A kind of yellow masterbatch and preparation technology thereof

A yellow masterbatch and preparation process technology, applied in the field of plastic processing and color matching, can solve problems such as color inconsistency, achieve high light resistance, solve metamerism, and have obvious advantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

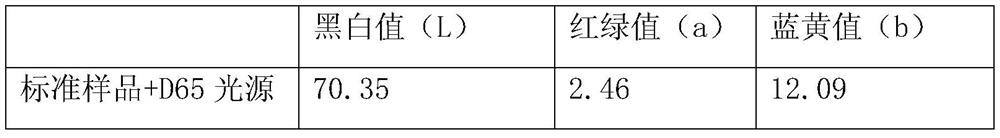

[0020] A yellow masterbatch, including the following components:

[0021] components Dosage(*100g) buy manufacturers product name carrier resin 66.9 LeanderBasell EP300R Dispersant 4.0 Malaysia KLK EBSWAX Titanium dioxide 22.0 Pangang Group Co., Ltd. R-248 Nickel Titanium Yellow 2.7 BASF AG K2001 Zinc iron yellow 2.0 Nubile Y-805k Iron Chrome Brown 0.5 BASF AG K2795 cobalt blue 1.6 Nanjing Huicai BU612 carbon black 0.3 BASF AG BK 5200C

[0022] Its preparation method is as follows:

[0023] Step 1, mix the carrier resin, dispersant, titanium dioxide, nickel titanium yellow, zinc iron yellow, iron chrome brown, cobalt blue, and carbon black in a high-speed mixer after proportioning;

[0024] Step 2, melt and extrude the raw materials obtained in step 1 in the extruder, after cooling, enter the pelletizer to granulate to obtain granular bodies; the extruder is a twin-screw extruder, a...

Embodiment 2

[0032] A yellow masterbatch, including the following components:

[0033] components Dosage(*100g) buy manufacturers product name carrier resin 68.3 LeanderBasell EP300R Dispersant 3.8 Malaysia KLK EBSWAX Titanium dioxide 21.8 Pangang Group Co., Ltd. R-248 Nickel Titanium Yellow 2.5 BASF AG K2001 Zinc iron yellow 1.8 Nubile Y-805k Iron Chrome Brown 0.3 BASF AG K2795 cobalt blue 1.4 Nanjing Huicai BU612 carbon black 0.1 BASF AG BK 5200C

[0034] Its preparation method is as follows:

[0035] Step 1, mix the carrier resin, dispersant, titanium dioxide, nickel titanium yellow, zinc iron yellow, iron chrome brown, cobalt blue, and carbon black in a high-speed mixer after proportioning;

[0036] Step 2, melt and extrude the raw materials obtained in step 1 in the extruder, after cooling, enter the pelletizer to granulate to obtain granular bodies; the extruder is a twin-screw extruder, a...

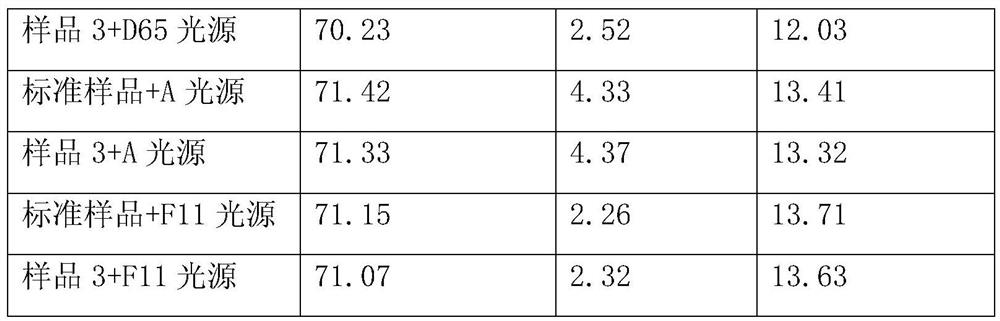

Embodiment 3

[0044] A yellow masterbatch, including the following components:

[0045] components Dosage(*100g) buy manufacturers product name carrier resin 65.5 LeanderBasell EP300R Dispersant 4.2 Malaysia KLK EBSWAX Titanium dioxide 22.2 Pangang Group Co., Ltd. R-248 Nickel Titanium Yellow 2.9 BASF AG K2001 Zinc iron yellow 2.2 Nubile Y-805k Iron Chrome Brown 0.7 BASF AG K2795 cobalt blue 1.8 Nanjing Huicai BU612 carbon black 0.5 BASF AG BK 5200C

[0046] Its preparation method is as follows:

[0047] Step 1, mix the carrier resin, dispersant, titanium dioxide, nickel titanium yellow, zinc iron yellow, iron chrome brown, cobalt blue, and carbon black in a high-speed mixer after proportioning;

[0048] Step 2, melt and extrude the raw materials obtained in step 1 in the extruder, after cooling, enter the pelletizer to granulate to obtain granular bodies; the extruder is a twin-screw extruder, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com