Production method of high-near-infrared-reflectivity titanium yellow

A technology of infrared reflection and production method, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve problems such as unstable product quality, achieve excellent near-infrared reflection ability, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

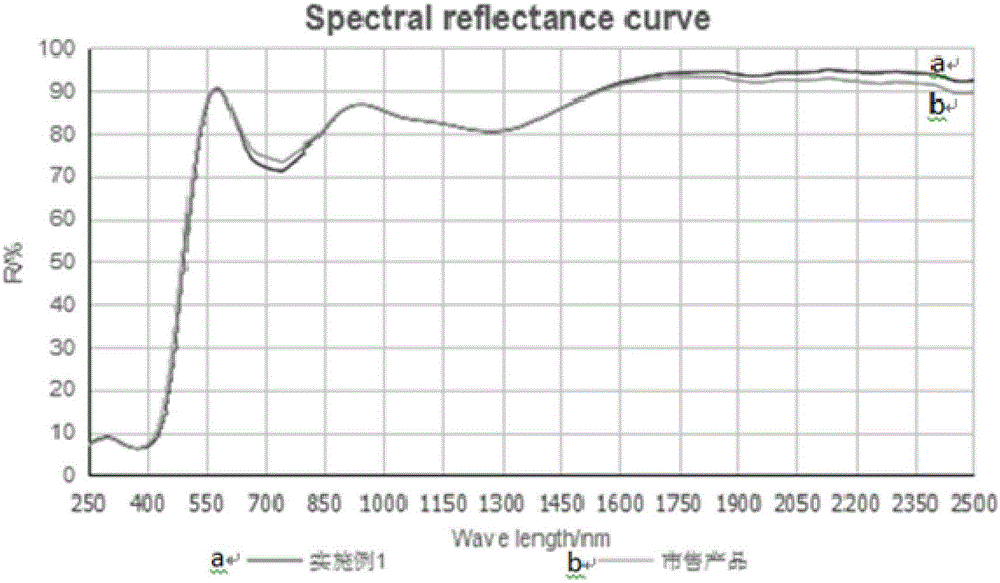

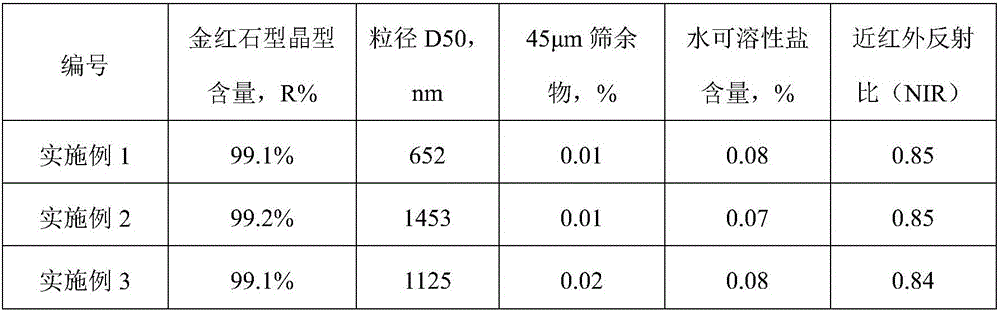

Embodiment 1

[0023] Take the hydrolyzed titanium dioxide hydrate prepared by the sulfuric acid method titanium dioxide production process, the sedimentation rate is 150mm / 20min, wash the hydrated titanium dioxide with tap water at 60-65°C, and the iron content (calculated as Fe) in the wastewater of one washing is 95mg / L; The hydrated titanium dioxide obtained by washing once with water is added with tap water to make a slurry, the concentration is 325g / L, the temperature is 60-65°C, and sulfuric acid (with H 2 SO 4 Calculated) is 49g / L, trivalent titanium (as Ti 2 o 3 Calculated) is 0.5g / L, after 2 hours of treatment to account for the TiO contained in the slurry to be treated 2 In terms of the mass fraction of the amount, add orthotitanic acid sol calcined seeds (calculated as TiO2), and the addition ratio is 5%; the acid-treated hydrated titanium dioxide is washed with desalted water at 55-60 ° C, and the iron in the wastewater is washed twice. The content (calculated as Fe2O3) is 8m...

Embodiment 2

[0025] Take the hydrolyzed product hydrated titanium dioxide prepared by the sulfuric acid method titanium dioxide production process, the sedimentation rate is 197mm / 20min, wash the hydrated titanium dioxide with 55-60°C tap water, and the iron content (calculated as Fe) in the once-washed wastewater is 85mg / L; The hydrated titanium dioxide obtained by washing once with water is added with tap water to make a slurry, the concentration is 372g / L, the temperature is 55-60°C, and sulfuric acid (with H 2 SO 4 Calculated) is 32g / L, trivalent titanium (as Ti 2 o 3 ) is 1.5g / L, after 1.5 hours of treatment, account for the mass fraction of TiO contained in the slurry to be treated, add orthotitanic acid sol calcined seed crystals (in TiO ), the addition ratio is 7%; ~65°C desalted water washes the acid-treated hydrated titanium dioxide with water, and the iron content in the secondary washing wastewater (measured as Fe 2 o 3 Total) is 10 mg / L; the hydrated titanium dioxide obtai...

Embodiment 3

[0027] Take the hydrolyzed titanium dioxide hydrate prepared by the sulfuric acid method titanium dioxide production process, the sedimentation rate is 175mm / 20min, wash the hydrated titanium dioxide with tap water at 55-60°C, and the iron content (calculated as Fe) in the once-washed wastewater is 85mg / L; The hydrated titanium dioxide obtained by washing once with water is added with tap water to make a slurry, the concentration is 365g / L, the temperature is at 65-70°C, and sulfuric acid (with H 2 SO 4 Calculated) is 38g / L, trivalent titanium (as Ti 2 o 3 Calculated) is 1.1g / L, after processing for 1 hour, account for the mass fraction of TiO contained in the slurry to be treated, add orthotitanic acid sol calcined seed (in TiO ), the addition ratio is 2%; with 55 ~60°C desalted water washes the acid-treated hydrated titanium dioxide with water, and the iron content in the secondary washing wastewater (measured as Fe 2 o 3 Total) is 9mg / L; the hydrated titanium dioxide ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com