Medium carbon low alloy steel for light high speed train wheel

A high-speed train and low-alloy steel technology, which is applied in the field of low-alloy steel for high-speed railway train wheels, can solve the problems of increased maintenance costs, soft wheels, and high probability of wheel tread peeling, and achieves easy control of the addition amount, low-cost alloy elements , good effect of heat damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

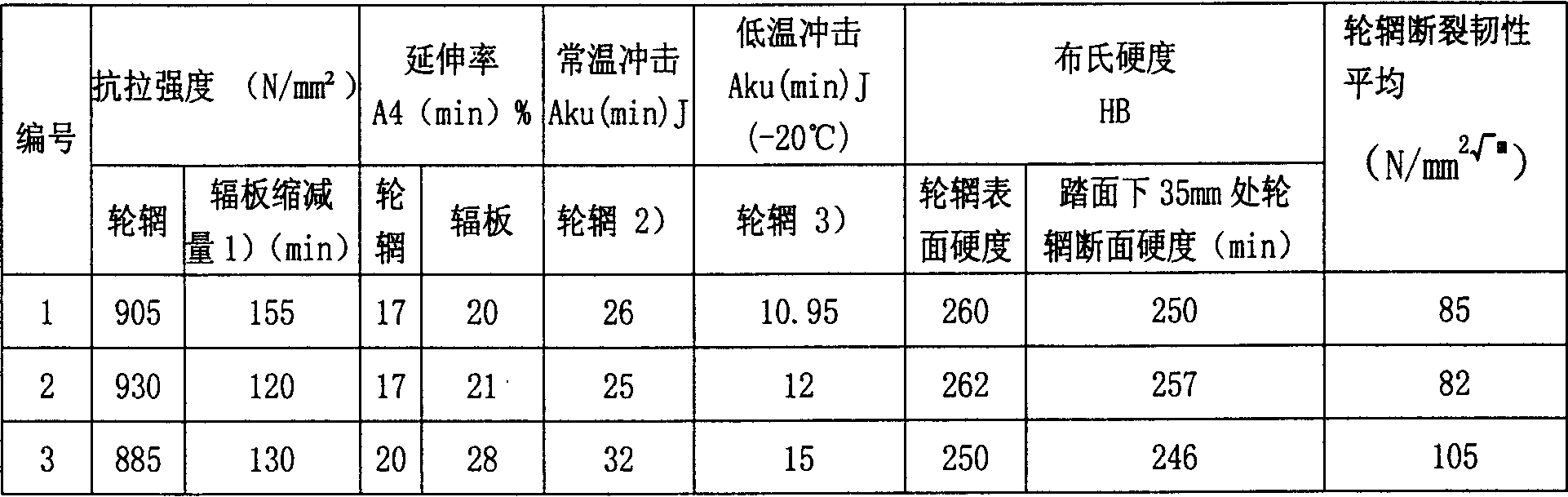

[0013] Using common smelting equipment such as converter, LF furnace and VD equipment, according to the composition and content of No. 1 in Table 1, using the usual steelmaking process for smelting, continuous casting into round billets; then the round billets are die-cut into blocks, heated, Forging is rolled by a wheel rolling mill; and then manufactured into wheels through processes such as heat treatment, machining, and finished product inspection. No. 1 in Table 2 lists the test results.

Embodiment 2

[0015] Repeat the method of Example 1 according to the components and contents of No. 2 in Table 1 respectively to produce wheels. No. 2 in Table 2 lists the test results.

[0016] Numbering

Embodiment 3

[0018] Repeat the method of Example 1 to produce the wheel according to the composition and content of No. 3 in Table 1 respectively, and No. 3 in Table 2 lists its test results.

[0019] Table 2

[0020]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com