High temperature and amine resistant PVC artificial leather and preparation method thereof

A technology of artificial leather and high temperature resistance, applied in textiles and papermaking, etc., can solve the problems of poor amine resistance stability, poor amine resistance performance, poor high temperature resistance performance, etc., and achieve the effect of excellent amine resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The first step: Weigh the raw materials according to the ratio of various materials in the formula. The ratio of PVC to plasticizer is 100:80-100, and then mix the raw materials evenly, including: 55 parts of PVC resin, 45 parts of plasticizer, 11 parts of solid stabilizer, 1 part of colorant; coating water-based paint on the surface of the base layer, the formula of the water-based paint includes: 85 parts of water-based polyurethane modified resin, 15 parts of auxiliary agent. The total amount of the above-mentioned water-based paint is coated on the surface of the above-mentioned base layer.

[0041] The mixing process is: confirm the weight of the slurry → convert the amount of white paste and color paste in the formula, input it into the computer → add plasticizer to the mixing tank → add stabilizer and other additives to the mixing tank → add PVC powder to the mixing tank → Stir at low speed → Stir at high speed → Vacuumize for 20 minutes → Pump back for 5 minutes...

Embodiment 2

[0048] The first step: Weigh the raw materials according to the ratio of various materials in the formula. The ratio of PVC to plasticizer is 100:80-100, and then mix the raw materials evenly, 50 parts of PVC resin, 50 parts of plasticizer, 13 parts stabilizer, 5 parts of colorants; the surface of the base layer is coated with water-based paint, and the formula of the water-based paint includes: 90 parts of water-based polyurethane modified resins, and 10 parts of auxiliary agents. The total amount of the above-mentioned water-based paint is coated on the surface of the above-mentioned base layer.

[0049] The mixing process is: confirm the weight of the slurry → convert the amount of white paste and color paste in the formula, input it into the computer → add plasticizer to the mixing tank → add stabilizer and other additives to the mixing tank → add PVC powder to the mixing tank → Stir at low speed → Stir at high speed → Vacuumize for 20 minutes → Pump back for 5 minutes → V...

Embodiment 3

[0056] The first step: Weigh the raw materials according to the ratio of various materials in the formula. The ratio of PVC to plasticizer is 100:80-100, and then mix the raw materials evenly, 70 parts of PVC resin, 30 parts of plasticizer, 18 parts stabilizer, 7 parts of colorants; the surface of the base layer is coated with water-based paint, and the formula of the water-based paint includes: 88 parts of water-based polyurethane modified resins, 12 parts of auxiliary agents. The total amount of the above-mentioned water-based paint is coated on the surface of the above-mentioned base layer.

[0057] The mixing process is: confirm the weight of the slurry → convert the amount of white paste and color paste in the formula, input it into the computer → add plasticizer to the mixing tank → add stabilizer and other additives to the mixing tank → add PVC powder to the mixing tank → Stir at low speed → Stir at high speed → Vacuumize for 20 minutes → Pump back for 5 minutes → Vacuu...

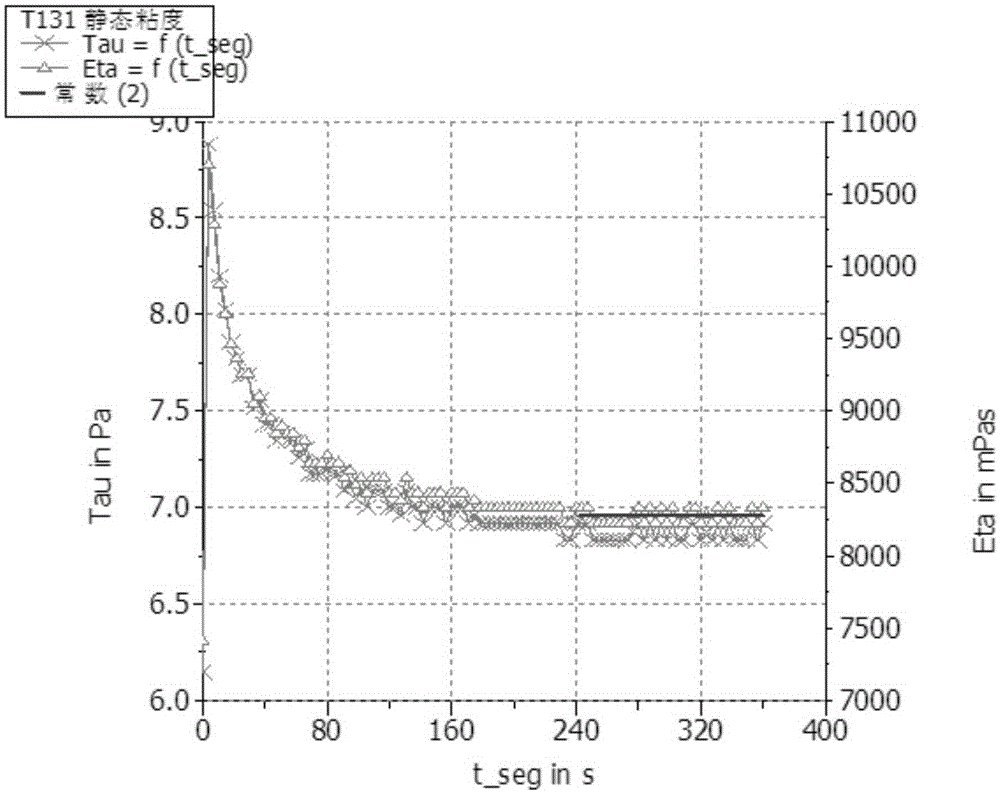

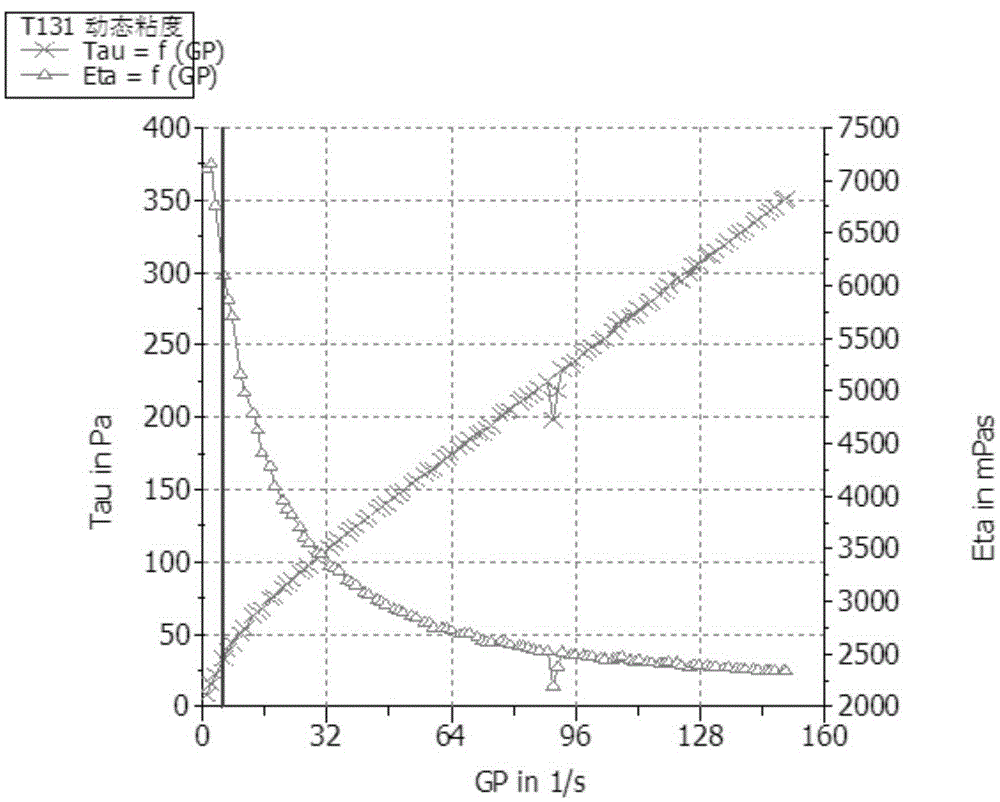

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com