Process for comprehensive utilization of waste acid containing titanium oxide

A technology of titanium dioxide waste acid and metatitanic acid, which is applied in the field of comprehensive utilization of titanium dioxide waste acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

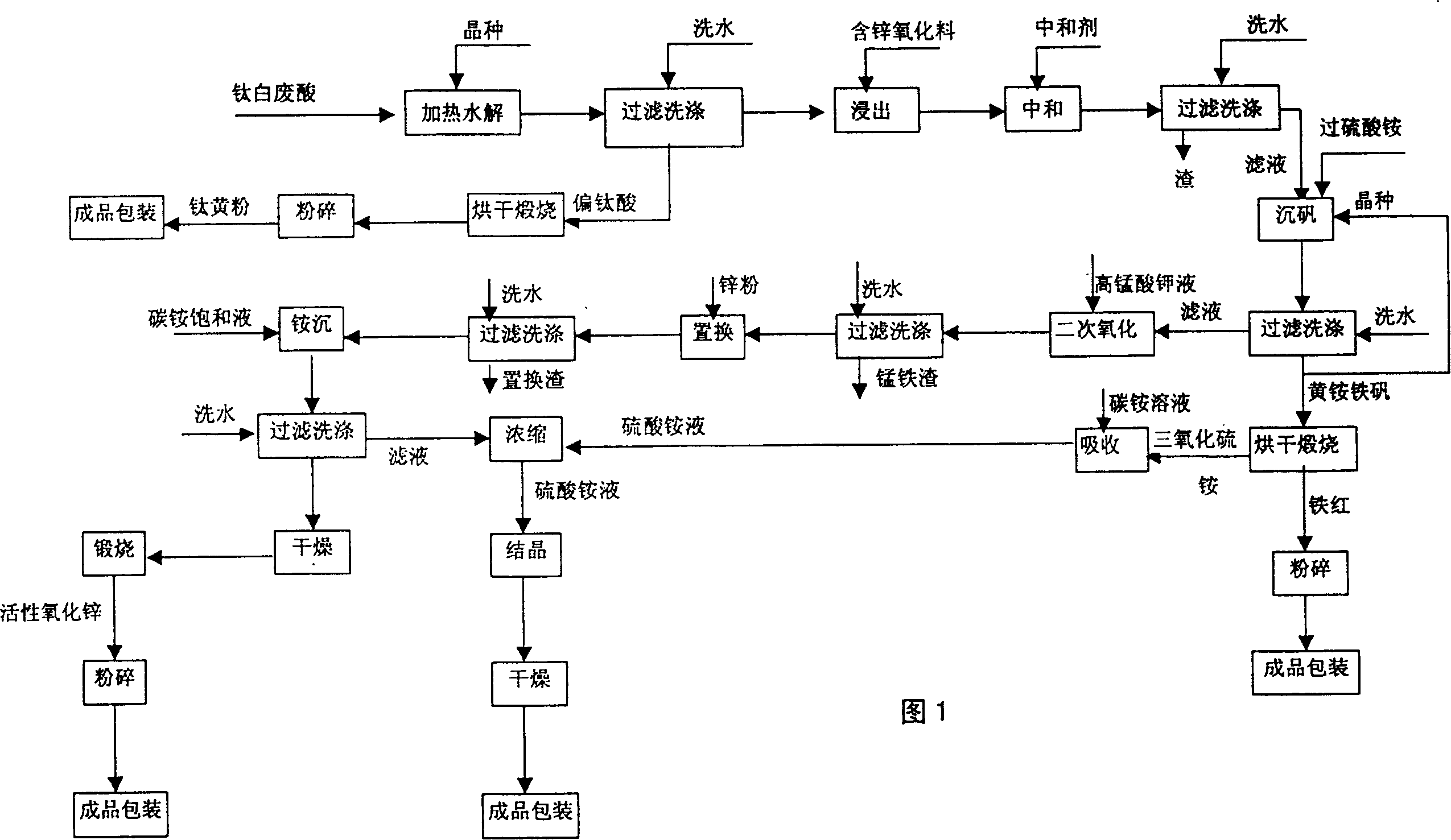

[0056] The process flow of the comprehensive utilization method of titanium dioxide waste acid in this example is shown in Figure 1, the titanium dioxide waste acid is heated and hydrolyzed, the metatitanic acid obtained from hydrolysis is used to prepare titanium yellow powder, and the filtrate obtained from hydrolysis is used to prepare active zinc oxide , iron red (Fe 2 o 3 ) and zinc-containing ammonium sulfate.

[0057] (1) Heating hydrolysis of titanium dioxide waste acid

[0058] The components of the processed titanium dioxide waste acid and the content (percentage by weight) of each component are as follows:

[0059] h 2 SO 4 20.3 Fe 2.4

[0060] Mg 0.5 Ca 0.0037

[0061] TiO 2 9.51 V 0.0009

[0062] Co 0.00095

[0063] The equipment used is a reaction kettle equipped with heating temperature control, condensation reflux device and stirrer. Process conditions: add 1% seed crystal (weight percentage), press TiO 2 For content ca...

Embodiment 2

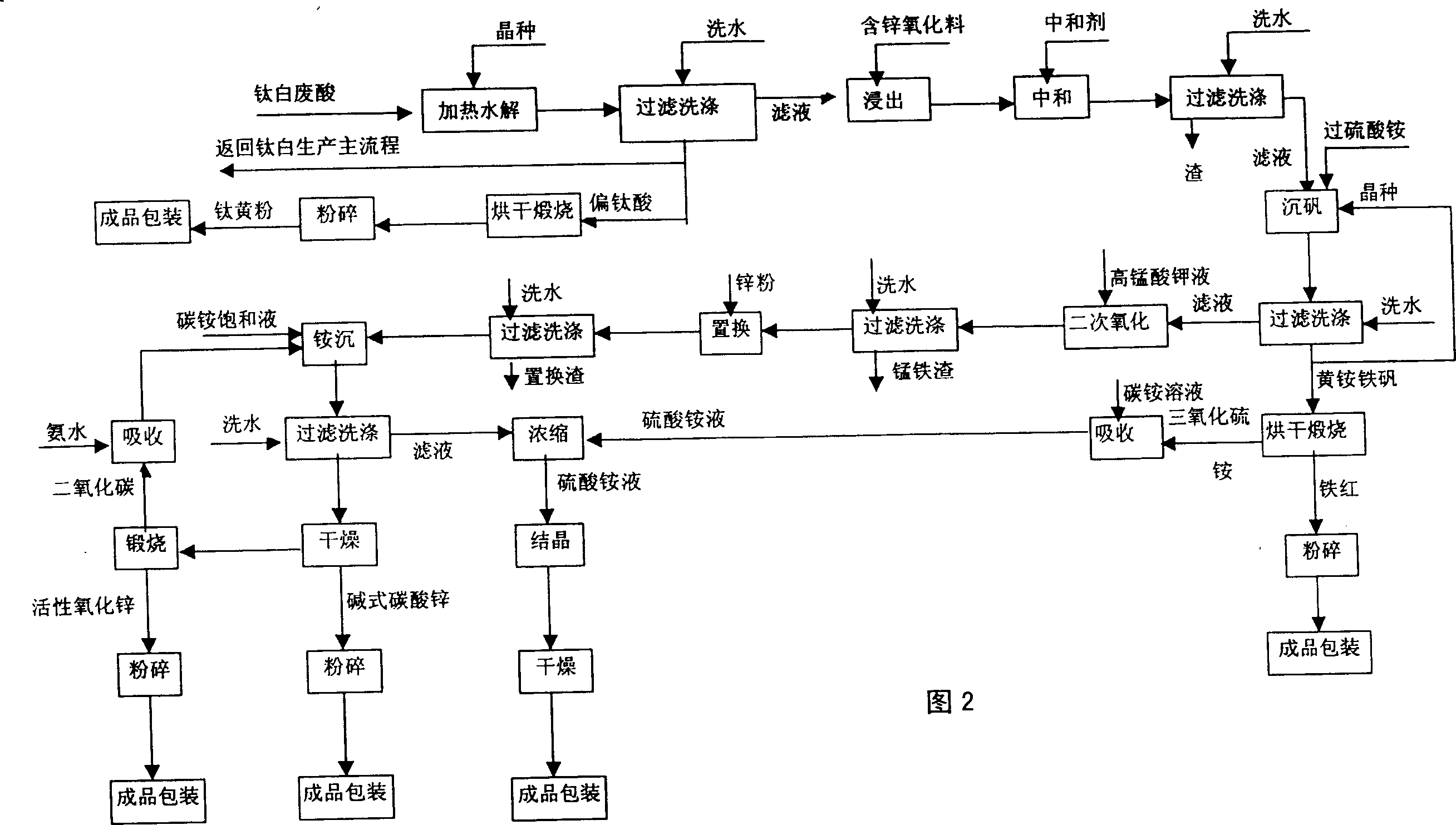

[0083] The process flow of the comprehensive utilization method of titanium dioxide waste acid in this example is shown in Figure 2. The titanium dioxide waste acid is heated and hydrolyzed, and the metatitanic acid obtained from the hydrolysis is returned to the main process of titanium dioxide production, and the filtrate obtained from the hydrolysis is used to prepare active oxidation Zinc, basic zinc carbonate, iron red (Fe 2 o 3 ) and zinc-containing ammonium sulfate.

[0084] The difference between this embodiment and embodiment 1 is as follows:

[0085] (1) The metatitanic acid obtained by hydrolysis is returned to the main process of titanium dioxide production.

[0086] (2) The zinc-containing oxide added in the leaching process of preparing basic zinc carbonate and active zinc oxide is formed by calcining and alkali leaching hot-dip galvanizing ash containing 77% zinc. The technical conditions of calcination are as follows: a calcination temperature of 500° C. and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com