Artificial rutile mother liquor comprehensive resource utilization method

An artificial rutile and comprehensive resource technology, applied in the direction of iron halide, titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of increasing processing costs, increasing production costs, and low iron ion concentration, so as to reduce energy consumption and reduce comprehensive The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

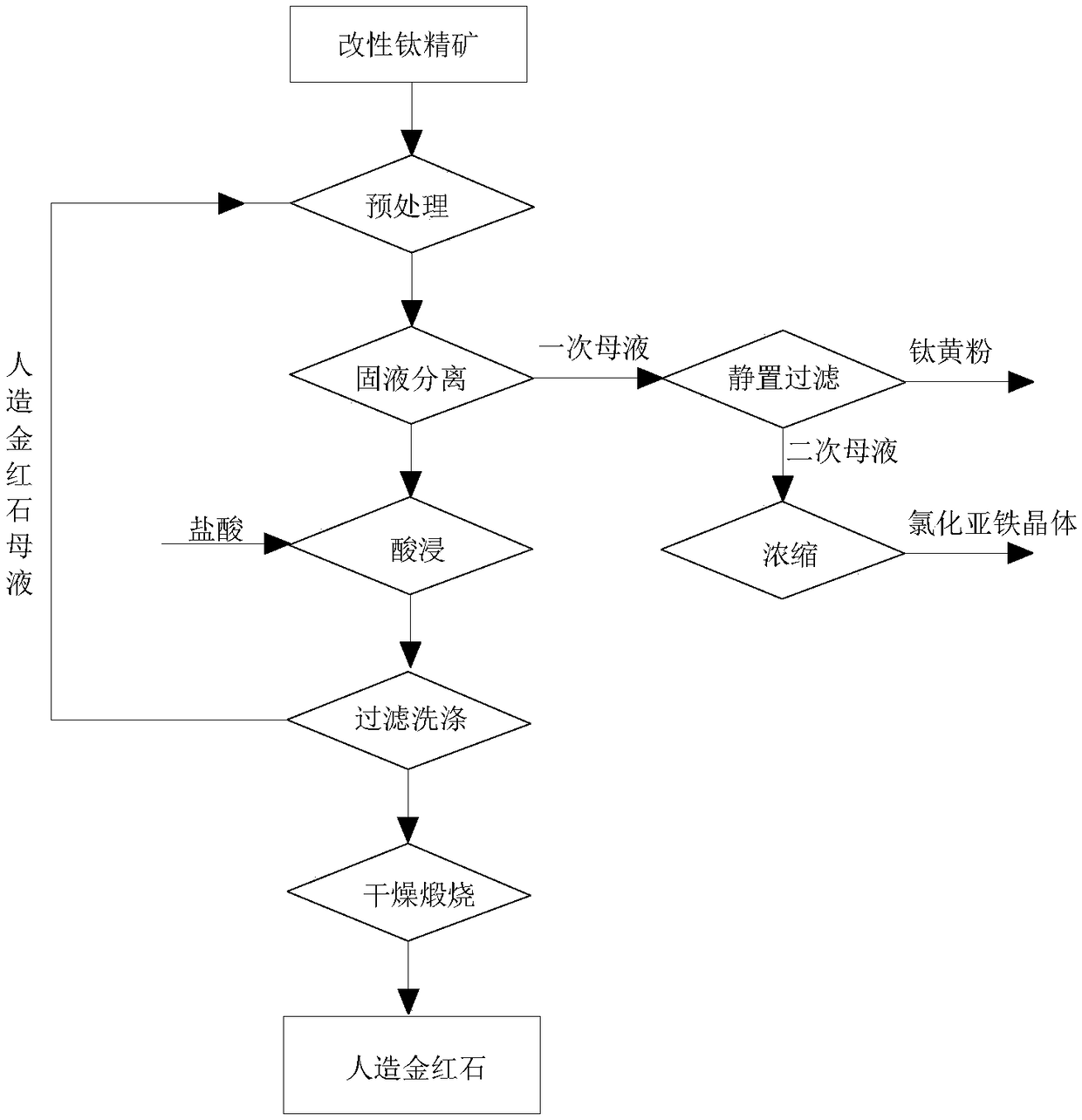

[0030] The main component is TiO 2 : 48.17%, SiO 2 : 2.16%, CaO: 0.23%, MgO: 0.77% titanium concentrates were redox modified in a fluidized furnace to obtain modified titanium concentrates; 300g modified titanium concentrates were weighed, and the Next, artificial rutile mother liquor was added for pretreatment, the mass ratio of modified titanium concentrate and artificial rutile mother liquor was 1:3, the leaching reaction temperature was 90°C, the leaching reaction time was 6h, and the stirring speed during the reaction was 50r / min;

[0031] After the reaction, the solid-liquid separation was carried out to obtain the primary mother liquor and the pretreated titanium concentrate. The primary mother liquor was allowed to stand for 6 hours, and then filtered. After the obtained filter cake was dried, 8.8 g of titanium yellow powder was obtained; the secondary mother liquor obtained by filtration was detected, and the second FeCl in secondary mother liquor 2 +FeCl 3 The m...

Embodiment 2

[0035] The main component is TiO 2 : 48.17%, SiO 2 : 2.16%, CaO: 0.23%, MgO: 0.77% ilmenite concentrates were redox modified in a fluidized furnace to obtain modified ilmenite concentrates; 300g of modified ilmenite concentrates were weighed, and the Next, artificial rutile mother liquor was added for pretreatment, the mass ratio of modified titanium concentrate and artificial rutile mother liquor was 1:2, the leaching reaction temperature was 80°C, the leaching reaction time was 9h, and the stirring speed during the reaction was 80r / min;

[0036] After the reaction, the solid-liquid separation was carried out to obtain the primary mother liquor and the pretreated titanium concentrate. The primary mother liquor was allowed to stand for 5 hours, and then filtered. After the obtained filter cake was dried, 9.6 g of titanium yellow powder was obtained; the secondary mother liquor obtained by filtration was detected. FeCl in secondary mother liquor 2 +FeCl 3 The mass concentr...

Embodiment 3

[0040] The main component is TiO 2 : 48.17%, SiO 2 : 2.16%, CaO: 0.23%, MgO: 0.77% ilmenite concentrates were redox modified in a fluidized furnace to obtain modified ilmenite concentrates; 300g of modified ilmenite concentrates were weighed, and the Next, artificial rutile mother liquor is added for pretreatment, the mass ratio of modified titanium concentrate and artificial rutile mother liquor is 1:5, the leaching reaction temperature is 110°C, the leaching reaction time is 4h, and the stirring speed during the reaction is 50r / min;

[0041] After the reaction, the solid-liquid separation was carried out to obtain the primary mother liquor and the pretreated titanium concentrate. The primary mother liquor was allowed to stand for 9 hours, and then filtered, and the obtained filter cake was dried to obtain 9.2 g of titanium yellow powder; the secondary mother liquor obtained by filtration was detected, and the second FeCl in secondary mother liquor 2 +FeCl 3 The mass con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com