A kind of brown masterbatch and preparation technology thereof

A kind of masterbatch and brown technology, which is applied in the field of brown masterbatch and its preparation, can solve the problems of color inconsistency, achieve high light resistance, solve metamerism, and have obvious advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

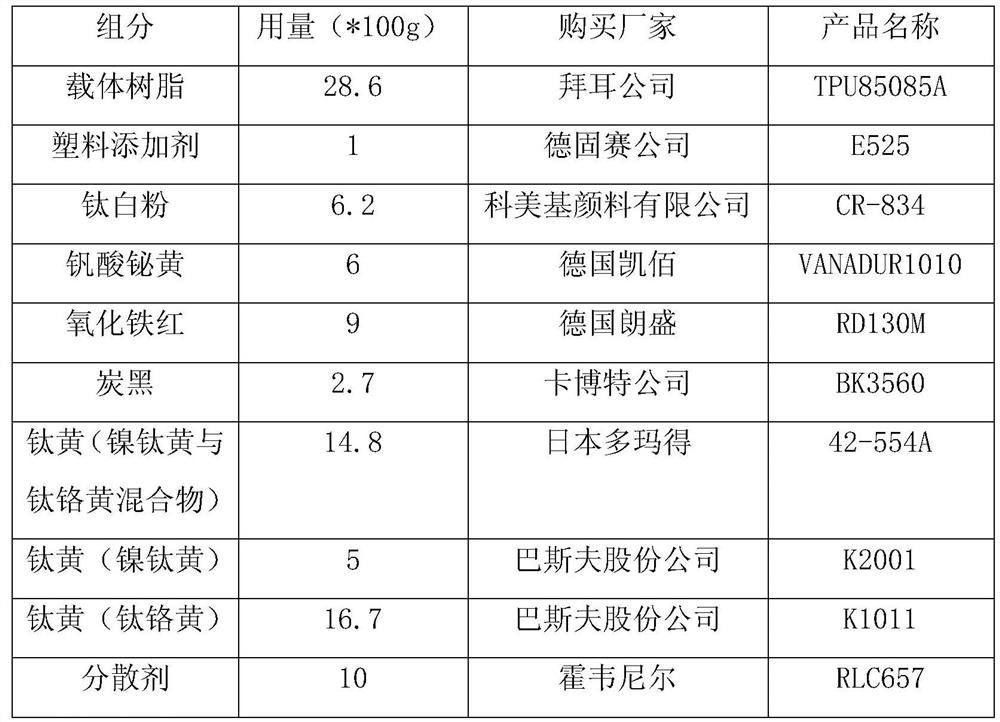

[0021] A brown masterbatch, including the following components:

[0022]

[0023] Its preparation method is as follows:

[0024] Step 1, mix the carrier resin, plastic additives, dispersant, titanium dioxide, iron oxide red, bismuth vanadate yellow, titanium yellow, and carbon black in a high-speed mixer after proportioning;

[0025] Step 2, melt and extrude the raw materials obtained in step 1 in the extruder, after cooling, enter the pelletizer to granulate to obtain granular bodies; the extruder is a twin-screw extruder, and the twin-screw extruder The temperature is 180°C, and the speed is 400r / min;

[0026] Step 3, cooling and drying the granules obtained in Step 2 to obtain brown masterbatch.

[0027] The brown masterbatch of embodiment 1 is added in the plastic, and the prepared plastic is compared with the standard sample:

[0028] Standard sample: BMW Group, the color number is the standard color of Mocha.

[0029] Sample 1: Plastics added with the brown master...

Embodiment 2

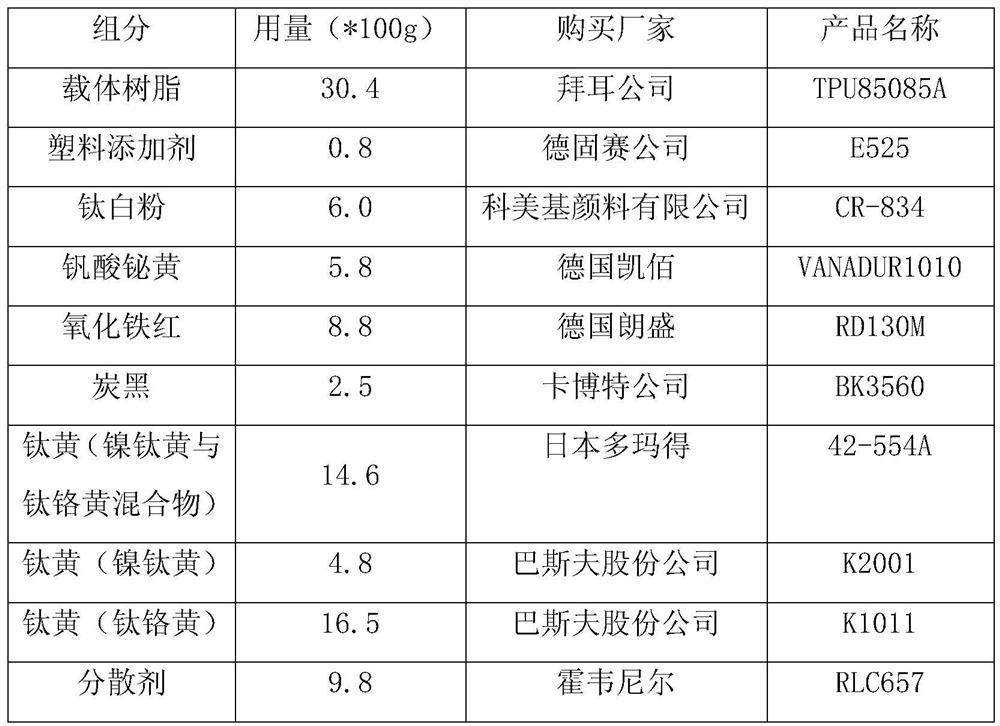

[0033] A brown masterbatch, including the following components:

[0034]

[0035] Its preparation method is as follows:

[0036] Step 1, mix the carrier resin, plastic additives, dispersant, titanium dioxide, iron oxide red, bismuth vanadate yellow, titanium yellow, and carbon black in a high-speed mixer after proportioning;

[0037] Step 2, melt and extrude the raw materials obtained in step 1 in the extruder, after cooling, enter the pelletizer to granulate to obtain granular bodies; the extruder is a twin-screw extruder, and the twin-screw extruder The temperature is 180°C, and the speed is 400r / min;

[0038] Step 3, cooling and drying the granules obtained in Step 2 to obtain brown masterbatch.

[0039] The brown masterbatch of embodiment 2 is added in the plastic, and the plastic that makes compares with standard sample:

[0040] Standard sample: BMW Group, the color number is the standard color of Mocha.

[0041] Sample 2: Plastics added with the brown masterbatch...

Embodiment 3

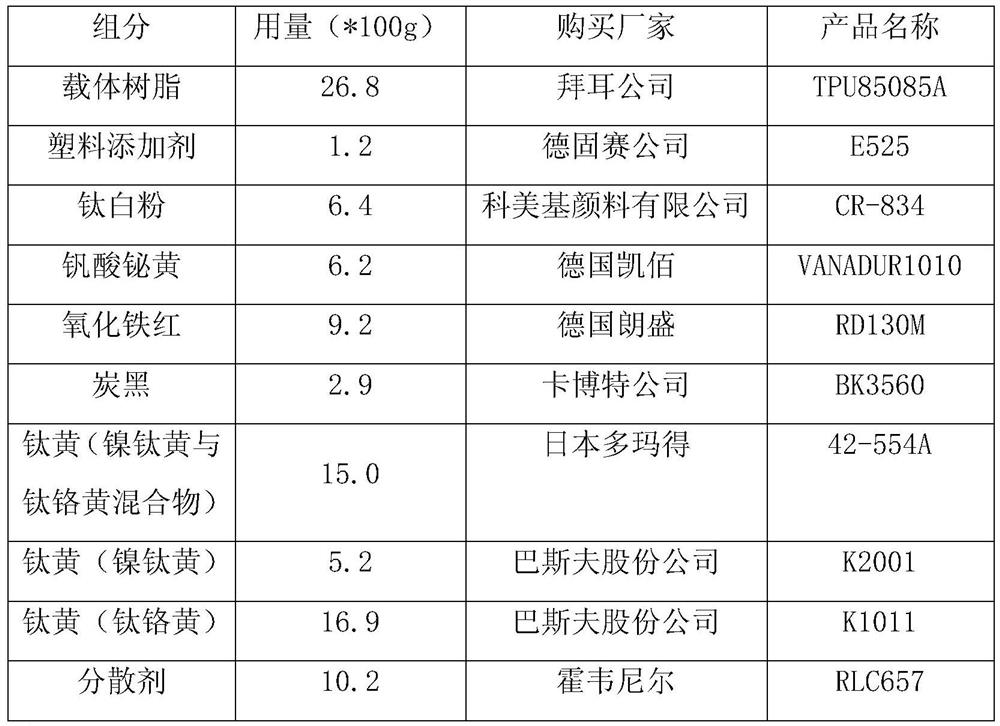

[0045] A brown masterbatch, including the following components:

[0046]

[0047] Its preparation method is as follows:

[0048] Step 1, mix the carrier resin, plastic additives, dispersant, titanium dioxide, iron oxide red, bismuth vanadate yellow, titanium yellow, and carbon black in a high-speed mixer after proportioning;

[0049] Step 2, melt and extrude the raw materials obtained in step 1 in the extruder, after cooling, enter the pelletizer to granulate to obtain granular bodies; the extruder is a twin-screw extruder, and the twin-screw extruder The temperature is 180°C, and the speed is 400r / min;

[0050] Step 3, cooling and drying the granules obtained in Step 2 to obtain brown masterbatch.

[0051] The brown masterbatch of embodiment 3 is added in the plastic, and the plastic prepared is compared with the standard sample:

[0052] Standard sample: BMW Group, the color number is the standard color of Mocha.

[0053] Sample 3: Plastics added with the brown master...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com