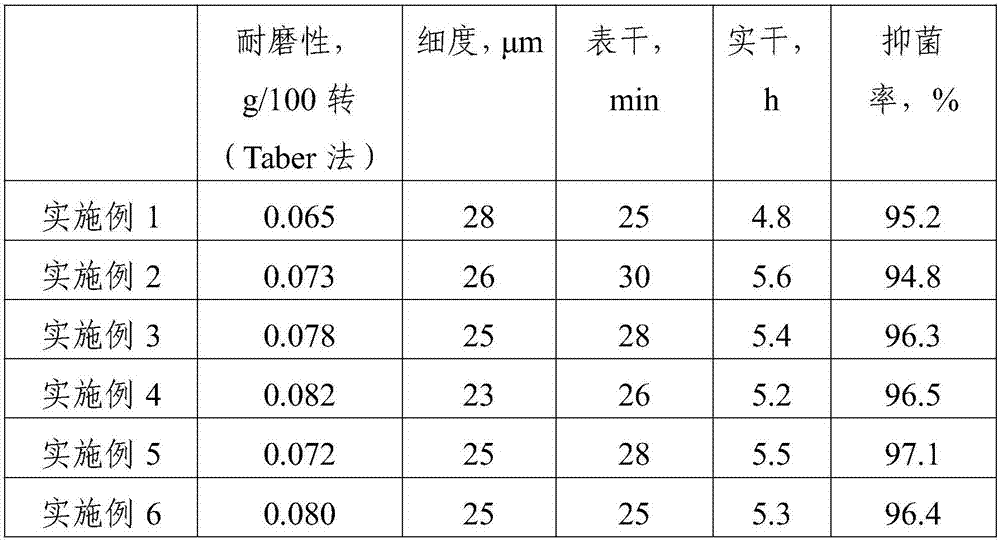

Examples

Embodiment 1

[0027] A modified acrylic polyurethane water-based paint for wood, comprising the following components in parts by weight: 45 parts of acrylate emulsion, 40 parts of polyurethane emulsion, 2 parts of polyethyleneimine, 2 parts of polyvinyl butyral, 4.5 parts of coupling agent , 0.5 parts of brucite fiber, 7 parts of additives, 12 parts of deionized water, 25 parts of epoxy resin emulsion, 4 parts of silica sol, and 2 parts of nano-zinc oxide.

[0028] Among them, the coupling agent is a composition of γ-aminopropyl triethoxysilane and 3-glycidyl etheroxypropyl triethoxysilane with a mass ratio of 2:1; the auxiliary agents include emulsifiers, anti-mold and bactericidal agent, co-solvent, defoamer, film-forming aid, each component accounts for the mass percentage of the aid, and the content is 20% of emulsifier, 2% of anti-mold and fungicide, 8% of defoamer, 4% of film-forming aid, Co-solvent balance; co-solvent is the composition of polyethylene glycol 1000, acetone.

[0029]...

Embodiment 2

[0035] A modified acrylic polyurethane water-based paint for wood, comprising the following components in parts by weight: 50 parts of acrylate emulsion, 42 parts of polyurethane emulsion, 4 parts of polyethyleneimine, 2 parts of polyvinyl butyral, and 6.5 parts of coupling agent , 2.5 parts of brucite fiber, 6 parts of additives, 10 parts of deionized water, 30 parts of epoxy resin emulsion, 6 parts of silica sol, and 2 parts of nano-zinc oxide.

[0036] Among them, the coupling agent is a composition of γ-aminopropyl triethoxysilane and 3-glycidyl etheroxypropyl triethoxysilane with a mass ratio of 2:1; the auxiliary agents include emulsifiers, anti-mold and bactericidal agent, co-solvent, defoamer, film-forming aid, each component accounts for the mass percentage of the aid, and the content is 22% of emulsifier, 3% of anti-mold and fungicide, 5% of defoamer, 3% of film-forming aid, The balance of co-solvent; co-solvent is polyethylene glycol 1000, acetone, methyl tert-butyl...

Embodiment 3

[0039] A modified acrylic polyurethane water-based paint for wood, comprising the following components in parts by weight: 60 parts of acrylate emulsion, 50 parts of polyurethane emulsion, 5 parts of polyethyleneimine, 1.5 parts of polyvinyl butyral, and 7 parts of coupling agent , 3 parts of brucite fiber, 6 parts of additives, 15 parts of deionized water, 15 parts of epoxy resin emulsion, 8 parts of silica sol, and 1 part of nano zinc oxide.

[0040]Among them, the coupling agent is a composition of γ-aminopropyl triethoxysilane and 3-glycidyl etheroxypropyl triethoxysilane with a mass ratio of 2:1; the auxiliary agents include emulsifiers, anti-mold and bactericidal agent, co-solvent, defoamer, film-forming aid, each component accounts for the mass percentage of the additive, and the content is 30% of emulsifier, 6% of anti-mold and fungicide, 10% of defoamer, 5% of film-forming aid, Co-solvent balance; co-solvent is polyethylene glycol 1200.

[0041] The preparation metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com