Aluminum titanate ceramic for casting and preparation method thereof

A technology of aluminum titanate and ceramics, which is applied in the field of aluminum titanate ceramics for casting and its preparation, and achieves the effects of saving energy consumption, saving production costs and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

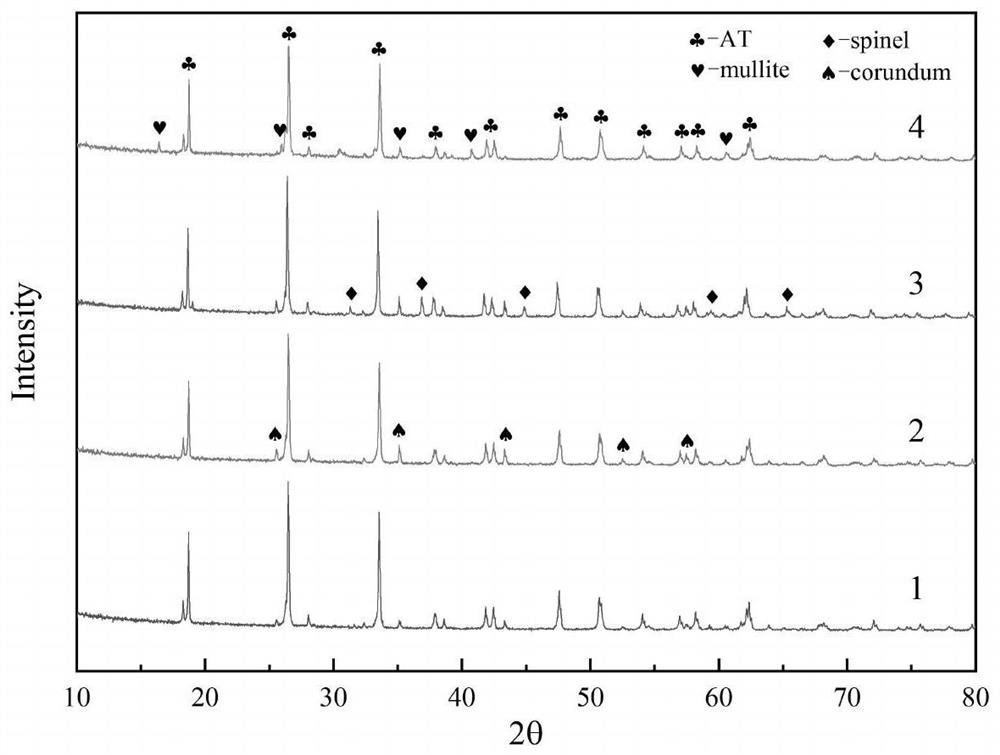

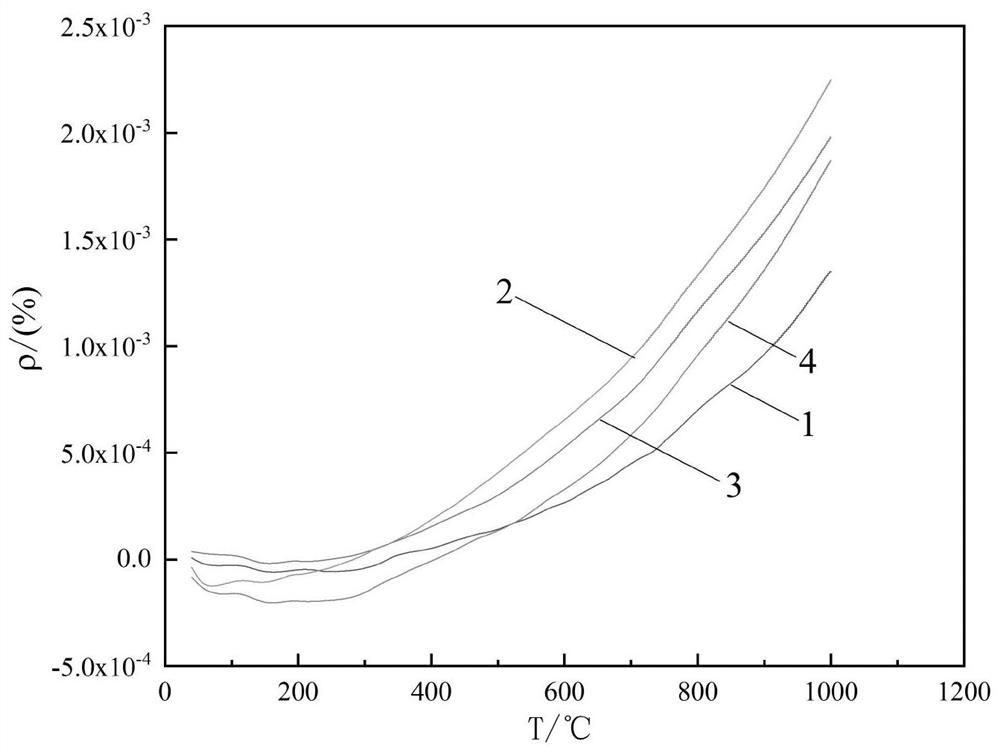

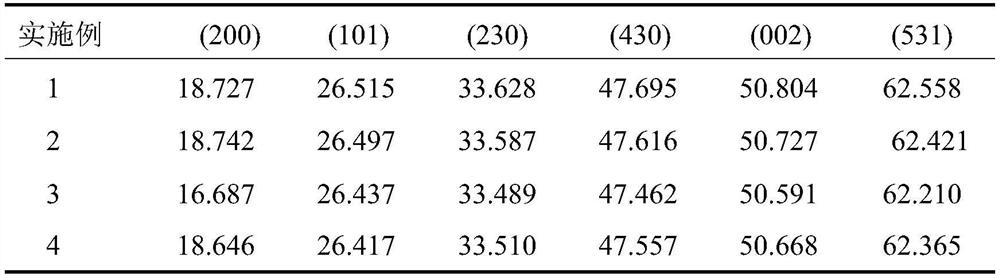

Embodiment 1

[0026] A method for preparing aluminum titanate ceramics for casting, wherein the raw materials and proportions for making the aluminum titanate ceramics are: α-Al 2 o 3 54.34wt%, titanium yellow powder 42.72wt%, magnesium carbonate 1.94wt%, silicon dioxide 1wt%; the steps of its manufacture are:

[0027] (1) Raw material treatment: α-Al with ball milling fineness of 200 mesh 2 o 3 , titanium yellow powder, magnesium carbonate, silicon dioxide raw materials.

[0028] (2) Mixing of raw materials: mix according to the proportion of each raw material, and use a planetary ball mill for ball milling for 12 hours at a speed of 400r / min to obtain a slurry; the mixing of the above raw materials is made by wet ball milling, and the ball milling medium used is none Water ethanol, the ball mill is a zirconia ceramic ball mill, and the mass ratio of the raw material, ball mill and alcohol is 1:3:1.25.

[0029] (3) Granulation: Pour the slurry into a container and dry it in an electric...

Embodiment 2

[0035] A method for preparing aluminum titanate ceramics for casting, the raw material and the proportion thereof for making the green body are: α-Al 2 o 3 58.22wt%, titanium yellow powder 38.78wt%, magnesium carbonate 1.5wt%, silicon dioxide 1.5wt%; the steps of its manufacture are:

[0036] (1) Raw material treatment: α-Al with ball milling fineness of 200 mesh 2 o 3 , titanium yellow powder, magnesium carbonate, silicon dioxide raw materials.

[0037] (2) Mixing of raw materials: mix according to the proportion of each raw material, and use a planetary ball mill for ball milling for 12 hours at a speed of 400r / min to obtain a slurry; the mixing of the above raw materials is made by wet ball milling, and the ball milling medium used is none Water ethanol, the ball mill is a zirconia ceramic ball mill, and the mass ratio of the raw material, ball mill and alcohol is 1:3:1.25.

[0038] (3) Granulation: Pour the slurry into a container and dry it in an electric blast drying...

Embodiment 3

[0044] A method for preparing aluminum titanate ceramics for casting, the raw material and the proportion thereof for making the green body are: α-Al 2 o 3 56.42wt%, titanium yellow powder 37.58wt%, magnesium carbonate 5wt%, silicon dioxide 1wt%; The steps of its manufacture are:

[0045] (1) Raw material treatment: α-Al with ball milling fineness of 200 mesh 2 o 3 , titanium yellow powder, magnesium carbonate, silicon dioxide raw materials.

[0046] (2) Mixing of raw materials: mix according to the proportion of each raw material, and use a planetary ball mill for ball milling for 12 hours at a speed of 400r / min to obtain a slurry; the mixing of the above raw materials is made by wet ball milling, and the ball milling medium used is none Water ethanol, the ball mill is a zirconia ceramic ball mill, and the mass ratio of the raw material, ball mill and alcohol is 1:3:1.25.

[0047] (3) Granulation: Pour the slurry into a container and dry it in an electric blast drying ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com