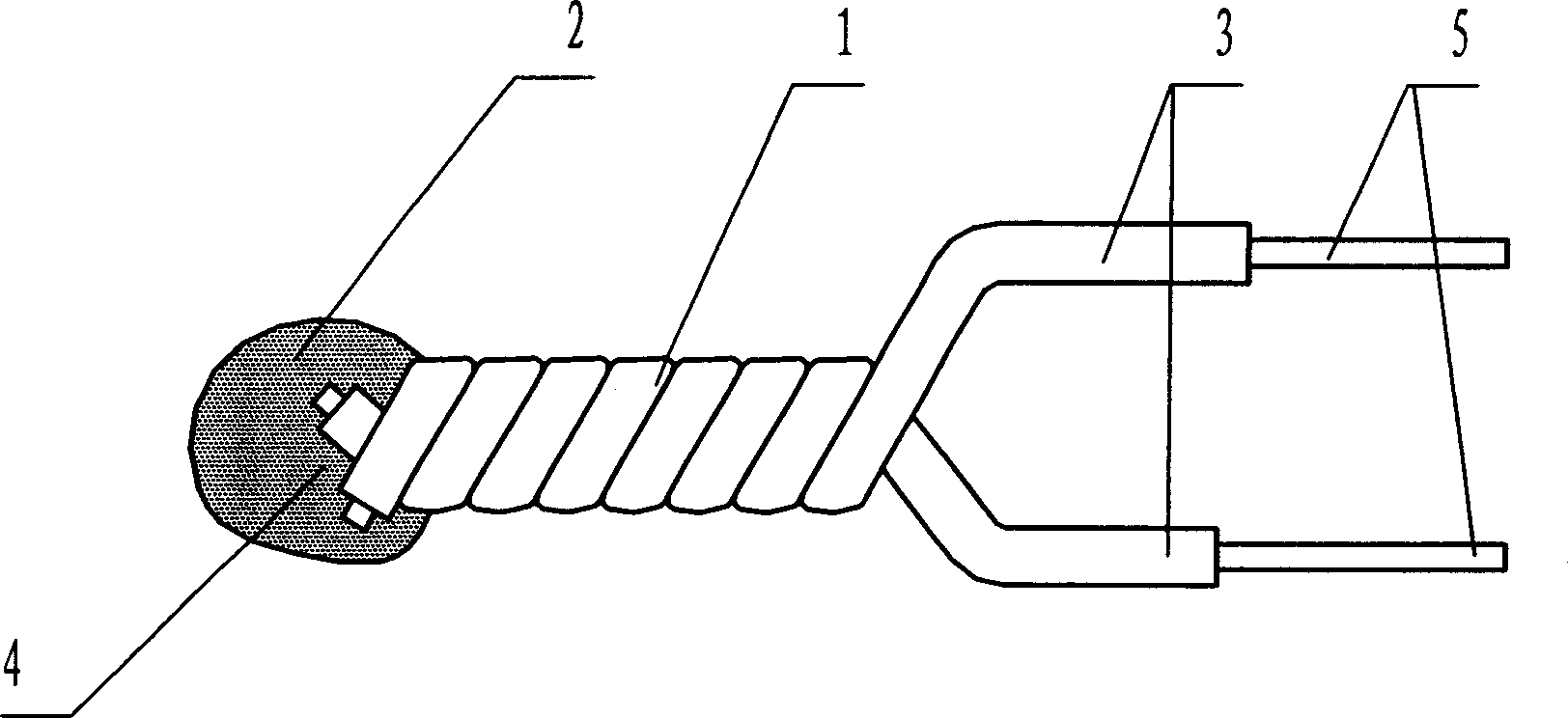

Bridgeless ignitior

A technology of ignition head and ignition wire, applied in the direction of combustion ignition, ignition by electric spark, combustion method, etc., can solve the problems of low ignition reliability, low ignition rate, low reliability, etc., and achieve excellent thermal stability and mechanical Wear-resistant electrical insulation performance, good mechanical wear resistance, moderate electrostatic sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

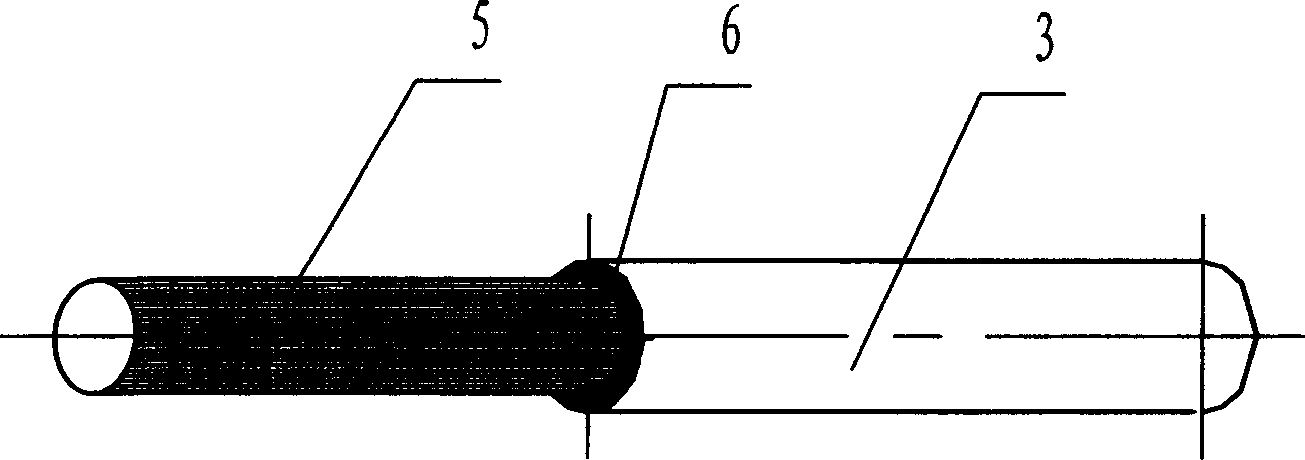

[0016] Nickel-plated copper wire is used as the conductor, and polytetrafluoroethylene with a thickness of 0.1mm is used as the insulating layer. The ignition bridge head adopts the ignition powder formula based on lead styphate, and the specific mass percentage formula is: lead styphate 50%, barium nitrate 48%, magnesium powder and aluminum powder combined total 2%.

[0017] The distance between the poles of the two wires of the ignition head is 1 mm; 100 rounds each at a low temperature of -40°C, a normal temperature of +23°C and a high temperature of +80°C, all of which were ignited normally with piezoelectric ceramics. 100 rounds were placed at high temperature +100°C for 2 hours and then dropped to normal temperature, all of which were ignited normally when triggered by piezoelectric ceramics.

Embodiment 2

[0019] Tinned copper wire is used as the conductor, and polyfluoroethylene propylene with a thickness of 0.0.5mm is used as the insulating layer. The ignition bridge head adopts the ignition powder formula based on lead styphate, and the specific mass percentage formula is: 75% lead styphate, Sodium perchlorate 23%, magnesium powder, aluminum powder and sulfur powder combined total 2%.

[0020] The pole distance between the two wires of the ignition head is 1.5mm; 100 rounds each at a low temperature of -40°C, a normal temperature of +23°C and a high temperature of +80°C, all of which are ignited normally with piezoelectric ceramics. 100 rounds were placed at high temperature +100°C for 2 hours and then dropped to normal temperature, all of which were ignited normally when triggered by piezoelectric ceramics.

Embodiment 3

[0022] Silver-plated copper wire is used as the conductor, and polyperfluoroethylene propylene with a thickness of 0.2mm is used as the insulating layer. The ignition bridge head adopts the ignition powder formula based on lead styphate, and the specific mass percentage formula is: lead styphate and azide The eutectic of lead chloride is 35%, the total of magnesium nitrate and sodium chlorate is 63%, and the combination of titanium powder, aluminum powder and sulfur powder is 2%.

[0023] The pole distance between the two wires of the ignition head is 2 mm; 100 rounds each at low temperature -40°C, normal temperature +23°C and high temperature +80°C, all of which are ignited normally with piezoelectric ceramics. 100 rounds were placed at high temperature +100°C for 2 hours and then dropped to normal temperature, all of which were ignited normally when triggered by piezoelectric ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com