Preparation method of bi-color or multi-color extruded PTFE (Polytetrafluoroethylene) insulated wire

A technology of PTFE and insulated wires, which is applied in the manufacture of cables/conductors, electrical components, circuits, etc. It can solve the problems of easily damaged marks, insufficient temperature resistance of insulated wires, and poor firmness of digital marks, etc., so as to save costs and improve The effect of temperature resistance class

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

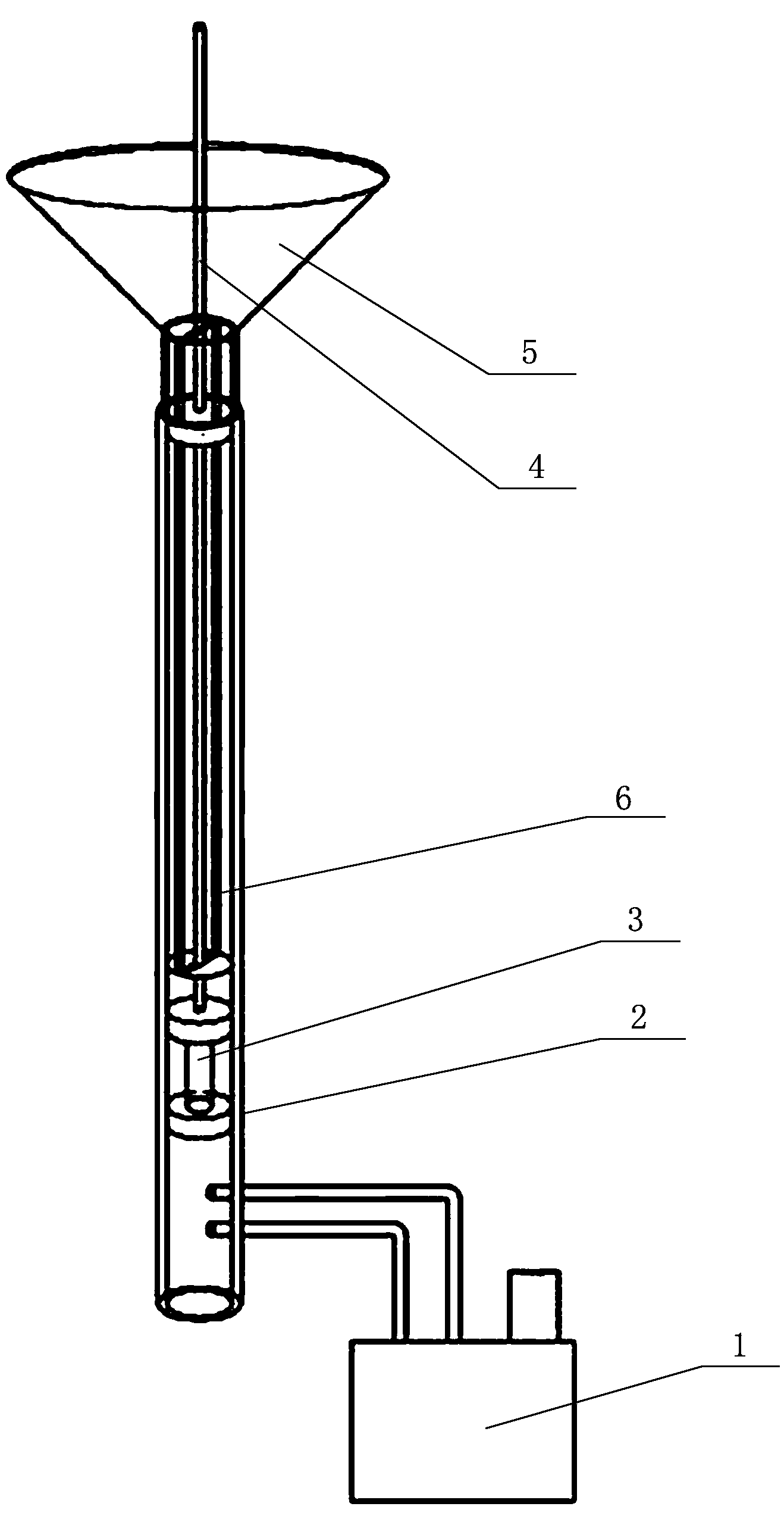

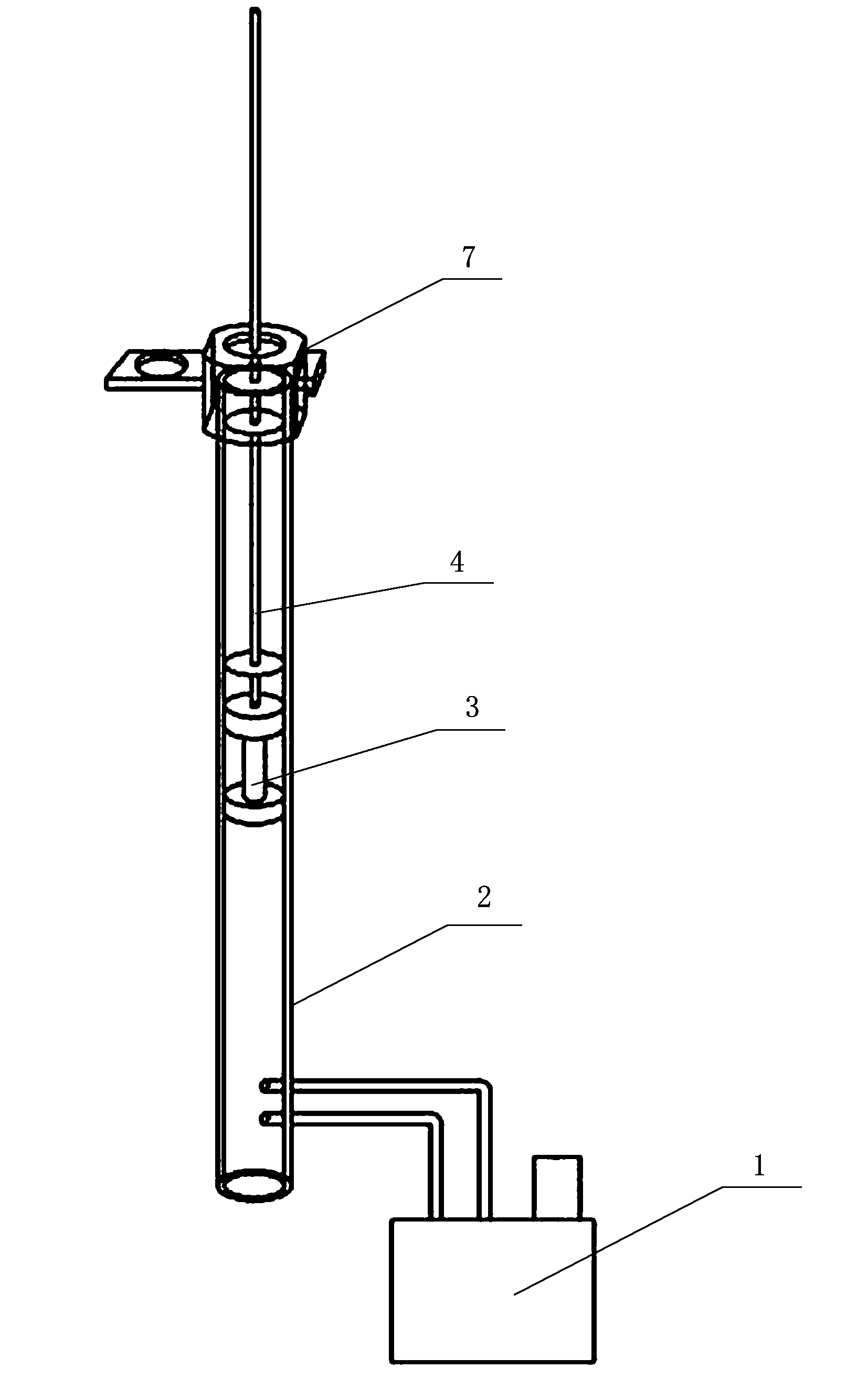

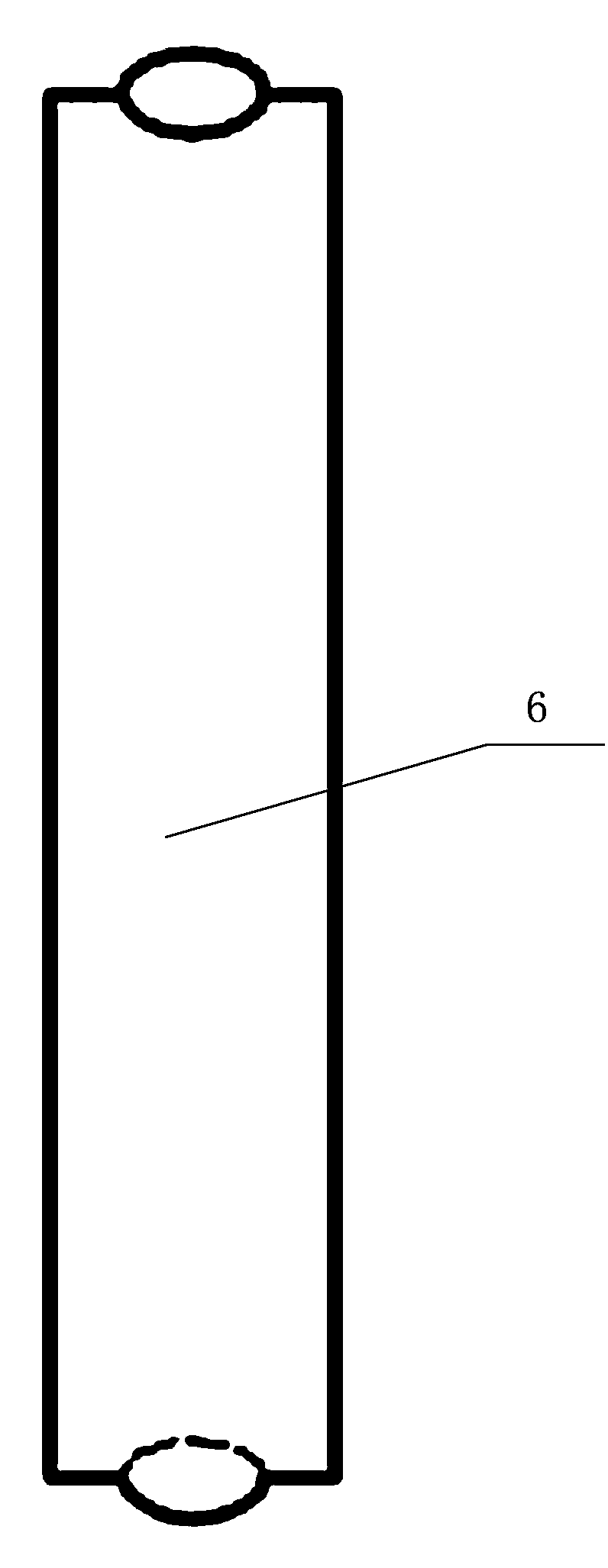

[0022] Such as figure 1 , 2 Shown in and 3, a kind of two-color or multi-color extruded PTFE insulated wire preparation method of the present invention adds raw material, and described raw material comprises conductor and base material, and described conductor is the silver-plated copper wire of stranded, and described base The material is made by mixing PTFE, petroleum ether solvent and two kinds of water-based pigments. The base material is cut into stainless steel sheets by pre-pressing molding equipment, and 1500g of PTFE, 250g of petroleum ether solvent and 30g of blue water-based pigment are added to one side , add 1500g of PTFE, 250g of petroleum ether solvent and 30g of yellow water-based pigment to the other side, press it into a two-color preform, and slowly push the preform into the PTFE horizontal pushing host equipment through the preform sleeve, through the traction The two-color base material is coated on the surface of the conductor to form a two-color PTFE in...

Embodiment 2

[0026] Such as figure 1 , 2Shown in and 4, a kind of two-color or multi-color extruded PTFE insulated wire preparation method of the present invention adds raw material, and described raw material comprises conductor and base material, and described conductor is the silver-plated copper wire of stranding, and described base The material is made by mixing PTFE, petroleum ether solvent and two kinds of water-based pigments. The base material is cut into stainless steel sheets by pre-pressing molding equipment, and 1000g of PTFE, 150g of petroleum ether solvent and 20g of blue water-based pigment are added to one side , add 1000g of PTFE, 150g of petroleum ether solvent and 20g of yellow water-based pigment to one side, add 1000g of PTFE, 150g of petroleum ether solvent and 20g of red water-based pigment to one side, press into a three-color preform, pass through the preform The sleeve slowly pushes the preform into the PTFE horizontal pushing host equipment, and wraps the three...

Embodiment 3

[0029] Such as figure 1 , 2 Shown in and 5, a kind of two-color or multi-color extruded PTFE insulated wire preparation method of the present invention adds raw material, and described raw material comprises conductor and base material, and described conductor is the silver-plated copper wire of stranded, and described base The material is made by mixing PTFE, petroleum ether solvent and two kinds of water-based pigments. The base material is cut into stainless steel sheets by pre-pressing molding equipment, and 800g of PTFE, 100g of petroleum ether solvent and 15g of blue water-based pigment are added to one side , add 800g of PTFE, 100g of petroleum ether solvent and 15g of yellow water-based pigment on one side, add 800g of PTFE, 100g of petroleum ether solvent and 15g of red water-based pigment on one side, add 800g of PTFE and 100g of petroleum ether on one side Solvent and 15g of green water-based pigment are pressed into four-color preforms, and the preforms are slowly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com