Patents

Literature

49 results about "Titanium yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium yellow, also nickel antimony titanium yellow, nickel antimony titanium yellow rutile, CI Pigment Yellow 53, or C.I. 77788, is a yellow pigment with the chemical composition of NiO·Sb₂O₃·20TiO₂. Its CAS number is 8007-18-9. It is a complex inorganic compound. Its melting point lies above 1000 °C, and has extremely low solubility in water.

Colorized reflection heat insulation coating and color card thereof

ActiveCN102181217AModulation shortcutHigh Solar ReflectanceReflecting/signal paintsMulticolor effect coatingsHigh reflectivityMaterials science

The invention discloses a colorized reflection heat insulation coating. Carbon black, iron oxide red, organic yellow, phthalocyanine green, phthalocyanine blue, and other conventional common pigments are replaced by the pigments, namely nickel iron chromite black, nickel iron chromite red, cobalt blue, titanium yellow and cobalt green, so that the colorized reflection heat insulation coating can meet the demand of the external wall decoration on colors and has high reflectivity to solar energy and a good heat insulation effect. The invention also provides a color card by which a colorized coating is formed by mixing the nickel iron chromite black, the nickel iron chromite red, the cobalt blue, the titanium yellow and the cobalt green, a user can quickly mix the coating of the corresponding colors according to the pigment formula corresponding to each color in the color card, and the color card is convenient to use.

Owner:NIPPON PAINT GUANGZHOU

Heat insulating reflecting anticorrosive paint

InactiveCN101585992AAdd supportImprove performanceAnti-corrosive paintsPolyurea/polyurethane coatingsSurface oceanWeather resistance

A heat insulating reflecting anticorrosive paint, in a coordinated system composed of bottom, surface and middle layer paints coated on surface of concrete or metal, is suitable for sea climate and chemical engineering air severe atmosphere, which breaks convention of making the heat reflecting surface paint in white in prior market. Surface paints in present coordinated system is added with dye infrared transparent block powder with special function or gray, yellow and brown series made of titanium yellow powder so that the color of paints is versatile, which enlarges use scale. The whole paint system has excellent heat insulating, solar heat reflecting property by rational match and good heavy-duty anticorrosive property as well as excellent weather resistance. Thickness of total dry film does not exceed 250microns. Heat reflecting effect of surface paint in various colors is similar to that of white paint which has greater reflectivity and insulating effect. Compared with a tank coating aluminum powder chlorinated rubber solvent, the tank coating the paint has inner temperature 15 DEG.. C lower, surface temperature 23 DEG.. C.

Owner:袁泉利

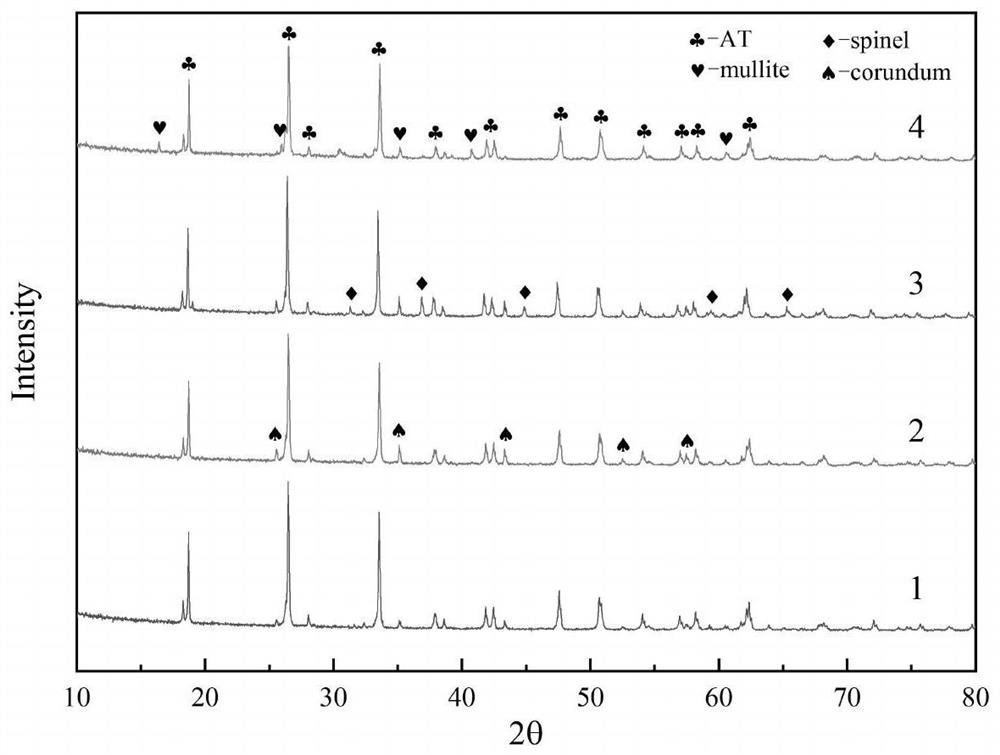

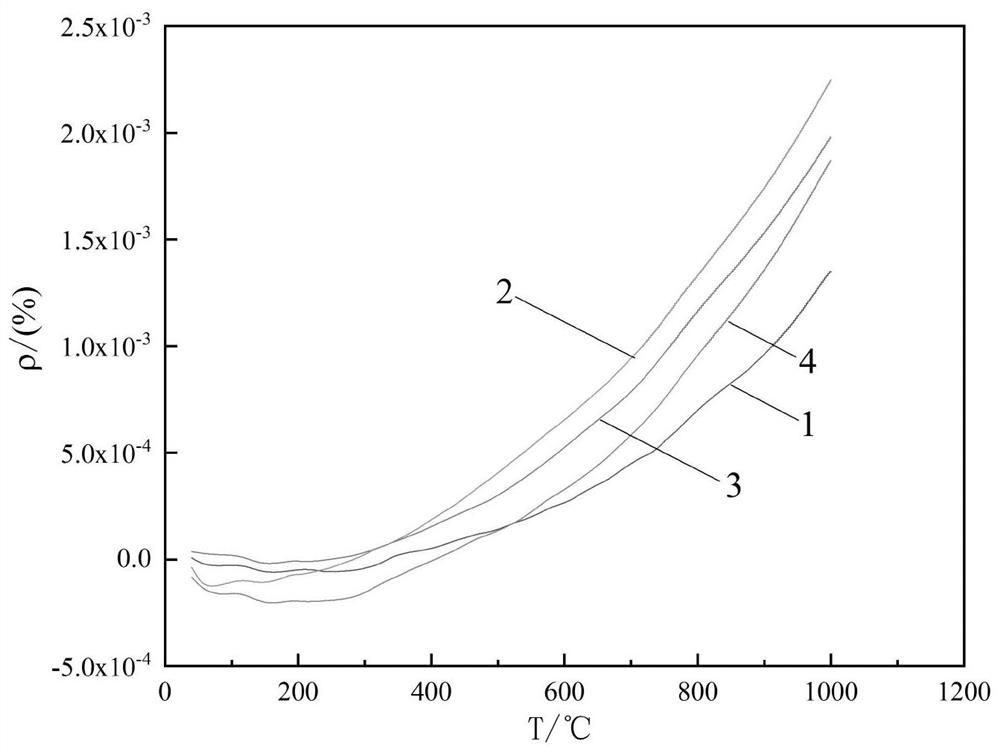

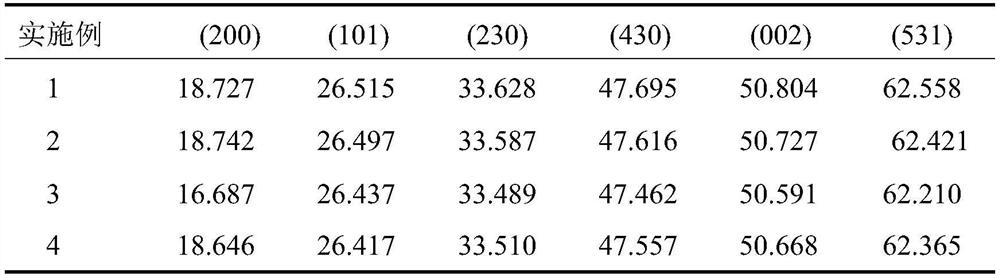

Fiber reinforced aluminum titanate composite material and preparation method of products thereof

The invention discloses fiber reinforced aluminum titanate composite material and a preparation method of products thereof. Alpha-Al2O3 and titanium yellow powder taken as raw material are in-situ synthesized into aluminum titanate by adopting one-step method, stabilizing agent for preventing the aluminum titanate from being decomposed and mullite fiber with reinforcement effect are added in the batch mixture, vacuum slip casting is performed after wet ball milling in a ball mill, and the products are obtained by sintering after being dried. The material comprises the following components of raw materials: 49 to 55 percent of Alpha-Al2O3, 35 to 42 percent of titanium yellow powder, 3 to 6 percent of stabilizing agent, and 3 to 6 percent of mullite fiber, wherein, the stabilizing agent is compounded by magnesium oxide and cerium oxide. The prepared fiber reinforced aluminum titanate composite material has the advantages of small thermal expansion coefficient, high thermal stability and chemical stability, and can greatly improve the service life of composite material. Vacuum slip casting is adopted, the technology is simple, the microstructure texture of the product is uniform, and the products can be used for preparing cast aluminum riser tubes, thermoelectric couple protecting sleeves and crucibles, and other products.

Owner:ANJI HANGDA REFRACTORY

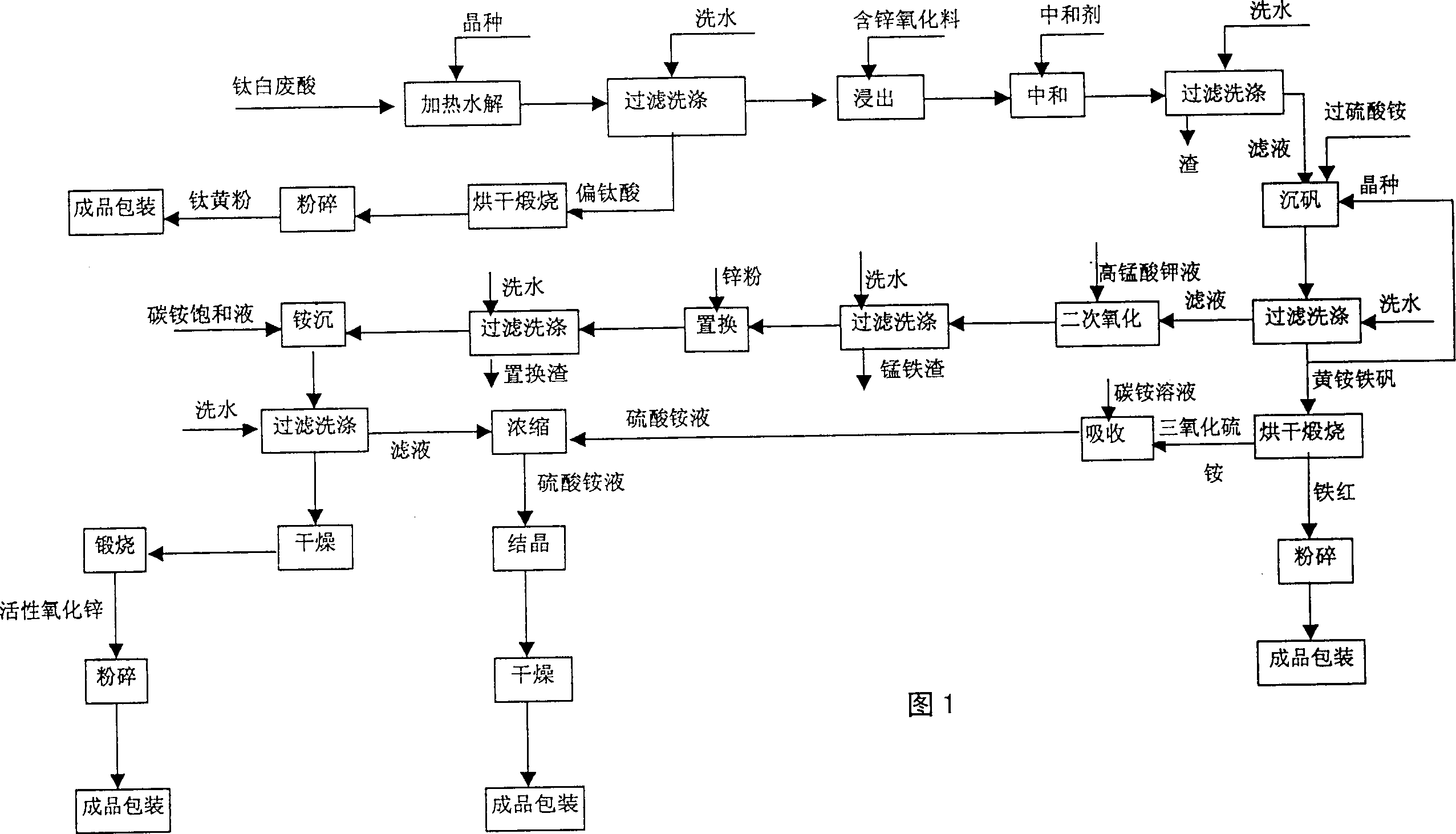

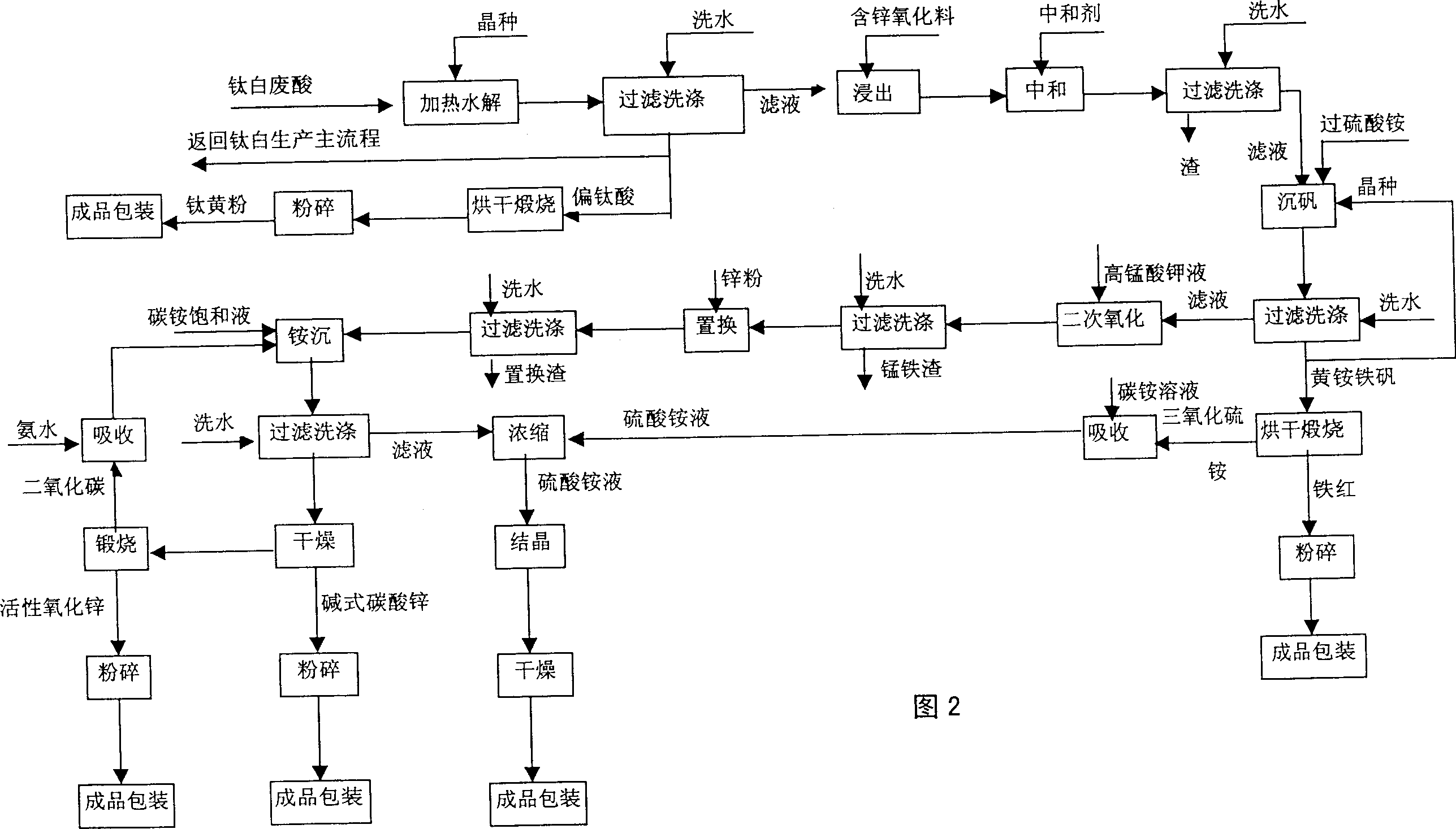

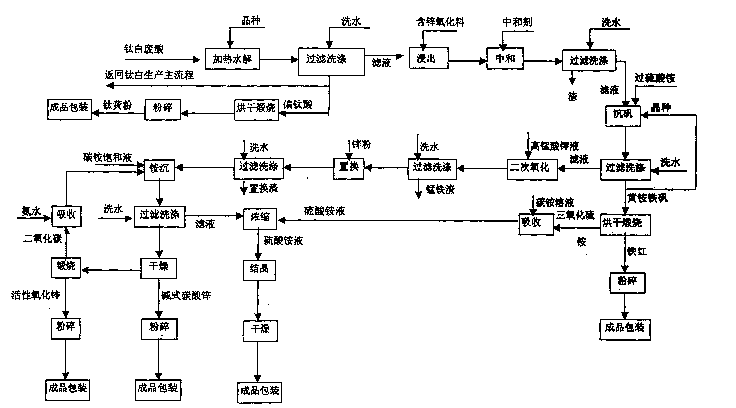

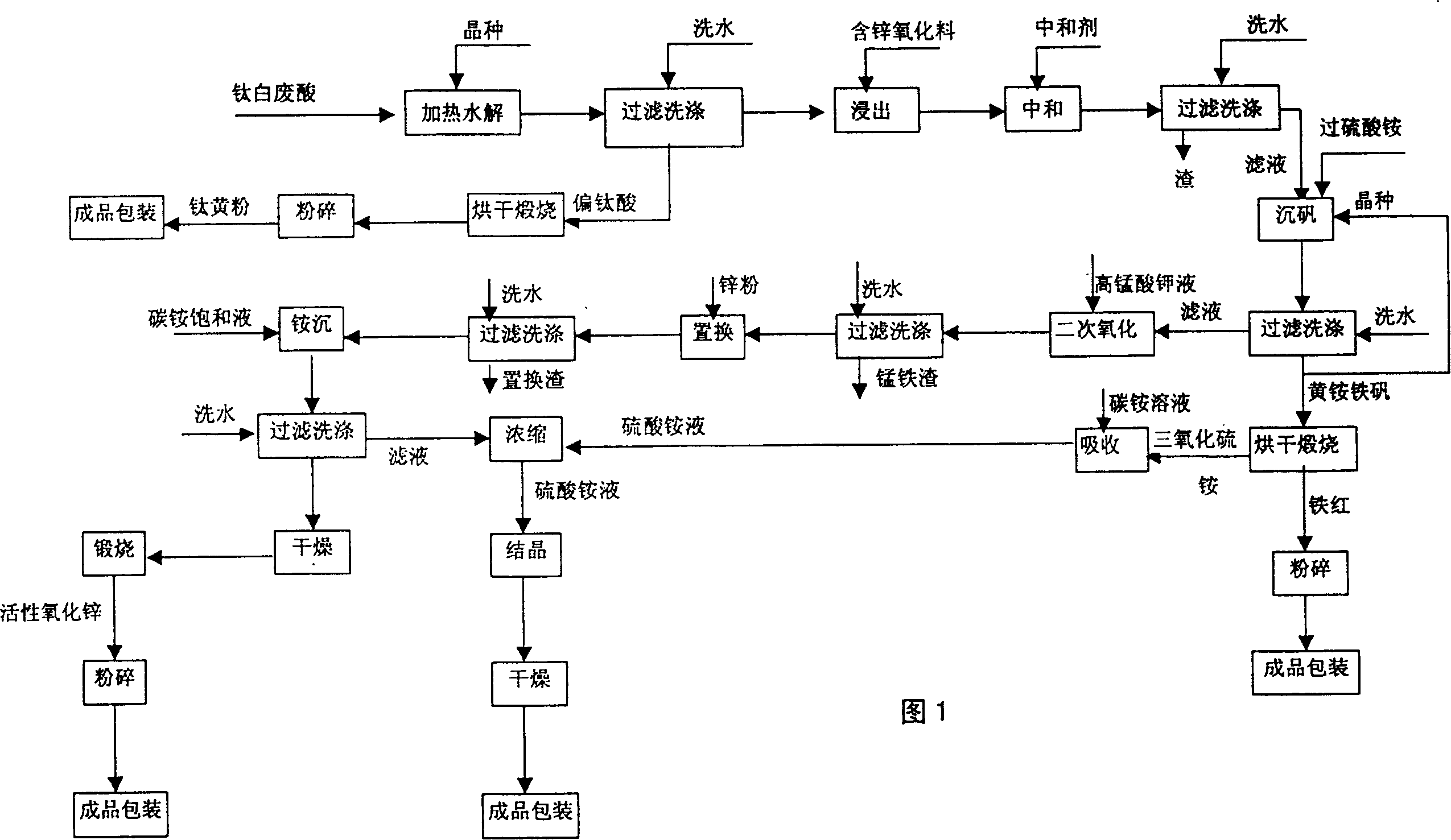

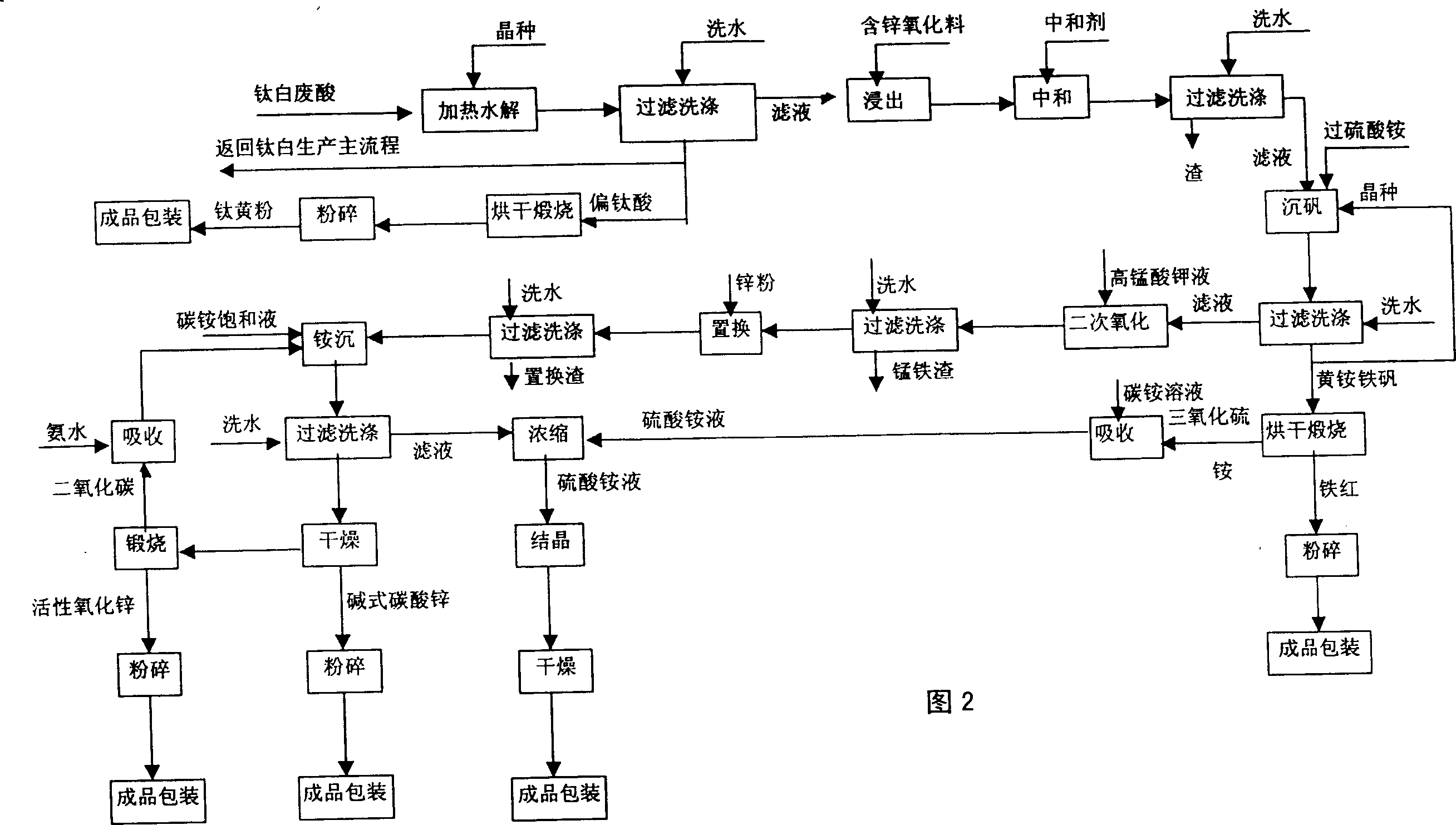

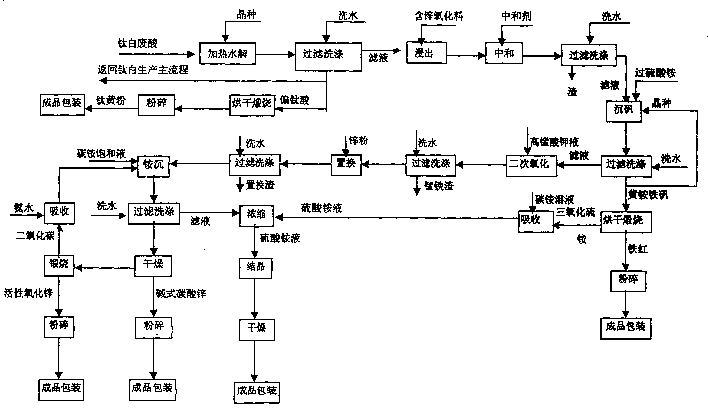

Process for comprehensive utilization of waste acid containing titanium oxide

A process for reclaiming the water acid generated during preparing titanium oxide includes such steps as heating waste acid for hydrolysis to obtain metatitanic acid, returning it to the production line to prepare titanium yellow powder; and wet metallurgy of the filtrate generated by the said hydrolysis and the zinc contained oxide to obtain active zinc oxide, alkaline zinc carbonate, Fe2O3 and Zn-contained ammonium sulfate.

Owner:SICHUAN UNIV

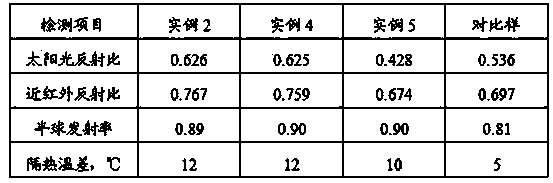

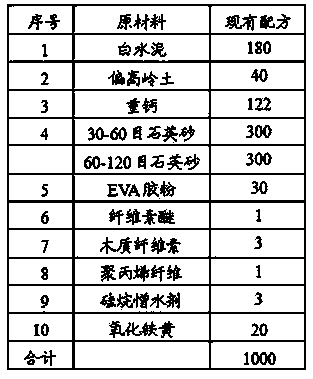

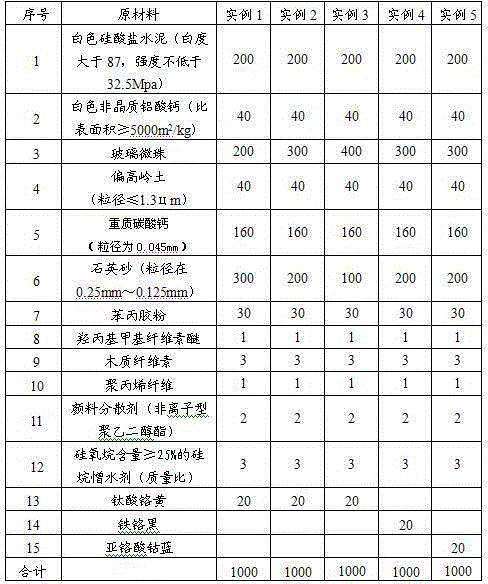

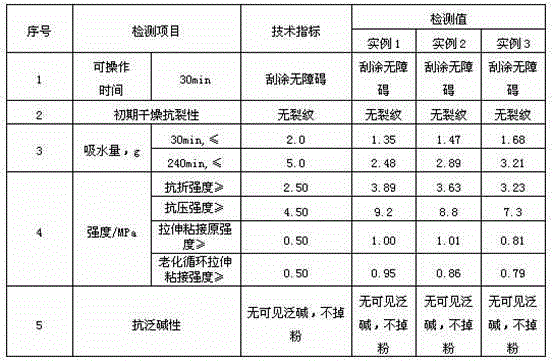

Color thermal insulation mortar with heat reflection function for exterior wall

The invention provides a color thermal insulation mortar with a heat reflection function for an exterior wall. The color thermal insulation mortar comprises the following components by weight percent: 20-25% of white cement, 4-6% of early strength agent, 2-4% of active admixture, 10-20% of finer filler, 20-40% of light filling, 10-30% of fine sand, 1-3% of pigment and 4-6% of additive, wherein the early strength agent is white amorphous calcium aluminate of which the specific surface area is greater than or equal to 5,000m<2>kg; the light filling is a glass bead, which has a honeycomb mesh structure and of which the particle size is 0.09-0.60mm, the bulk density is 270-400Kg / m<3>, the cylinder compressive strength is greater than 2.0MPa, and the pigment is chromium titanium yellow, nickel titanate yellow, chromite-cobalt blue or ferrochromium black. The color thermal insulation mortar disclosed by the invention not only has the characteristics of being light in weight, strong in strength and low in water absorption rate by adding an inorganic composite pigment burnt at high temperature and the glass bead with a special structure, but also has high near infrared solar reflectance and low coefficient of thermal conductivity. Compared with the common mortar, the color thermal insulation mortar has better insulating and cooling effects, and is especially applicable to decoration of the exterior wall.

Owner:广东龙湖科技股份有限公司

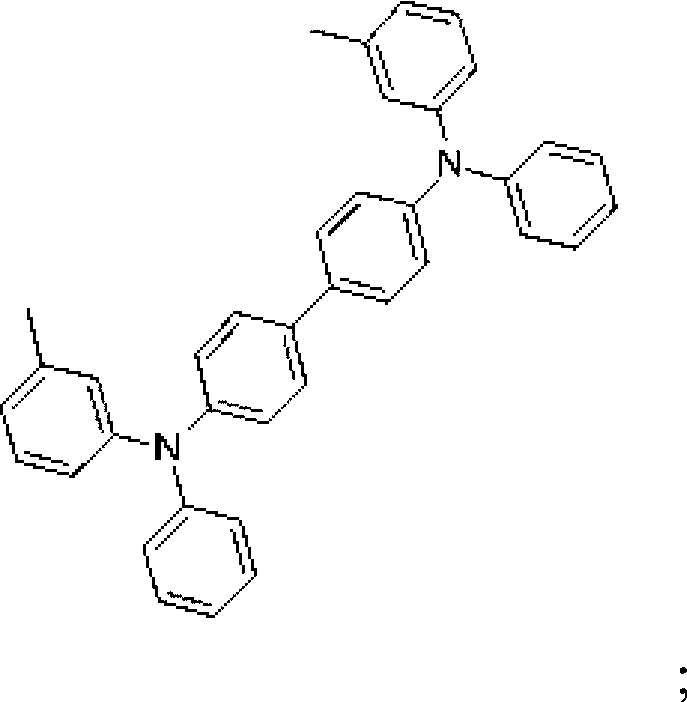

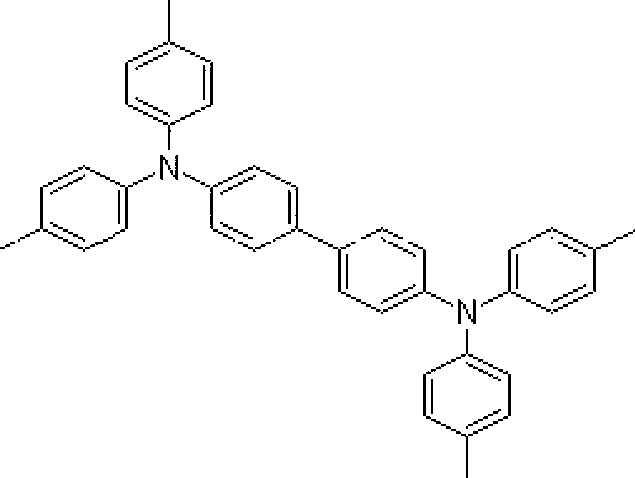

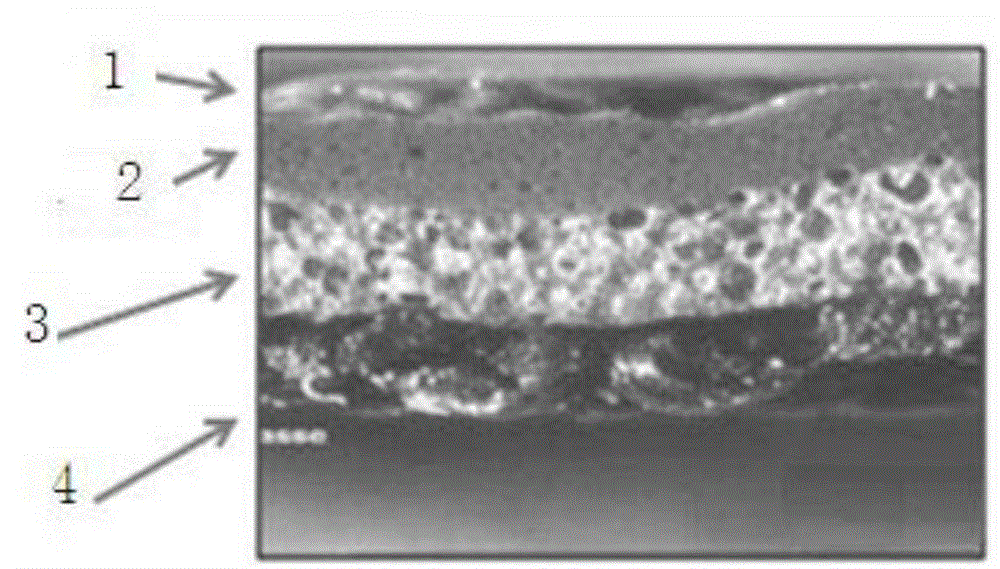

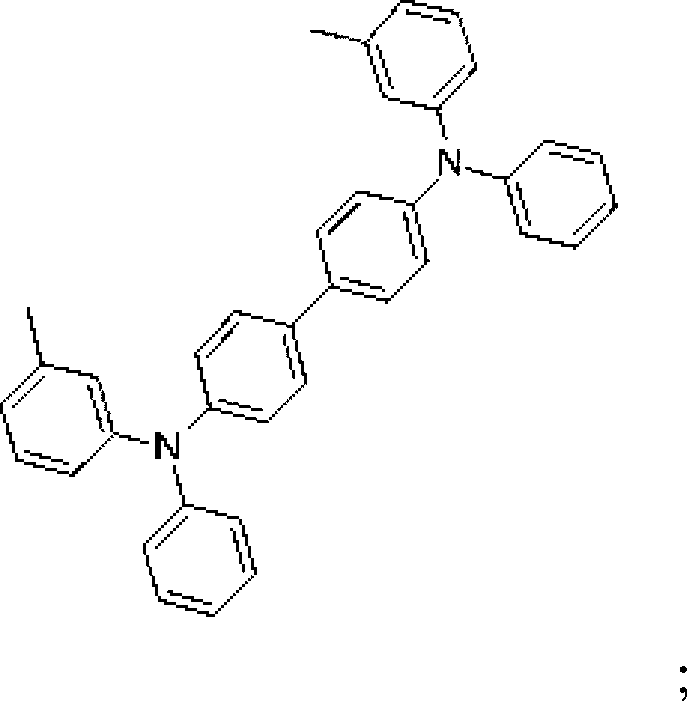

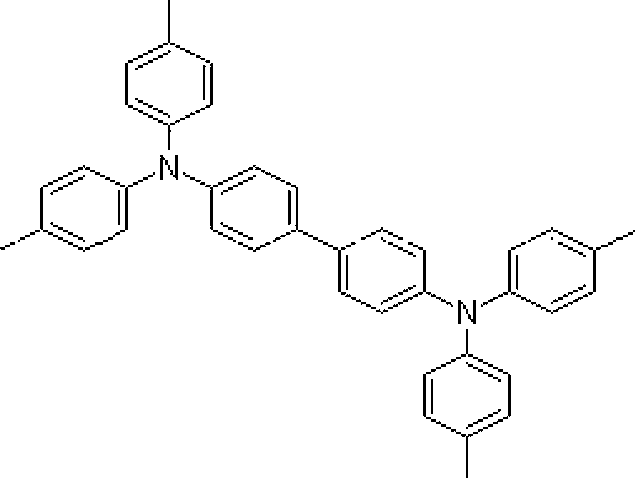

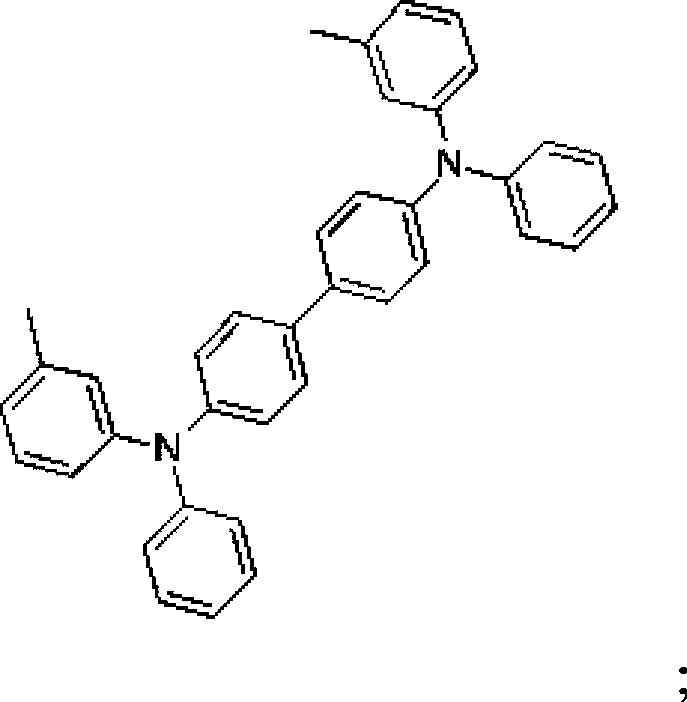

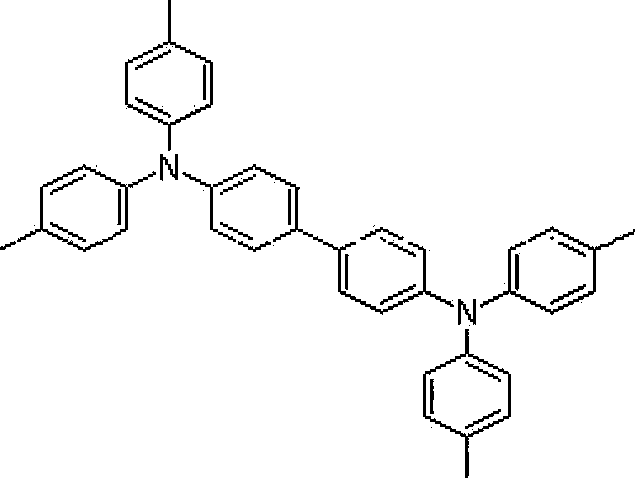

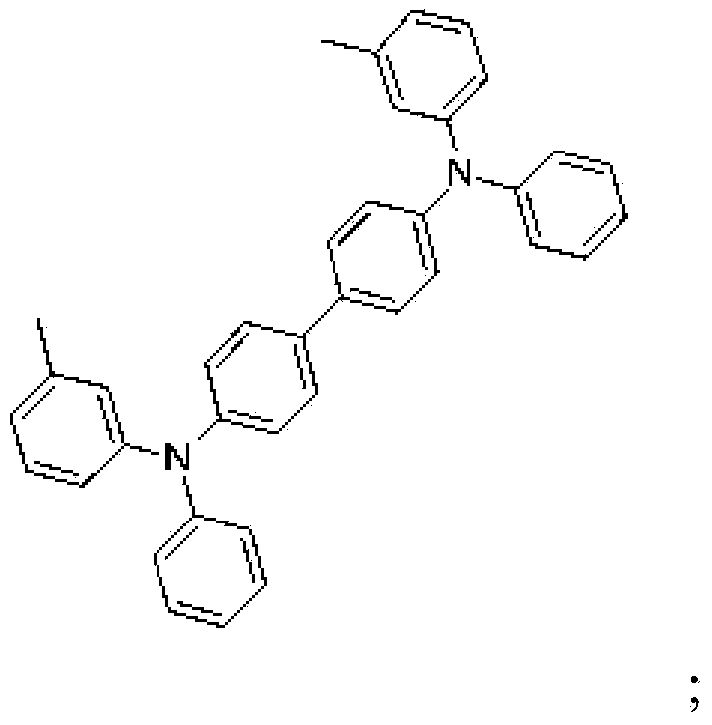

Three-layer coating process and photosensitive drum prepared by adopting same

InactiveCN102998917ASimple preparation processEasy to storeElectrography/magnetographyPolyamide coatingsMass ratioPhthalocyanine

The invention discloses a three-layer coating process and a photosensitive drum prepared by adopting the three-layer coating process. The three-layer coating process comprises the following steps of: 1, coating a carrier barrier layer coating on a drum base to form a carrier barrier layer, wherein the carrier barrier layer coating contains titanium dioxide, titanium yellow and nylon rein, the mass ratio of the titanium dioxide to the titanium yellow is 1:1-2:1, the mass ratio of the TiO2 to the nylon resin is 1:1-2:1; 2, coating a carrier forming layer coating on the carrier barrier layer to form a carrier forming layer, the carrier forming layer coating contains titanyl phthalocyanine and polyvinyl butyral resin with a proportion of 1:1-1.5:1; and 3, coating a carrier transmission layer coating on the carrier forming layer to form a carrier transmission layer. The three-layer coating process can ensure that a coating material for coating an organic photosensitive drum has good photoelectric property and a coating solution is stable without crystallizing; and the photosensitive drum has the characteristics of high black degree, high wear resistance and low cost.

Owner:珠海惠尔美打印耗材有限公司

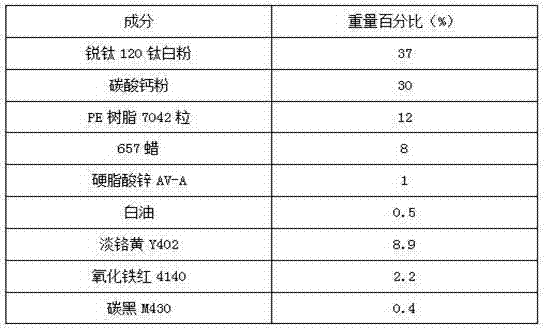

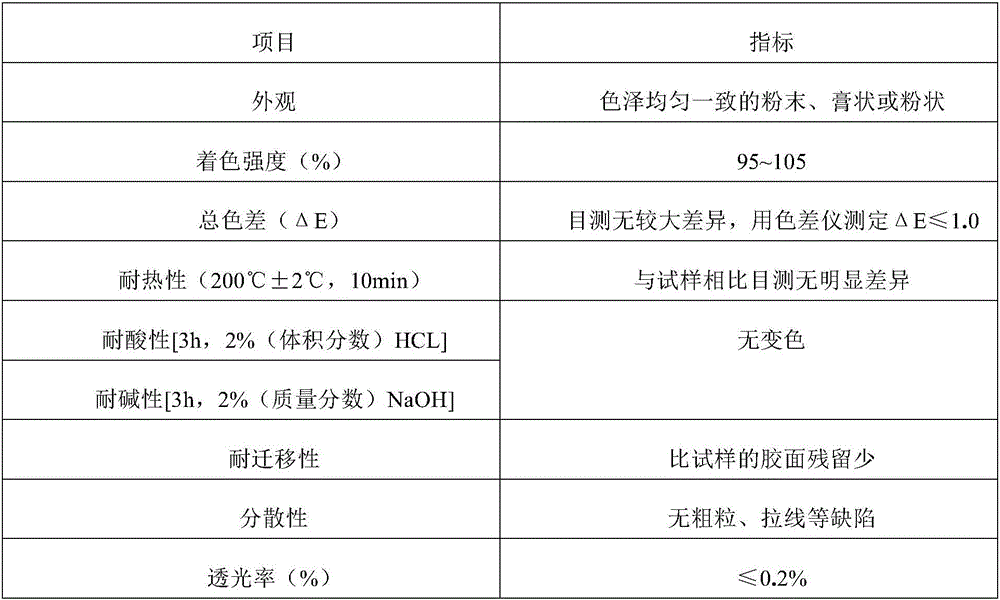

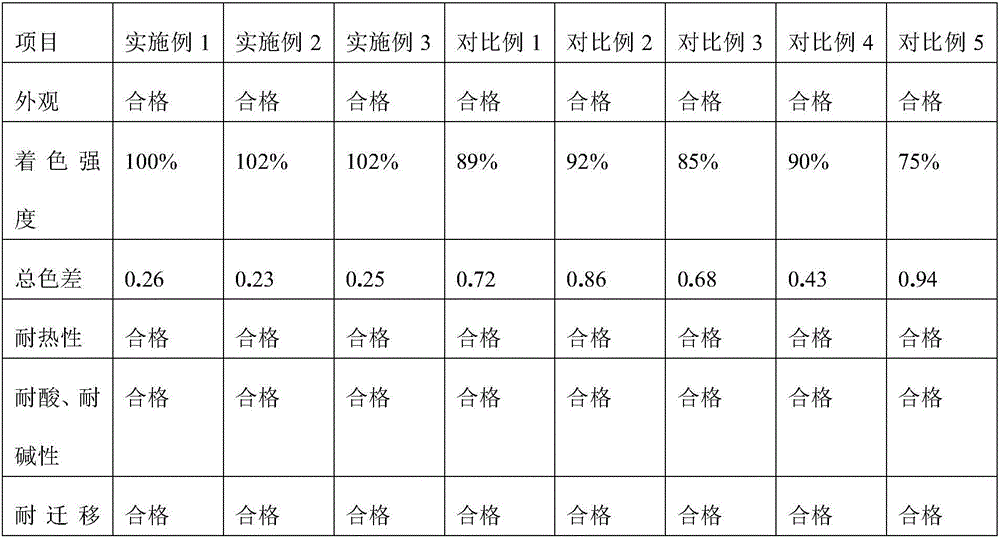

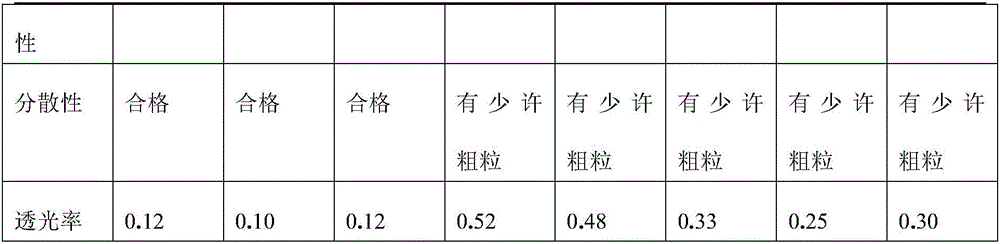

Coloring masterbatch for PPR tube and preparation method of coloring masterbatch

The invention relates to a coloring masterbatch for a PPR tube. The masterbatch is prepared from the following raw materials in percentage by mass: 50-65 percent of rutile titanium dioxide, 28-40 percent of PPR resin, 3.9-9 percent of iron oxide red, 1.0-1.5 percent of titanium yellow, 0.1-0.5 percent of carbon black and 0.5-1.5 percent of polysiloxane, wherein the rutile titanium dioxide has an average grain size of 0.2-0.25 mu m and a refractive index of 2.7, has strong covering power and strong ultraviolet absorbability, and can be used for resisting temperature of 300 DEG C; and the carbon black is produced by a channel process and has an average grain size of 10-27nm. The invention further discloses a preparation method of the coloring masterbatch. The method comprises the steps of selecting raw materials, metering, mixing raw materials, cooling, granulating, packaging and the like. The coloring masterbatch has the advantages of high content of titanium dioxide, good dispersion, good light covering performance and discoloration prevention.

Owner:成都菲斯特新材料有限公司

Compound masterbatch and preparation method thereof

The invention belongs to the field of high polymer chemistry and polymers, and particularly relates to a compound masterbatch and a preparation method thereof. The compound masterbatch is prepared from the following components in parts by weight: 20-60 parts of a carrier, 20-40 parts of titanium dioxide, 20-30 parts of titanium yellow, 1-6 parts of iron oxide red, 0.5-3 parts of carbon black, 1-5 parts of a stabilizing agent, 25-55 parts of a plasticizer, 100-200 parts of antimonous oxide, 0.5-4 parts of a lubricating agent and 2-6 parts of nano-calcium carbonate. According to the compound masterbatch, nano-calcium carbonate is added into the compound masterbatch to serve as a dispersing agent, the grain size and specific surface area of nano-calcium carbonate are strictly controlled, and the problem of poor dispersibility of high-content titanium dioxide can be solved; furthermore, the crystal form and the grain size of titanium dioxide are selected, and the proportion of titanium dioxide with different grain sizes is controlled, so that titanium dioxide has higher dispersibility and covering power, and a compound masterbatch with high quality is prepared and is suitable for large-scale application.

Owner:FOSHAN SHUNDE BAOSITE PIGMENT +1

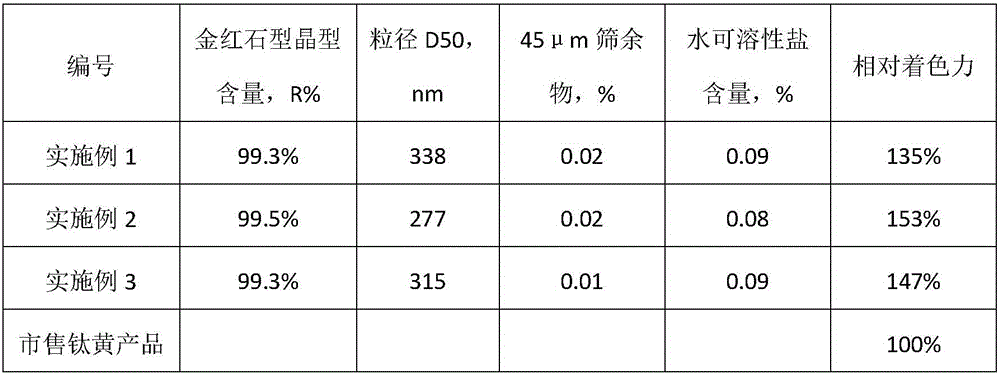

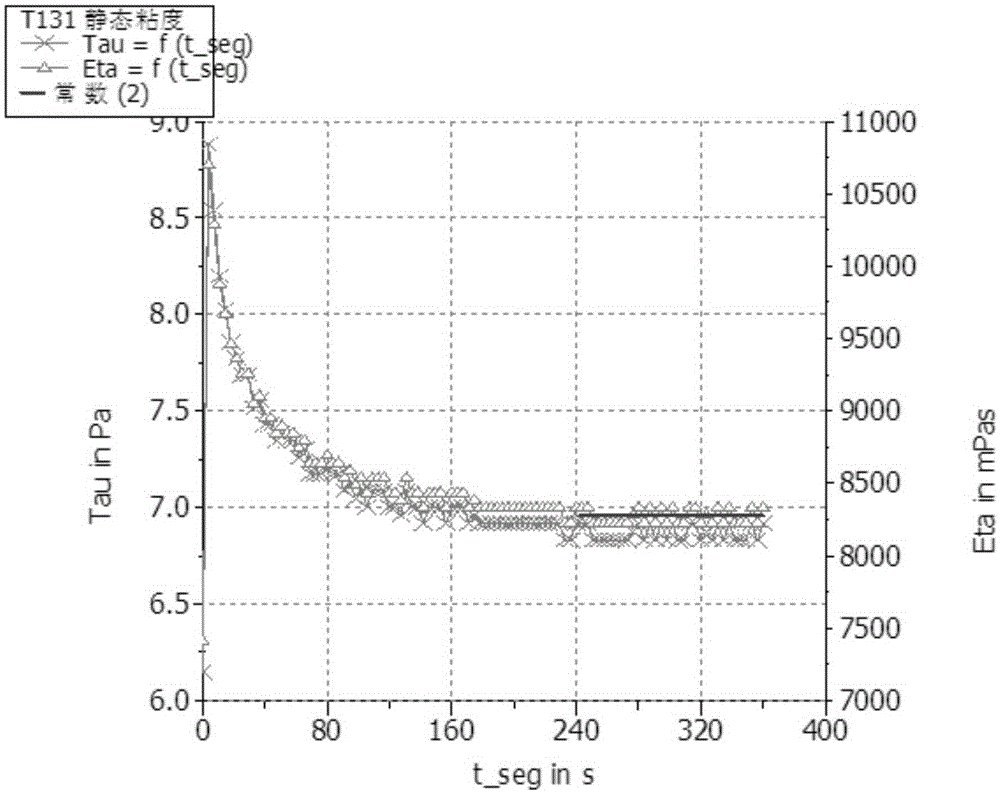

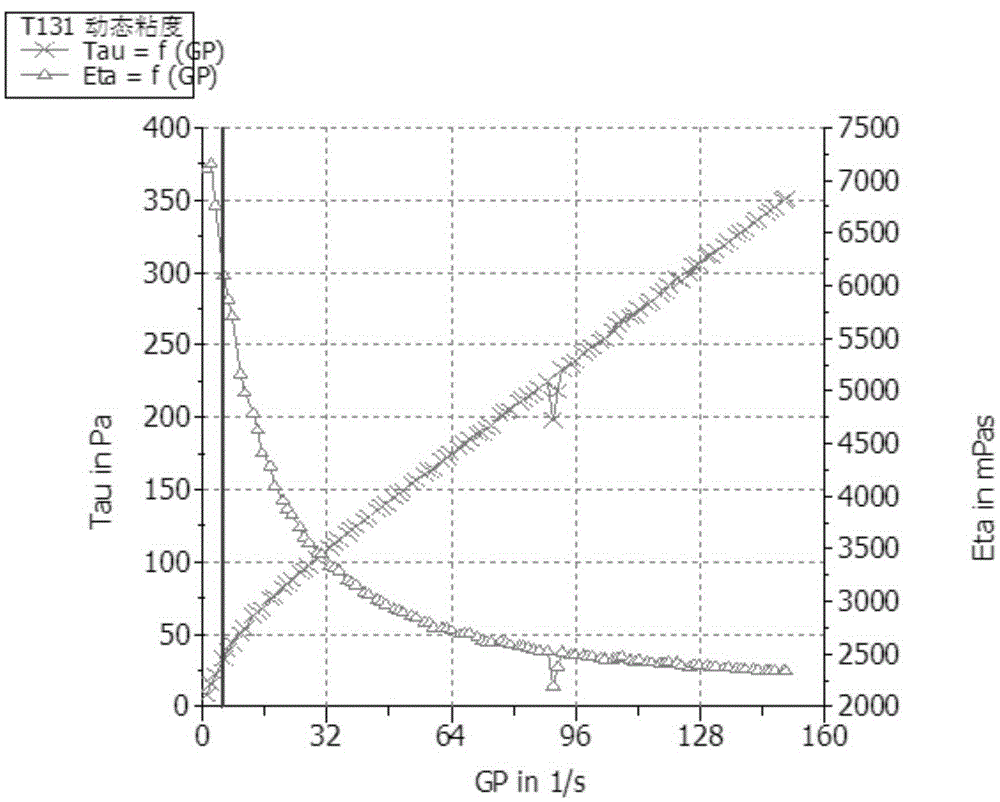

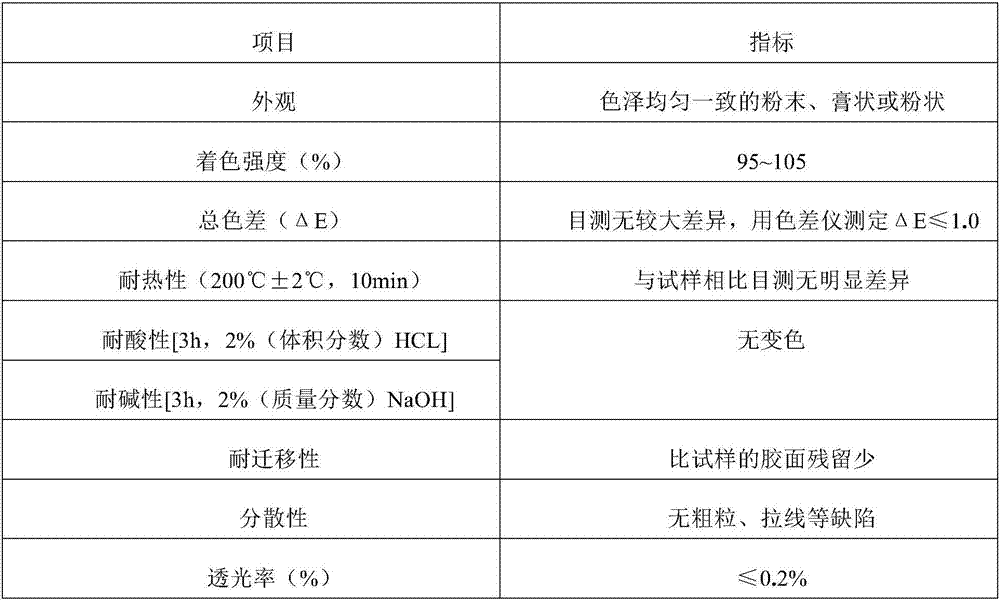

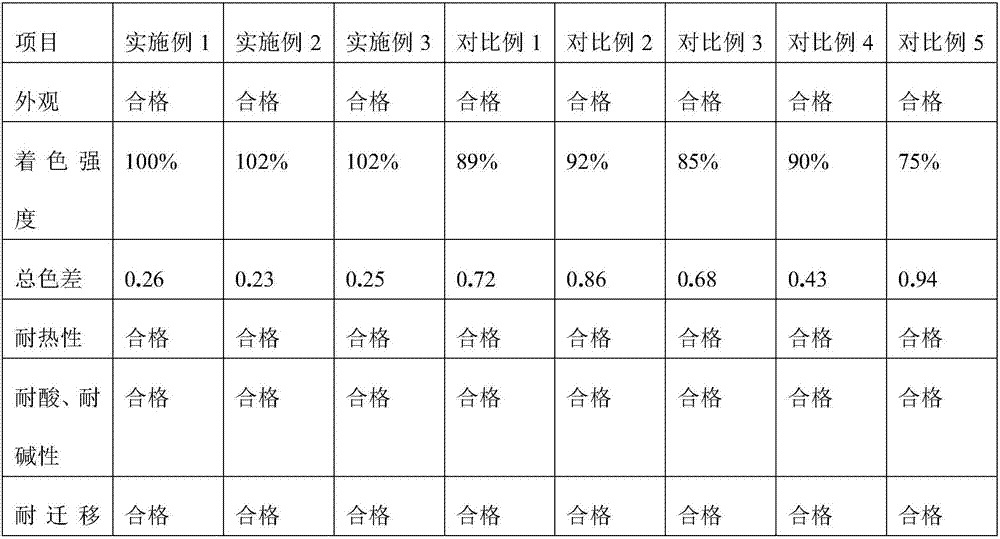

High-tinting-strength pigment level titanium yellow production method

ActiveCN106675112AImproved particle size distributionParticle Size Controlled GrowthPigment treatment with non-polymer organic compoundsPhosphoric acidPhotodegradation

The invention discloses a high-tinting-strength pigment level titanium yellow production method. According to the method, high reaction activity of nanoscale hydrous titanium dioxide is utilized, and appropriate nanoscale hydrous titanium dioxide is selected. A product of pigment level titanium yellow can be obtained by using the hydrous titanium dioxide as base and adding additives of photodegradation sol, zinc element, antimony oxide, aluminum salt, phosphoric acid, nickel oxide and the like and through the steps of high-temperature calcinating, smashing and desalting. The product has the obvious characteristics of small particle diameter, concentrated distribution, bright color, easiness in scattering and strong tinting strength and can serve as an ideal upgraded substitute product of a current commercial-use yellow pigment.

Owner:JIANGSU TOP FINE NEW RAW MATERIAL CO LTD

High temperature and amine resistant PVC artificial leather and preparation method thereof

InactiveCN105401452AComply with high temperature requirementsExcellent amine resistanceTextiles and paperTO-18Plasticizer

The invention relates to a high temperature and amine resistant PVC artificial leather, which is composed of the following components in parts by weight: 50 to 70 parts of PVC resin, 30 to 50 parts of plasticizer, and 1 to 7 parts of pigment, and aqueous paint, which comprises 85 to 90 parts of aqueous polyurethane modified resin and 10 to 15 parts of auxiliary agent; wherein the plasticizer is a low-volatile linear polymer plasticizer, the pigment comprises one or more of chromium-antimony-titanium yellow, iron red, and titanium dioxide; and the auxiliary agent comprises one or more of wetting auxiliary agent, antifoaming auxiliary agent, and thickening auxiliary agent. The PVC artificial leather also comprises 11 to 18 parts of solid stabilizing agent. The solid stabilizing agent contains perchlorate. The amine resistant performance of the perchlorate-containing solid stabilizing agent is stronger than that of organic liquid stabilizing agent, and the high temperature resistant performance of the perchlorate-containing solid stabilizing agent is better than that of epoxy liquid stabilizing agent. The prepared PVC artificial leather has excellent high temperature and amine resistant properties.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

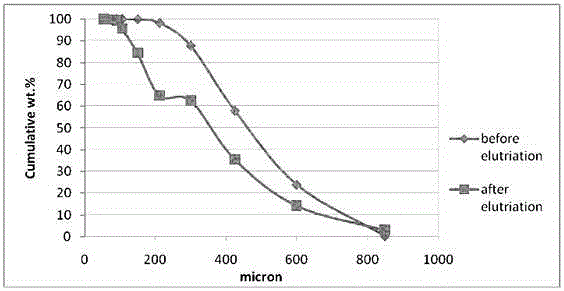

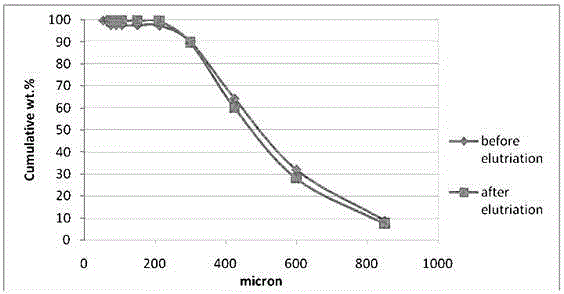

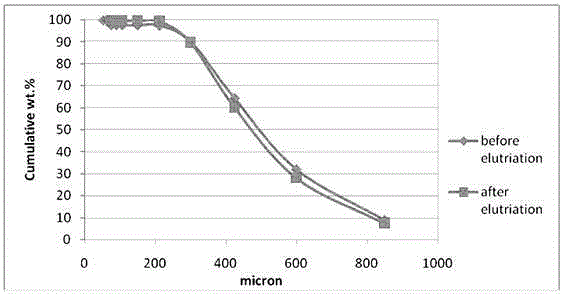

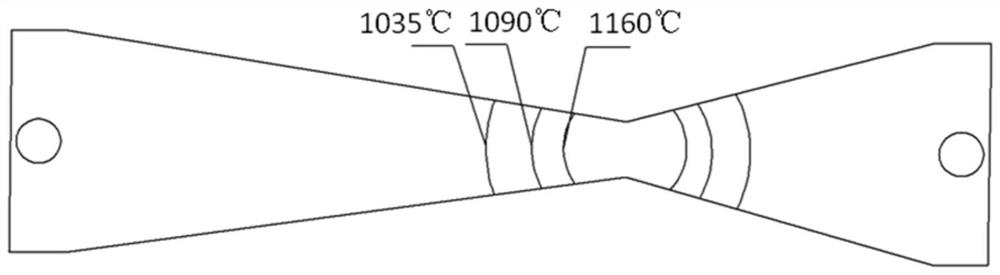

Method for recycling chloride process titanium dioxide chlorination furnace blown-out materials containing fine-grain rutile

The invention provides a method for recycling chloride process titanium dioxide chlorination furnace blown-out materials containing fine-grain rutile. Various impurities in rutile-containing waste residues are removed through physical methods such as screening, multi-stage combined shaking table wet process reselection, deposition and drying, and titanium-rich materials containing 92% to 95% of titanium dioxide are regained. The method belongs to physical concentration methods, and is suitable for recycling, concentrating and recycling waste materials. The recycling rate of waste residues can reach up to 25% to 40% due to different titanium contents of waste residues. Rutile particles obtained through the method are fine, are ground, milled, granulated, screened, dried, sintered and screened till the particle size reaches 840 micrometers to 178 micrometers (20 to 80 mesh) and are sintered into spheres at a temperature of 1100 DEG C to 1160 DEG C. The circular degree of the rutile particles is larger than 0.8, the volume density of the rutile particles ranges from 1.65 to 1.71, and the content of sintered balls with the strength lower than 28 MPa is smaller than 40%. The titanium dioxide content of rutile processed through the method ranges from 92% to 95%, and 100% of the physical phase is rutile. The regenerated high-grade raw material can be used for chloride process titanium dioxide and processed into titanium yellow materials or directly used for producing titanium yellow materials.

Owner:阿斯创钛业(营口)有限公司

Environment-friendly titanium pigment prepared by using complexation-precipitation process

ActiveCN103613958ANarrow particle sizeBright colorPigment treatment with non-polymer organic compoundsAir atmosphereAntimony trioxide

The invention discloses environment-friendly titanium pigment prepared by using a complexation-precipitation process. The process comprises the following steps: quantitatively weighing titanium dioxide or titanium dioxide and antimonous oxide to be added into a solution into which a surfactant is dissolved, and dispersing uniformly; adding a mixture solution of coloring ions R<+1> and a complexing agent, controlling the contents of the complexing agent and the coloring ions so as to establish a stable system of the coloring irons and the complexing agent, adjusting the pH value of the system and enabling the system to be in a stable state; performing precipitation reaction on the coloring ions and an dropped alkali solution; aging and subsequently washing and filtering the reaction system so as to remove impurity ions; performing spraying drying treatment; adding a mineralizer into the dry powder, uniformly mixing, subsequently calcining in air atmosphere in a muffle furnace, and controlling the temperature and the temperature preserving time so as to obtain expected powder. The pigment overcomes the defects that in the conventional titanium yellow preparation, the particle size of the pigment is large, the distribution interval is wide, the color is not bright, agglomeration happens, the coloring capability is poor, and the like, and the cost of the titanium pigment is greatly lower than that of a developed product in market.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

Hydrochloric-acid-method titanium yellow powder production technology

InactiveCN103539201AEfficient productionProduction qualifiedCalcium/strontium/barium chloridesFerric oxidesSlagCarbide

The invention provides a hydrochloric-acid-method titanium yellow powder production technology. According to the technology, titanium concentrate powder is leached by hydrochloric acid, after leaching is ended, solid-liquid separation is carried out, and a filter cake is washed, is calcined at the temperature of 750-950 DEG C, is cooled and screened and then is packaged into titanium yellow powder finished products; leaching mother liquor obtained through mixing mother liquor and washing liquid is separated and is neutralized by lime milk (or carbide slag slurry) until the pH value is 9-13, then, solid-liquid separation is carried out, a filter cake is washed and then is calcined, so as to obtain FeO3, and washing liquid is subjected to evaporative concentration so as to obtain a CaCl2 product. The technology has the advantages that the problem of pollution is solved while titanium yellow powder with high quality is produced, and beneficial byproducts are obtained.

Owner:ZIGONG YATAI CHEM SCI & TECH CO LTD

Polypropylene material and preparing method thereof

The invention discloses a polypropylene material and a preparing method thereof. The polypropylene material is prepared from 50-100 parts of polypropylene, 5-35 parts of an ethylene-octylene copolymer, 3-10 parts of POE-grafted maleic anhydride, 3-10 parts of a synergistic coloring reinforcing agent, 0.5-5 parts of coloring master batches, 0.1-0.5 part of an antioxidant and 0.1-1.0 part of a lubricating agent through mixing and melt extrusion pelleting; the coloring master batches are prepared from ultralow-viscosity polypropylene, titanium dioxide, phthalo blue, phthalein green, titanium yellow powder, carbon black and iron oxide red through mixing and extrusion pelleting. According to the polypropylene material and the preparing method thereof, the low-viscosity polypropylene is introduced, and the whole liquidity and processability of the polypropylene material are guaranteed; through the cooperation effect of the coloring master batches and the synergistic coloring reinforcing agent, the whole material has good coloring capacity and good toner dispersity while the stability of the mechanical property of the material is kept.

Owner:HEFEI GENIUS NEW MATERIALS

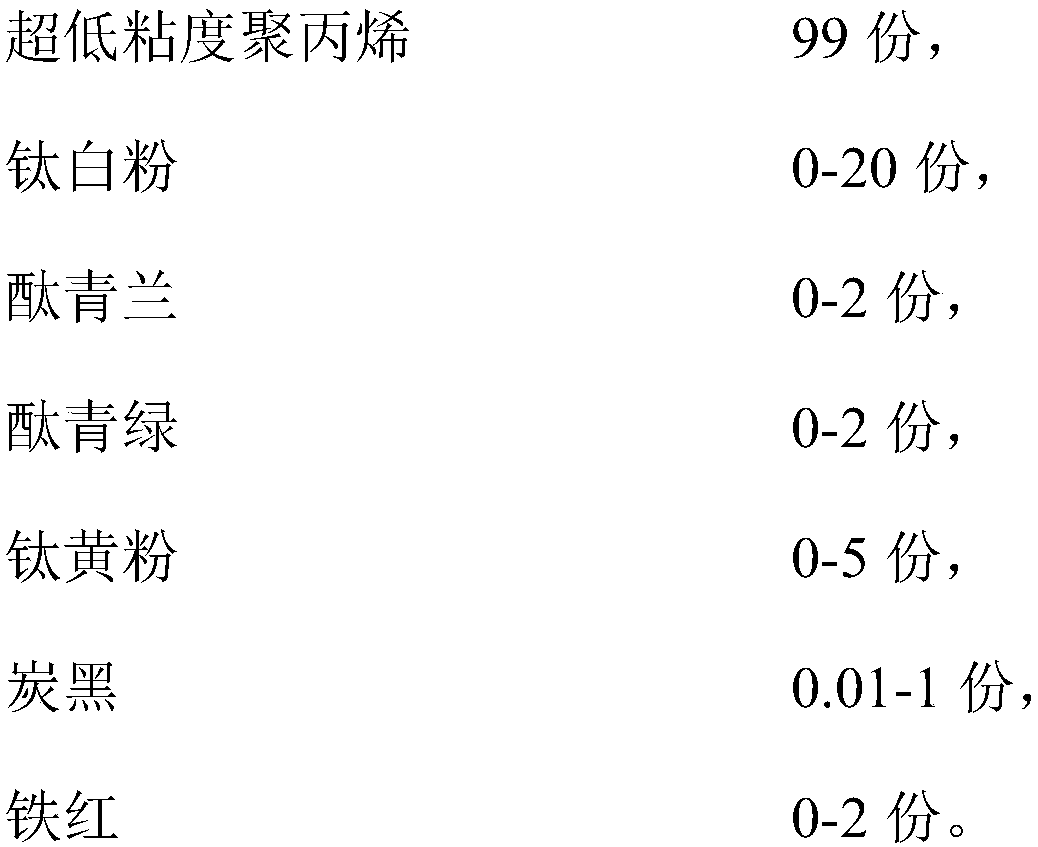

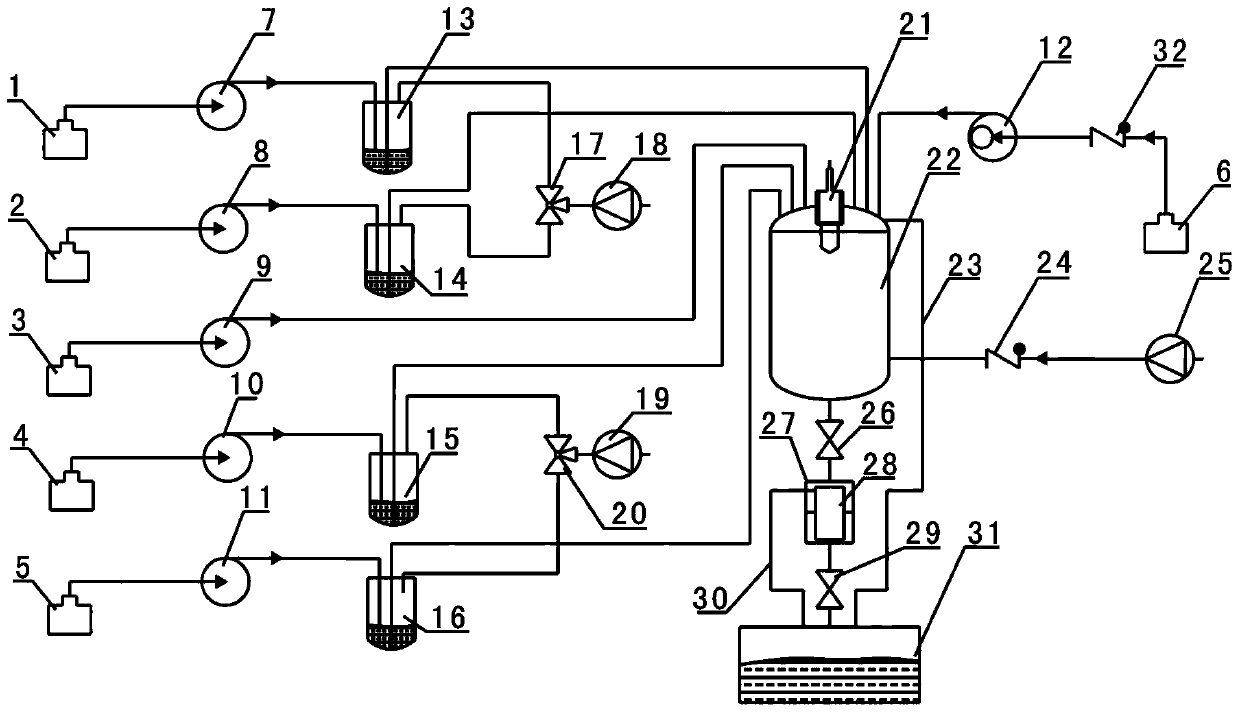

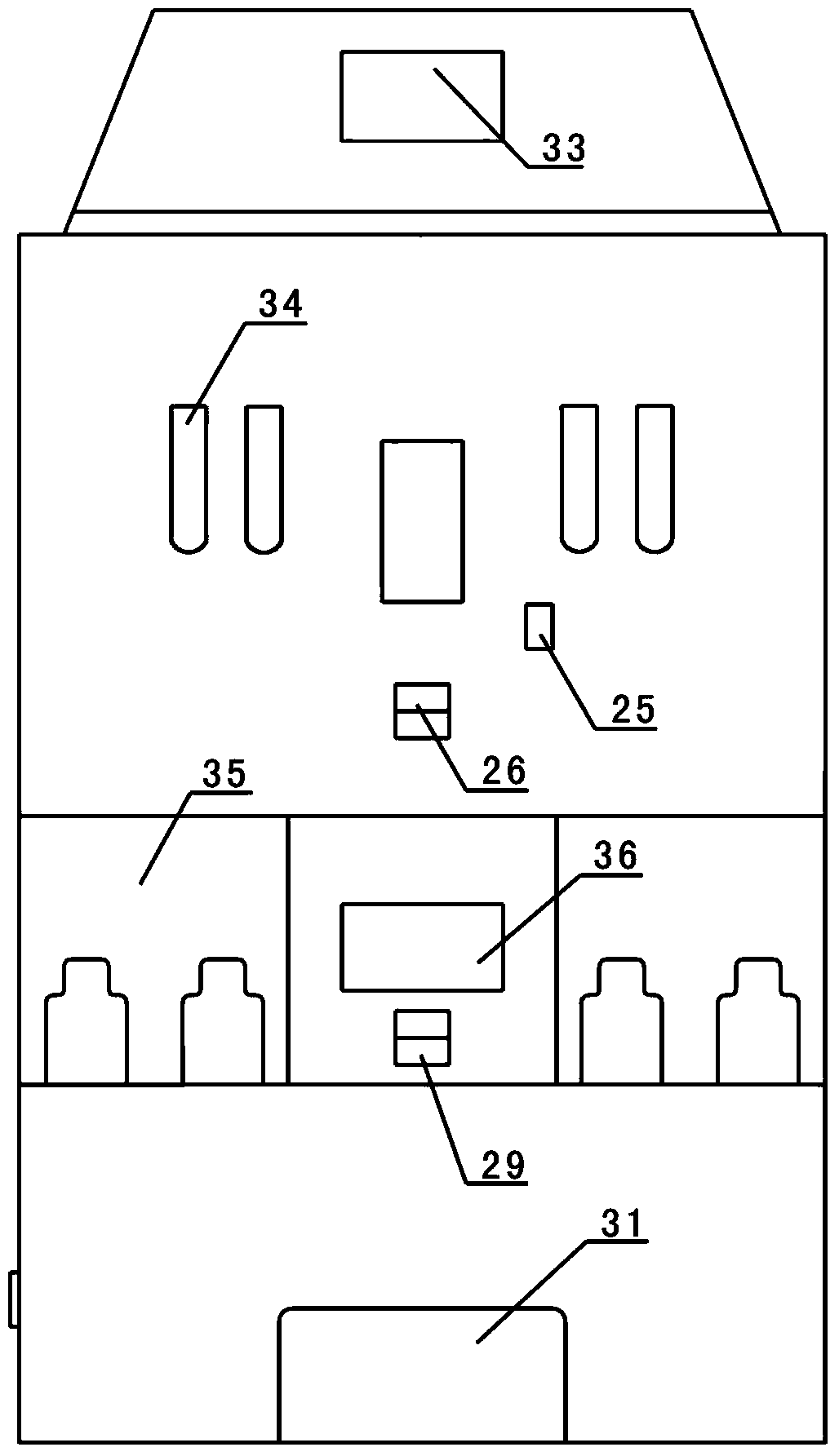

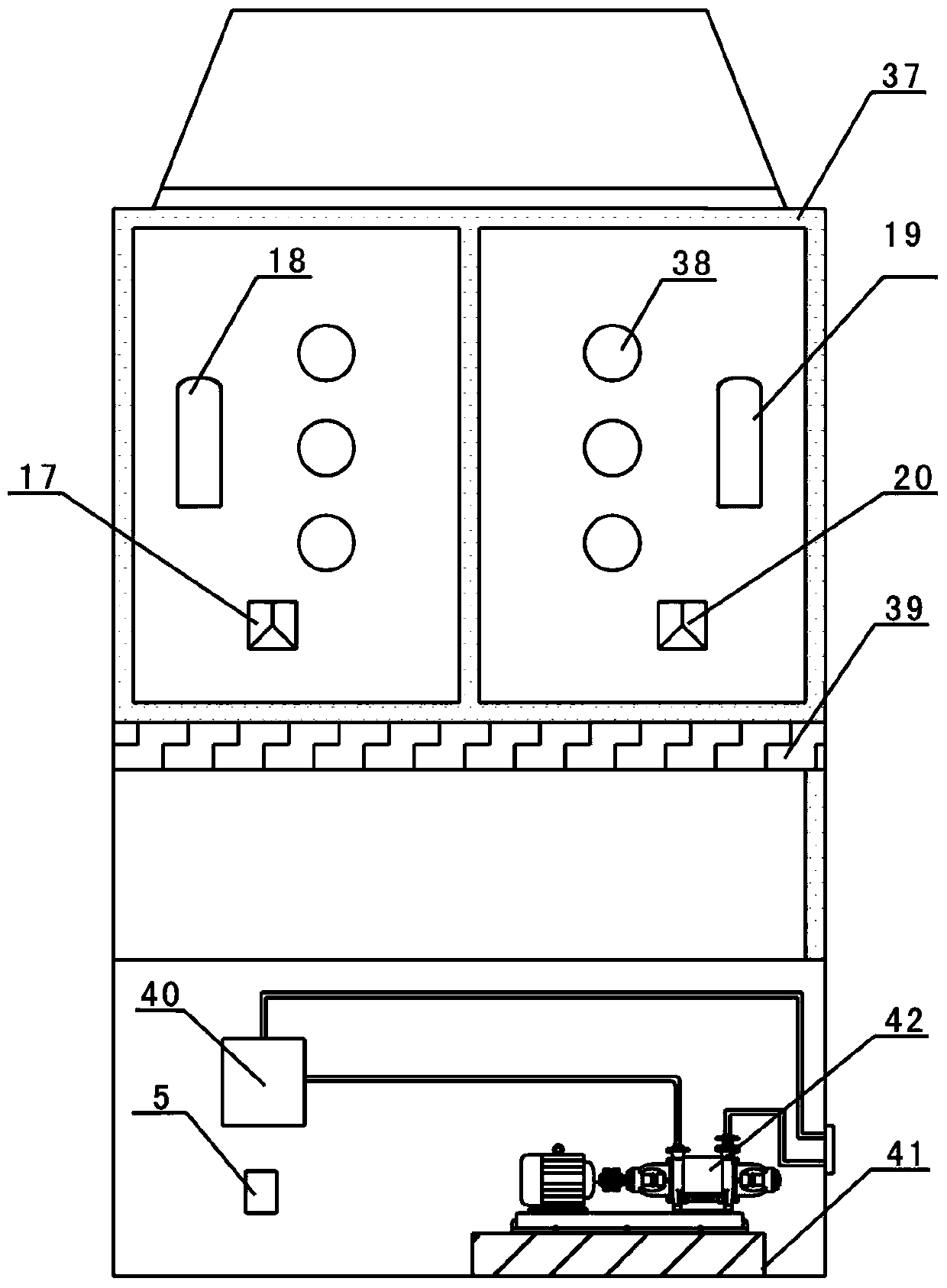

Method for monitoring content of total cadmium in water and device for automatically monitoring content of total cadmium in water on line

ActiveCN104198411ANo secondary pollutionComplexation characteristic reaction completeMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsVitamin CColorimetric analysis

The invention discloses a method for monitoring content of total cadmium in water. The method comprises the following steps: after pretreating a water sample obtained by water sampling, pumping the water sample into a constant volume container and keeping a constant volume; respectively pumping a tween-80 solution, a titanium yellow solution, a sodium hydroxide solution and a vitamin C solution into a constant volume container and keeping constant volume; sequentially pumping the water sample, the tween-80 solution, the titanium yellow solution, the sodium hydroxide solution and the vitamin C solution with constant volume into an absorption tank to obtain a mixed solution, diluting the mixed solution to a fixed volume with distilled water and injecting gas to the bottom in the absorption tank; performing colorimetric analysis, i.e., after gas injection, discharging all the solutions from the absorption tank into a colorimetric tank and reading by a photometer; sending data read by the photometer to a processor, and displaying a result after computation, thereby accomplishing the monitoring on the content of total cadmium in water. The invention also discloses a device for automatically monitoring content of total cadmium in water on line, which is implemented in match with the method. The application of titanium yellow and tween-80 which respectively serve as a color developing agent of cadmium ions is conductive to the realization of engineering of online monitoring of the content of total cadmium in water.

Owner:成都海兰天澄科技股份有限公司

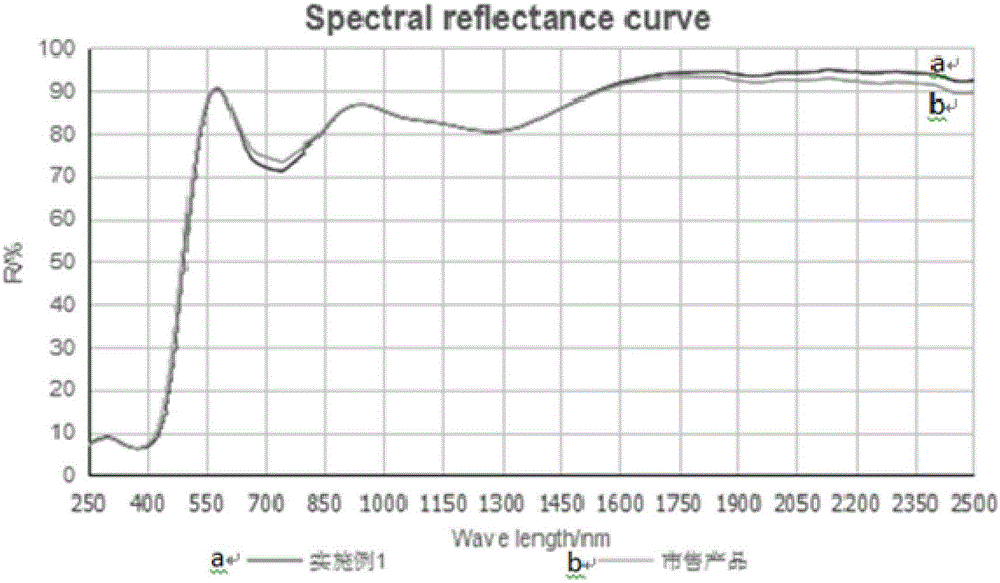

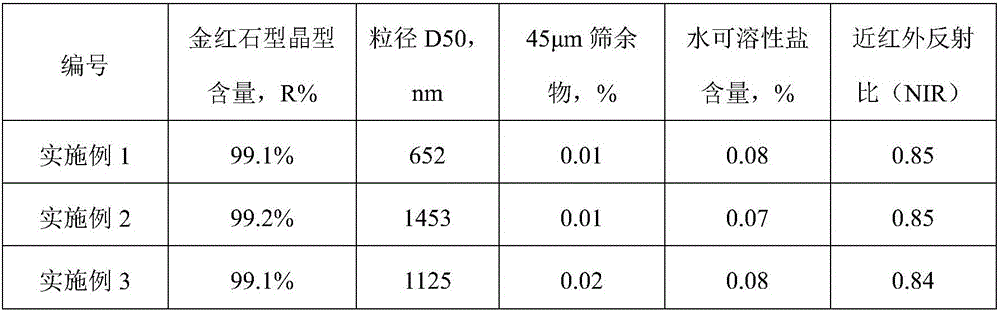

Production method of high-near-infrared-reflectivity titanium yellow

ActiveCN106752112AImproved particle size distributionExcellent near-infrared reflection abilityPigment physical treatmentDispersityPhosphoric acid

The invention discloses a production method of high-near-infrared-reflectivity titanium yellow. The method comprises the following steps: by utilizing high reaction activity of nano titanium dioxide hydrate, adopting the appropriate nano titanium dioxide hydrate, adding a titanic acid sol, a zinc element, antimony oxide, phosphoric acid, nickel oxide and other additives, carrying out high-temperature calcination, pulverizing and removing salts to obtain the high-near-infrared-reflectivity titanium yellow. The product has the outstanding characteristics of reasonable particle size distribution, moderate color, high dispersity and high near-infrared reflectivity, and is an ideal yellow near-infrared reflection functional material product.

Owner:JIANGSU TOP FINE NEW RAW MATERIAL CO LTD

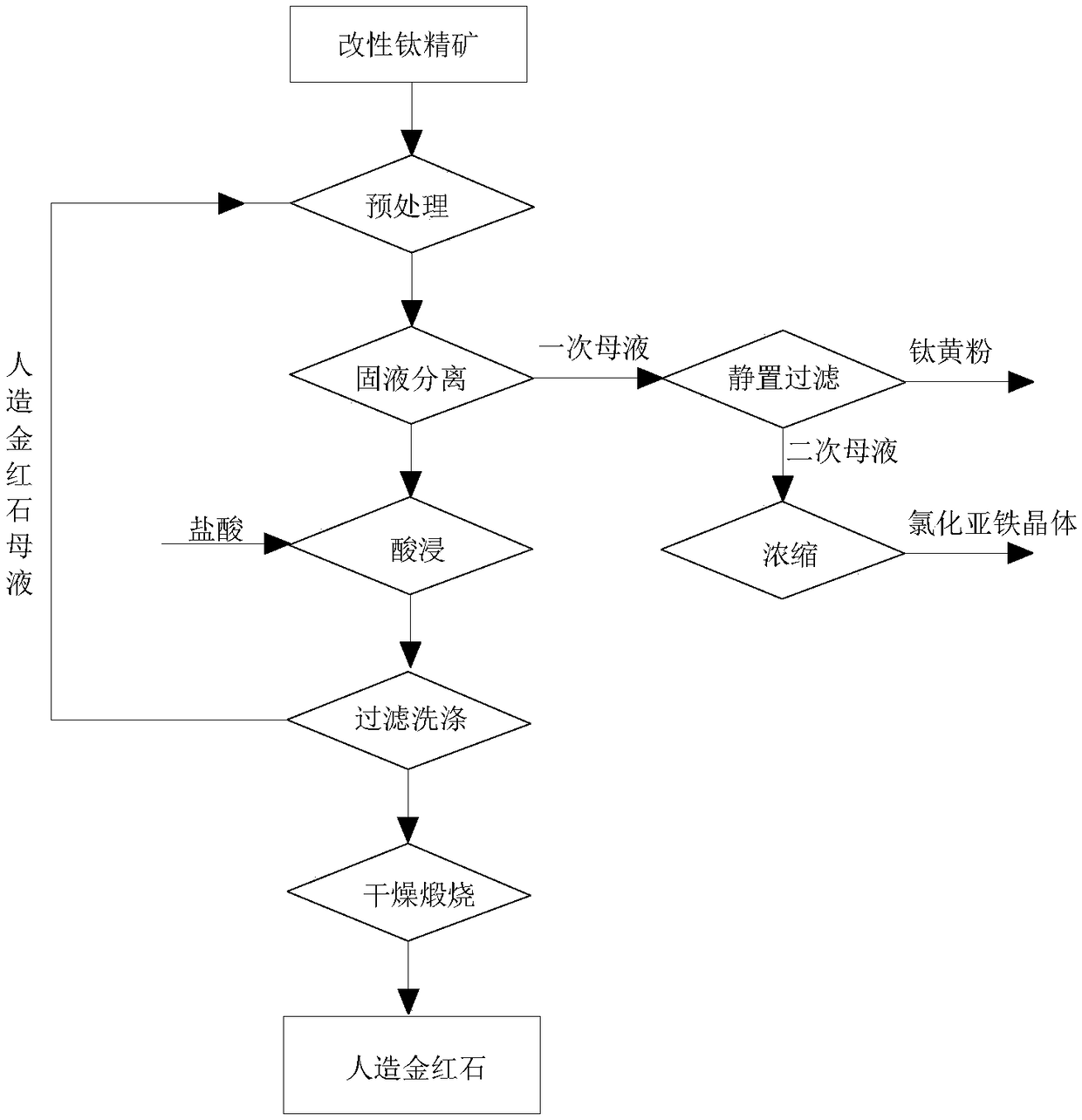

Artificial rutile mother liquor comprehensive resource utilization method

InactiveCN109467123AReduce usageReduce consumptionTitanium dioxideIron halidesResource utilizationIlmenite

The invention discloses an artificial rutile mother liquor comprehensive resource utilization method which comprises the following steps: (1) preprocessing, that is, adding artificial rutile mother liquor into modified ilmenite concentrate before acid leaching to carry out preprocessing, wherein a mass ratio of the modified ilmenite concentrate to the artificial rutile mother liquor is 1: (2 to 5); (2) after preprocessing, carrying out solid-liquid separation to obtain primary mother liquor and preprocessed ilmenite concentrate, enabling the obtained preprocessed ilmenite concentrate to entera subsequent acid leaching process to continuously process, and after performing standing on the obtained primary mother liquor, filtering to obtain titanium yellow powder and secondary mother liquor;and (3) carrying out concentration on the obtained secondary mother liquor, and filtering to obtain ferrous chloride crystals and filtrate. According to the invention, about 10% of residual hydrochloric acid in the artificial rutile mother liquor is sufficiently utilized, energy consumption in the subsequent mother liquor concentration crystallization process is reduced, comprehensive energy consumption can be reduced by 30% or more, and meanwhile, residual TiO2 in the artificial rutile mother liquor is recovered.

Owner:YIBIN TIANYUAN GRP CO LTD

Four-layer coating process of organic photoconductor drum and organic photoconductor drum prepared by adopting same

ActiveCN102998918ASimple preparation processEasy to storeElectrography/magnetographyPolyamide coatingsCharge carrierPhthalocyanine

The invention discloses a four-layer coating process of an organic photosensitive drum and the organic photosensitive drum prepared by adopting the four-layer coating process. The four-layer coating process comprises the following steps of: 1, forming a carrier barrier layer on a drum base of the organic photosensitive drum; 2, forming a carrier barrier layer 2 on the carrier barrier layer 1, a carrier forming layer coating 2 contains titanium dioxide, titanium yellow and nylon; 3, forming a carrier generating layer on the carrier barrier layer 2, wherein the carrier generating layer contains titanyl phthalocyanine and polyvinyl butyral resin with the weight proportion of 1:1-1.5:1; and 4, forming a carrier transmission layer on the carrier generating layer. According to the four-layer coating process, the coating cost can be controlled to be below ** / pcs, and the relatively high production cost pressure of a manufacturer is relieved.

Owner:珠海中凯打印机耗材有限公司

Process for comprehensive utilization of waste acid containing titanium oxide

A process for reclaiming the water acid generated during preparing titanium oxide includes such steps as heating waste acid for hydrolysis to obtain metatitanic acid, returning it to the production line to prepare titanium yellow powder; and wet metallurgy of the filtrate generated by the said hydrolysis and the zinc contained oxide to obtain active zinc oxide, alkaline zinc carbonate, Fe2O3 and Zn-contained ammonium sulfate.

Owner:SICHUAN UNIV

Aluminum titanate ceramic for casting and preparation method thereof

The invention relates to an aluminum titanate ceramic for casting and a preparation method thereof, alpha-Al2O3 and titanium yellow powder are used as raw materials, magnesium carbonate and silicon dioxide are added as stabilizers, the components of the raw materials are as follows: 53-59 wt% of alpha-Al2O3, 37.58-42.72 wt% of titanium yellow powder and 3-6 wt% of the total amount of the stabilizers, and the raw materials are subjected to wet ball milling mixing, granulation, isostatic cool pressing and firing to obtain the aluminum titanate ceramic. The aluminum titanate material is directlyprepared by adopting a one-step method so that the preparation process is simplified, the production cost is greatly saved, the economic benefit is good, and meanwhile, the prepared material is high in mechanical strength and low in thermal expansion coefficient, and can be used for preparing products such as riser tubes and crucibles for casting.

Owner:WUHAN UNIV OF TECH +1

A kind of exterior wall color heat insulation mortar with heat reflection function

The invention provides a color thermal insulation mortar with a heat reflection function for an exterior wall. The color thermal insulation mortar comprises the following components by weight percent: 20-25% of white cement, 4-6% of early strength agent, 2-4% of active admixture, 10-20% of finer filler, 20-40% of light filling, 10-30% of fine sand, 1-3% of pigment and 4-6% of additive, wherein the early strength agent is white amorphous calcium aluminate of which the specific surface area is greater than or equal to 5,000m<2>kg; the light filling is a glass bead, which has a honeycomb mesh structure and of which the particle size is 0.09-0.60mm, the bulk density is 270-400Kg / m<3>, the cylinder compressive strength is greater than 2.0MPa, and the pigment is chromium titanium yellow, nickel titanate yellow, chromite-cobalt blue or ferrochromium black. The color thermal insulation mortar disclosed by the invention not only has the characteristics of being light in weight, strong in strength and low in water absorption rate by adding an inorganic composite pigment burnt at high temperature and the glass bead with a special structure, but also has high near infrared solar reflectance and low coefficient of thermal conductivity. Compared with the common mortar, the color thermal insulation mortar has better insulating and cooling effects, and is especially applicable to decoration of the exterior wall.

Owner:广东龙湖科技股份有限公司

A kind of composite color cake and preparation method thereof

Owner:FOSHAN SHUNDE BAOSITE PIGMENT +1

Irreversible three-color temperature indicating paint based on isotherm identification and coating layer manufacturing method

InactiveCN111849346AAccurate temperature changeAccurately display temperature changesThermosensitive paintsXylyleneTitanium

The invention relates to an irreversible three-color temperature indicating paint based on isotherm identification and a coating manufacturing method. The irreversible three-color temperature indicating paint based on isotherm identification is composed of, by mass, 15.2%-17.2% of zinc titanium yellow, 2.8%-3.2% of antimony tin yellow, 15.5%-16.52% of zirconium dioxide, 0.9%-1.3% of yttria, 29.0%-31.0% of high-temperature organic resin 805, 26.8%-28.8% of xylene and 5.4%-6.4% of n-butyl alcohol. The irreversible three-color temperature indicating paint based on isotherm identification can accurately form an isotherm, so that the temperature distribution condition of the surface of an object can be conveniently and accurately judged.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

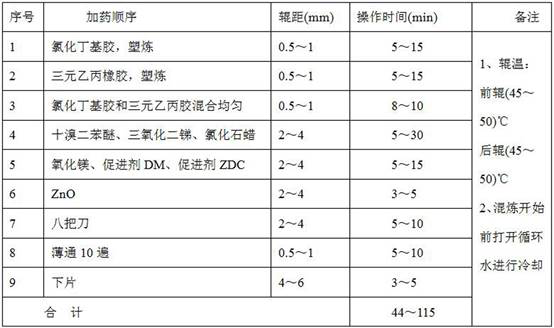

Formula of sizing material for yellow protective clothing and preparation method of sizing material

The invention discloses a formula of a sizing material for a yellow protective clothing and a preparation method of the sizing material. The formula comprises the following components in parts by weight: 75 parts of CIIR, 25 parts of ethylene propylene diene monomer, 8 parts of ZnO, 0.5 part of an accelerant DM, 2 parts of an accelerant ZDC, 0.5-1 part of magnesium oxide, 8-15 parts of chlorinatedparaffin, 30-50 parts of decabromodiphenyl ether, 15 parts of antimonous oxide and 10-15 parts of titanium yellow. According to the formula of the invention, sulfur in the formula is replaced by a ZnO+accelerant vulcanization system, and the ZnO+accelerant vulcanization system can be adjusted, so that a novel formula is developed and invented, the problem of chromatic aberration can be effectively solved, the discoloration phenomenon is eliminated, and good color and appearance of the protective clothing are ensured.

Owner:SHANXI XINHUA CHEM

Manufacture method of ultrahigh wear-resistant nano ceramic coating

The invention discloses a manufacture method of an ultrahigh wear-resistant nano ceramic coating. The method comprises the following steps: A, weighing various raw materials in percentage as follows:20% of silicon dioxide, 30% of methyltrimethoxysilane, 15% of isopropanol, 10% of titanium dioxide, 8% of titanium yellow, 4% of silicon carbide, 5% of polyetheretherketone, 2% of silicone oil and 6%of aluminum oxide; B, grinding: putting the isopropanol, the titanium dioxide, the titanium yellow, the silicon carbide, the polyetheretherketone, the aluminum oxide and the silicone oil in a grindingmiller so as to be ground at a high speed for 4 hours; C, curing: mixing and curing the silicon dioxide and the methyltrimethoxysilane for 24 hours, then mixing together with raw materials ground instep B by using a blender; and D, coating a smooth aluminum plate subjected to sanding treatment with liquid which is mixed in step C by using an air spraying mode, and then roasting for 10 minutes at280 DEG C. The manufacture method is simple in process, the manufacture is convenient, and the manufactured coating is good in wear resistance.

Owner:清远市伟畅达化工有限公司

Toilet cover with drainage function and preparation method thereof

The invention discloses a toilet cover with a drainage function, and relates to the toilet cover. The toilet cover comprises polypropylene A, polypropylene B, polypropylene C, a flame retardant, a newwater agent, talcum powder, an antioxidant, titanium dioxide, black powder, titanium yellow and iron brown, has a certain drainage effect, can effectively prevent the toilet cover from being contaminated by stains or dirt during the actual use and ensure the toilet cover to be clean, and further can bring beauty and provides a lot of convenience to a user.

Owner:SHENZHEN HUA WAN CAI IND

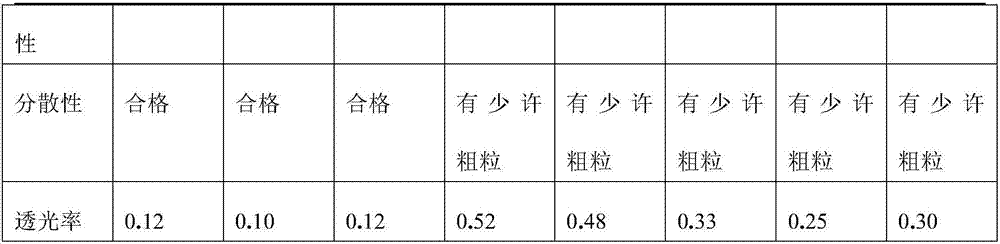

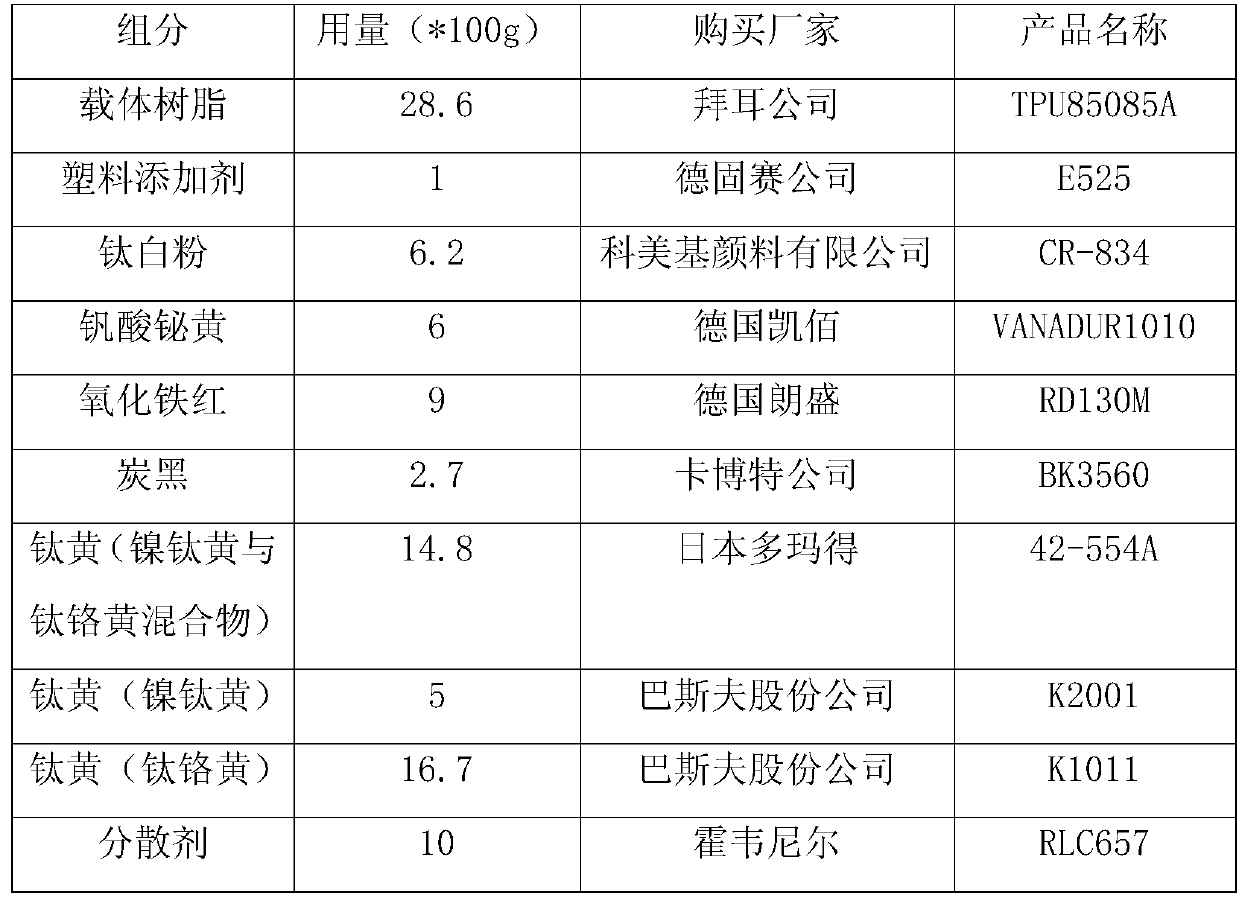

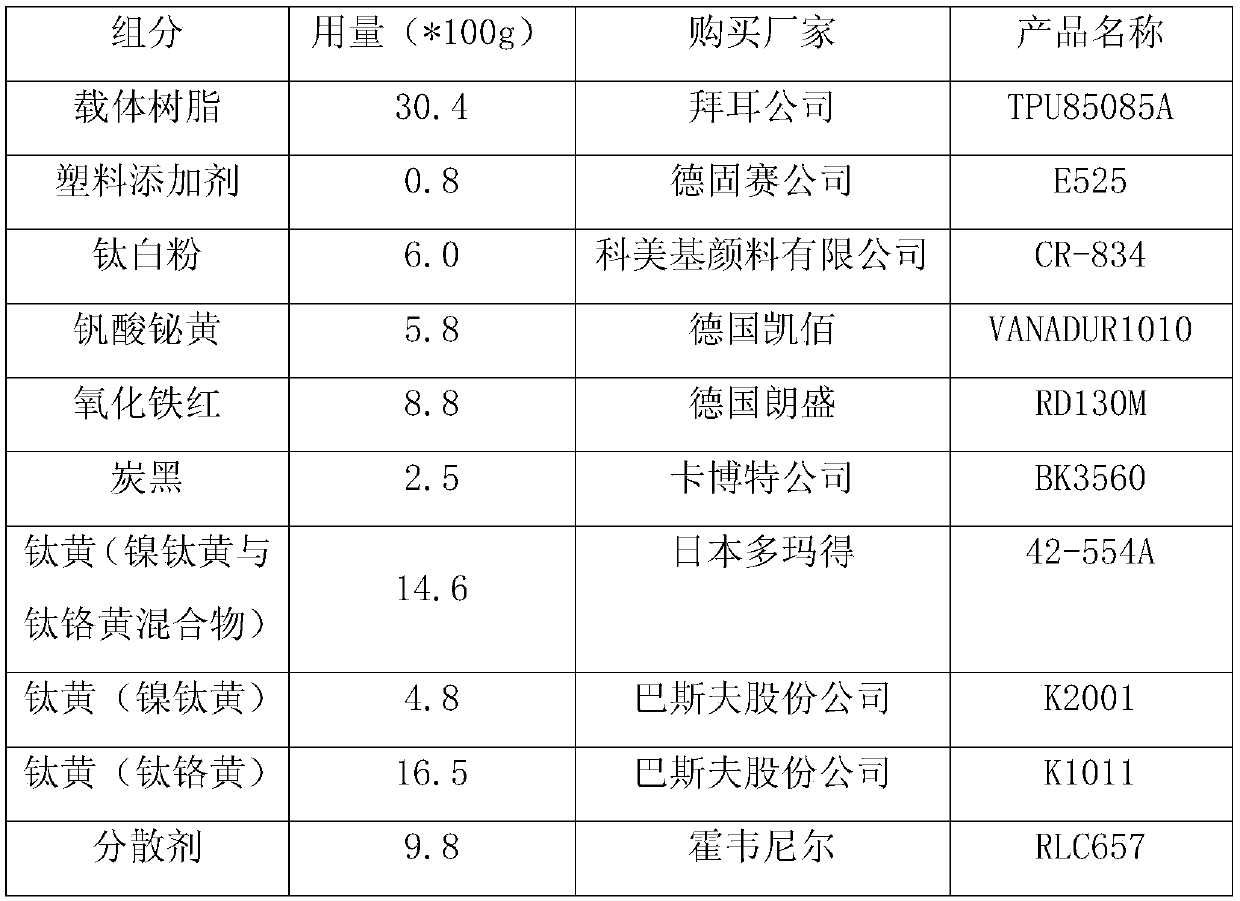

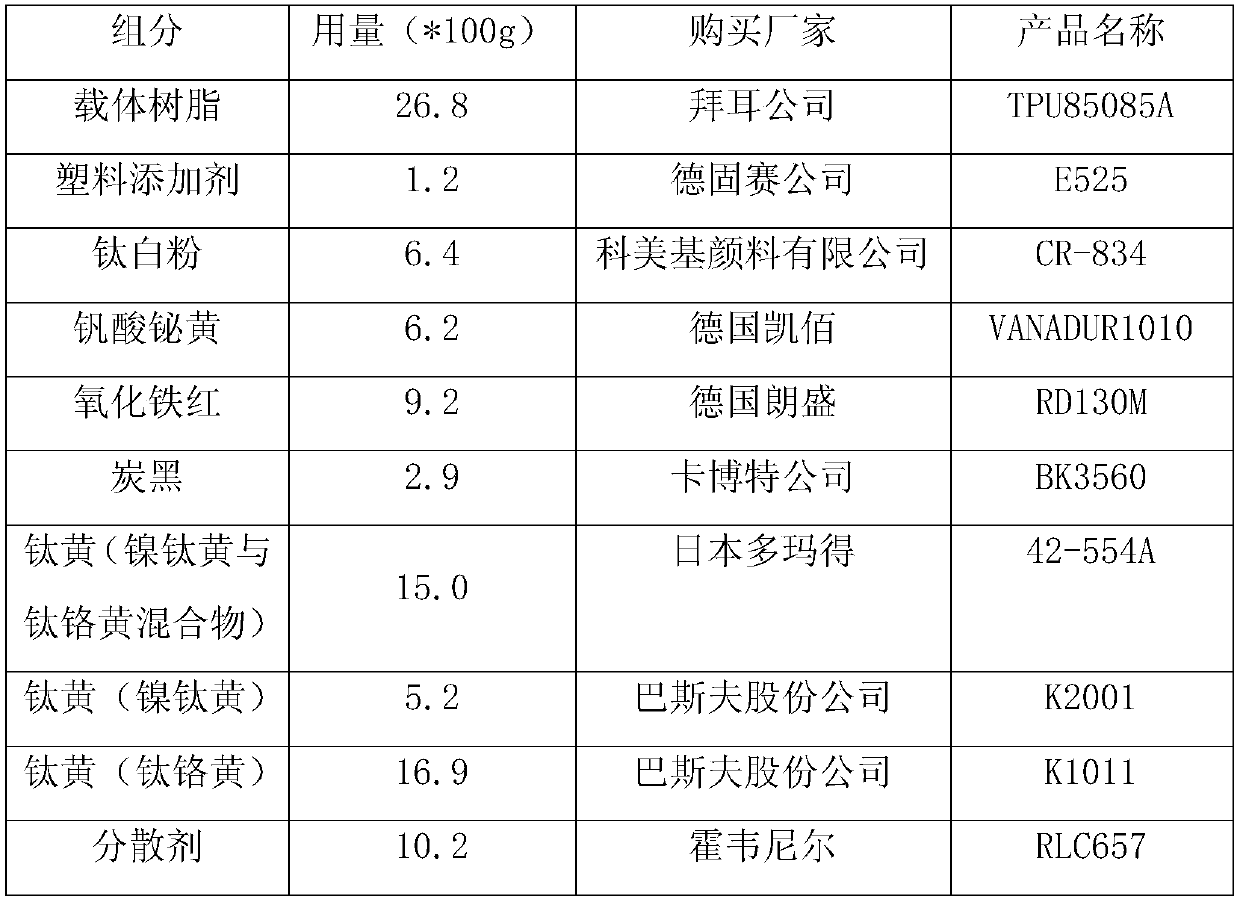

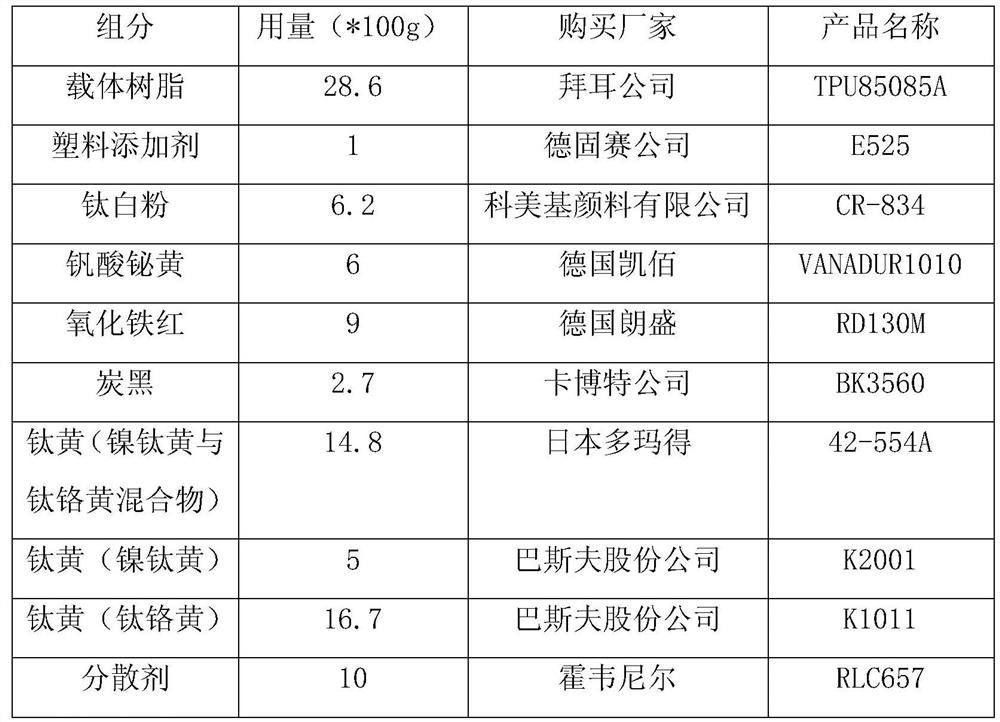

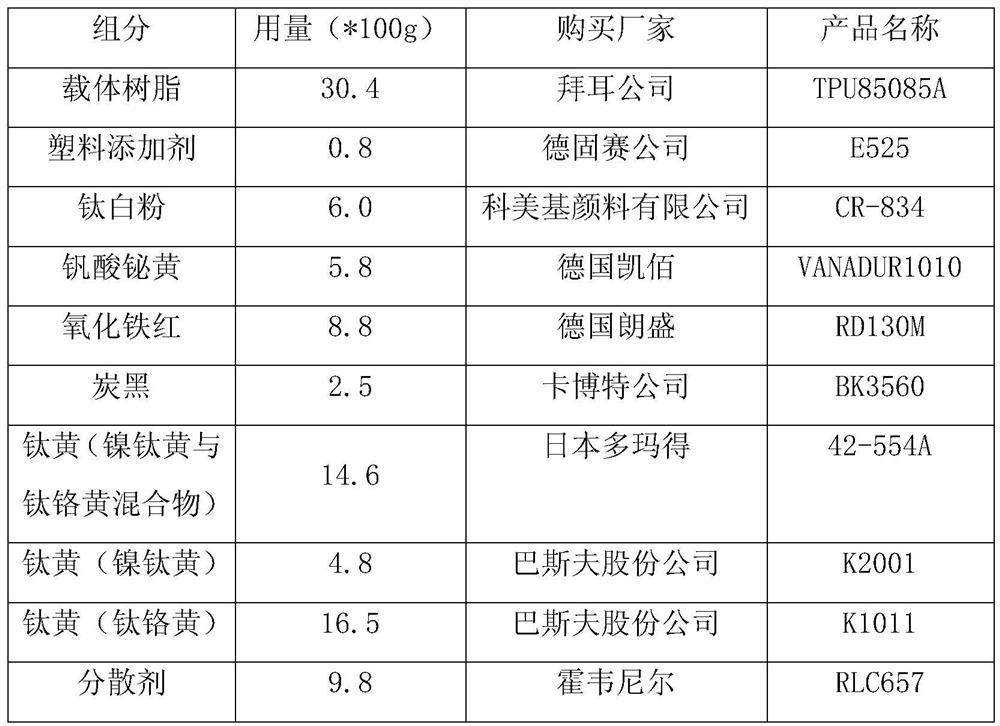

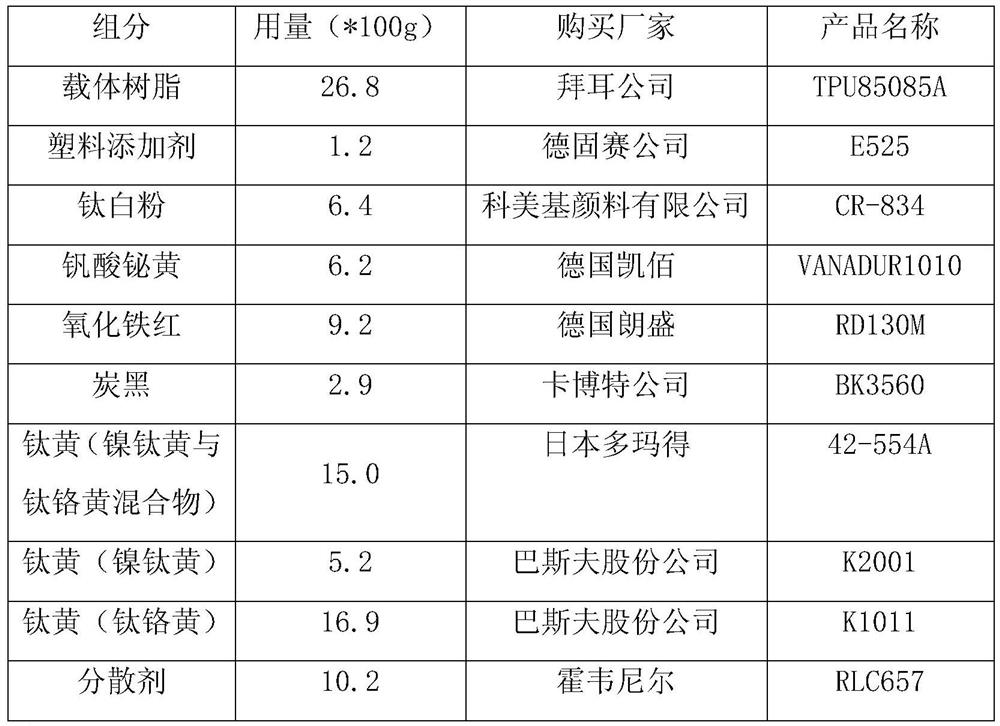

Brown master batch and preparation process thereof

The invention discloses brown master batch, which comprises the following components in parts by weight: 26.8-30.4 parts of carrier resins, 0.8-1.2 parts of plastic additives, 9.8-10.2 parts of dispersants, 6.0-6.4 parts of titanium dioxide, 8.8-9.2 parts of iron oxide red, 5.8-6.2 parts of bismuth vanadate yellow, 35.9-37.1 parts of titanium yellow and 2.5-2.9 parts of carbon black. The brown master batch is safe and environment-friendly, the color of the product prepared by adding the brown master batch to the plastic is completely consistent with that of the target sample under different light source conditions, and thus the problem of metamerism between the product and the target sample is effectively solved; 99% of the color developing substances in the brown master batch adopt inorganic toner, compared with organic toner, the inorganic toner has higher light resistance, light resistance and corrosion resistance, and has obvious advantages in the automobile industry.

Owner:上海晋升塑料科技有限公司

Clean production method of titanium dioxide and titanium yellow powder

ActiveCN106830070ASolve outputSolve the pollution of the environmentPigmenting treatmentTitanium dioxideFiltrationResource utilization

The invention belongs to the technical field of titanium product production, particularly relates to a clean production method of titanium dioxide and titanium yellow powder, and aims to solve the problems that an existing titanium yellow powder production method generates a large amount of waste gas and waste water, is low in resource utilization rate, pollutes environments, and the like. The cleaning production method includes: mechanically activating fine titanium powder, performing normal-pressure acid hydrolysis, performing thermal filtration and extraction, performing titanium liquid hydrolysis, washing, drying, calcining to prepare the titanium yellow powder, performing pressurized acid leaching to prepare the titanium dioxide, and the like. The clean production method has the advantages that a titanium yellow powder production process, a titanium dioxide production process, a hydrochloric acid concentration process and the like are combined effectively, production waste acid can be recycled basically, the discharge of the waste gas, the waste water and industrial residues is reduced, and production cost and energy consumption are reduced; industrial production of the titanium yellow powder and the titanium oxide can be achieved by the method, and the method is environmentally friendly, capable of saving energy and reducing consumption, capable of saving production cost and good in economic benefits.

Owner:攀枝花中达钛业科技有限公司

A kind of brown masterbatch and preparation technology thereof

The invention discloses a brown masterbatch, which comprises the following components in parts by weight: 26.8-30.4 parts of carrier resin, 0.8-1.2 parts of plastic additive, 9.8-10.2 parts of dispersant, 6.0-6.4 parts of titanium dioxide, and red iron oxide 8.8-9.2 parts, bismuth vanadate yellow 5.8-6.2 parts, titanium yellow 35.9-37.1 parts, carbon black 2.5-2.9 parts. The brown masterbatch prepared by the present invention is safe and environmentally friendly. The color of the product obtained by adding the brown masterbatch to the plastic is completely consistent with the color of the target sample under different light source conditions, which effectively solves the problem between the product and the target sample. For the problem of metamerism, 99% by weight of the chromogenic substance in the present invention adopts inorganic toner, which has higher light fastness, light fastness and corrosion resistance compared with organic toner, and is used in automobiles. The industry has obvious advantages.

Owner:上海晋升塑料科技有限公司

Three-layer coating process and photosensitive drum prepared by adopting same

InactiveCN102998917BSimple preparation processEasy to storeElectrography/magnetographyPolyamide coatingsMass ratioPhthalocyanine

The invention discloses a three-layer coating process and a photosensitive drum prepared by adopting the three-layer coating process. The three-layer coating process comprises the following steps of: 1, coating a carrier barrier layer coating on a drum base to form a carrier barrier layer, wherein the carrier barrier layer coating contains titanium dioxide, titanium yellow and nylon rein, the mass ratio of the titanium dioxide to the titanium yellow is 1:1-2:1, the mass ratio of the TiO2 to the nylon resin is 1:1-2:1; 2, coating a carrier forming layer coating on the carrier barrier layer to form a carrier forming layer, the carrier forming layer coating contains titanyl phthalocyanine and polyvinyl butyral resin with a proportion of 1:1-1.5:1; and 3, coating a carrier transmission layer coating on the carrier forming layer to form a carrier transmission layer. The three-layer coating process can ensure that a coating material for coating an organic photosensitive drum has good photoelectric property and a coating solution is stable without crystallizing; and the photosensitive drum has the characteristics of high black degree, high wear resistance and low cost.

Owner:珠海惠尔美打印耗材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com