Patents

Literature

76results about How to "The amount added is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

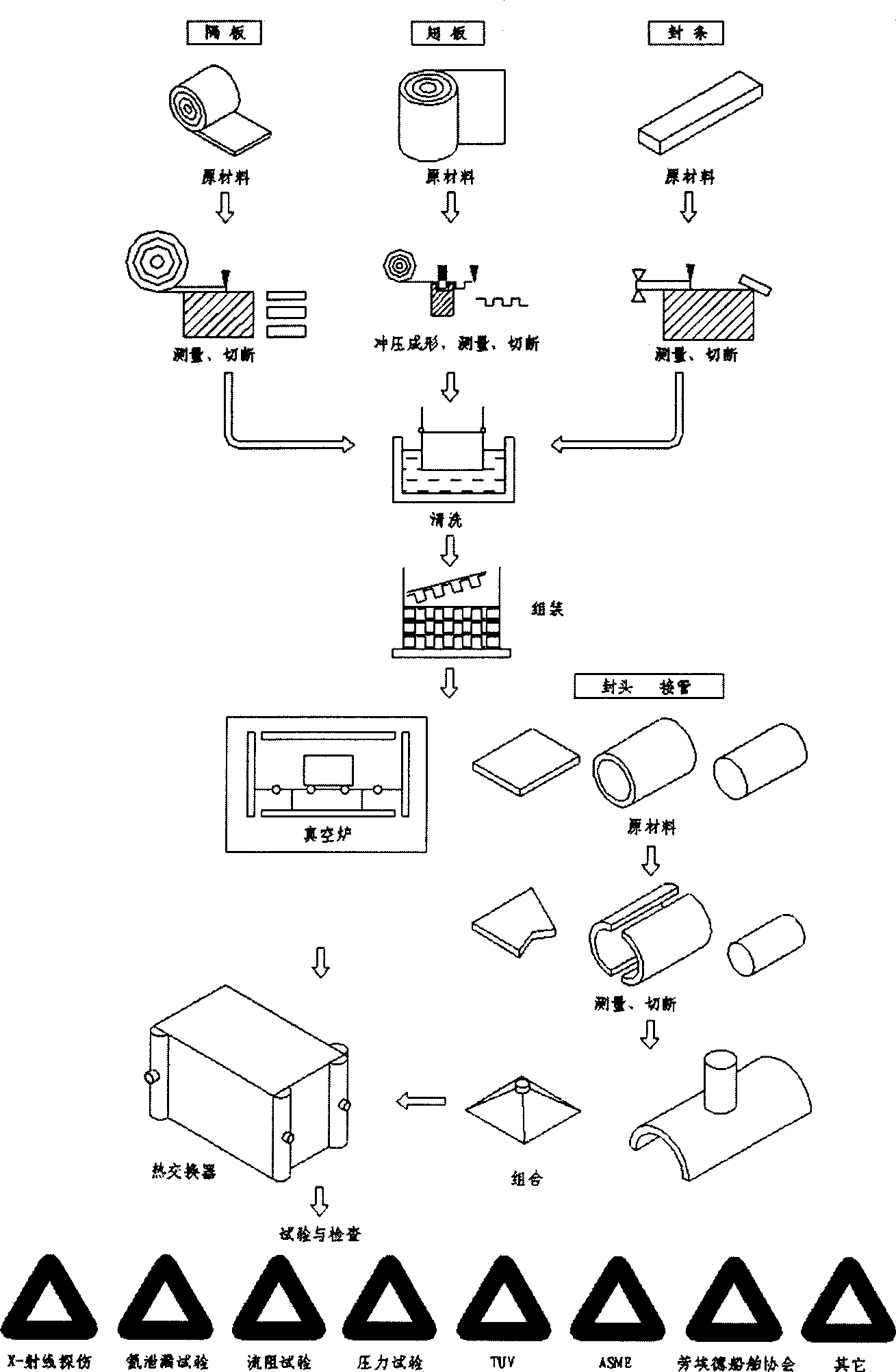

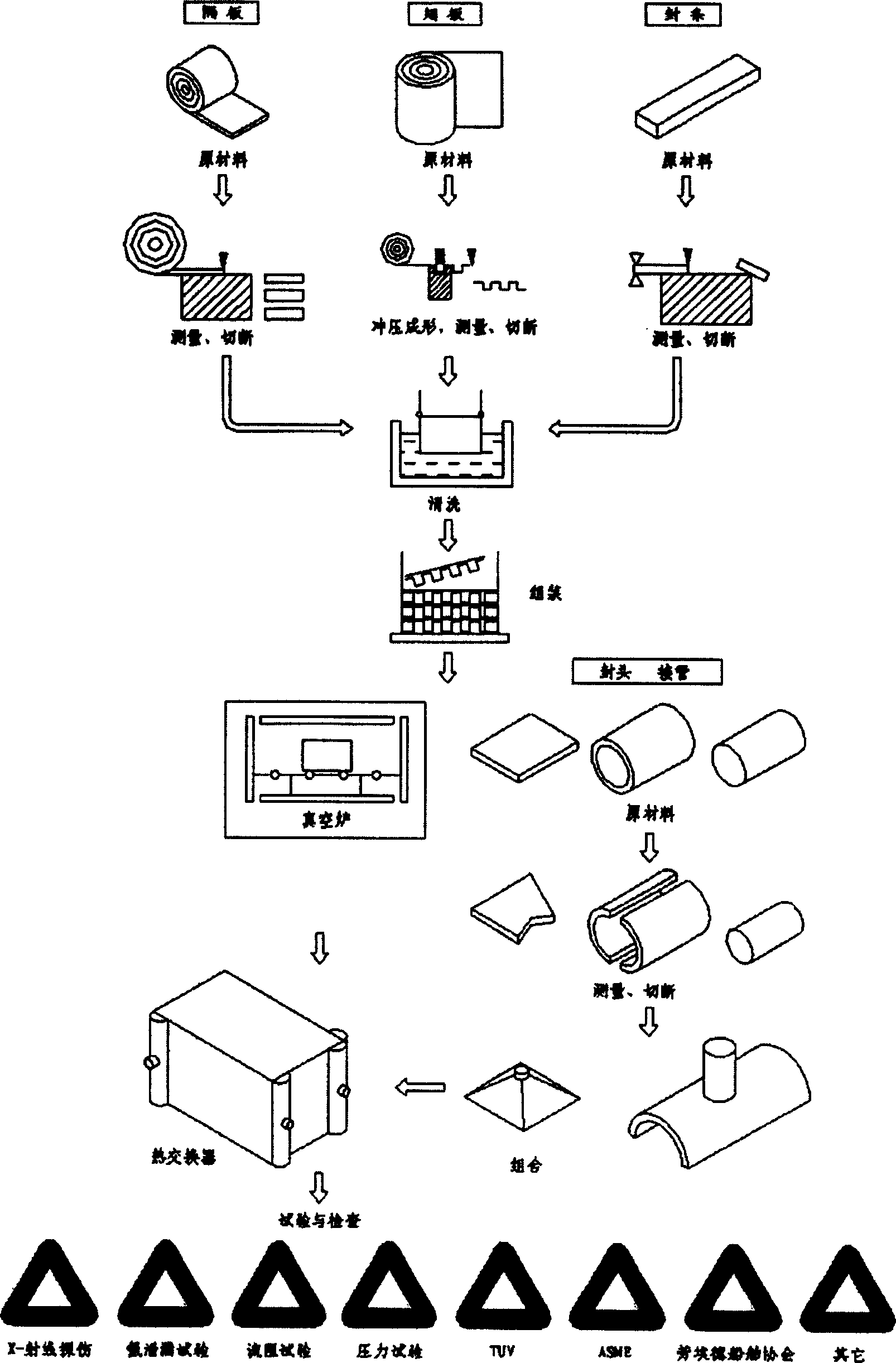

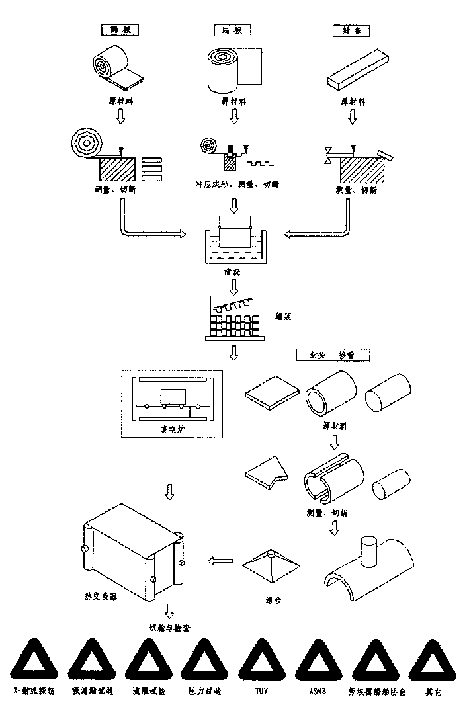

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

Nitrile rubber production process

The invention relates to the technical field of rubber production, aiming to provide an improved nitrile rubber production process, which comprises polymerization, degassing and condensation. Raw materials including acrylonitrile, butadiene, desalinated and deoxidized water, condensed water and molecular weight regulators are fed into a polymerization position, convergence is carried out in a header pipe at the polymerization position, the converged mixture is pre-emulsified sequentially through a pipe pump and a pipe mixer, heat exchange is carried out through an ammonia-cooling heat exchanger for cooling, the cooled mixture, initiator emulsion and activator solution are sequentially fed into a plurality of reactors for polymerization to produce latex, the latex taken out of the reactorsand terminating defoamer solution are fed into a maturing reactor and are fully mixed when the rate of polymerization and conversion reaches 70 plus or minus 5 percent, and the mixture is then fed into a degassing tower to be degassed and into a condensation reactor for condensation. The problem of blockage of the heat exchanger can be avoided, the process is simple, the production process is stable and economical, the Mooney of rubber can be controlled easily, and the produced nitrile rubber has high quality.

Owner:NINGBO SHUNZE RUBBER

Preparation method of starch base paper packing adhesive

InactiveCN101838508AEasy to transportEasy to useNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveOxidizing agent

The invention belongs to the technical field of the adhesive, and particularly relates to a preparation method of starch base paper packing adhesive, which comprises the steps of mixing, oxidizing and modifying, wherein the mixing step is: water, Urea hydrogen peroxide and starch are added into a reactor to be uniformly mixed, and the mass ratio of the water, the Urea hydrogen peroxide and the starch is: 10 to 16 parts of water, 1 to 4 parts of Urea hydrogen peroxide and 8 to 12 parts of starch; the oxidizing step is: the pH value is adjusted to 8 to 10, catalyst is added to be mixed for 20 to 40 minutes, and then the mixture is statically held for1 to 2 hours; and the modifying step is: modifier and filler are added to be uniformly mixed. The Urea hydrogen peroxide is used as the oxidant of the starch, so not only the production cost is low, the glue consumption quantity is less, but also the production process is free from utilizing defoamer and is free from peculiar smell, and the environmental protection can be realized.

Owner:HUZHOU SIYI STARCH IND

Method for synthesizing tetrabasic lead sulfate by utilizing positive electrode waste lead plaster and application thereof

InactiveCN103482690ALead sulfate accurateLead oxide accurateWaste accumulators reclaimingLead sulfatesCapacity lossElectrical battery

The invention discloses a method for synthesizing tetrabasic lead sulfate by utilizing positive electrode waste lead plaster and application thereof. The method comprises the following steps of washing, filtering, separating, dehydrating, drying, sieving and purifying the positive electrode waste lead plaster, and then, carrying out chemical analysis on a treated mixture, thereby obtaining contents of various components of lead sulfate, lead oxide and free lead in the treated mixture according to chemical analysis, adding lead powder to carry out mixing, grinding and sieving, so that the molar ratio of the lead oxide to lead sulfate after hybrid reaction is (4-5):1; and preserving the heat and presintering the sieved mixture in a resistance furnace, and then heating up to sinter, cooling and drying to obtain the tetrabasic lead sulfate. The method can be used for a storage battery manufacturer to prepare according to convenient conditions of the manufacturer, is simple and easy to implement; the prepared tetrabasic lead sulfate can completely satisfy performance requirements while being applied to battery production, so that early capacity loss of a lead storage battery is restrained, various electrical performances of the battery and a cycle life of the storage battery are greatly improved and prolonged, respectively, thereby not only solving a treatment problem of lead-containing waste materials of the storage battery enterprises, but also lowering production cost of enterprises and changing waste into things of value.

Owner:TIANNENG GRP JIANGSU SPECIAL POWER SUPPLY

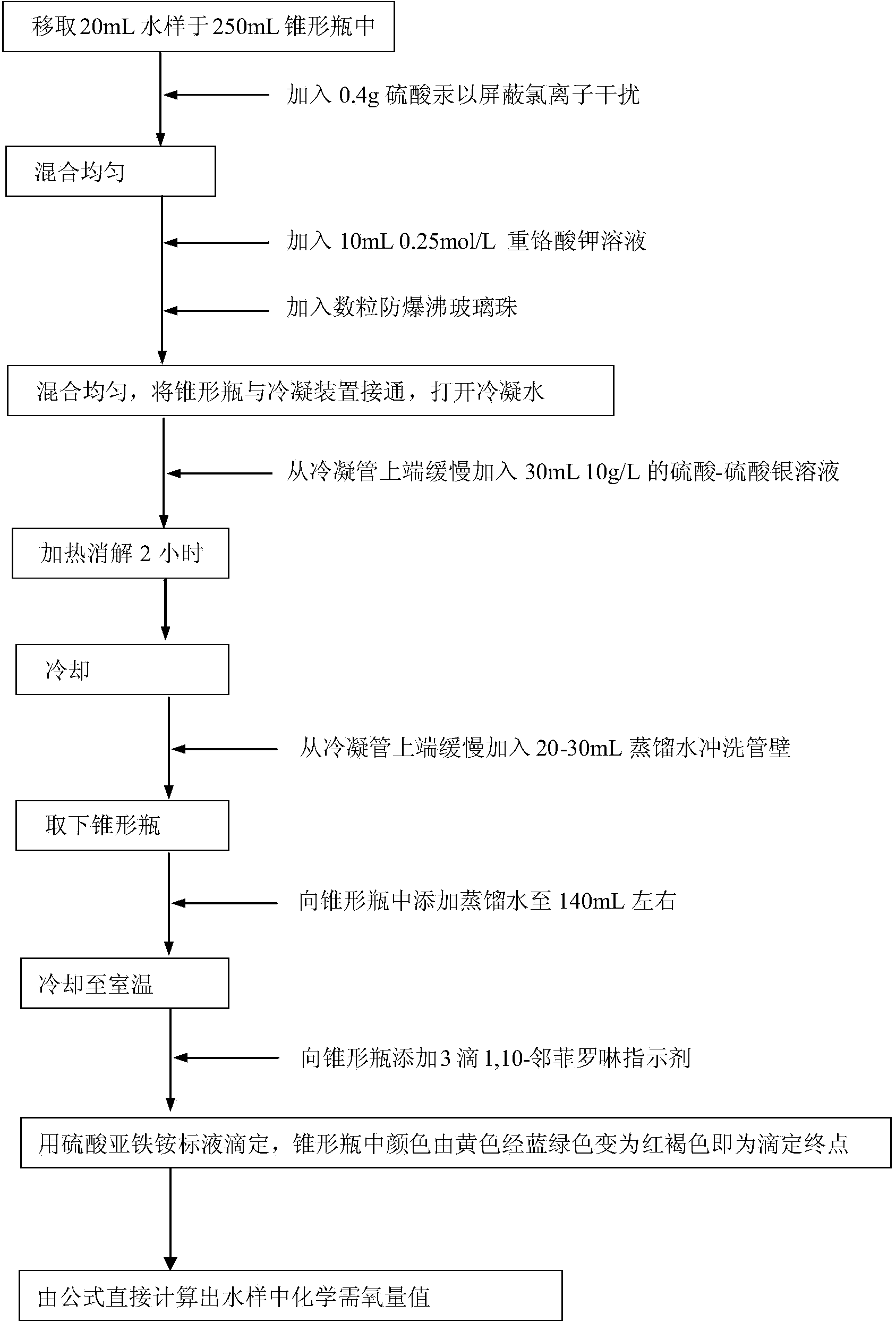

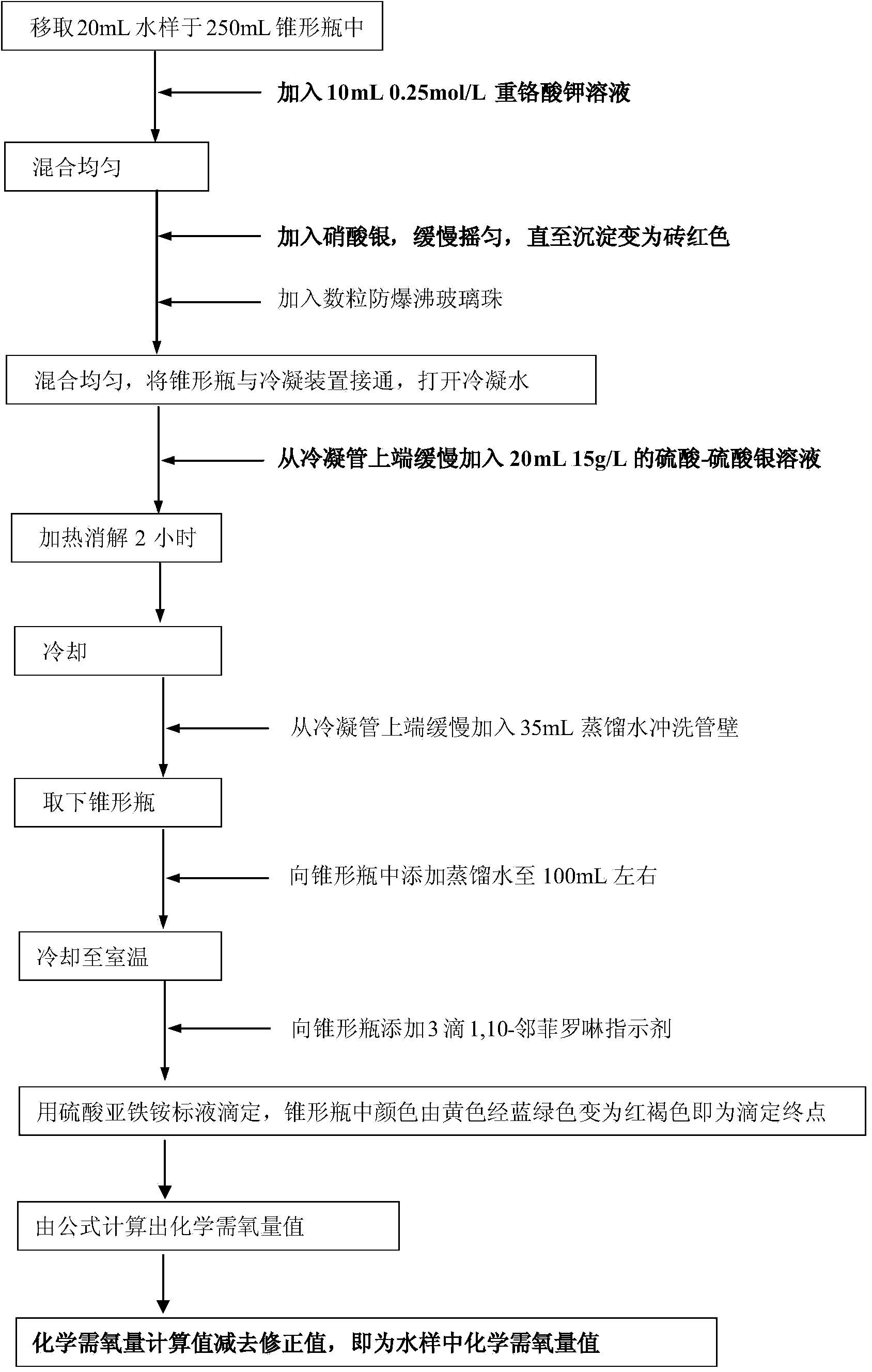

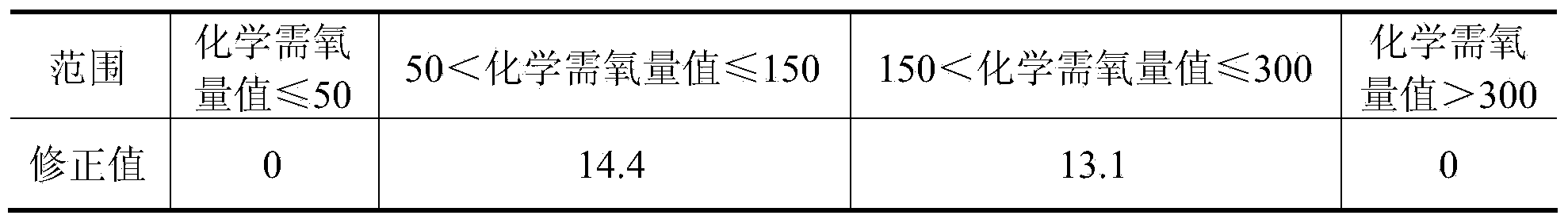

Method for determining chemical oxygen demand of high-chlorine waste water

InactiveCN104020170APrevent hazards to the health of experimentersAvoid secondary pollutionMaterial analysis by observing effect on chemical indicatorIonEnvironmental chemistry

The invention discloses a method for determining the chemical oxygen demand of high-chlorine waste water. The method comprises the following steps: (1) adding a potassium dichromate solution into a water sample put in a conical flask, and then uniformly mixing; (2) adding silver nitrate adopted as a chloride ion screening agent into the water sample put of the conical flask; after chloride ions and silver nitrate in the water sample completely form silver chloride precipitation, combining excessive silver nitrate with potassium dichromate to generate brick-red silver chromate precipitation, wherein when the brick-red precipitation appears in the conical flask, silver nitrate is not added; (3) adding 20mL15g / L of sulfuric acid-silver sulfate solution into the water sample of the conical flask, and then carrying out operation according to a standard potassium dichromate method to calculate the chemical oxygen demand value through a formula; (4) subtracting a modified value from the calculated chemical oxygen demand value to obtain the chemical oxygen demand value in the water sample. The method can prevent mercury sulfate from harming health of experimenters, prevents secondary pollution, is easy and convenient to operate, and can improve accuracy.

Owner:CNOOC ENERGY TECH & SERVICES +1

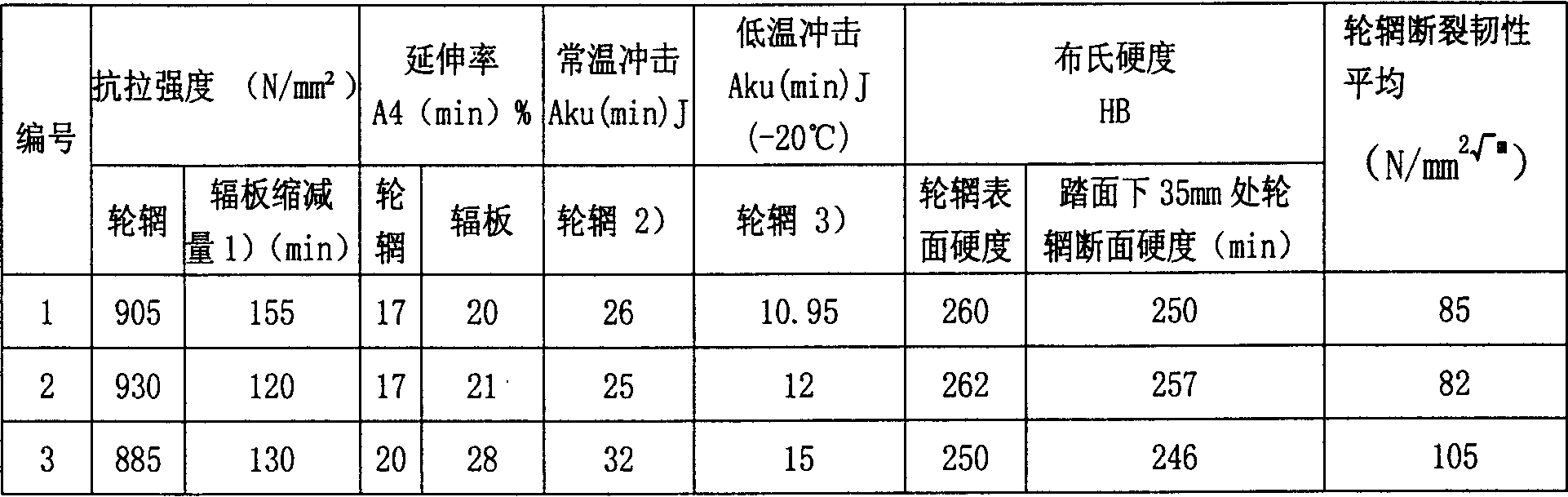

Medium carbon low alloy steel for light high speed train wheel

This invention relates to a type of midst-carbon and low-alloy steel which used for wheel of light super-speed railroad train. Account for weight it includes : 0.40-0.50%C 0.20-0.70%Si 0.50-0.80%Mn 0.20-0.30%Cr 0.015-0.035%Als S<=0.02% P<=0.02%,the rest is Fe and impurity element. The invention lowers the carbon inside steel, increases the Si, and adds trace quantity Al and Cr. Compared with the background technology, this invention has better property but lower cost.

Owner:MAANSHAN IRON & STEEL CO LTD

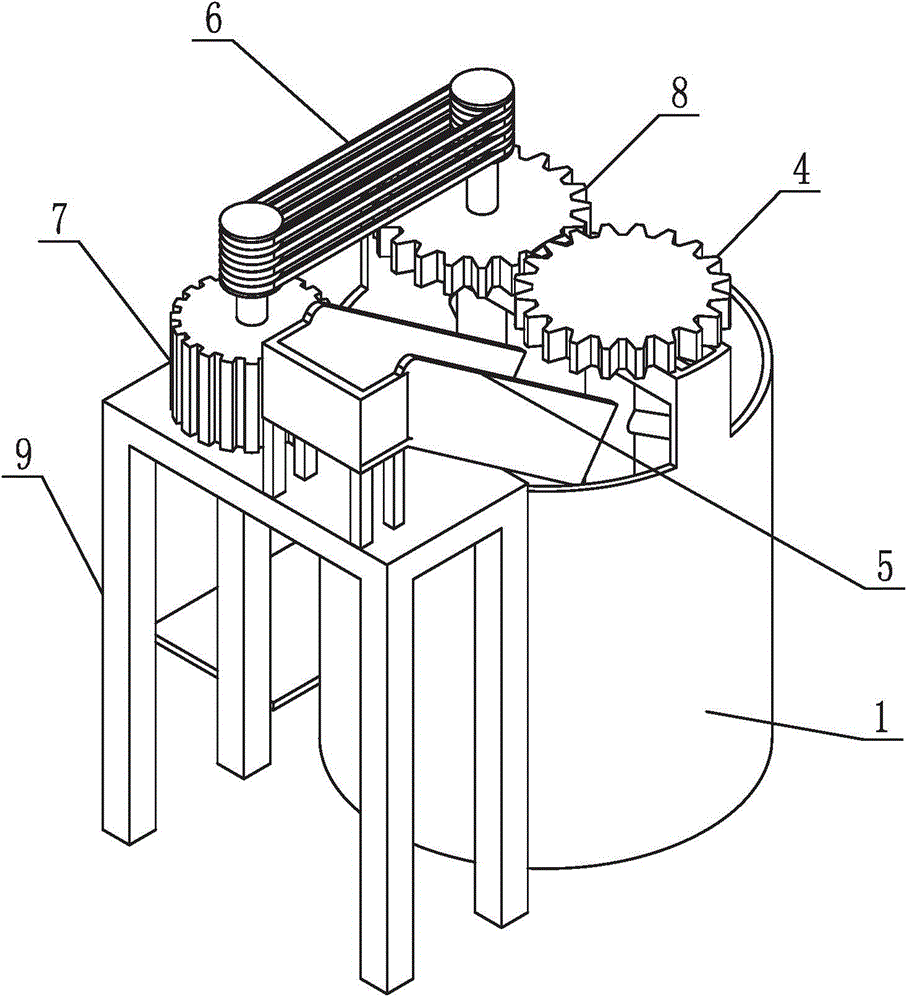

Food raw material mixing device

InactiveCN104128111ASimple structureEasy to useRotary stirring mixersFood materialMechanical engineering

The invention relates to a food raw material mixing device, which is used for mixing different solid materials. The mixing device comprises a material mixing bucket, a driven rotating disk, a transmission belt, a driving rotating disk, a bracket and a discharging gate, wherein a motor and a feeding device are fixed on the bracket; a driving revolving shaft is fixed in the middle of the driving rotating disk; and the driven revolving shaft is fixed in the middle of the driven rotating disk. The food raw material mixing device related to the invention is simple in structure, and is convenient to use. The adding quantity of materials to be mixed is easy to control, mixing dead corners are avoided, and the working efficiency is increased.

Owner:SUZHOU XINWEN FOOD

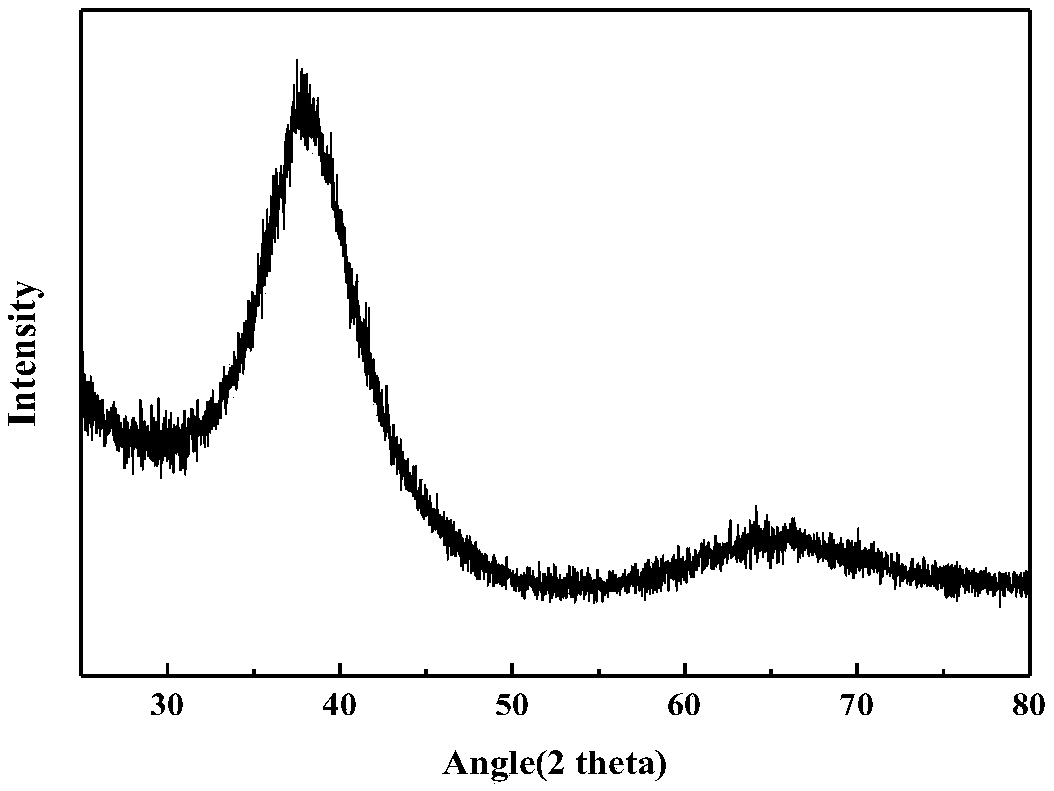

Aluminum-boron-carbon-nitrogen master alloy and preparation method thereof

ActiveCN101928862AHigh grain refinement efficiencyImprove particle propertiesMetallic materialsIngot

The invention belongs to the metal material field, and relates to an aluminum-boron-carbon-nitrogen master alloy for thinning magnesium and magnesium alloy and a preparation method thereof. The aluminum-boron-carbon-nitrogen master alloy is characterized by comprising the following elements in percentage by mass: 94.00 to 99.00 percent of aluminum, 0.10 to 4.00 percent of boron, 0.10 to 2.00 percent of carbon, and 0.01 to 0.50 percent of nitrogen. The preparation method for the aluminum-boron-carbon-nitrogen master alloy comprises the following steps of: melting pure aluminum in an intermediate frequency furnace and heating the aluminum melt to between 1,000 and 1,200 DEG C, then adding the preheated aluminum-boron and aluminum-carbon master alloy into the aluminum melt in turn while continuously blowing dried pure nitrogen into the aluminum melt, preserving the heat at the temperature of between 1,200 and 1,400 DEG C, stirring the mixture for 2 to 30 minutes, and casting the mixture to form ingots or wires. The prepared aluminum-boron-carbon-nitrogen master alloy has obvious grain thinning effect on the magnesium and the magnesium alloy.

Owner:SHANDONG UNIV

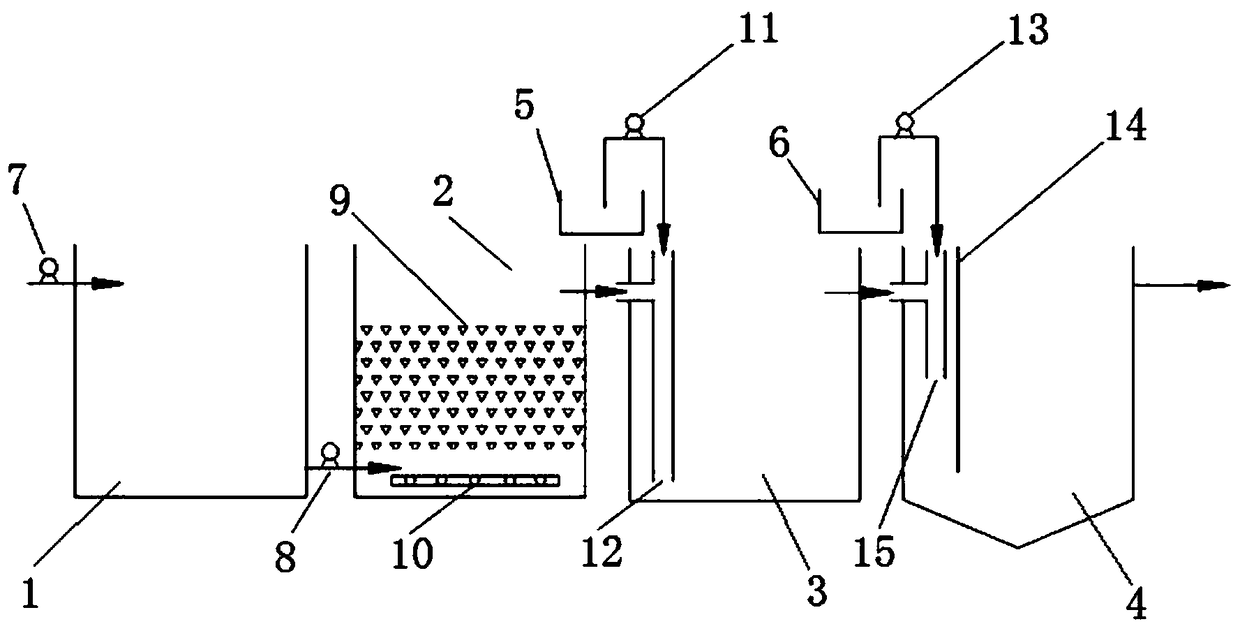

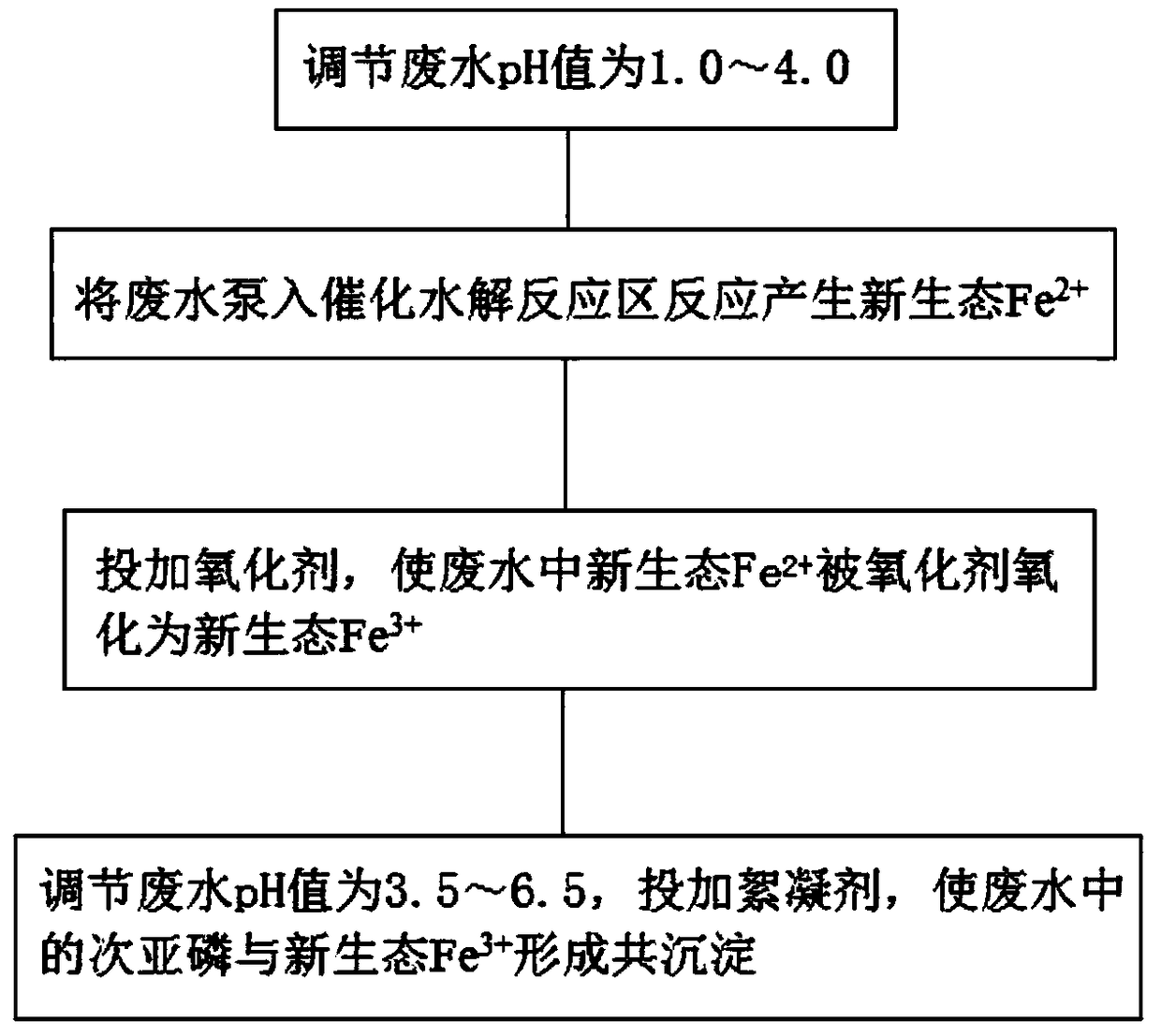

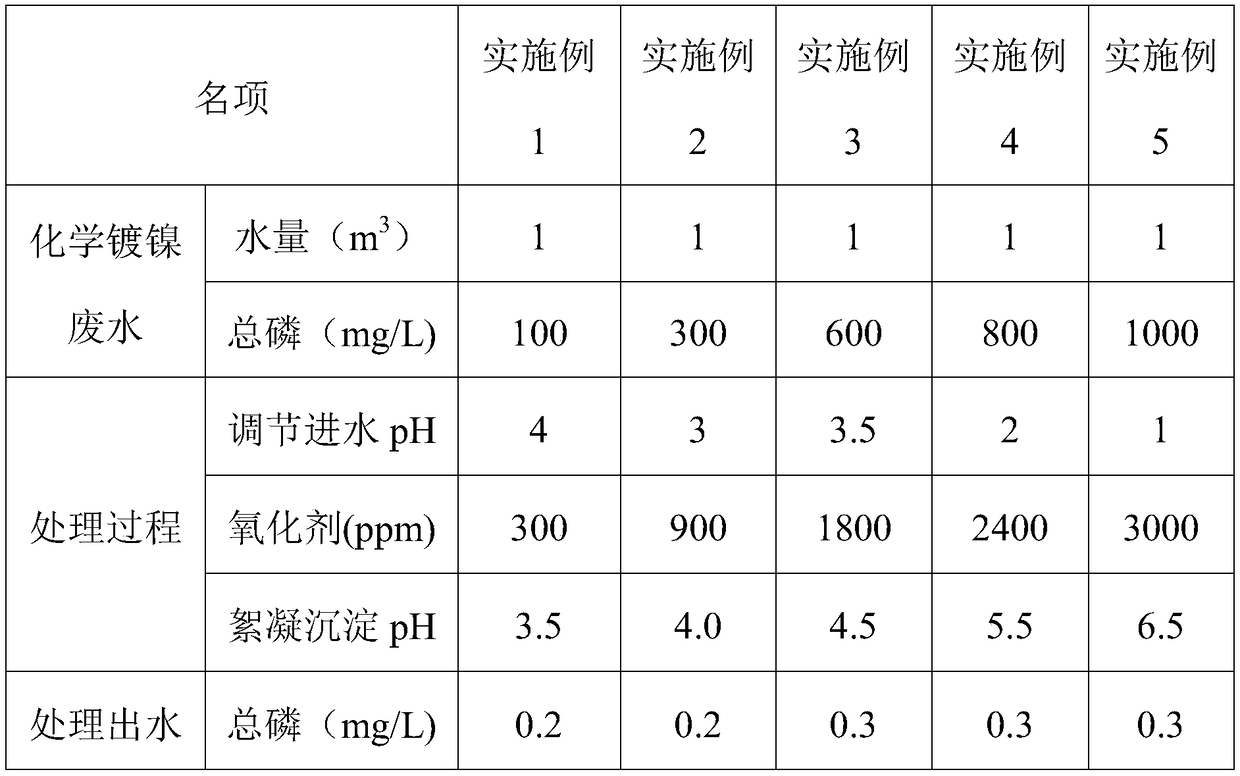

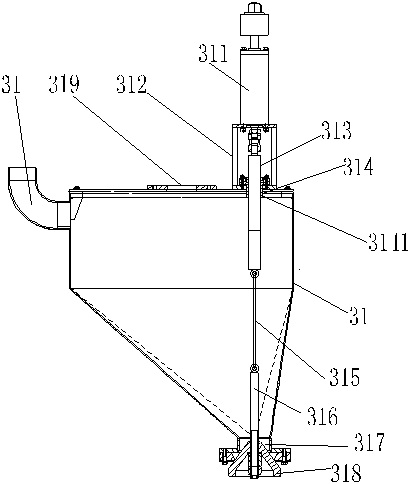

Device and method used for removing hypophosphites and phosphites in chemical nickel plating waste water

PendingCN109293074AEasy to joinThe amount added is easy to controlWater contaminantsMultistage water/sewage treatmentSludgeWater processing

The invention belongs to the field of waste water processing, and more specifically relates to a device and a method used for removing hypophosphites and phosphites in chemical nickel plating waste water. The device comprises an adjusting pool, a catalytic hydrolysis reaction pool, an oxidation pool, and a flocculation sedimentation basin which are connected successively through pipelines, and also comprises an oxidizing agent storage pool and a flocculating agent storage pool; the oxidizing agent storage pool is connected with the oxidation pool; the flocculating agent storage pool is connected with the flocculation sedimentation basin; a first elevator pump is arranged at a water inlet of the adjusting pool; a second elevator pump is arranged on the pipeline used for connecting the adjusting pool with the catalytic hydrolysis reaction pool; a first metering pump is arranged on the pipeline used for connecting the oxidizing agent storage pool with the oxidation pool; and a second metering pump is arranged on the pipeline used for connecting the flocculating agent storage pool with the flocculation sedimentation basin. The device is used for processing chemical nickel plating wastewater, sludge production amount is small, operation cost is low, and hypophosphites and phosphites in chemical nickel plating waste water can be removed completely with high efficiency.

Owner:深圳瑞赛环保科技有限公司

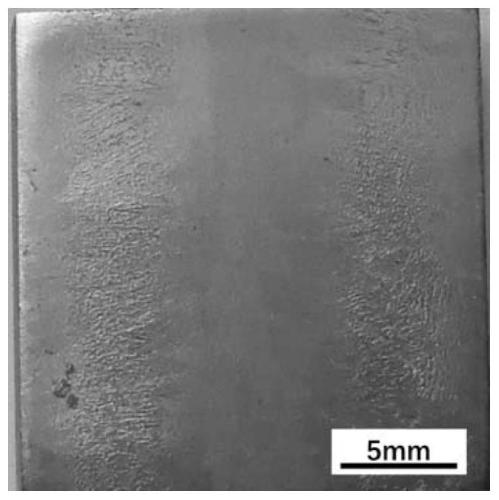

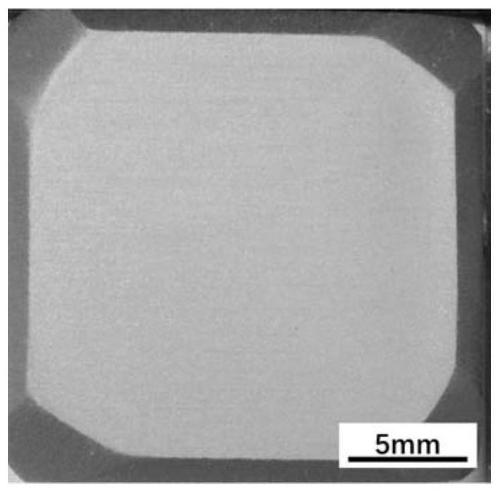

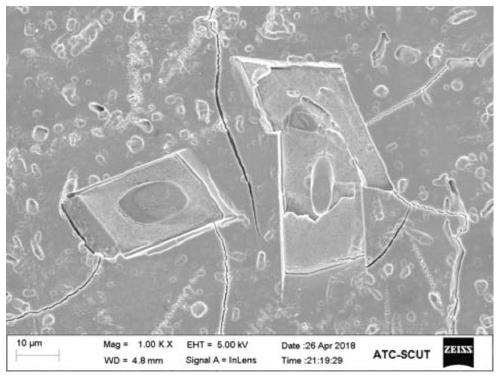

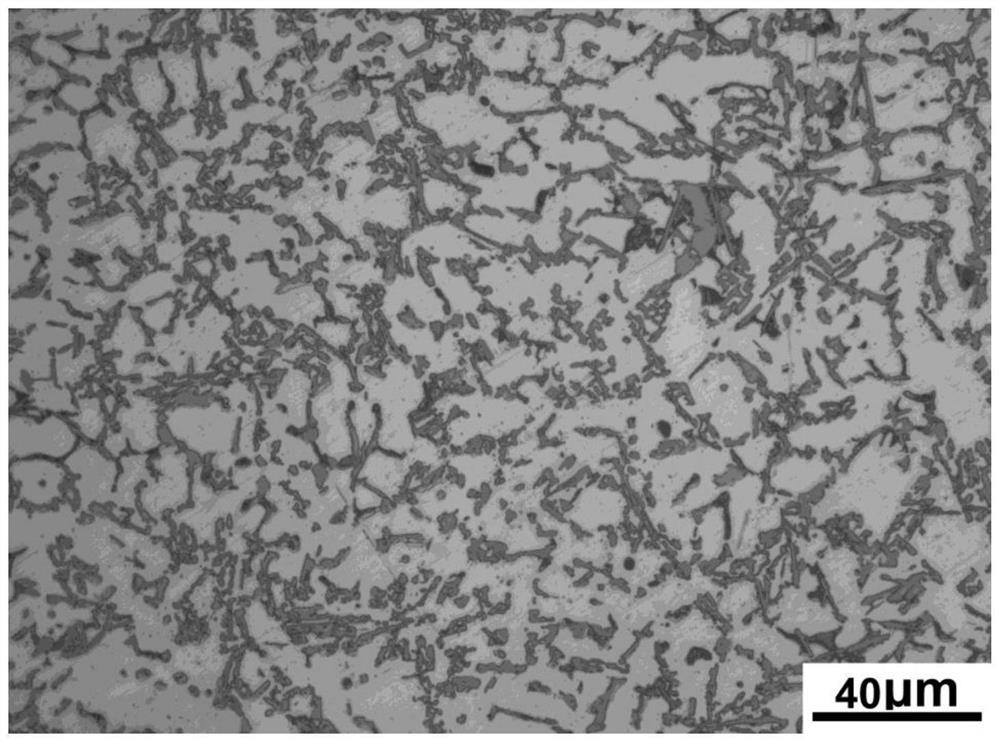

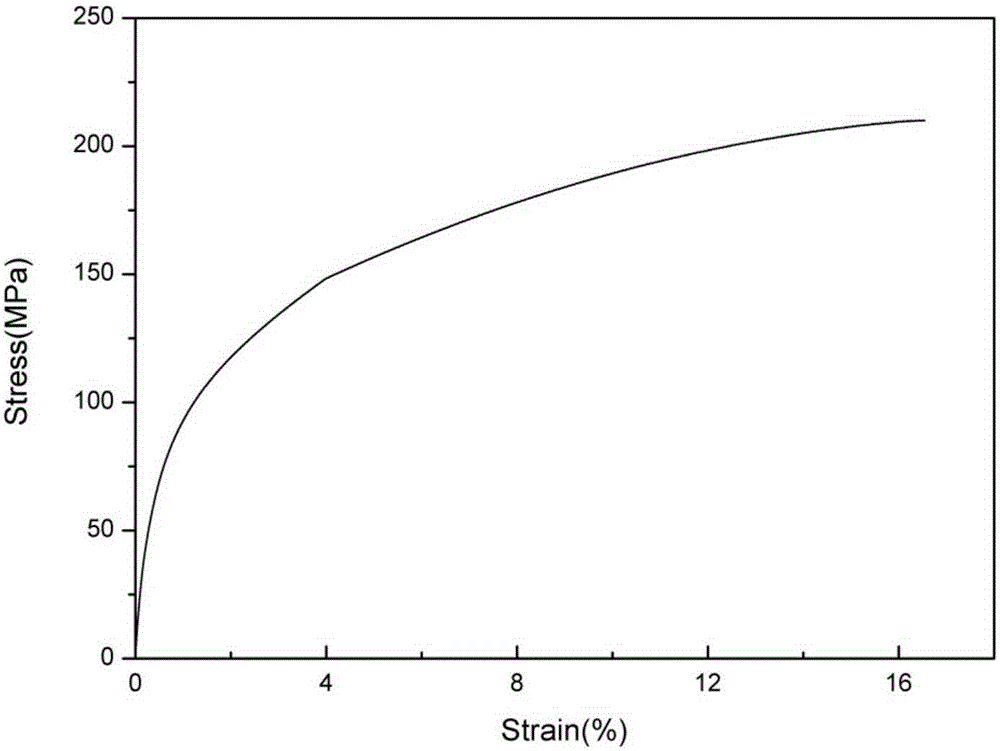

Anodizable Al-Mn series cast aluminum alloy and anodizing process thereof

The invention discloses anodizable Al-Mn series cast aluminum alloy and an anodizing process thereof. The alloy comprises, by weight, 2.0% of Mn, 0.7-1.2 % of Co, 0.2-0.4% of Sc, 0.1-0.3 % of Ti, andthe balance being Al. The alloy anodizing process comprises the following steps: cutting, grinding, degreasing, alkali washing, ash removing, cleaning and drying the alloy; and then soaking the obtained aluminum alloy sample in an electrolyte, carrying out anodizing treatment on the aluminum alloy in a direct-current constant-current mode, taking out the workpiece, cleaning the workpiece with deionized water, and drying the workpiece to obtain an anodic oxide film. The tensile strength of the alloy is greatly improved, and the film obtained after anodizing is thick, smooth in surface, uniformin color and attractive; moreover, the alloy has good corrosion resistance, and is suitable for manufacturing a protective shell of a 3C electronic product.

Owner:SOUTH CHINA UNIV OF TECH

Ultrahigh-temperature ceramic-based composite material and preparation method thereof

InactiveCN110563479AThe amount added is easy to controlReduce erosionInterface layerUltrahigh temperature ceramics

The invention relates to an ultrahigh-temperature ceramic-based composite material and a preparation method thereof. The preparation method comprises the following steps: mixing ceramic powder and thermosetting phenolic resin to prepare a slurry; compounding the slurry and carbon cloth by adopting a hot melt adhesive film method to obtain a prepreg; laying and stacking the prepreg and preparing amould pressing flat plate; carrying out thermal cracking on the mould pressing flat plate to obtain a carbon / carbon green body; treating the carbon / carbon green body to obtain a carbon / carbon green body with an anti-silicification interface layer; carrying out densification treatment on the carbon / carbon green body with the anti-silicification interface layer by adopting a PIP process to obtain acarbon / carbon matrix; and covering the carbon / carbon matrix with silicon powder, and carrying out melt siliconizing by using a reaction infiltration method to obtain the ultrahigh-temperature ceramic-based composite material. The composite material prepared by the method has excellent mechanical properties, and has substantive benefits in the field of space flight and aviation.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Vanadiferous magnesium intermediate alloy grain refiner and preparation method and application thereof

The invention discloses a vanadiferous magnesium intermediate alloy grain refiner and a preparation method and application thereof. The grain refiner comprises, by mass, 90-99% of magnesium and the balance vanadium compound which is composed of at least one of VC, VN, VC<x>N<1-x>, and in VC<x>N<1-x>, x is larger than 0 and less than 1. The invention further discloses the preparation method of the vanadiferous magnesium intermediate alloy grain refiner. According to the vanadiferous magnesium intermediate alloy grain refiner, the vanadium compound can be used as an effective heterogeneous nucleation core of magnesium alloy and prepared into magnesium intermediate alloy, the adding amount is easier to control, using is convenient, the yield is high, and limiting of the content of the magnesium alloy is avoided (the grain refiner can be added into both magnesium alloy containing Al and magnesium alloy free of Al); and after the grain refiner is added into the magnesium alloy, the grain of the magnesium alloy is effectively refined, magnesium and the magnesium alloy are strengthened, and the comprehensive mechanical property of the magnesium alloy is improved.

Owner:CHONGQING UNIV OF ARTS & SCI

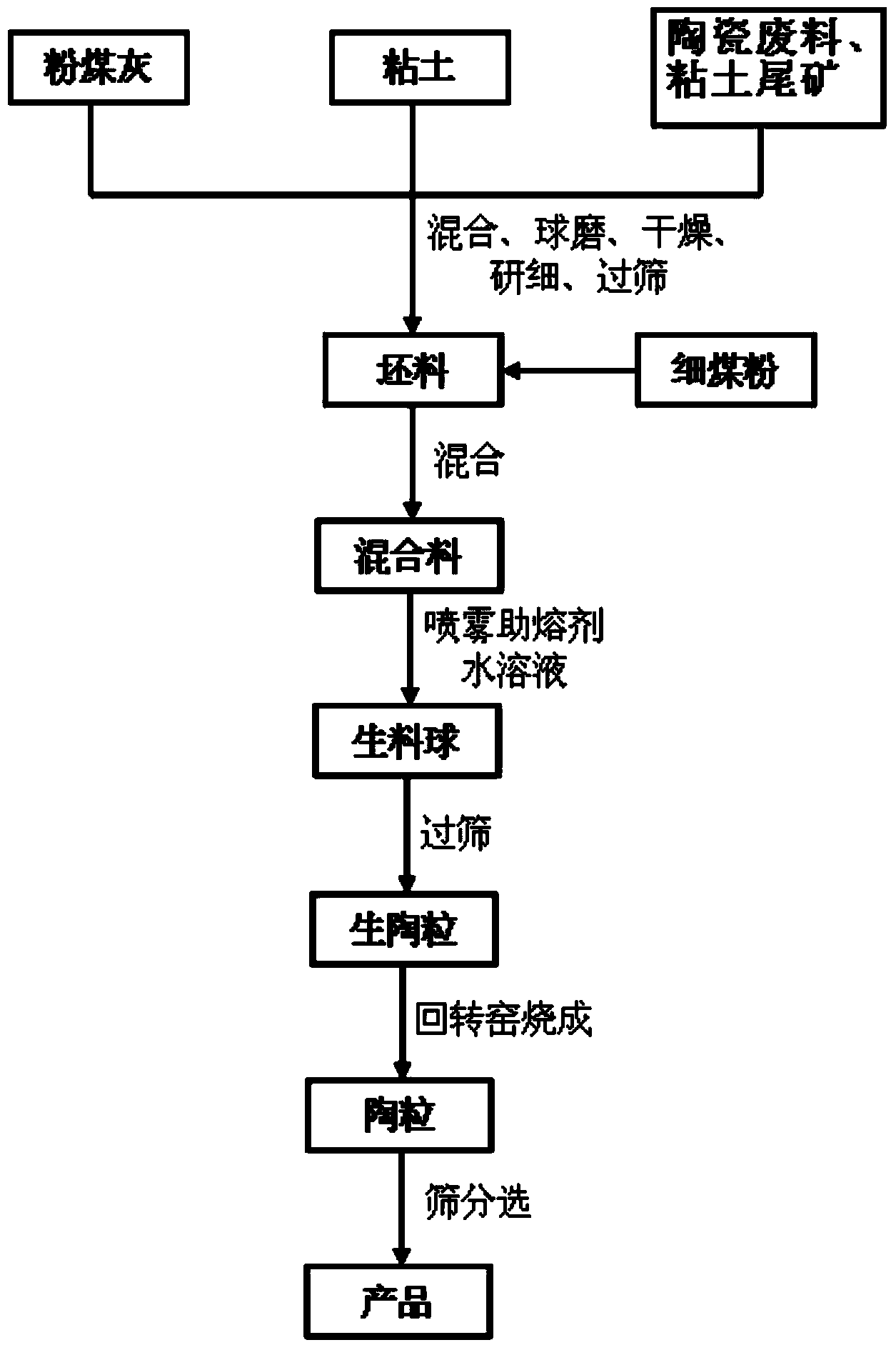

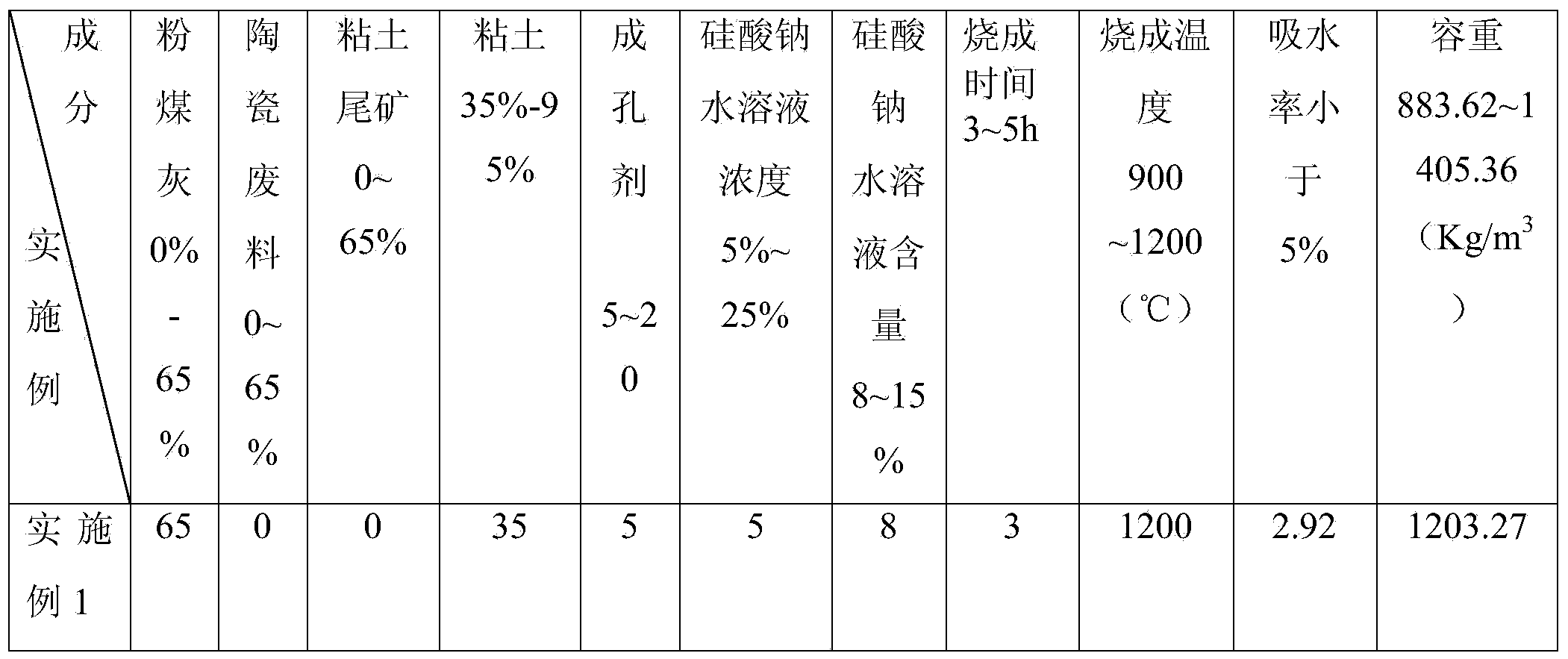

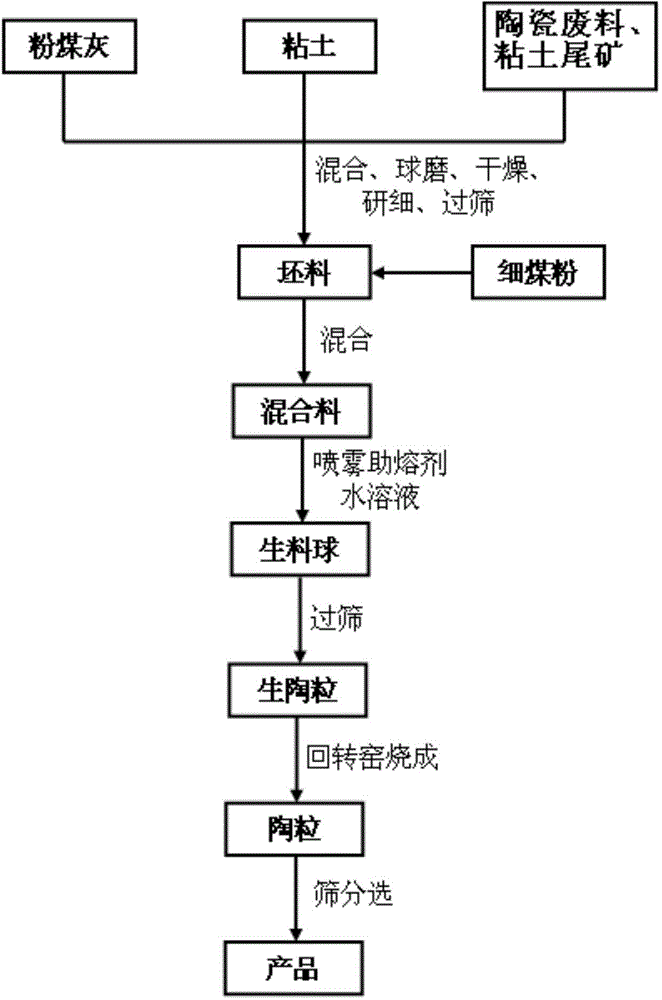

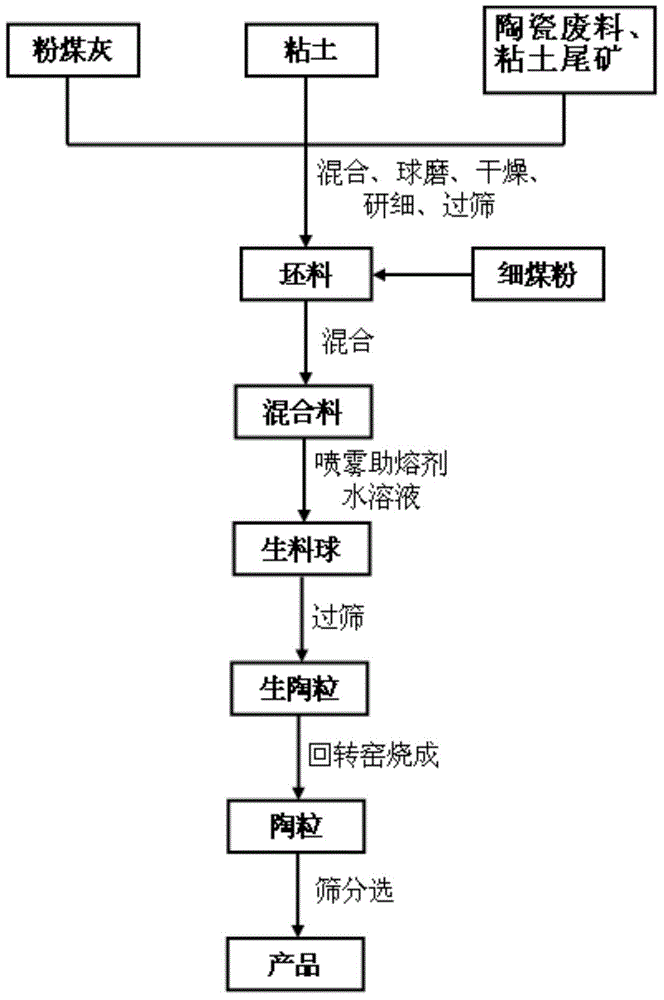

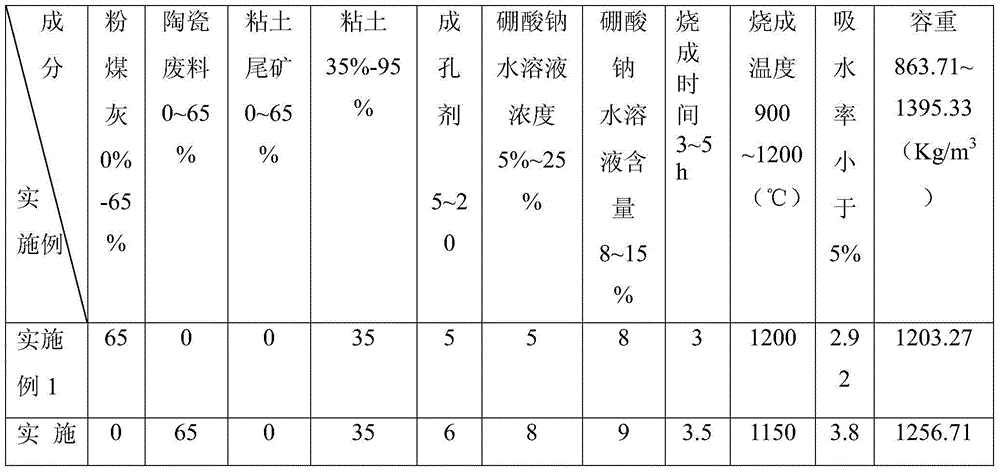

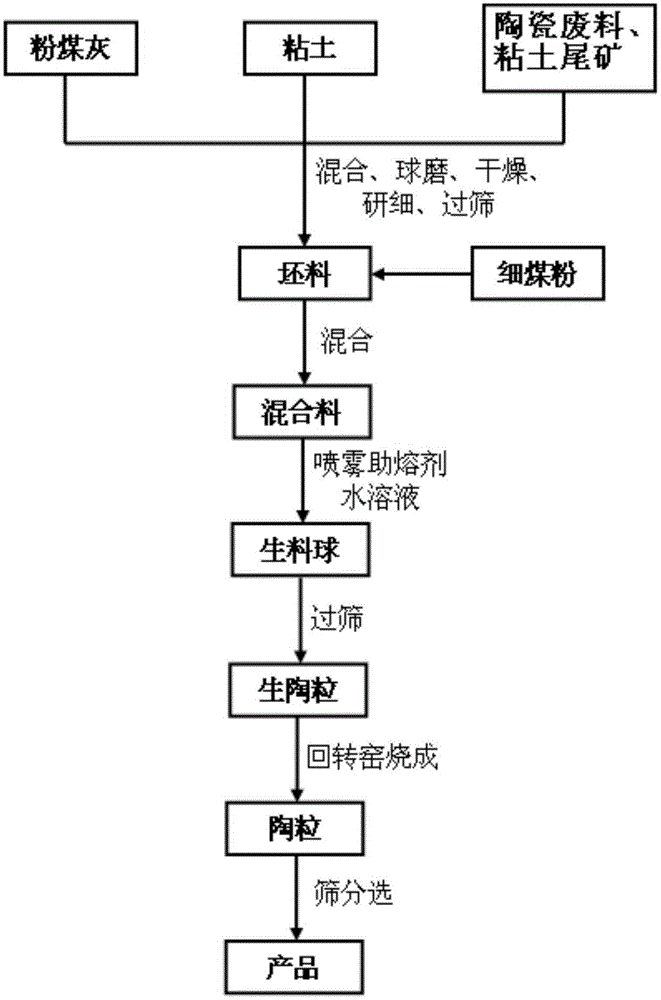

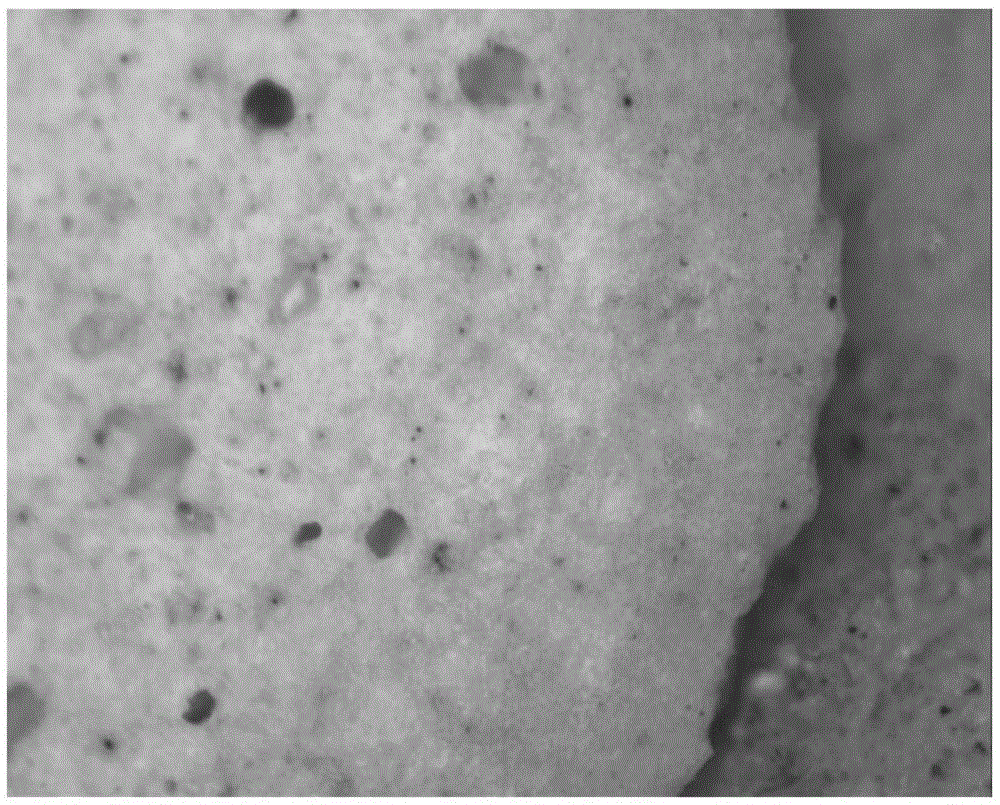

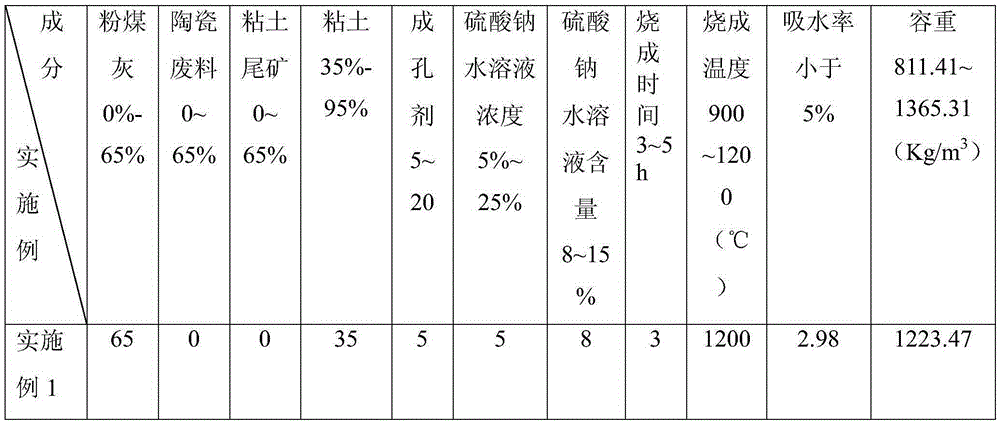

Sodium silicate surface co-sintered light ceramsite and preparation method thereof

ActiveCN104291786ALow costSimple processCeramic materials productionCeramicwareSurface layerHigh volume manufacturing

The invention relates to sodium silicate surface co-sintered light ceramsite and a preparation method thereof. The light ceramsite and the preparation method have the beneficial effects that by spraying a 5-25% sodium silicate solution step by step, during drying, sodium ions dissolved in water diffuse toward the surfaces along with the moisture and gather on the shells of surfaces of raw meal nodules, the sodium ions on the surface layers react with other matters in the sintering process to form fusible matters, thus playing a role of co-sintering agents, and the content of the sodium ions in the co-sintering agents below the surface layers of the raw meal nodules is very low; the ceramsite sintered at a surface layer sintering temperature has relatively low water absorption but the unsintered density of core regions below the surface layers is lower, so that the light ceramsite with low water absorption and low overall density is finally obtained; the problems that the ceramsite not only requires low water absorption and high strength but also requires light volume weight are solved; the preparation method of the sodium silicate surface co-sintered light ceramsite is simple in process and safe to operate, can be used for volume production and is low in cost.

Owner:SHAANXI UNIV OF SCI & TECH

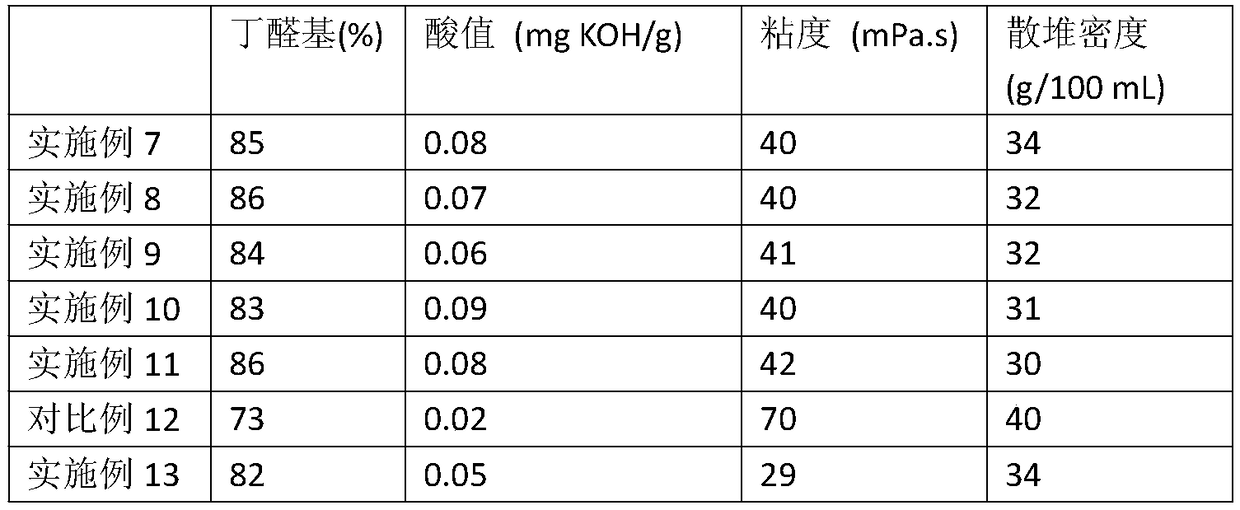

Preparation method for polyvinyl butyral resin

ActiveCN109053936AThe amount added is easy to controlEasy to prepareInorganic saltsOrganic sulfonic acid

The invention relates to a method for preparing polyvinyl butyral by utilizing organic sulfonic acid catalysis. A sulfonic acid catalyst with a long chain structure is chosen and added with inorganicsalt to promote the process of reaction, consequently, while the sufficient reaction of the materials is ensured, the efficiency is increased, on the other hand, the molecular structure is regulated on the microcosmic level, and thereby a novel low-viscosity product is obtained.

Owner:吉林诺德高科新材料有限公司

Preparation process of sevelamer carbonate

InactiveCN105732865AAvoid wastingThe amount added is accurateOrganic active ingredientsMetabolism disorderSevelamerCarbonate

The invention relates to the technical field of production of sevelamer carbonate. A preparation process of sevelamer carbonate comprises the steps as follows: firstly, an epichlorohydrin acetonitrile solution is added to a poly (allylamine hydrochloride) solution in proportion, curing is performed, and polymerized jelly is obtained; after polymerization, the jelly is milled to 50 meshes by a colloid mill, then a 4% sodium hydroxide aqueous solution is added, the stirring reaction is performed, and sevelamer alkali is obtained; finally, purified water is added to the sevelamer alkali, then the temperature is raised, carbon dioxide is fed in, centrifugation and drying are preformed after heat-preserved stirring reaction, and sevelamer carbonate is obtained. By adopting the preparation process of sevelamer carbonate, the product energy consumption can be greatly lowered, the product quality is improved, and the problem of production of waste water is solved; meanwhile, the labor intensity can also be reduced, and the labor productivity is raised; the product quality is improved, the qualified rate of finished products reaches 99.6%, and the yield reaches 64.7%.

Owner:JIANGSU TIANHE PHARMA CO LTD

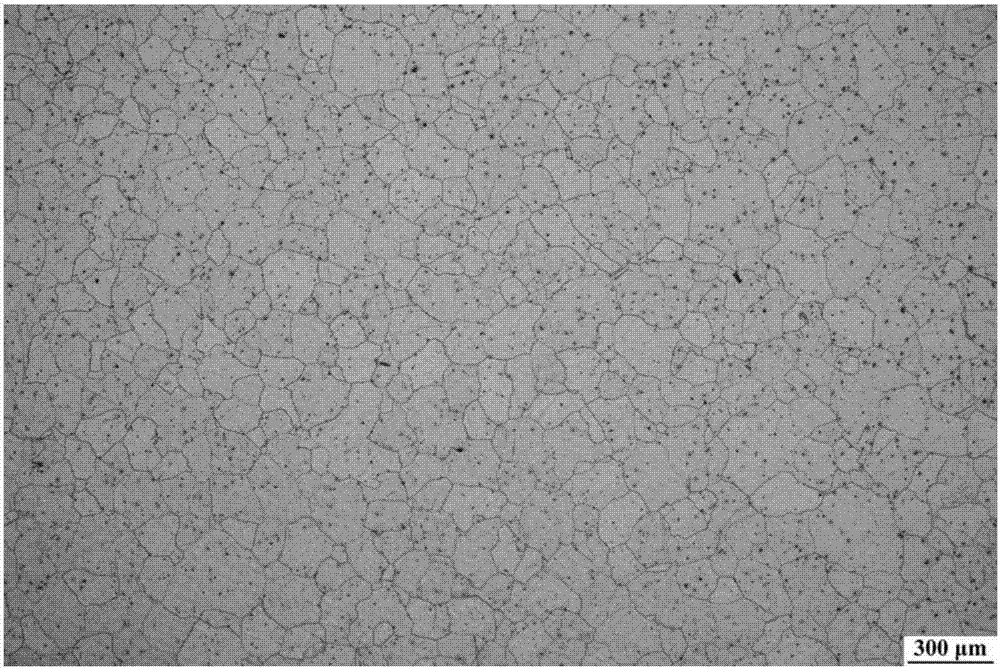

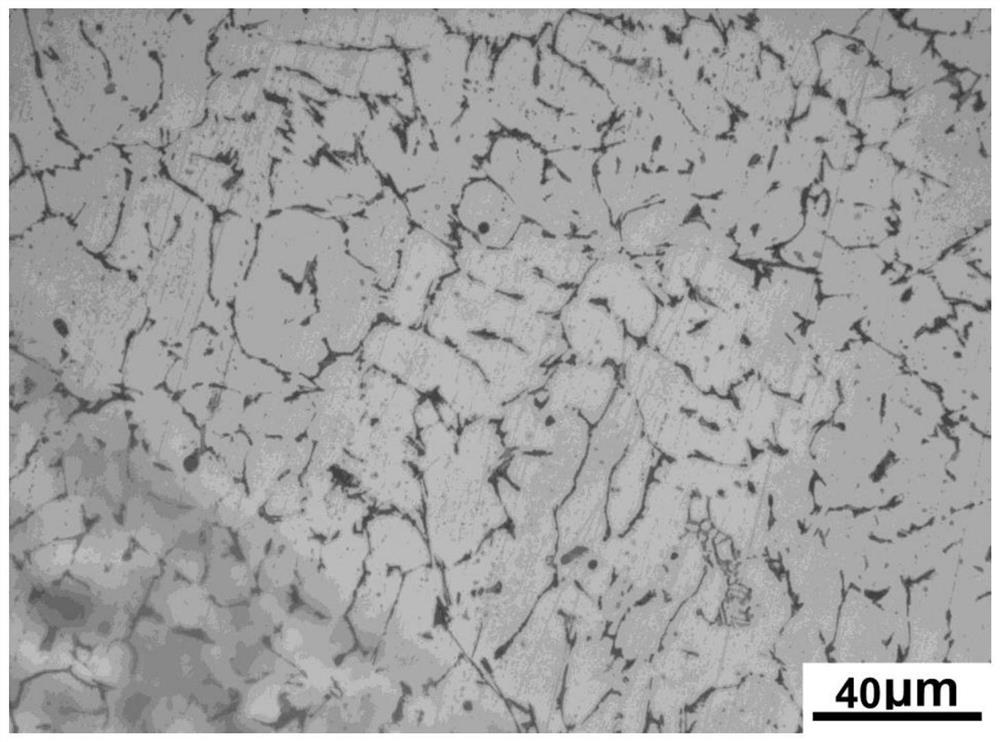

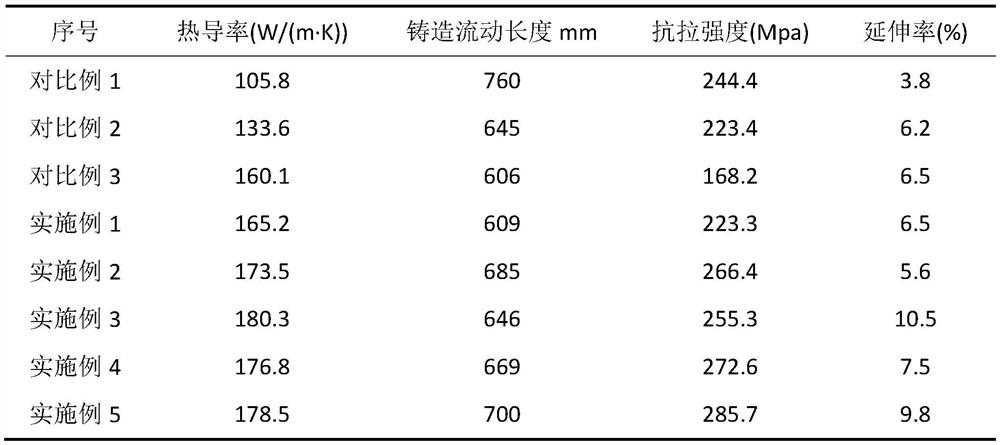

High-thermal-conductivity and low-expansion wrought aluminum alloy and preparation method thereof

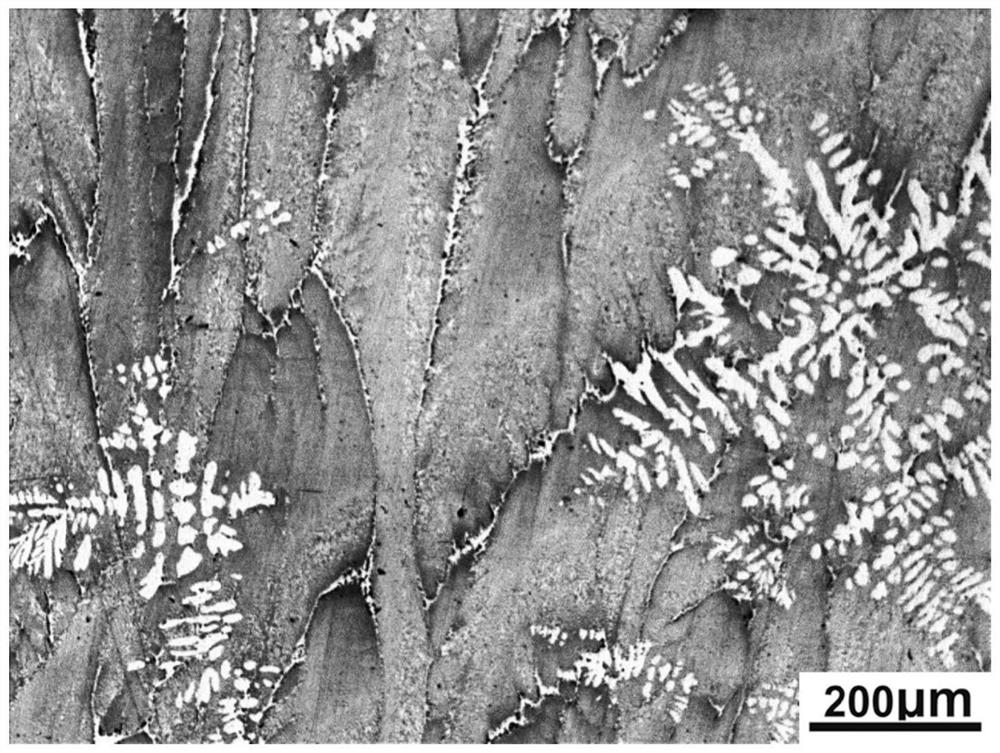

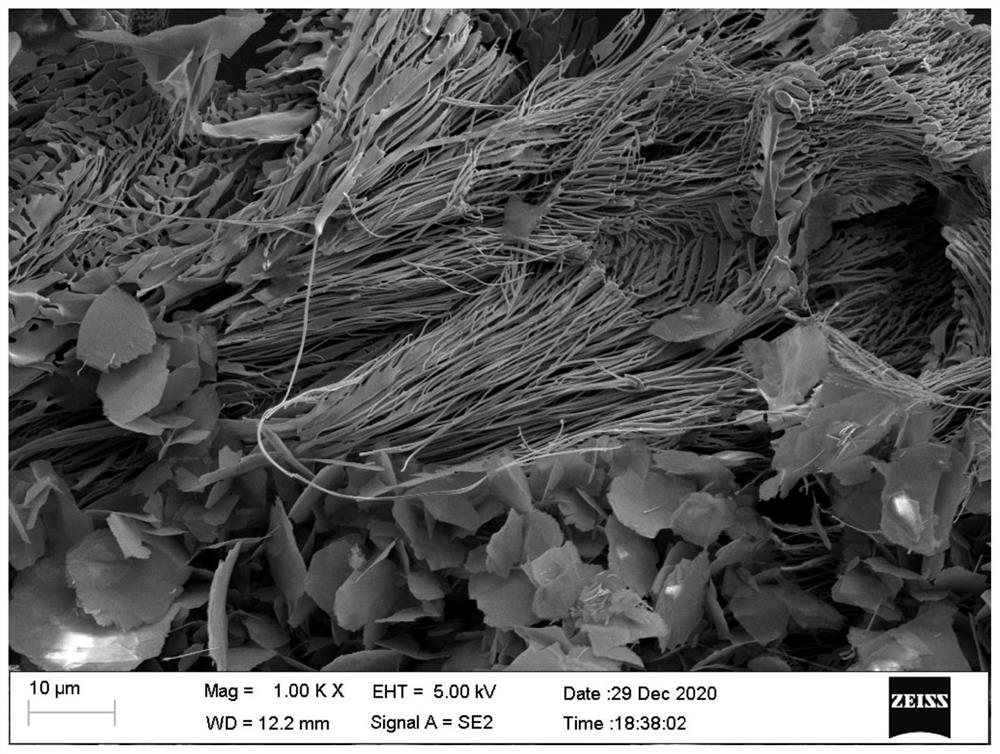

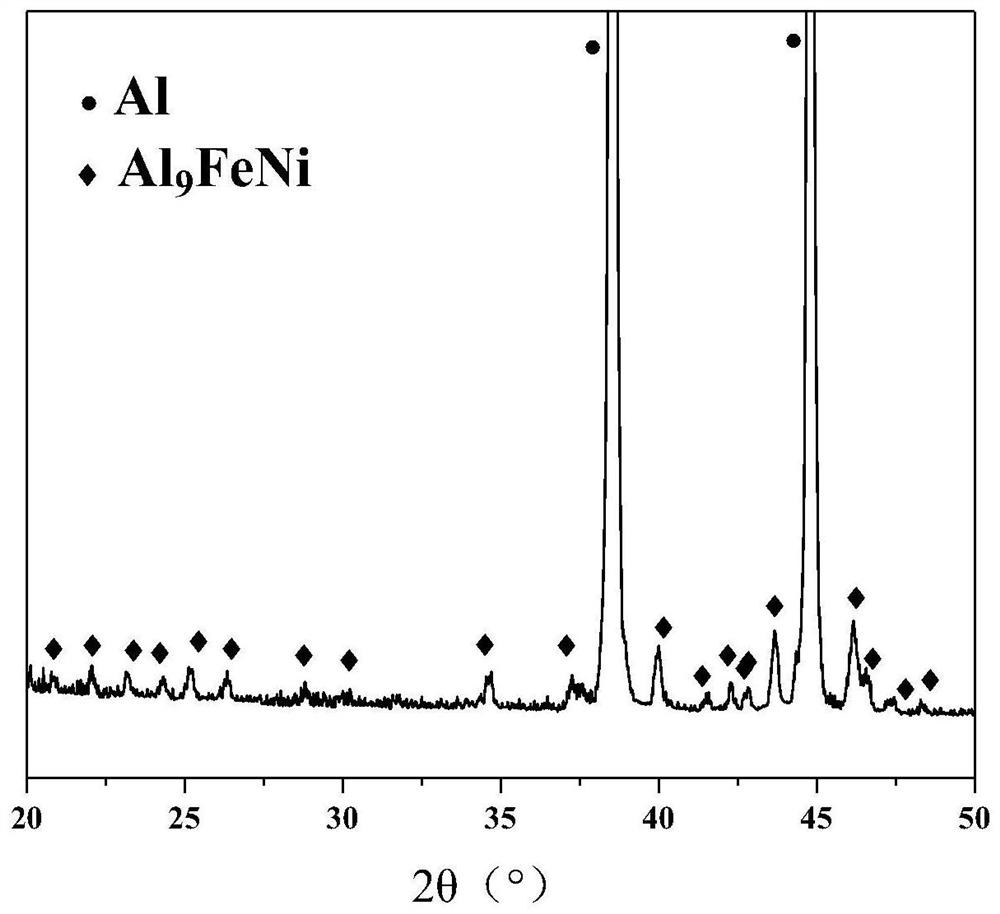

ActiveCN113502419ALittle impact on thermal conductivityThermal balance optimizationSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationMicrostructure morphology

The invention belongs to the technical field of wrought aluminum alloys and discloses a high-thermal-conductivity and low-expansion wrought aluminum alloy and a preparation method thereof. The wrought aluminum alloy comprises the following components in percentage by mass: 1.5-2.5% of Fe, 1.0-2.0% of Ni, 0-0.5% of Yb, 0-0.5% of Mg and the balance of Al, wherein Yb and Mg are not 0 at the same time; the wrought aluminum alloy is obtained by performing mechanical vibration casting on a melt; or after mechanical vibration casting is completed, annealing treatment and rolling deformation treatment are carried out. The invention further discloses a preparation method of the wrought aluminum alloy. According to the high-thermal-conductivity and low-expansion wrought aluminum alloy and the preparation method thereof, Yb and / or Mg compound modification and vibration casting are used for improving the microstructure morphology of the alloy; and multi-target balance optimization of the heat-conducting property, the thermal expansion coefficient and the mechanical performance of the alloy is achieved. The wrought aluminum alloy has high thermal conductivity, low expansibility and high mechanical performance.

Owner:SOUTH CHINA UNIV OF TECH +1

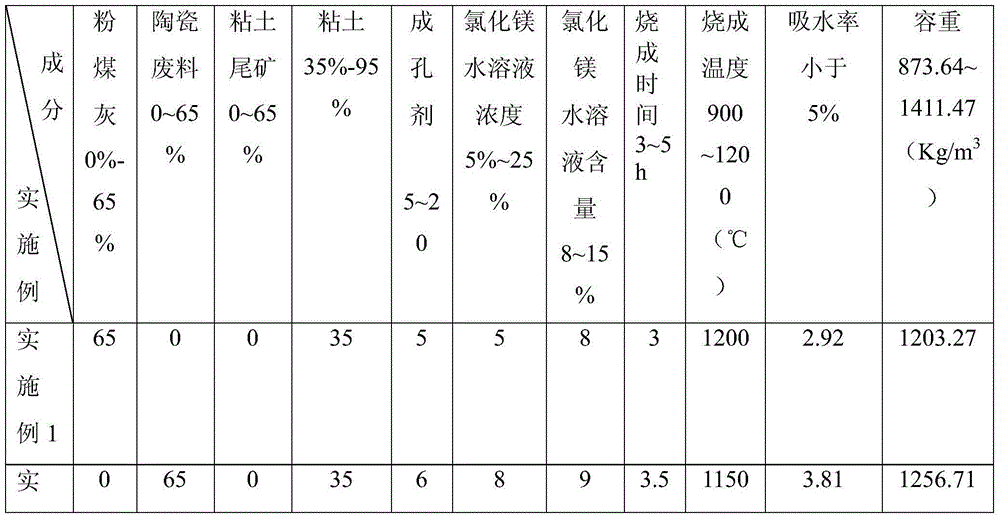

Light ceramsite co-sintered on surface by virtue of magnesium chloride and preparation method of light ceramsite

The invention relates to light ceramsite co-sintered on the surface by virtue of magnesium chloride and a preparation method of the light ceramsite. The preparation method of the light ceramsite co-sintered on the surface by virtue of magnesium chloride comprises the following steps: spraying a 5-25% magnesium chloride solution in steps, drying and sintering, wherein during drying, magnesium ions dissolved in water diffuse toward the surface along with moisture and are enriched on a shell of the surface of each raw nodule; and during sintering, reaction is carried out on the magnesium ions in the surface layer and other substances to form fusible substances, an effect of a sintering aid is realized, content of magnesium ions in the sintering aid below the surface layer of each raw nodule is very low, the ceramsite sintered on the surface layer at a sintering temperature is relatively low in water absorption rate while density of an unsintered core region below the surface layer is relatively low, and finally the light ceramsite with low water absorption rate and low overall density is obtained. The preparation method of the light ceramsite co-sintered on the surface by virtue of magnesium chloride has the advantages that the problems that the water absorption rate of the ceramsite is low, strength is high and volume weight is low are solved; meanwhile, a technology is simple, operation is safe, mass production can be realized, and cost is low.

Owner:铜川秦瀚陶粒有限责任公司

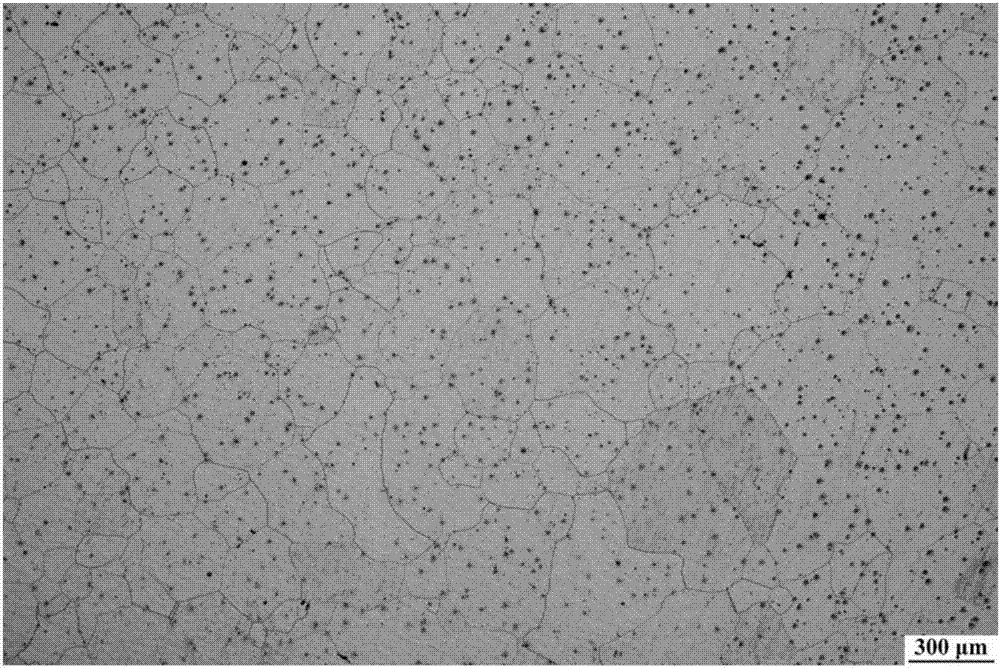

A kind of cast aluminum alloy with high thermal conductivity, high strength and low Si and preparation method thereof

ActiveCN111485146BGood casting fluidityMeet casting performance requirementsCo elementThermal conductivity

The invention discloses a cast aluminum alloy with high thermal conductivity, high strength and low Si and a preparation method thereof; the raw material components are: 2.5-4.5% Si; 2.0-3.0% Zn; 0.8-1.2% Fe; 0.2-0.4% Mg; 0.1-0.3% Co; 0.03-0.1% Sr; 0.02%-0.05% B; 0.05-0.15% RE; the balance is Al; the preparation method includes high-temperature melting aluminum alloy, supplementary elements and trace elements multi-component alloying treatment, Refining slag removal, casting molding. The invention makes full use of the composite synergistic effect of auxiliary alloying of Mg and Co elements and microalloying of Sr, B and RE elements, solves the problem of mutual restriction between the strengthening of the alloy and the improvement of the thermal conductivity of the material, and realizes the thermal conductivity and high thermal conductivity of the cast aluminum alloy. With the synchronous improvement of mechanical properties, a low-Si cast aluminum alloy material for communication and heat dissipation devices with high thermal conductivity and high strength has been obtained.

Owner:SOUTH CHINA UNIV OF TECH

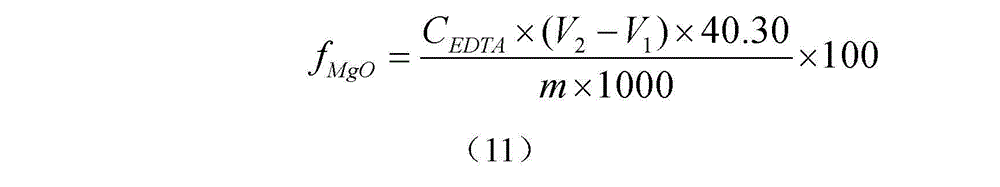

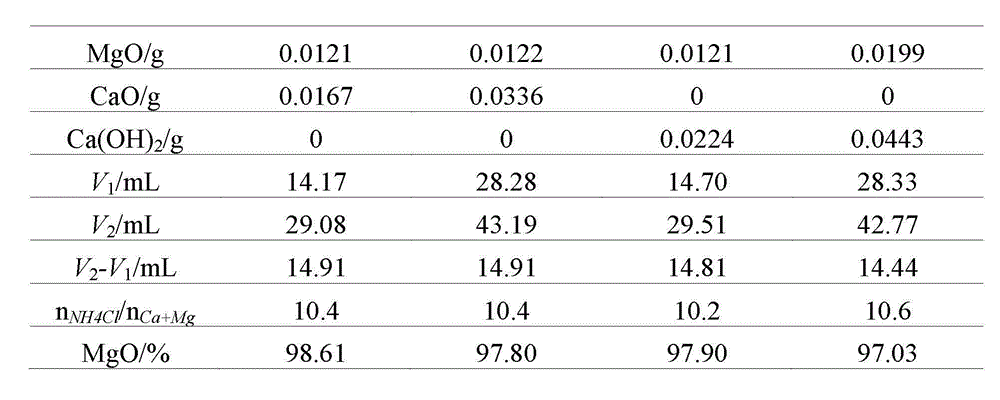

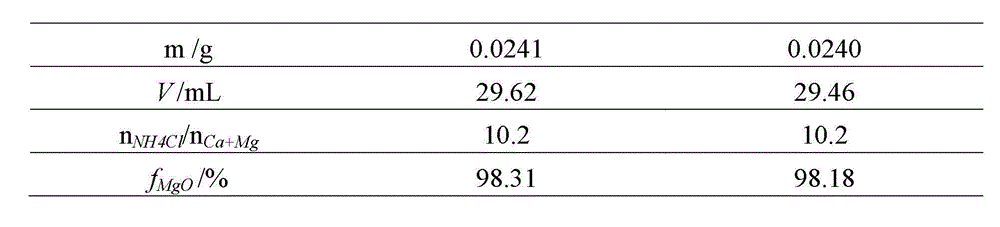

Method for measuring content of free magnesium oxide in steel slag

ActiveCN102914619ADetermination of free magnesium oxide contentAffect precisionAnalysis using chemical indicatorsChemical analysis using titrationSlagSubstance amount

The invention relates to a method for measuring the content of free magnesium oxide in steel slag, and particularly adopts an ammonium chloride-glycol-ethanol method to measure the content of the free magnesium oxide in the steel slag. A catalyst ammonium chloride is added into a glycol-ethanol solution to achieve the aim of rapidly extracting the content of the free magnesium oxide in the steel slag. The best adding amount of the ammonium chloride is determined; when the ratio of magnesium in a solution to be detected to the total substance amount of calcium and magnesium is less than 0.1, the more suitable ratio of the ammonium chloride to the total substance amount of the calcium and the magnesium is (12-25):1; and when the ratio of magnesium in the solution to be detected to the total substance amount of the calcium and the magnesium is more than 0.1, the more suitable ratio of the ammonium chloride to the total substance amount of the calcium and the magnesium is (18-30):1. The determination method has the advantages of simple determination process, short needed time, low cost, high accuracy and strong practical applicability.

Owner:BEIJING UNIV OF CHEM TECH

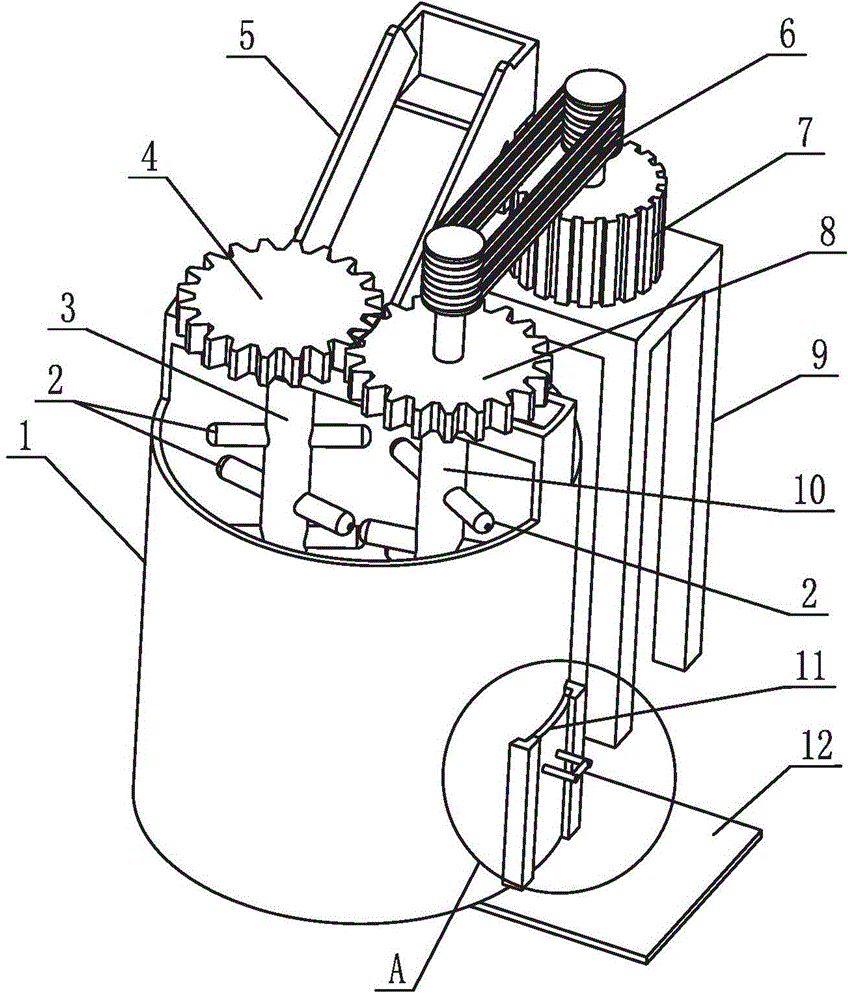

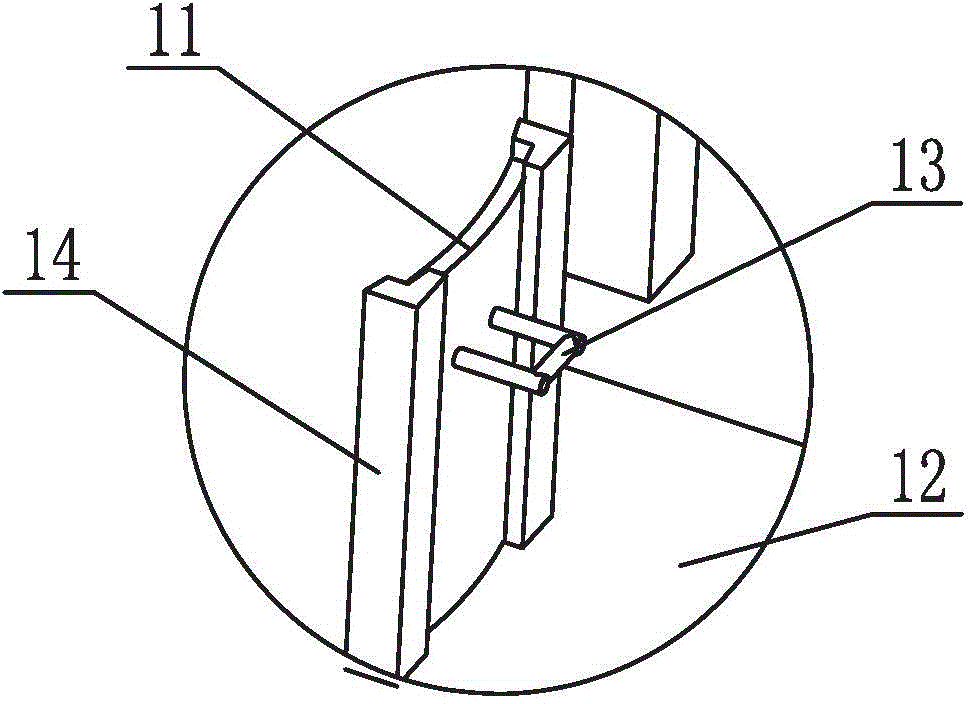

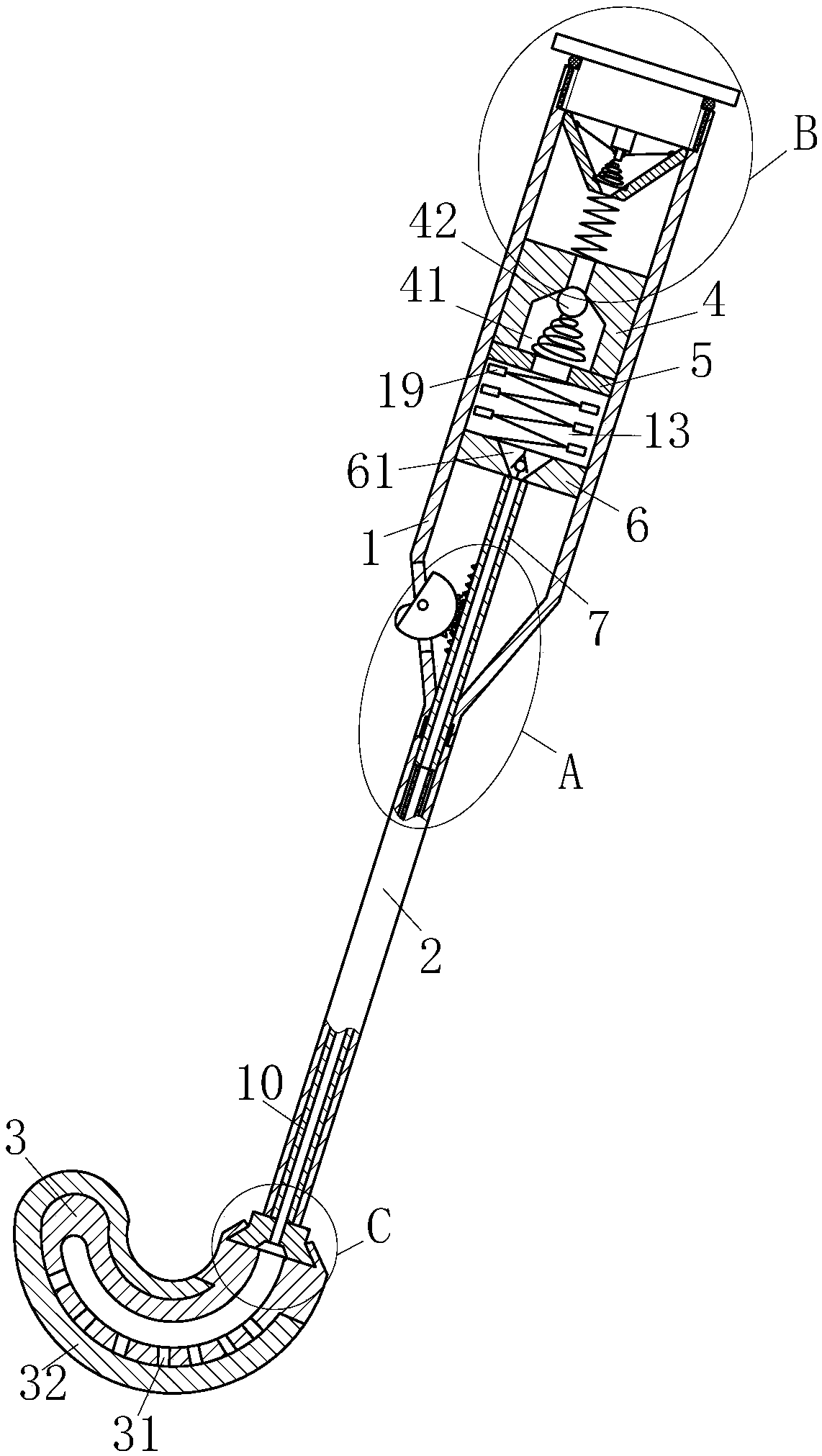

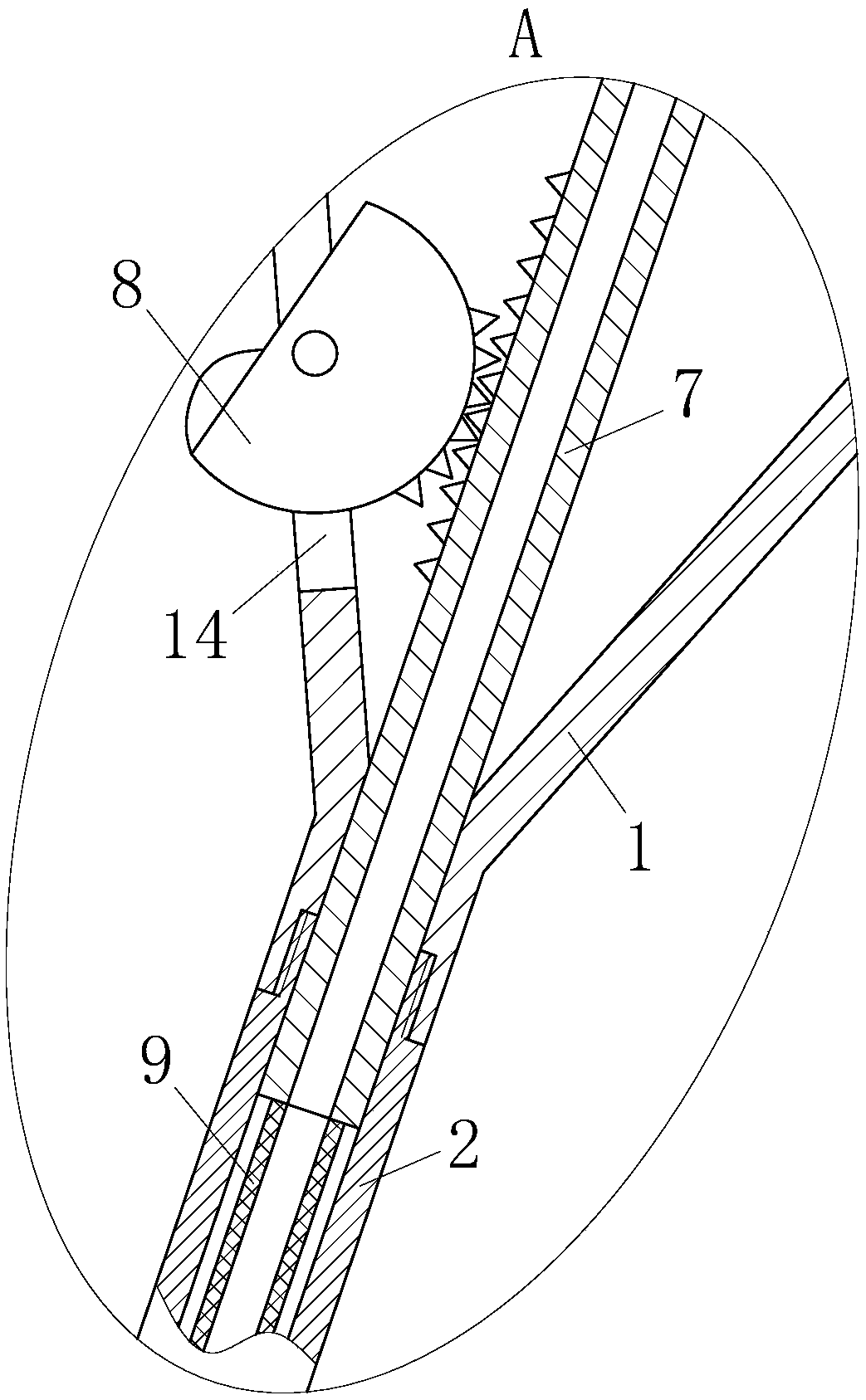

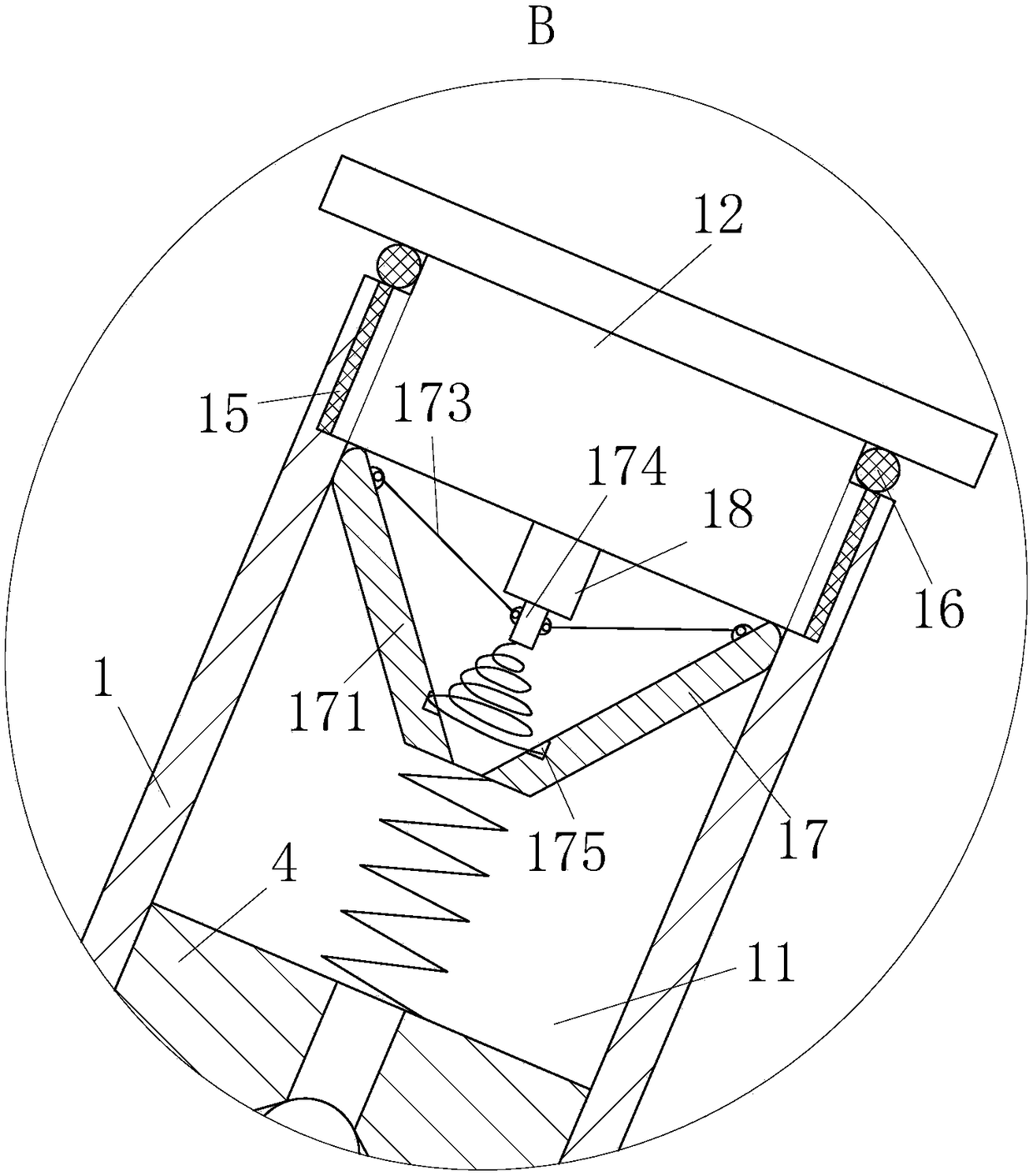

Bathroom toilet brush

ActiveCN109008182AImprove practicalityAvoid the problem of not finding the cleaning agentBristleBathroom accessoriesFixed frameBathroom Equipment

The invention belongs to the technical field of bathroom equipment and particularly relates to a bathroom toilet brush. The toilet brush includes a fixing frame, a mounting rod, a brush head, a clapboard, a pressing plate, a piston, a piston rod, a rotary knob, a rubber pipe and a liquid guiding pipe. The fixing frame is of a cylindrical structure, and an inner thread is arranged at the lower endof the fixing frame; an outer thread is arranged at the upper end of the mounting rod, and the mounting rod is connected with the lower end of the fixing frame through the thread; the brush head is ofan arc structure and is internally provided with a passage. The clapboard is positioned in the fixing frame; the pressing plate is positioned in the fixing frame and fixed to the lower portion of theclapboard; the piston is slidingly installed in the fixing frame; the upper end of the piston rod is installed at the lower end of the piston, the piston rod can slide in the mounting rod, and teethare arranged on one side of the piston rod. A rectangular passage is formed in the fixing frame; the rotary knob is installed in the rectangular passage, teeth are arranged on the arc surface of the rotary knob, and the teeth on the rotary knob are meshed with the teeth on the piston rod; the upper end of the rubber pipe is connected with the piston rod; the liquid guiding pipe is positioned in the mounting rod, and the lower end of the liquid guiding pipe is connected with the passage in the brush head.

Owner:山东华尊建筑有限责任公司

Light ceramsite co-sintered on surface by virtue of sodium borate and preparation method of light ceramsite

The invention relates to light ceramsite co-sintered on the surface by virtue of sodium borate and a preparation method of the light ceramsite. The preparation method of the light ceramsite co-sintered on the surface by virtue of sodium borate comprises the following steps: spraying a 5-25% sodium borate solution in steps, drying and sintering, wherein during drying, sodium ions dissolved in water diffuse toward the surface along with moisture and are enriched on a shell of the surface of each raw nodule; and during sintering, reaction is carried out on the sodium ions in the surface layer and other substances to form fusible substances, an effect of a sintering aid is realized, content of sodium ions in the sintering aid below the surface layer of each raw nodule is low, the ceramsite sintered on the surface layer at a sintering temperature is relatively low in water absorption rate while density of an unsintered core region below the surface layer is relatively low, and finally the light ceramsite with low water absorption rate and low overall density is obtained. The preparation method of the light ceramsite co-sintered on the surface by virtue of sodium borate has the advantages that the problems that the water absorption rate of the ceramsite is low, strength is high and volume weight is low are solved; meanwhile, a technology is simple, operation is safe, mass production can be realized, and cost is low.

Owner:SHAANXI UNIV OF SCI & TECH

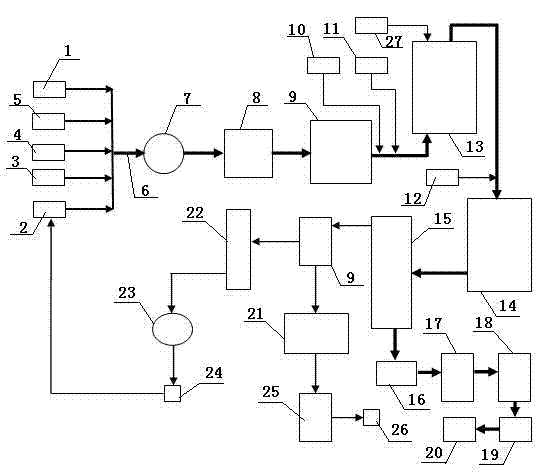

Yellowing automatic control system in production of short fiber stock solution viscose

ActiveCN102393694BReal-time controlEffective controlTotal factory controlProgramme total factory controlAutomatic controlControl system

The invention provides a yellow automation control system in the production of short -fiber jelly glue. By improving and optimizing the existing automatic control system, the redundant process control software is used to build a redundant process control system.The automatic control system in production, including the control unit in order: alkaline fiber feed control unit, real vacuum control unit, CS2 feed control unitMaterial control unit and yellow chemical machine flushing control unit; this control system can accurately control the amount of materials added to each material, ensure the quality of sticky glue after the last yellowing, reduce artificial labor, save costs, and improve production efficiency.

Owner:YIBIN HIEST FIBER +1

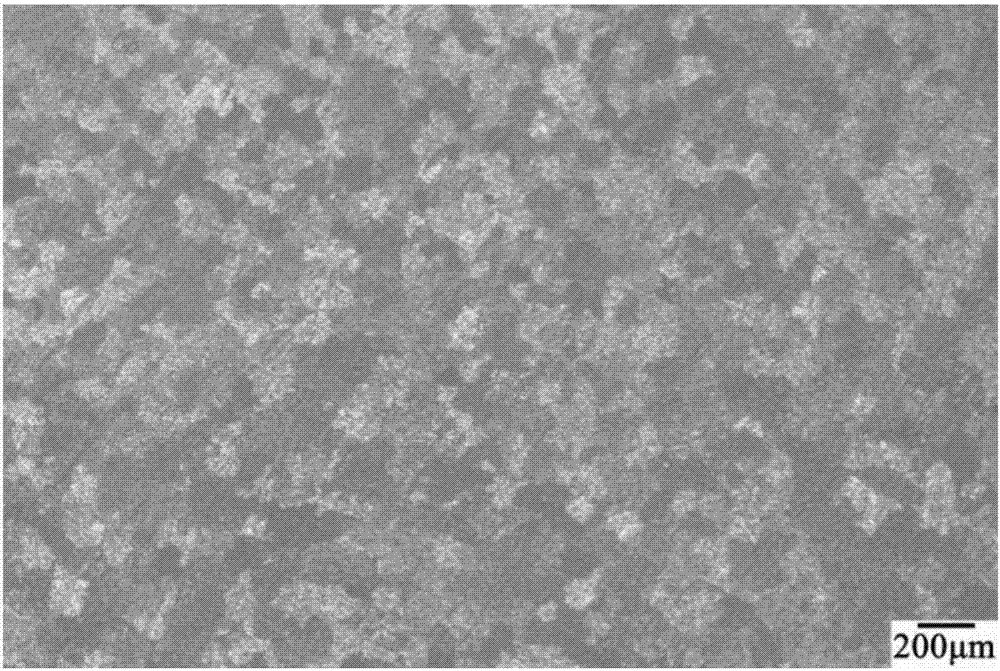

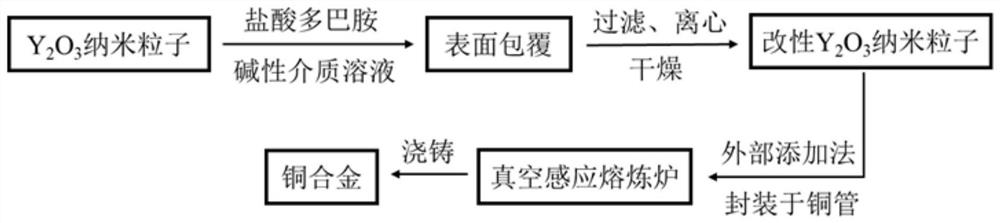

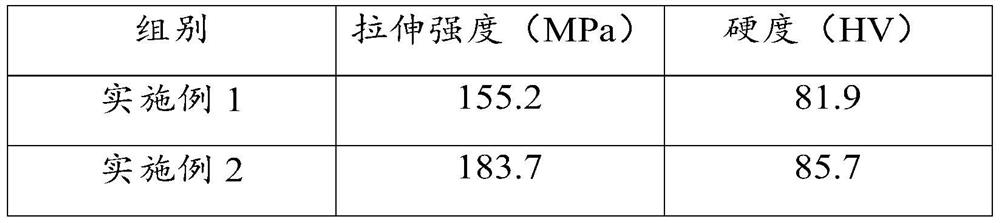

Modified nanoparticle dispersion strengthened copper alloy, preparation method and application thereof, electronic element and mechanical element

ActiveCN111893343ALarge specific surface areaHigh reactivityMaterial nanotechnologyMetallurgyElectronic component

The invention provides a modified nanoparticle dispersion strengthened copper alloy, a preparation method and application thereof, an electronic element and a mechanical element. The modified nanoparticle dispersion strengthened copper alloy comprises copper and modified nanoparticles dispersed in the copper, wherein the modified nanoparticles comprise nanoparticles and polydopamine coating the surfaces of the nanoparticles; and the preparation method of the copper alloy comprises the following steps that (a) the nanoparticles and dopamine hydrochloride react under the alkaline condition, andthe modified nanoparticles are obtained; and (b) the modified nanoparticles are added into copper liquid, uniformly mixing is conducted, then casting is conducted, and the modified nanoparticle dispersion strengthened copper alloy is obtained. The preparation method is scientific and simple in process, free of special mechanical equipment, easy to implement, low in production cost, capable of greatly shortening the production technological process, wide in application range, high in practicability, obvious and stable in obtained effect, and suitable for industrial large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

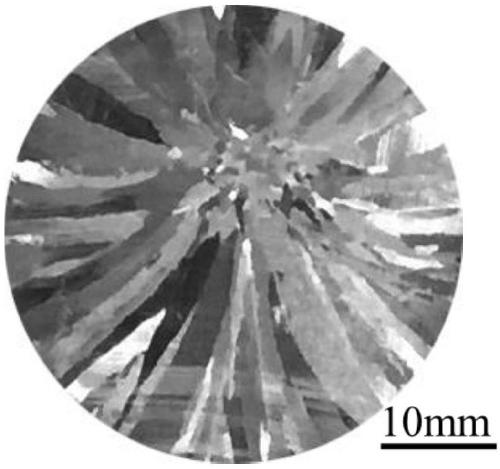

Magnesium and magnesium alloy grain refining method

The invention discloses a magnesium and magnesium alloy grain refining method. The magnesium and magnesium alloy grain refining method comprises the following steps that an intermediate carrier containing a zirconium-based amorphous alloy is prepared, the long-strip-shaped zirconium-based amorphous alloy is shorn into small fragments, in addition, an alloy cutting machine is used for cutting a high-purity magnesium ingot into small magnesium alloy pieces, magnesium scraps generated during cutting are collected and cleaned through absolute ethyl alcohol after collection, the magnesium scraps are placed at the shade place to be dried in the shade, and by mass percent, 20%-40% of the zirconium-based amorphous alloy fragments and 60%-80% of magnesium cuttings are pressed and formed after beingsufficiently mixed; secondly, Mg or the Mg alloy is melted, the intermediate carrier containing the zirconium-based amorphous alloy is added, and stirring is conducted; and thirdly, after standing and heat preservation are conducted, furnace discharging and casting are conducted. Under the conditions that the grain refining method is low in cost, and the technology is simple, the advantages thatthe adding amount is easy to control, pollutant discharging is avoided, the grain refining efficiency is high, the grain refining effect is stable, and the treatment time is short are achieved.

Owner:北京科技大学广州新材料研究院

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1181944CImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weld scaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING TECH UNIV

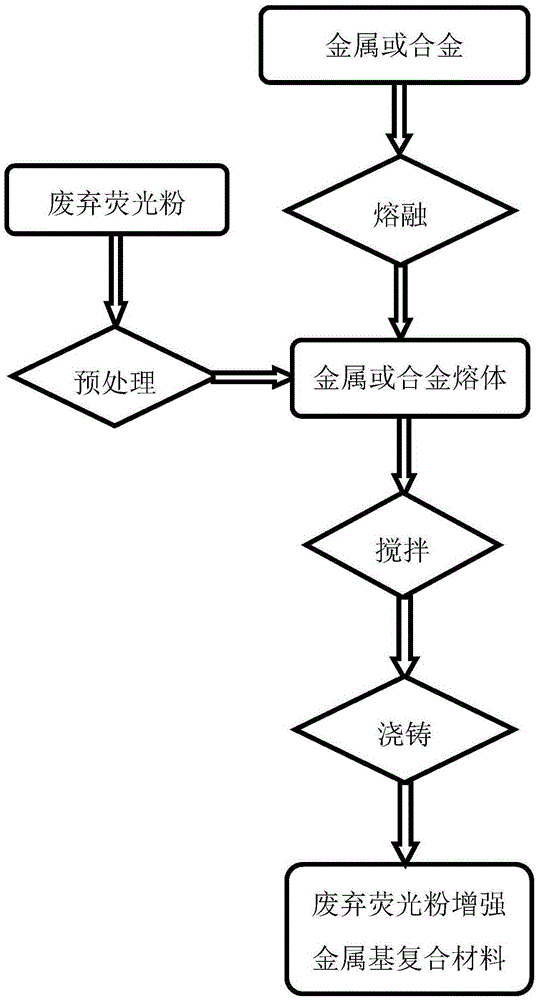

Magnesium and aluminum metal-matrix composite material enhanced through waste fluorescent powder and preparation method of magnesium and aluminum metal-matrix composite material enhanced through waste fluorescent powder

The invention discloses a magnesium and aluminum metal-matrix composite material enhanced through waste fluorescent powder and a preparation method of the magnesium and aluminum metal-matrix composite material enhanced through the waste fluorescent powder and belongs to the technical field of recycling of the waste fluorescent powder and preparing of metal-matrix composite materials. The preparation method comprises the steps that the waste fluorescent powder is placed in a drying box or an oven to be pretreated; and pure metal or alloy is placed in a crucible to be molten to be in liquid state, melt is heated, a certain amount of pretreated waste fluorescent powder is added into the melt, the melt is stirred for a period of time by means of a stirring device, the melt is poured in a metal die or a sand die after dross on the surface layer of the melt is removed, and then the magnesium and aluminum metal-matrix composite material enhanced through the waste fluorescent powder is obtained. The magnesium and aluminum metal-matrix composite material enhanced through the waste fluorescent powder and the preparation method of the magnesium and aluminum metal-matrix composite material enhanced through the waste fluorescent powder have the advantages that the preparation method of the composite material is easy and convenient to implement, particles are evenly dispersed, the composite material is well bonded with a matrix interface, environmental friendliness is achieved, and cost is low.

Owner:北京中联浩科技服务有限公司

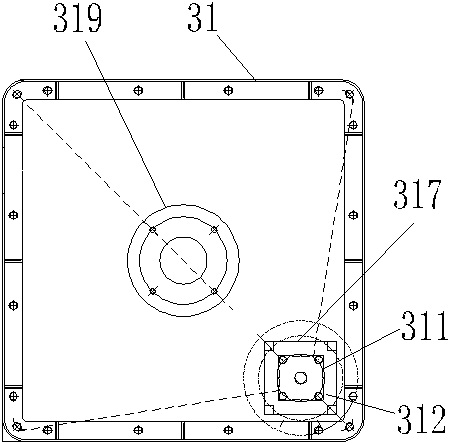

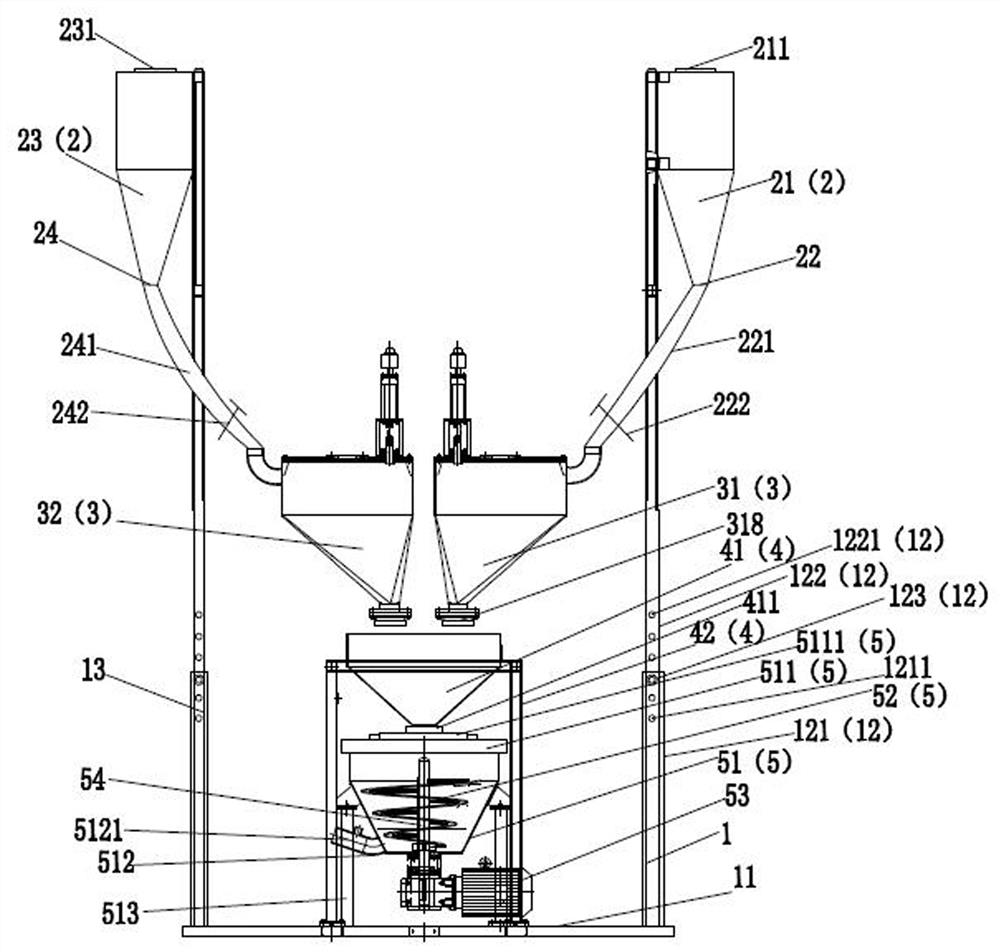

A catalytic titanium dioxide treatment system and method thereof

The invention relates to the field of the titanium white salt catalytic treatment and in particular to a treatment system for catalyzing titanium white salt and a method thereof. The treatment systemfor catalyzing the titanium white salt comprises a bracket, a material storage mechanism, a first discharging mechanism, a second discharging mechanism and a stirring mechanism. The material storage mechanism is symmetrically installed at two sides of the bracket. The lower part of the first discharging mechanism is correspondingly provided with the second discharging mechanism. The second discharging mechanism is installed corresponding to the stirring mechanism. The stirring mechanism is coincided with an axis in the second discharging mechanism. The bracket comprises a base bracket, a firstvertical bracket and a second vertical bracket. A preparation method for titanium dioxide is simple and rational. Feeding is convenient, and an addition quantity is easy to be controlled. The preparation method comprises the following steps: adding solution, uniformly stirring, after calcining, evaporating liquid and gas, and enabling metal tungsten and vanadium to be remained on the surface of titanium white particles, wherein the prepared titanium dioxide is high in catalytic efficiency, long in service life, slow in lose efficacy and the like.

Owner:中钛集团焦作市裕盛钛业有限公司

A kind of lightweight ceramsite assisted sintering on the surface of sodium sulfate and preparation method thereof

ActiveCN104310951BLow costSimple processCeramic materials productionClaywaresMetallurgySodium sulfate

The invention relates to light ceramsite co-sintered on the surface by virtue of sodium sulphate and a preparation method of the light ceramsite. The preparation method of the light ceramsite co-sintered on the surface by virtue of sodium sulphate comprises the following steps: spraying a 5-25% sodium sulphate solution in steps, drying and sintering, wherein during drying, sodium ions dissolved in water diffuse toward the surface along with moisture and are enriched on a shell of the surface of each raw nodule; and during sintering, reaction is carried out on the sodium ions in the surface layer and other substances to form fusible substances, an effect of a sintering aid is realized, content of sodium ions in the sintering aid below the surface layer of each raw nodule is low, the ceramsite sintered on the surface layer at a sintering temperature is relatively low in water absorption rate while density of an unsintered core region below the surface layer is relatively low, and finally the light ceramsite with low water absorption rate and low overall density is obtained. The preparation method of the light ceramsite co-sintered on the surface by virtue of sodium sulphate has the advantages that the problems that the water absorption rate of the ceramsite is low, strength is high and volume weight is low are solved; meanwhile, a technology is simple, operation is safe, mass production can be realized, and cost is low.

Owner:SHAANXI UNIV OF SCI & TECH

A grain refinement method for mg or mg alloy

InactiveCN104195360BWide variety of sourcesOvercome the disadvantages of complex preparation processAlloyProcess conditions

The present invention discloses a grain refinement method of MG or MG alloy, including the following steps: (1) preparing the intermediate carrier containing industrial zinc ash: the industrial zinc ash and weight percentage of industrial zinc ash with a weight of 20-40 % are 60 percentage of 60 percentage of 20 to 40 %.~ 80 % of the mg powder is mixed after mixing; (2) melting MG or MG alloys, adding an intermediate carrier containing industrial zinc ash and stirring;The invention has the advantages of simple process operations, easy to control the amount of process operations, simple process operations under the condition of achieving waste recycling and reuse of waste, and simple craftsmanship.The refinement of the MG 合al alloy refinement is particularly significant.

Owner:东莞市镁皓镁合金科技有限公司

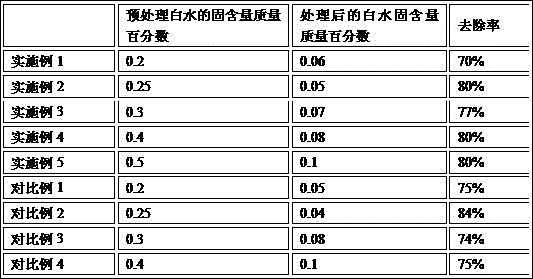

A kind of white water treatment flocculant and using method thereof

InactiveCN105217753BReduce dosageUniform compositionMultistage water/sewage treatmentWaste water treatment from plant processingWater flowProcess conditions

The invention relates to the technical field of clean papermaking production, in particular to a flocculant for white water treatment and its use method. The flocculant for white water treatment includes raw soybean milk, and the flocculant has excellent white water purification performance and low cost; the flocculant for white water treatment The method of use comprises the following steps: step A, tailings white water purification and recovery pretreatment to obtain pretreated white water for standby; step B, performing dissolved air treatment on clarified white water, and placing the clarified white water completely dissolved in air in a dissolved air tank , for standby; step C, adding the pretreated white water obtained in step A and the clarified white water in the air-dissolving tank together in the air flotation tank, and simultaneously adding flocculant to the white water inlet of the air flotation tank; Scraping of floating pollutants, the use method has simple process, easy control of process conditions, easy control of the amount of flocculant added, strong operability, good repeatability, good purification effect, and high purification efficiency.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com