Four-layer coating process of organic photoconductor drum and organic photoconductor drum prepared by adopting same

A technology of organic photoconductive drum and coating process, applied in coating, optics, polyamide coatings, etc., can solve problems such as sedimentation, crystallization, solidification, loss of photoelectric properties of coatings, destruction of physical and chemical properties of coatings, etc., and achieve excellent photoelectricity. Excellent performance, optoelectronic properties, easy to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Carrier blocking layer coating 1: 78g of nylon resin CM-8000 (purchased from Nippon Materials Co., Ltd.), 1600ml of methanol, and 400ml of n-butanol to form a coating with a solid content of about 3.5%. A 0.5-1 μm thick coating is coated on the turning drum base to form the carrier blocking layer 1 .

[0037] Carrier blocking layer coating 2: 54.6g of titanium yellow FX-50 (purchased from Nippon Materials Corporation), 54.6g of titanium dioxide CR-90 (purchased from Nippon Materials Corporation), nylon resin CM-8000 (purchased from Nippon Materials Corporation) 54.6g, 1.63g of dispersant BYK-180 (purchased from Nippon Materials Co., Ltd.), 1200ml of methanol, 400ml of n-butanol, made into a coating with a solid content of about 11.5%. A 2-2.5 μm thick coating is coated on the carrier blocking layer 1 to form the carrier blocking layer 2 .

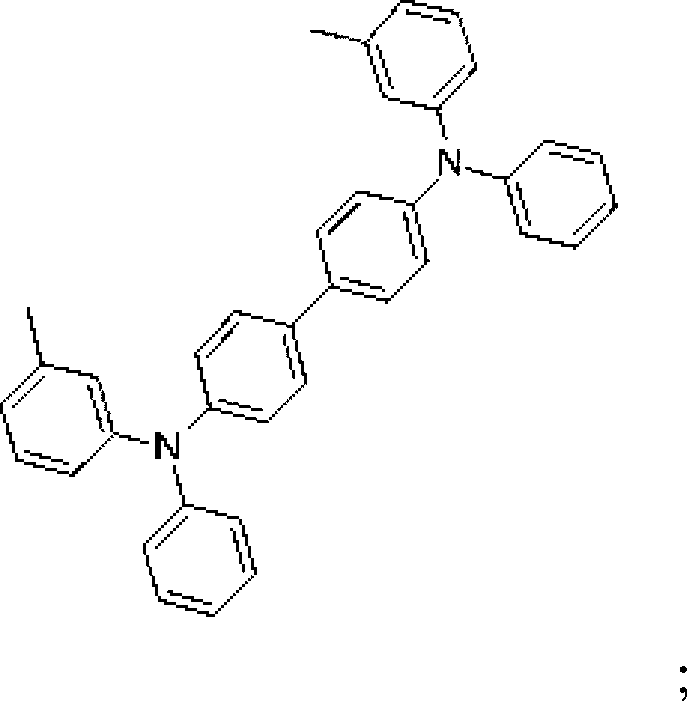

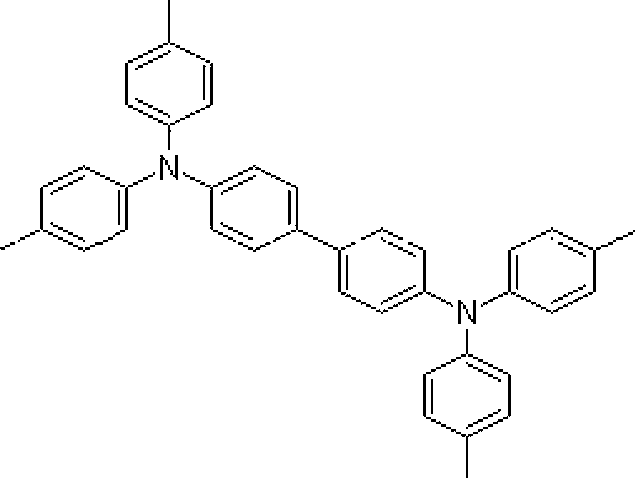

[0038]Carrier generation layer coating: polyvinyl butyral B-90 (purchased from Japan Materials Co., Ltd.) 11g, γ-type titanium pht...

Embodiment 2

[0043] Carrier blocking layer coating 1 formula: 78g of nylon resin CM-8000 (purchased from Japan Materials Co., Ltd.), 1000ml of methanol, 400ml of n-butanol, made into a coating with a solid content of about 4.5%, and coated with a thickness of 0.5~1μm .

[0044] Carrier blocking layer coating 2: 54.6g of titanium yellow FX-50 (purchased from Nippon Materials Corporation), 54.6g of titanium dioxide CR-90 (purchased from Nippon Materials Corporation), nylon resin CM-8000 (purchased from Nippon Materials Corporation) 54.6g, 1.63g of dispersant BYK-180 (purchased from Japan Materials Co., Ltd.), 1200ml of methanol, 400ml of n-butanol, make a coating with a solid content of about 11.5%, and apply a 2~2.5μm thick coating.

[0045] Carrier generation layer coating: polyvinyl butyral B-9011g (purchased from Japan Materials Co., Ltd.), γ-type titanium phthalocyanine CG-01H 14.3g (purchased from IT-Chem), tetrahydrofuran 600ml (purchased from Guangzhou Guanghua Technology), cyclohex...

Embodiment 3

[0050] Carrier blocking layer coating 1: 78g of nylon resin CM-8000 (purchased from Japan Materials Co., Ltd.), 1200ml of methanol, 400ml of n-butanol, made into a coating with a solid content of about 4.0%, and coated with a thickness of 0.5~1μm.

[0051] Carrier blocking layer coating 2: 54.6g of titanium yellow FX-50 (purchased from Nippon Materials Corporation), 54.6g of titanium dioxide CR-90 (purchased from Nippon Materials Corporation), nylon resin CM-8000 (purchased from Nippon Materials Corporation) 54.6g, 1.63g of dispersant BYK-180 (purchased from Japan Materials Co., Ltd.), 1200ml of methanol, 400ml of n-butanol, make a coating with a solid content of about 11.5%, and apply a 2~2.5μm thick coating.

[0052] Carrier generation layer coating: polyvinyl butyral B-90 11.5g (purchased from Japan Materials Co., Ltd.), γ-type titanium phthalocyanine CG-01H 13.8g (purchased from IT-Chem), 650ml tetrahydrofuran (purchased from Guangzhou Guanghua Technology), 70ml of cyclohe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com