A kind of exterior wall color heat insulation mortar with heat reflection function

A technology of thermal insulation mortar and heat reflection, applied in the field of building mortar, can solve the problems of affecting the thermal insulation and cooling effect of the wall, poor thermal conductivity, not considering reflection and absorption, etc., to achieve excellent chemical stability, low water absorption, Easy adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

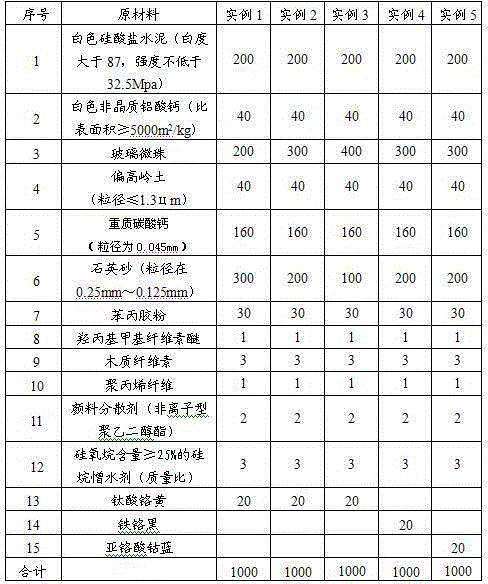

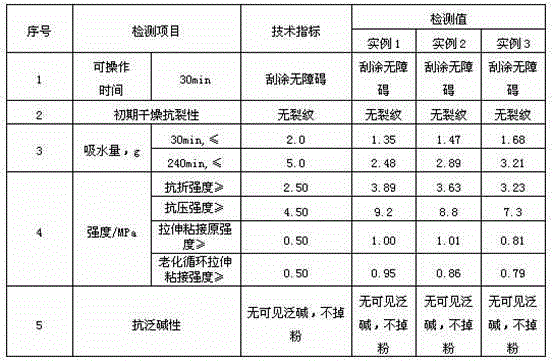

[0030] The following are specific examples of the present invention. These examples are only a detailed description of the colored heat-insulating mortar system for exterior walls with heat reflection function of the present invention, and are not intended to limit the protection scope of the present invention.

[0031] 1. Formula

[0032] (1) Mortar formulations of Examples 1-5

[0033]

[0034] The glass microspheres in the formula are made by crushing the pure glass products recovered from industrial or civil use into glass powders below 400 meshes, and then mixing them evenly with foaming agent and binder, and then melting them under high temperature conditions of 800-820°C. It is obtained by expanding, cooling and sieving; the glass beads are regular spherical particles with rough appearance, with a honeycomb network structure inside, a particle size of 0.09mm-0.60mm, a bulk density of 270-400Kg / m3, and a cylinder compressive strength Greater than 2.0MPa; the foaming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com