Coloring masterbatch for PPR tube and preparation method of coloring masterbatch

A coloring masterbatch and raw material technology, which is applied in the field of PPR pipe coloring masterbatch and its preparation, can solve the problems of PPR pipes such as poor shading, easy color change inner surface, poor dispersion, etc., and achieve excellent thermal stability, resistance Strong foaming and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

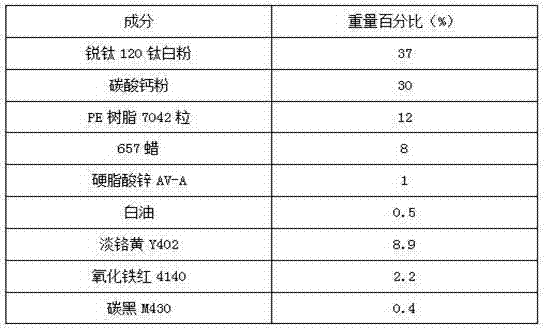

Image

Examples

Embodiment 1

[0047] A kind of coloring masterbatch for PPR pipe, including raw materials of following weight: rutile titanium dioxide 50kg, PPR resin 40kg, iron red 8kg, titanium yellow 1kg, carbon black 0.5kg, polyorganosiloxane 0.5kg; wherein rutile titanium dioxide Choose titanium dioxide with an average particle size of 0.2 μm and a refractive index of 2.7, which has strong hiding power, strong ultraviolet absorption ability, and can withstand a temperature of 300°C; the selected carbon black is pigment carbon black produced by the tank method, and its average particle size is The diameter is 10nm.

[0048] The equipment used to select rutile titanium dioxide is JL-1177 laser particle size distribution analyzer and refractometer, and select rutile titanium dioxide that meets the requirements.

[0049] The moisture content of the coloring masterbatch prepared in this embodiment is 0.04%.

Embodiment 2

[0051] A coloring masterbatch for PPR pipes, comprising the following raw materials: 65 kg of rutile titanium dioxide, 38 kg of PPR resin, 3.9 kg of iron red, 1.5 kg of titanium yellow, 0.1 kg of carbon black, and 1.5 kg of polyorganosiloxane; wherein rutile titanium The white powder chooses titanium dioxide with an average particle size of 0.25 μm and a refractive index of 2.7, which has strong hiding power, strong ultraviolet absorption ability, and can withstand a temperature of 300 ° C; the selected carbon black is pigment carbon black produced by the tank method, and its average The particle size is 27nm.

[0052] The equipment used to select rutile titanium dioxide is JL-1177 laser particle size distribution analyzer and refractometer, and select rutile titanium dioxide that meets the requirements.

[0053] In this example, the PPR resin is PPR4220 produced by Yanshan Chemical Plant, which has a low melting temperature below 146°C, high static compressive strength, and g...

Embodiment 3

[0062] A coloring masterbatch for PPR pipes, including the following raw materials: 55 kg of rutile titanium dioxide, 33 kg of PPR resin, 9 kg of iron red, 1.2 kg of titanium yellow, 0.8 kg of carbon black, and 1 kg of polyorganosiloxane; wherein the rutile titanium dioxide is selected Titanium dioxide with an average particle size of 0.22 μm and a refractive index of 2.7 has strong hiding power, strong ultraviolet absorption ability, and can withstand a temperature of 300°C; the selected carbon black is pigment carbon black produced by the tank method, and its average particle size is 20nm.

[0063] The equipment used to select rutile titanium dioxide is JL-1177 laser particle size distribution analyzer and refractometer, and select rutile titanium dioxide that meets the requirements.

[0064] In this embodiment, the PPR resin is PPR4220 produced by Yanshan Chemical Factory.

[0065] In this embodiment, the volatilization of small molecules of iron red, titanium yellow and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com