Polypropylene material and preparing method thereof

A polypropylene material and polypropylene technology, applied in the field of polypropylene material and its preparation, can solve the problems of material mechanical performance degradation, uneven dispersion of toner, inconsistent material color, etc., and achieve good performance, bright color and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

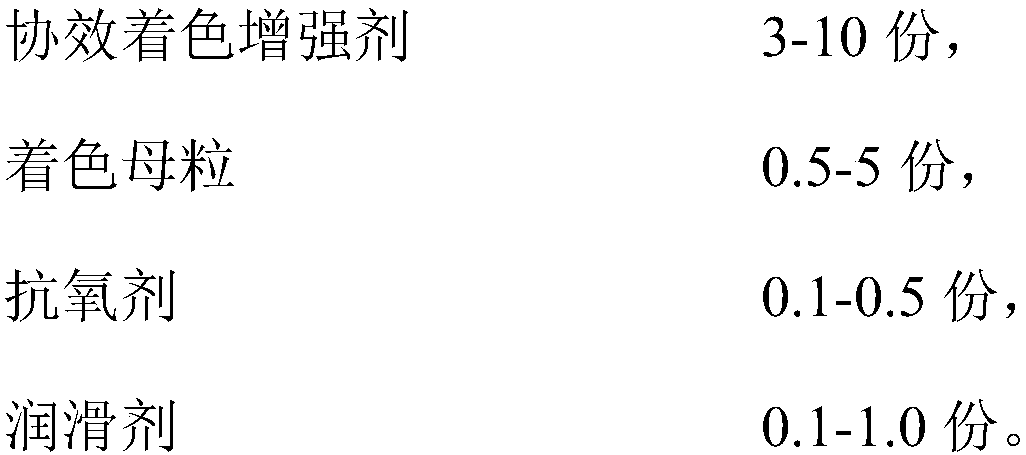

[0037] (1) Preparation of colored masterbatch: Add 99 parts of ultra-low viscosity polypropylene and 1 part of carbon black into a high-speed mixer and mix evenly, then extrude and granulate in a twin-screw extruder to obtain colored masterbatch. The processing conditions of the twin-screw extruder are: the temperature of the first zone is 200°C, the temperature of the second zone is 205°C, the temperature of the third zone is 210°C, the temperature of the fourth zone is 220°C, the temperature of the fifth zone is 220°C, and the temperature of the sixth zone is 220°C °C; the speed of the twin-screw main engine is 300rpm.

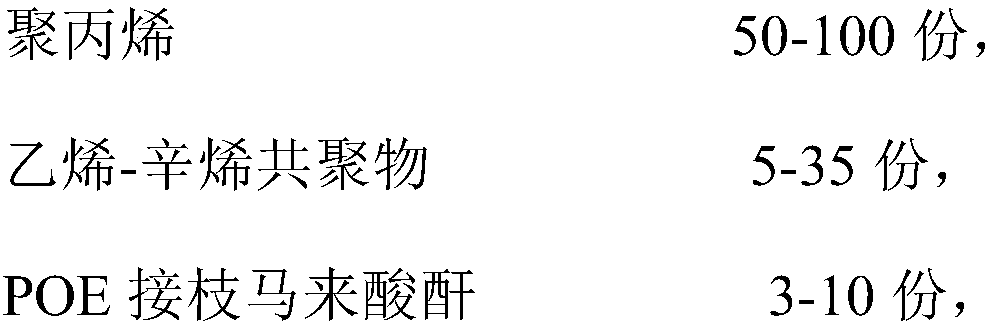

[0038] (2) Preparation of polypropylene material: Weigh and dry the following components by mass: 73 parts of polypropylene, 20 parts of ethylene-octene copolymer, 5 parts of POE grafted maleic anhydride, 5 parts of synergistic coloring enhancer 1 part, 1 part of coloring masterbatch, 0.5 part of antioxidant, 0.5 part of lubricant; the weighed polypropylene,...

Embodiment 2

[0040] (1) Preparation of coloring masterbatch: add 99 parts of ultra-low viscosity polypropylene, 15 parts of titanium dioxide, 0.5 part of phthalocyanine green, 1.0 part of iron red, and 0.01 part of carbon black into a high-speed mixer and mix evenly, and then extrude in a twin-screw Extrude and granulate in the machine to obtain colored masterbatch. The processing conditions of the twin-screw extruder are: the temperature of the first zone is 230°C, the temperature of the second zone is 230°C, the temperature of the third zone is 235°C, the temperature of the fourth zone is 235°C, the temperature of the fifth zone is 210°C, and the temperature of the sixth zone is 230°C °C; the rotational speed of the twin-screw main engine is 500rpm.

[0041] (2) Preparation of polypropylene material: Weigh and dry the following components by mass: 50 parts of polypropylene, 35 parts of ethylene-octene copolymer, 3 parts of POE grafted maleic anhydride, 10 parts of synergistic coloring en...

Embodiment 3

[0043] (1) Preparation of coloring masterbatch: add 99 parts of ultra-low viscosity polypropylene, 10 parts of titanium dioxide, 2.5 parts of titanium yellow powder, 0.5 part of iron red, and 0.01 part of carbon black into a high-speed mixer and mix evenly, and then extrude in a twin-screw Extrude and granulate in the machine to obtain colored masterbatch. The processing conditions of the twin-screw extruder are: the temperature of the first zone is 220°C, the temperature of the second zone is 215°C, the temperature of the third zone is 220°C, the temperature of the fourth zone is 230°C, the temperature of the fifth zone is 220°C, and the temperature of the sixth zone is 225 °C; the rotational speed of the twin-screw main engine is 200rpm.

[0044] (2) Preparation of polypropylene material: Weigh and dry the following components by mass: 100 parts of polypropylene, 5 parts of ethylene-octene copolymer, 10 parts of POE grafted maleic anhydride, 3 parts of synergistic coloring e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com