Formula of sizing material for yellow protective clothing and preparation method of sizing material

A technology of rubber formula and protective clothing, which is applied in the field of protective clothing materials, can solve problems such as color difference, and achieve the effect of uniform color, stable performance, and not easily affected by ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A sizing formula for yellow protective clothing, comprising parts by weight of the following components:

[0043] 75 parts of CIIR, 25 parts of EPDM rubber, 8 parts of ZnO, 0.5 parts of accelerator DM, 2 parts of accelerator ZDC, 1 part of magnesium oxide, 10 parts of chlorinated paraffin (70%), 35 parts of decabromodiphenyl ether , 15 parts of antimony trioxide, 12 parts of titanium yellow.

[0044] The preparation method of the sizing material of the above-mentioned yellow protective clothing is as follows:

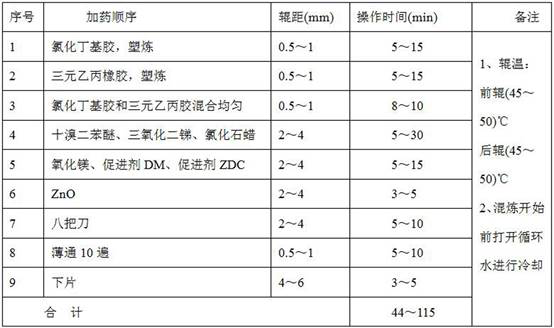

[0045] (1) Mixing process

[0046] The process is: CIIR and EPDM rubber (5min) → chlorinated paraffin, decabromodiphenyl ether, antimony trioxide, titanium yellow (15min) → magnesium oxide, accelerator DM, accelerator ZDC (5min) → ZnO (3min) → unloading, the specific operation is as follows:

[0047] a. The mixing of rubber materials is carried out with a Ф400mm open mill, start the equipment, and turn on the cooling circulating water;

[0048] b. Adjust the ...

Embodiment 2

[0063] A sizing formula for yellow protective clothing, comprising parts by weight of the following components:

[0064] 75 parts of CIIR, 25 parts of EPDM rubber, 8 parts of ZnO, 0.5 parts of accelerator DM, 2 parts of accelerator ZDC, 0.5 parts of magnesium oxide, 10 parts of chlorinated paraffin (70%), 50 parts of decabromodiphenyl ether , 15 parts of antimony trioxide, 15 parts of titanium yellow.

[0065] The preparation method of the sizing material of the above-mentioned yellow protective clothing is as follows:

[0066] (1) Mixing process

[0067] The process is: CIIR and EPDM rubber (10min) → chlorinated paraffin, decabromodiphenyl ether, antimony trioxide, titanium yellow (10min) → magnesium oxide, accelerator DM, accelerator ZDC (10min) → ZnO (5min) → unloading, the specific operation is as follows:

[0068] a. The mixing of rubber materials is carried out with a Ф400mm open mill, start the equipment, and turn on the cooling circulating water;

[0069] b. Adjust...

Embodiment 3

[0084] A sizing formula for yellow protective clothing, comprising parts by weight of the following components:

[0085] 75 parts of CIIR, 25 parts of EPDM rubber, 8 parts of ZnO, 0.5 parts of accelerator DM, 2 parts of accelerator ZDC, 1 part of magnesium oxide, 12 parts of chlorinated paraffin (70%), 50 parts of decabromodiphenyl ether , 15 parts of antimony trioxide, 15 parts of titanium yellow.

[0086] The preparation method of the sizing material of the above-mentioned yellow protective clothing is as follows:

[0087] (1) Mixing process

[0088] The process is: CIIR and EPDM rubber (15min) → chlorinated paraffin, decabromodiphenyl ether, antimony trioxide, titanium yellow (30min) → magnesium oxide, accelerator DM, accelerator ZDC (15min) → ZnO (5min) → unloading, the specific operation is as follows:

[0089] a. The mixing of rubber materials is carried out with a Ф400mm open mill, start the equipment, and turn on the cooling circulating water;

[0090] b. Adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com