Compound masterbatch and preparation method thereof

A composite color and carrier technology, applied in the field of polymer chemistry and polymers, can solve the problems of poor pigment dispersion, difficult to satisfy customers, and difficult to control color difference, and achieve the effect of small color difference, easy operation and strong tinting strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

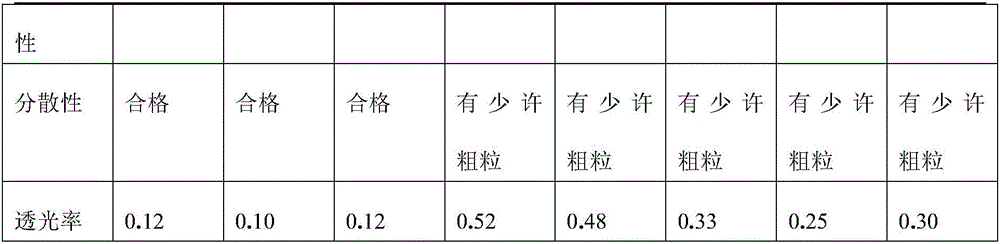

[0038] Embodiment 1, a kind of composite color cake

[0039] The color cake described in Example 1 of the present invention is composed of the following components in parts by weight: 20 parts of polyethylene, 20 parts of titanium dioxide, 20 parts of titanium yellow, 1 part of iron red, 0.5 parts of carbon black, and 1 part of calcium zinc stabilizer , 25 parts of plasticizer, 100 parts of antimony trioxide, 0.5 parts of zinc stearate and 2 parts of nano calcium carbonate. Wherein, the titanium dioxide is rutile-type titanium dioxide with an average particle size of 0.15 μm, wherein the proportion of particles with a particle size between 0.5 and 5 μm is 2.5%, and the average particle size of the carbon black is 5 nm. The particle size of nano calcium carbonate is 0.01μm, and the specific surface area is 33m 2 / g, the plasticizer consists of epoxidized soybean oil and 911P in a weight ratio of 1:0.1.

[0040] Preparation:

[0041] A) Weigh each raw material, put it into a ...

Embodiment 2

[0043] Embodiment 2, a kind of composite color cake

[0044]The color cake described in Example 2 of the present invention is composed of the following components in parts by weight: 40 parts of polyvinyl chloride, 28 parts of titanium dioxide, 24 parts of titanium yellow, 3.6 parts of iron red, 0.8 part of carbon black, 4 parts of calcium zinc stabilizer parts, 54 parts of plasticizer, 150 parts of antimony trioxide, 2 parts of zinc stearate and 3 parts of nano calcium carbonate. Wherein, the titanium dioxide is rutile-type titanium dioxide with an average particle size of 0.18 μm, wherein particles with a particle size between 0.5 and 5 μm account for 3.6%, and the average particle size of the carbon black is 9.7 nm. The particle size of the nano-calcium carbonate is 0.05 μm, and the specific surface area is 41m 2 / g, the plasticizer consists of epoxidized soybean oil and 911P in a weight ratio of 1:0.5.

[0045] The preparation method is as in Example 1.

Embodiment 3

[0046] Embodiment 3, a kind of composite color cake

[0047] The color cake described in Example 3 of the present invention is composed of the following components in parts by weight: 60 parts of polypropylene, 40 parts of titanium dioxide, 30 parts of titanium yellow, 6 parts of iron red, 3 parts of carbon black, and 5 parts of calcium zinc stabilizer , 55 parts of plasticizer, 200 parts of antimony trioxide, 4 parts of zinc stearate and 6 parts of nano calcium carbonate. Wherein, the titanium dioxide is rutile-type titanium dioxide with an average particle size of 0.2 μm, wherein particles with a particle size between 0.5 and 5 μm account for 4.8%, and the average particle size of the carbon black is 13 nm. The particle size of nano calcium carbonate is 0.06μm, and the specific surface area is 52m 2 / g, the plasticizer is composed of epoxidized soybean oil and 911P in a weight ratio of 1:1.

[0048] The preparation method is as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com