Patents

Literature

68results about How to "Improved resistance to crack growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Geotechnical articles

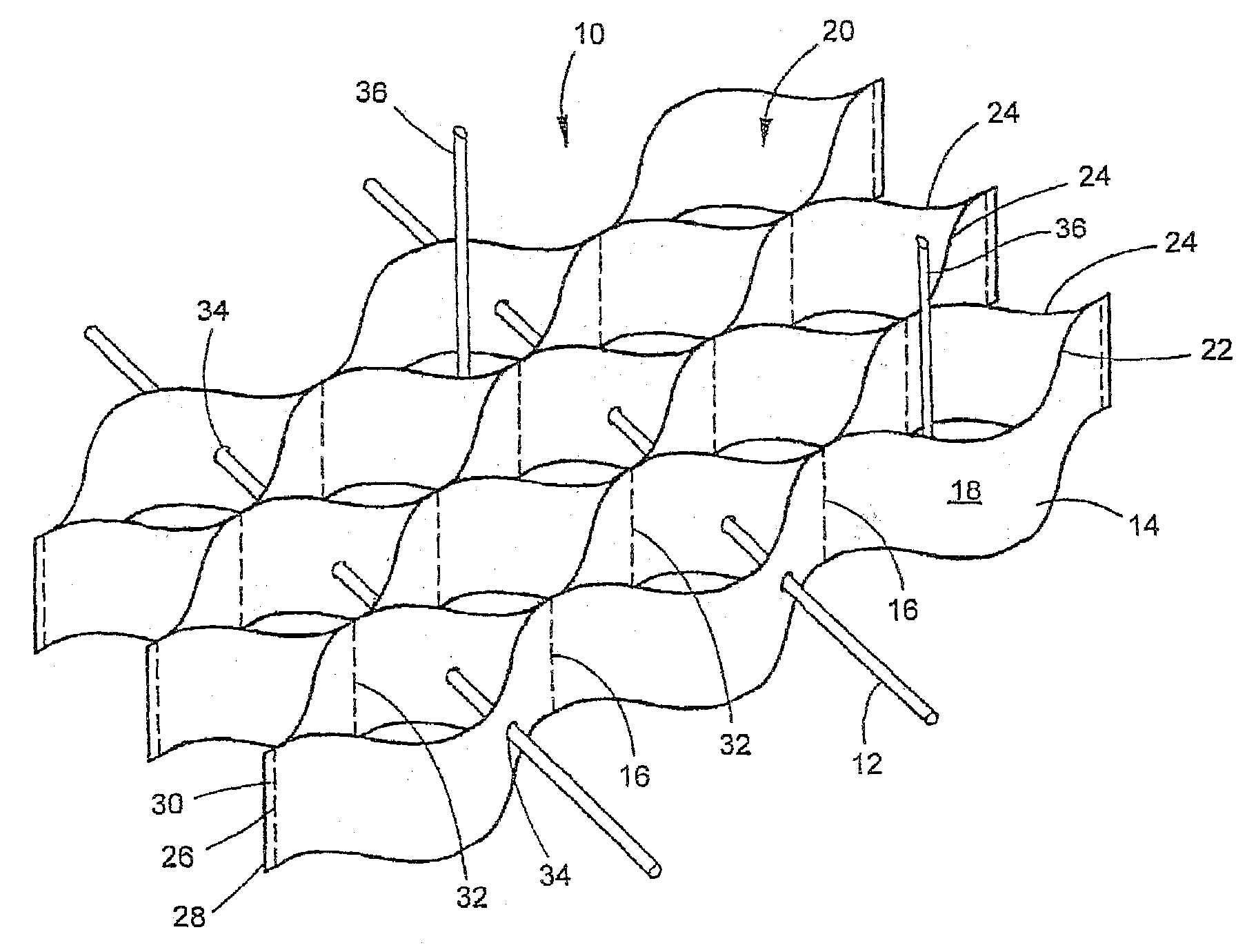

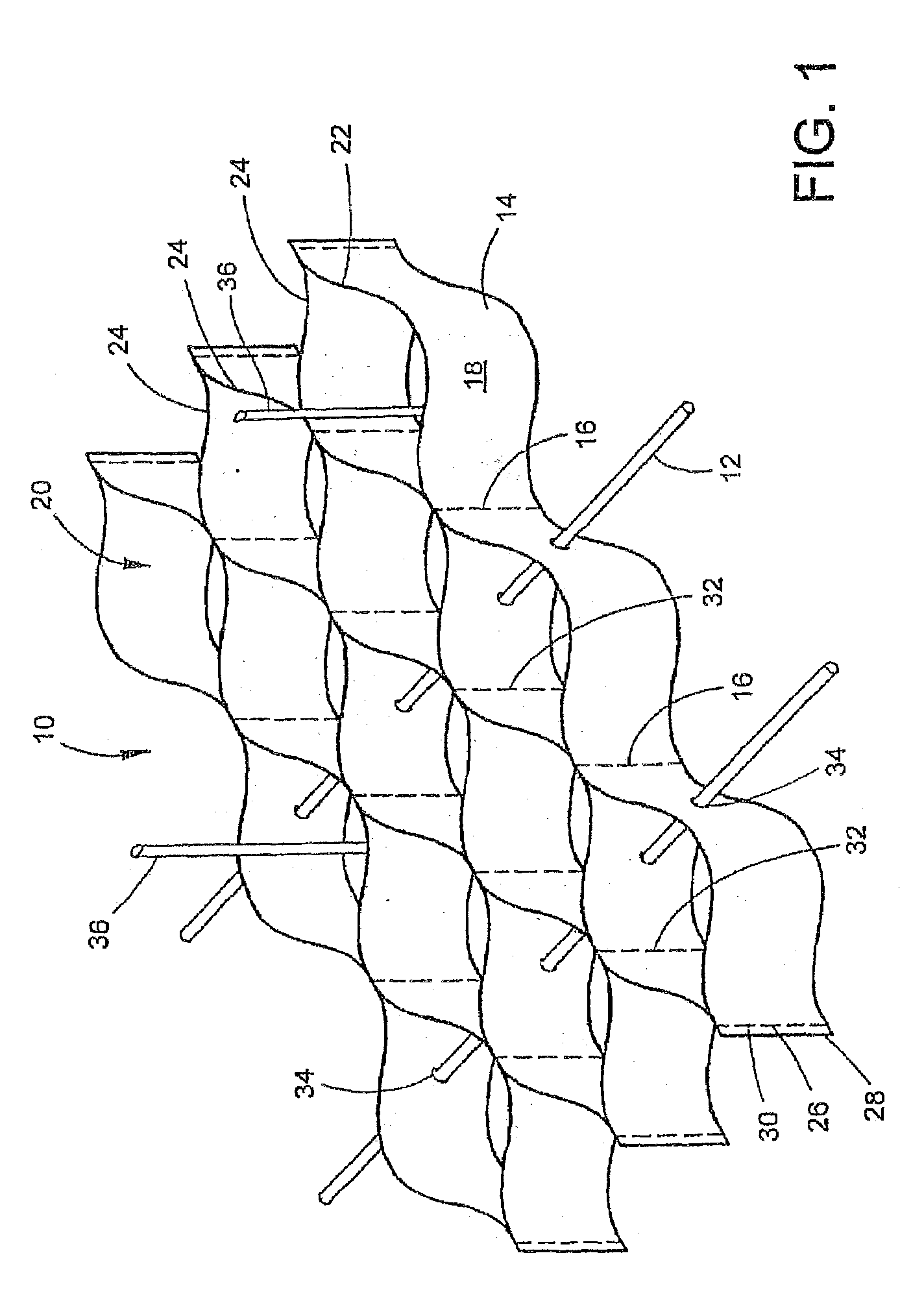

InactiveUS20080213521A1Improve creep resistanceImprove tear resistanceDomestic netsThin material handlingCold areaCellular confinement

A multiphase polymeric material comprises a first rigid continuous phase and a second elastic phase dispersed in the first phase. The multiphase polymeric material may be formed into polymeric strips and used to make a cellular confinement system which is suitable for use in cold areas.

Owner:PRS MEDITERRANEAN

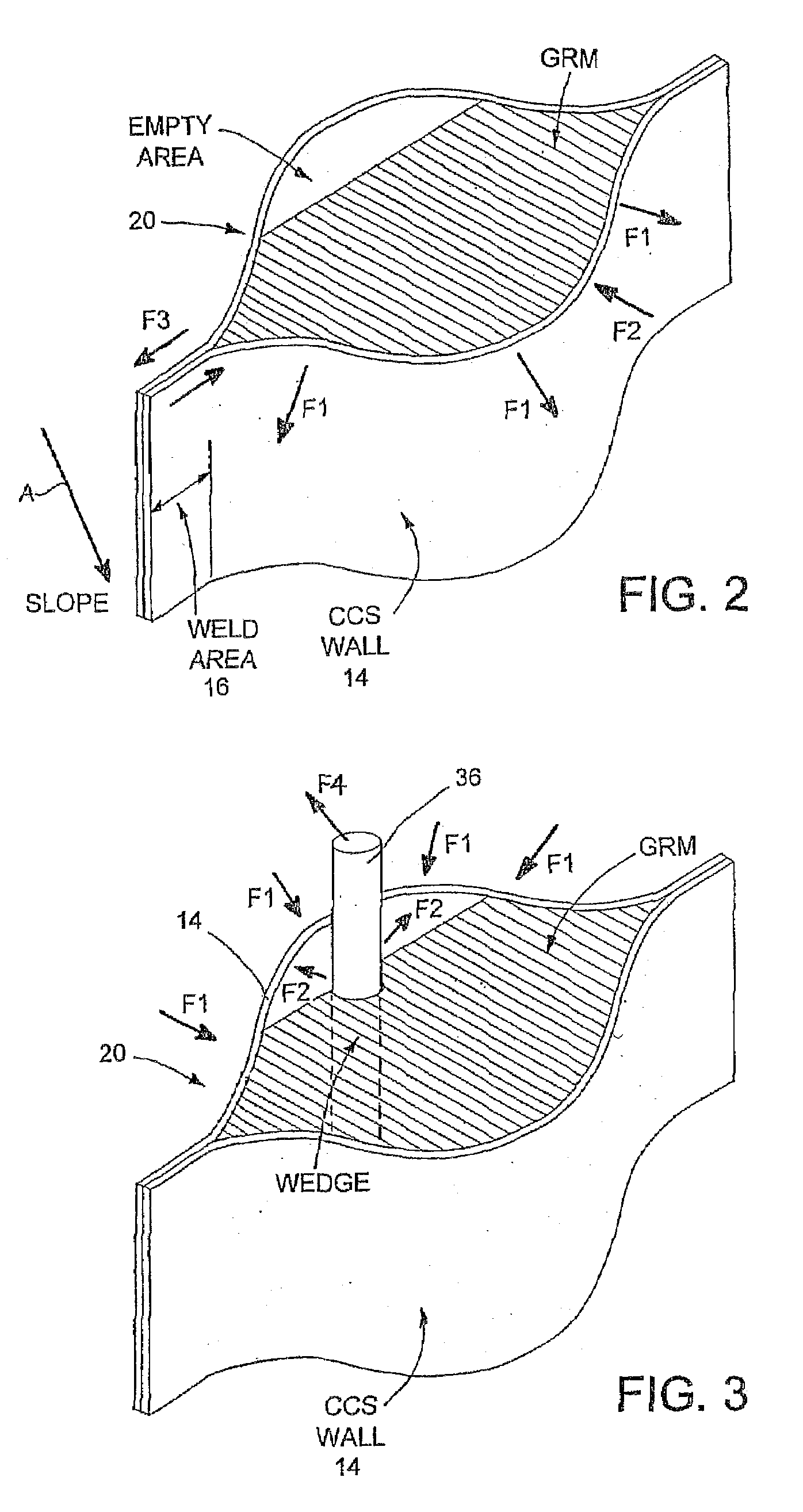

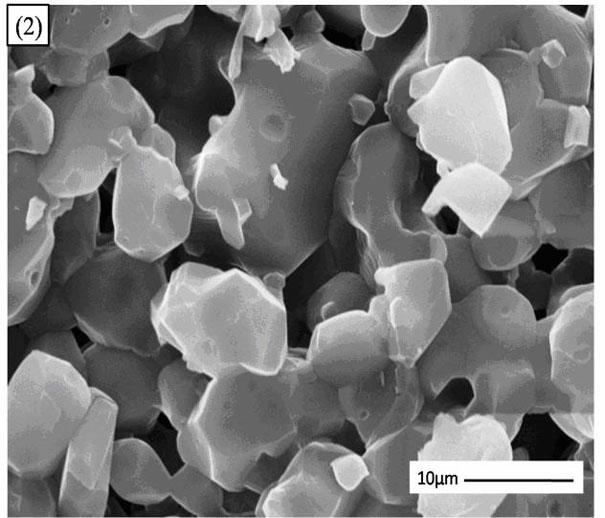

Machinable aluminium oxide ceramics and preparation method of machinable aluminium oxide ceramics

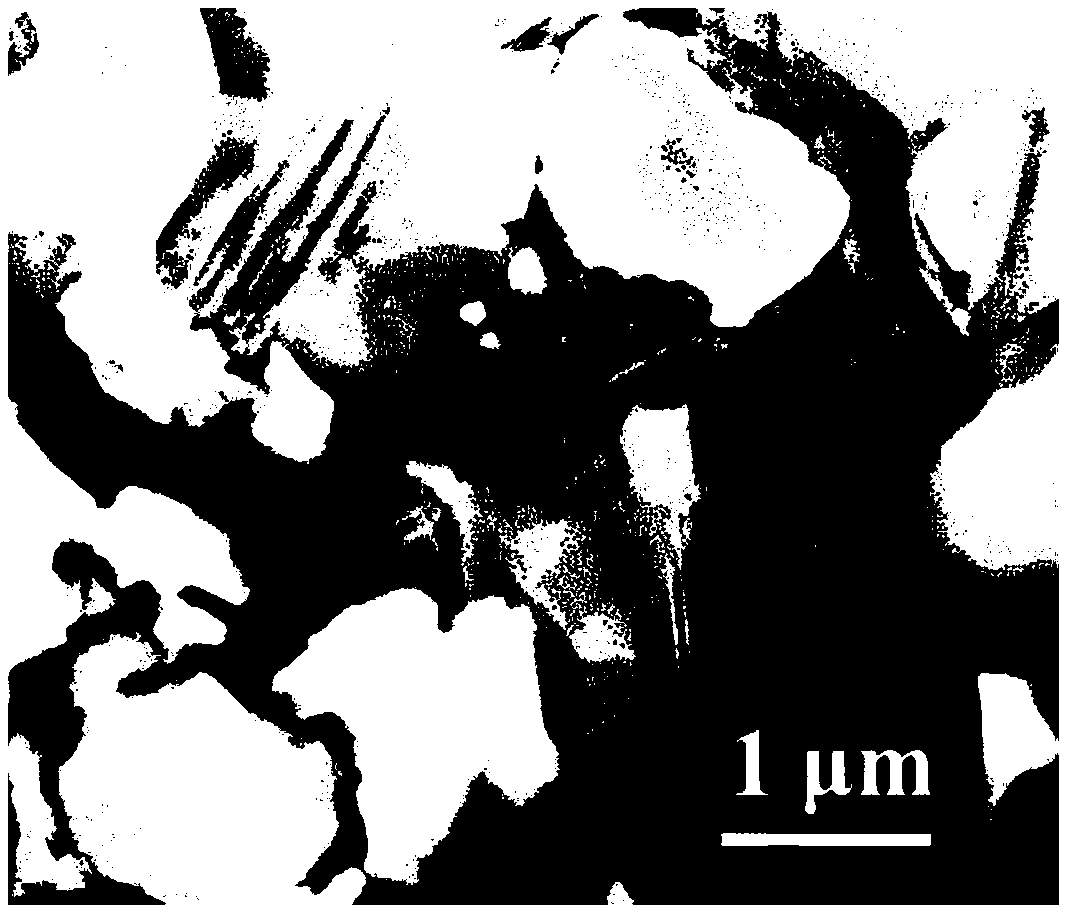

The invention discloses machinable aluminium oxide ceramics which is characterized in that the machinable aluminium oxide ceramics comprises the following components in percentage by mass: 60 percent to 68 percent of nano alumina, 30 percent to 36 percent of tabular alumina, 0.5 percent to 1.5 percent of magnesium oxide and 1 percent to 3 percent of titanium dioxide. A preparation method of the ceramics comprises the following steps of: preparing the nano alumina; after carrying out mixing and ball milling on the nano alumina, alumina, the magnesium oxide, titanium dioxide and absolute ethyl alcohol, drying the mixture, removing zirconium oxide grinding balls, and carrying out roasting, washing, filtering and drying on the obtained product to obtain composite powder; and after uniformly mixing the composite powder and a polyvinyl alcohol 1799 binder and pelleting the obtained mixture, carrying out dry-pressing forming to obtain a green body and placing the formed green body into a high temperature furnace to carry out sintering so as to obtain the ceramics. The bending strength of the ceramics reaches 526MPa. The fracture toughness of the ceramics reaches 6.4MPa.m1 / 2. The ceramicshave excellent machinable performance. The problems of complex structure and high cost and difficultly-controlled preparation process of the existing machinable ceramics are effectively solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

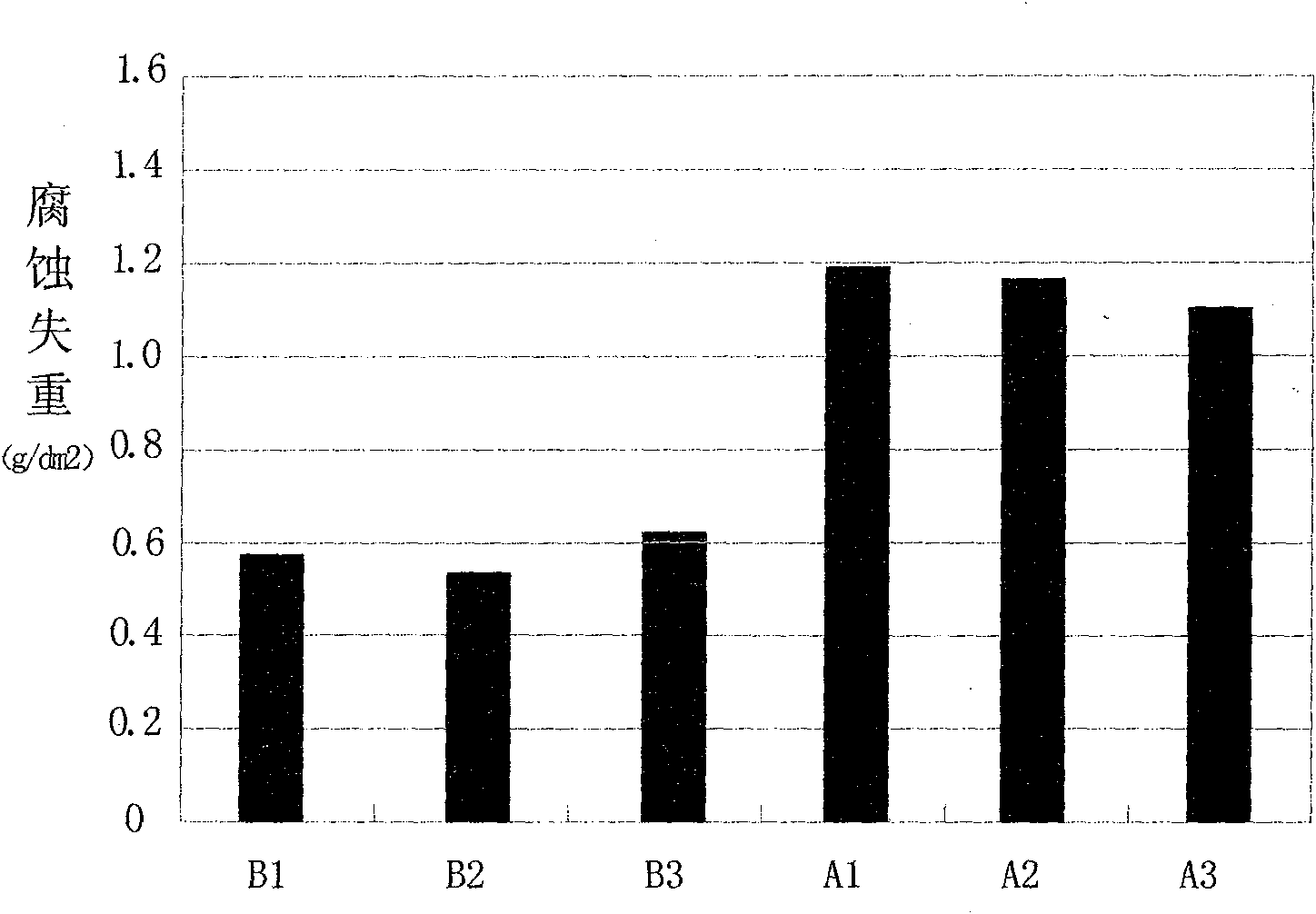

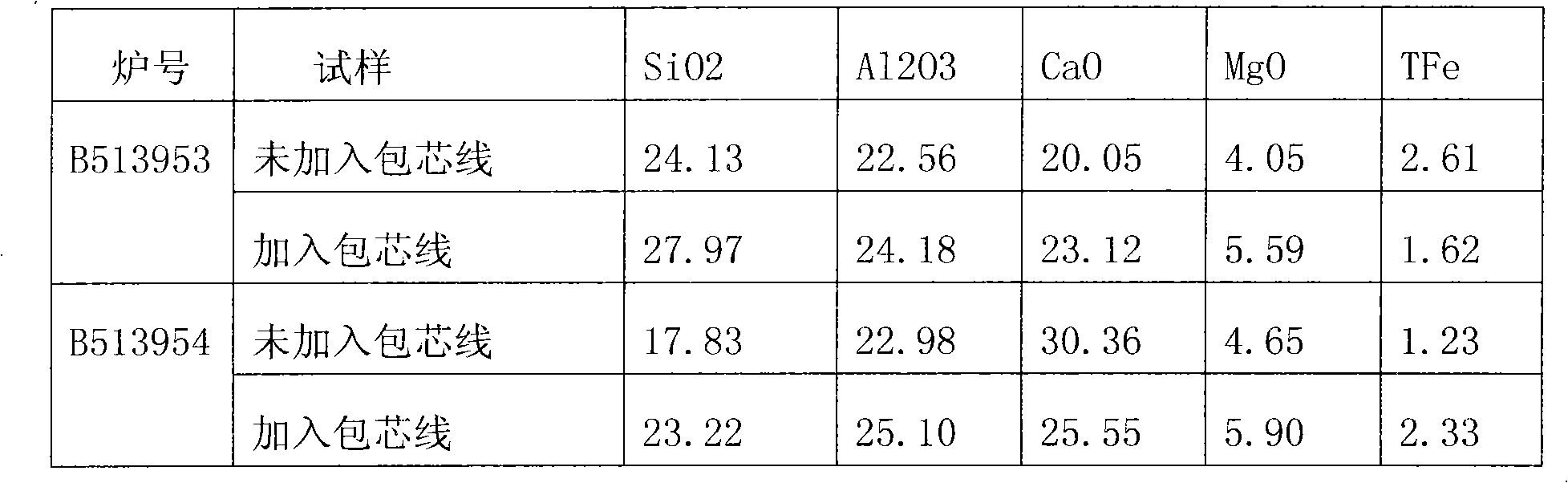

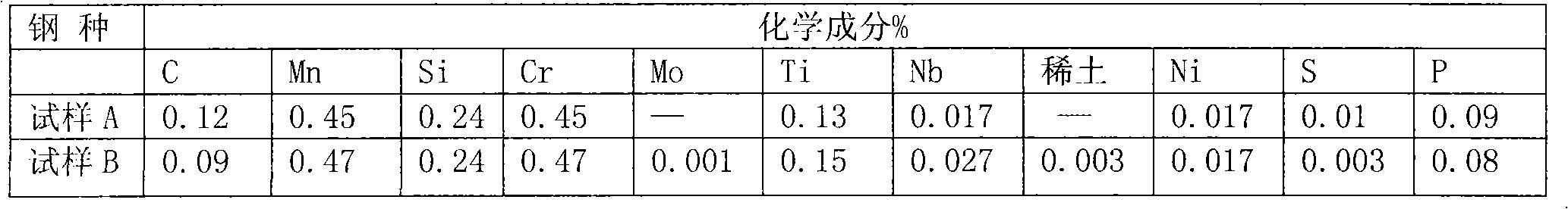

Novel weathering resistant steel microalloying compound core-spun yarn

The invention discloses a novel weathering resistant steel microalloying compound core-spun yarn comprising a steel sheath and a powdery inner core, wherein the powdery inner core is composed of the following chemical ingredients in percentage by weight: 20% of Ca, 0.5% of Mg, 38% of Si, 1.2% of Ba, 1.9% of rare-earth metal, 3.2% of Zr, 1.6% of Ti, 0.5% of B, 0.9% of Mo, 0.5% of Mn, 0.9% of Nb, 0.6% of V and the balance of Fe and inevitable impurity. The invention can obviously refine steel microstructure, improves the decay resistance of steel and lowers C, P and S content in steel by reasonably designing the chemical ingredients; and meanwhile the invention can reduce the amount of parts of alloy elements in steel so as to lower cost.

Owner:HUBEI KMK WELDING MATERIALS

Micro-alloying compound cored wire for high-strength steel

The invention relates to a micro-alloying compound cored wire for high-strength steel, comprising a carbon steel sheath and a powdery core, wherein the core is prepared from the following chemical components by weight percent: 23 to 28 wt% of Ca, 51 to 55 wt% of Si, 0.65 to 1.5 wt% of Mg, 1.3 to 2.5 wt% of Ba, 0.6 to 1.0 wt% of Re, 0.6 to 1.2 wt% of B, 1.6 to 3.5 wt% of Zr, 1.3 to 2.8 wt% of Ti, 0.6 to 1.2 wt% of Nb, and balance of ferrum and inevitable impurities. The invention reduces the content of C in high-strength steel through reasonably designing the chemical components and simultaneously and greatly enhances the grain sizes in continuous casting billets so that the grains are refined. The mechanical properties of the steel can be obviously improved, and the transverse impact properties of the steel are obviously enhanced to approximate to longitudinal impact value. Besides, the invention well solves the problems of center segregation and center porosity of the continuous casting billets, nonuniform impurity distribution, and the like.

Owner:HUBEI KMK WELDING MATERIALS

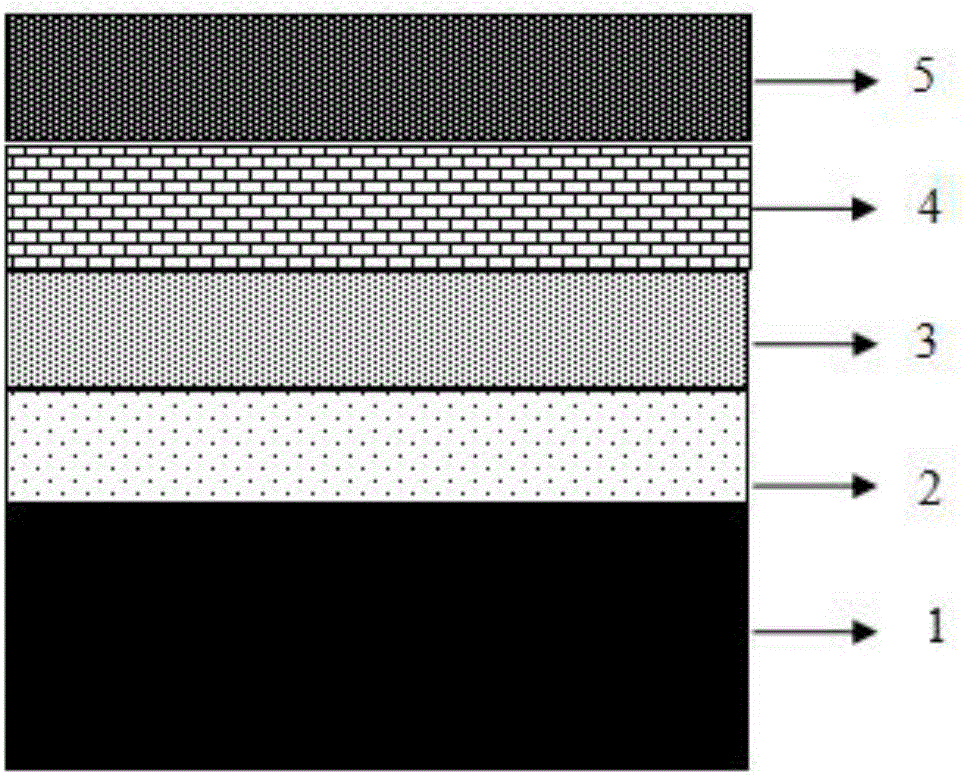

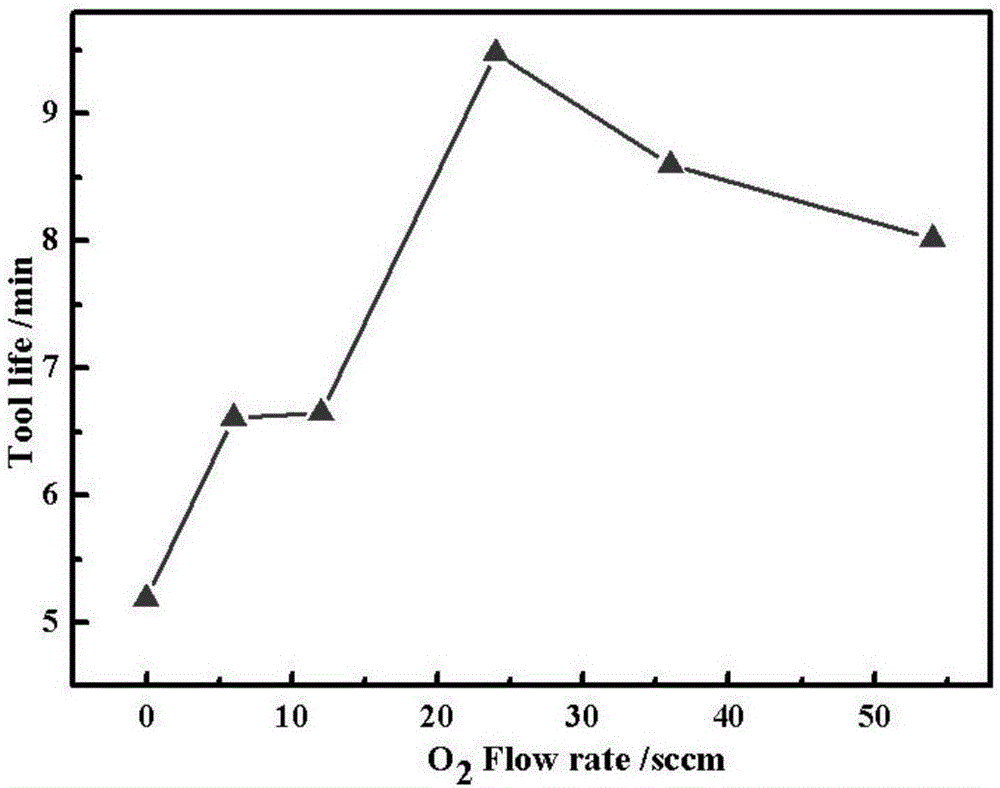

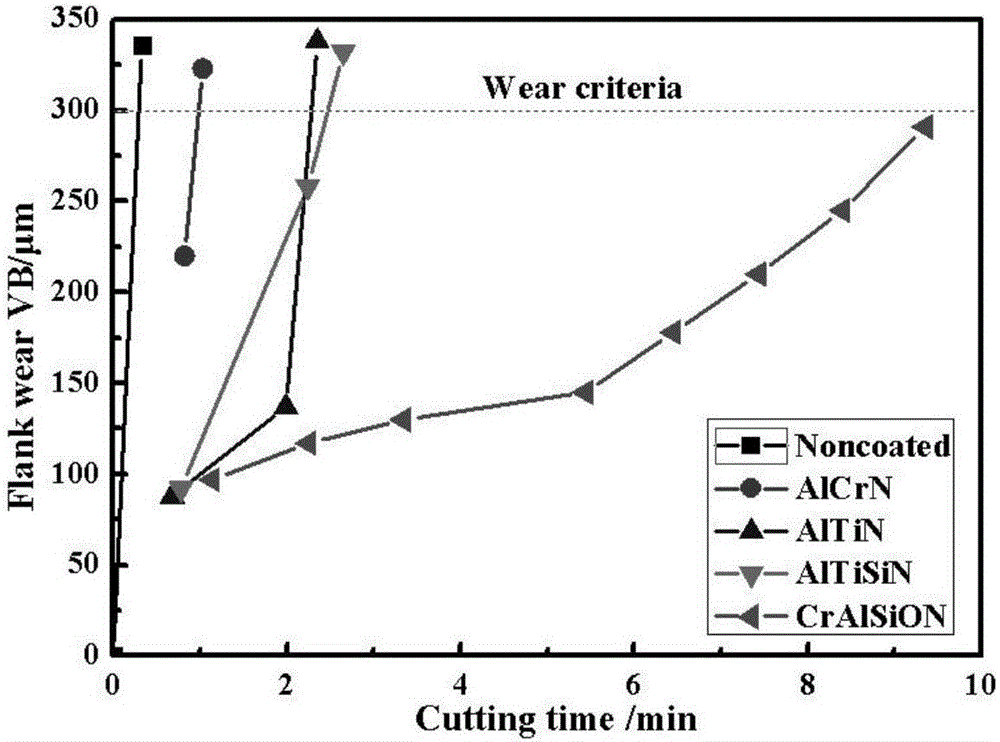

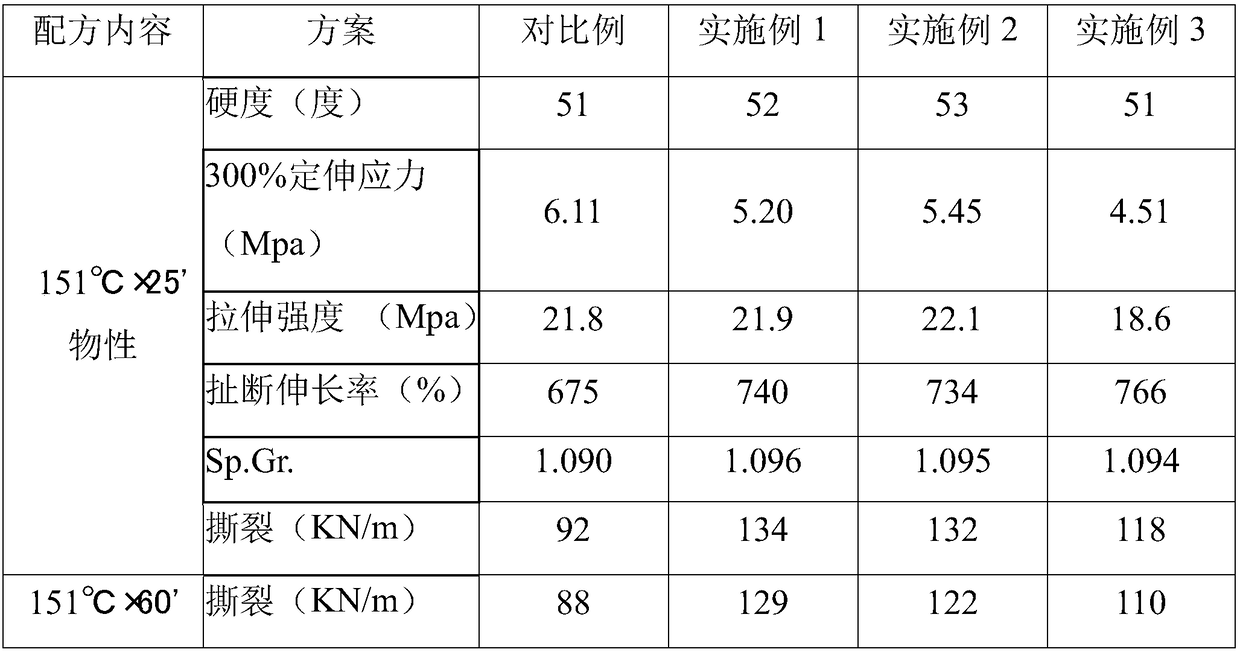

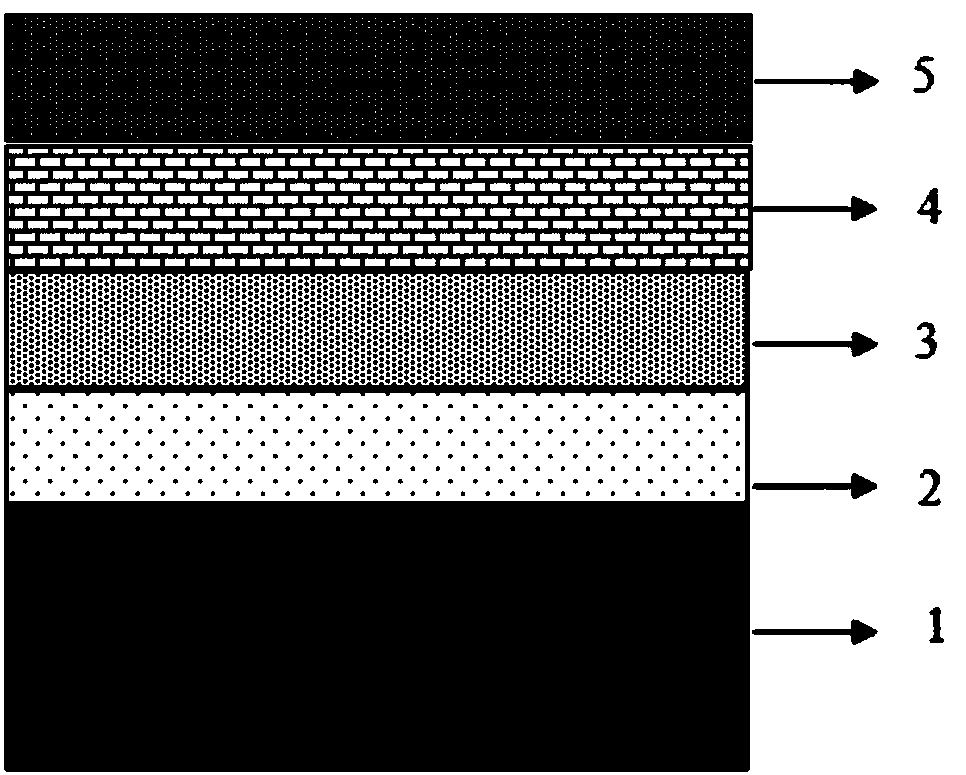

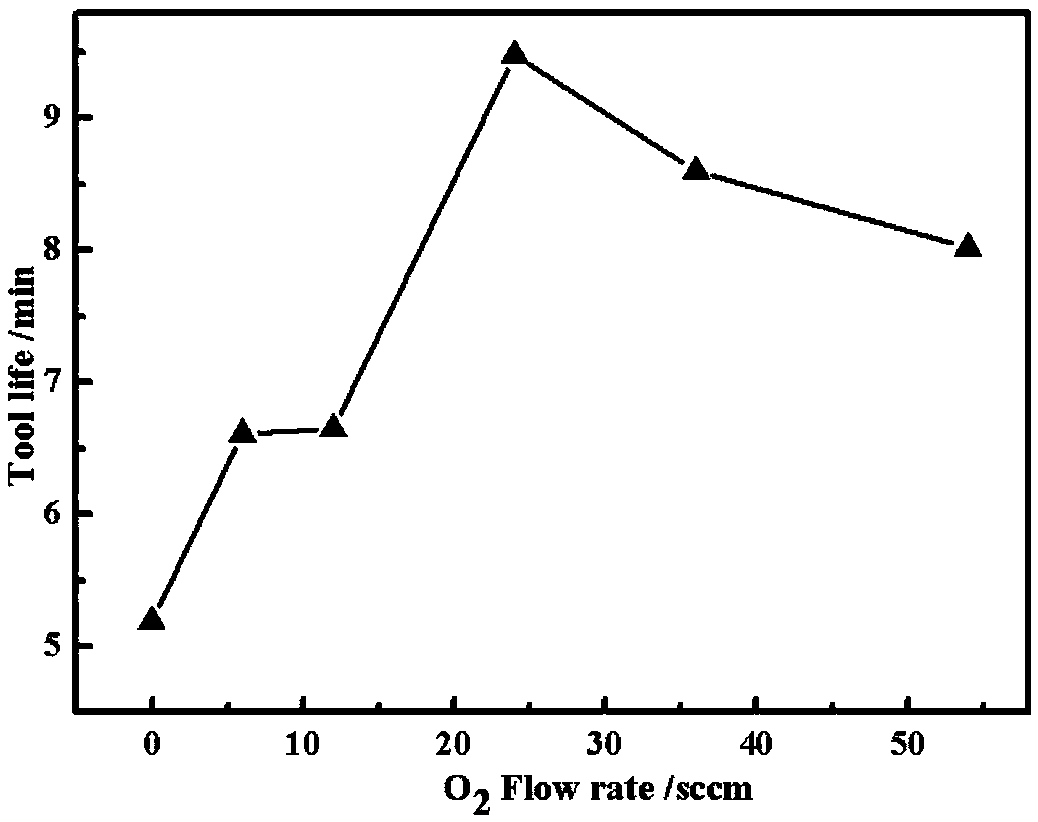

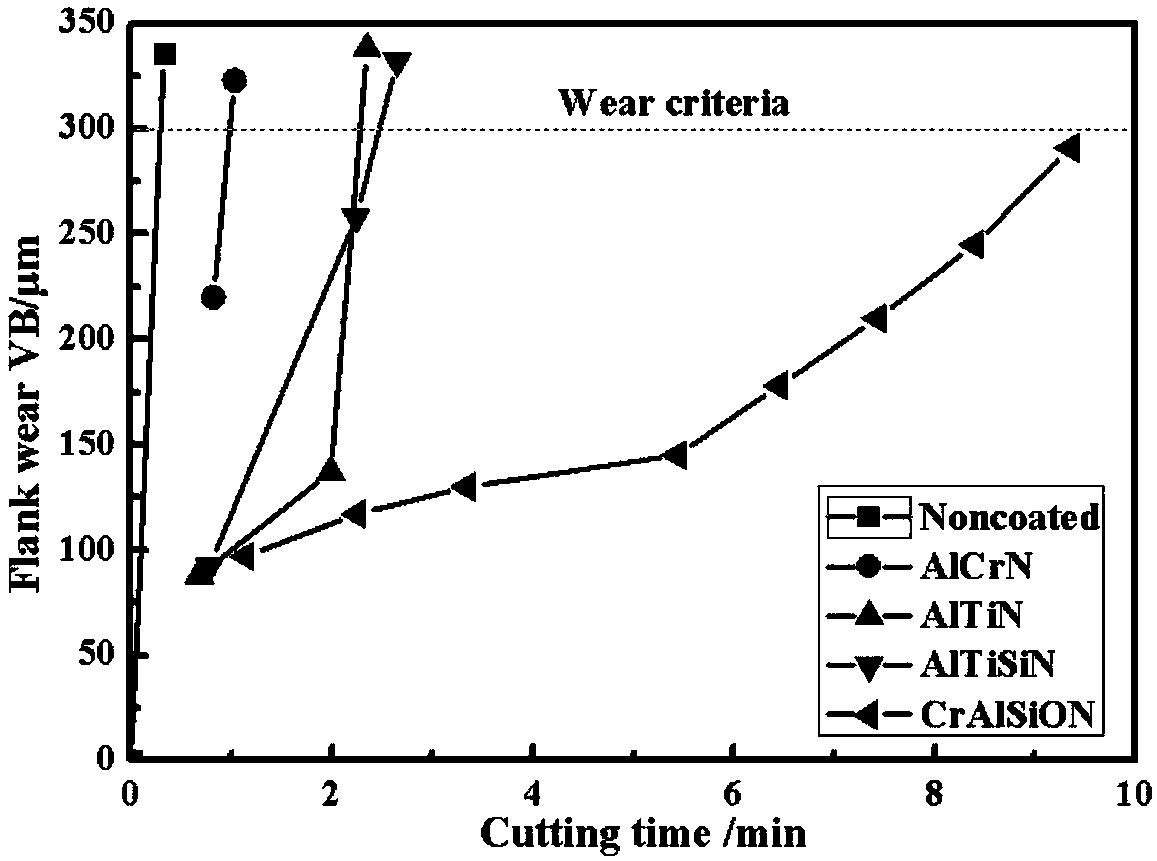

High-temperature abrasion-resistant CrAlSiON based nano-composite coating and preparation method and application thereof

ActiveCN106702331AReduce coefficient of frictionImprove bindingVacuum evaporation coatingSputtering coatingHardnessOxygen

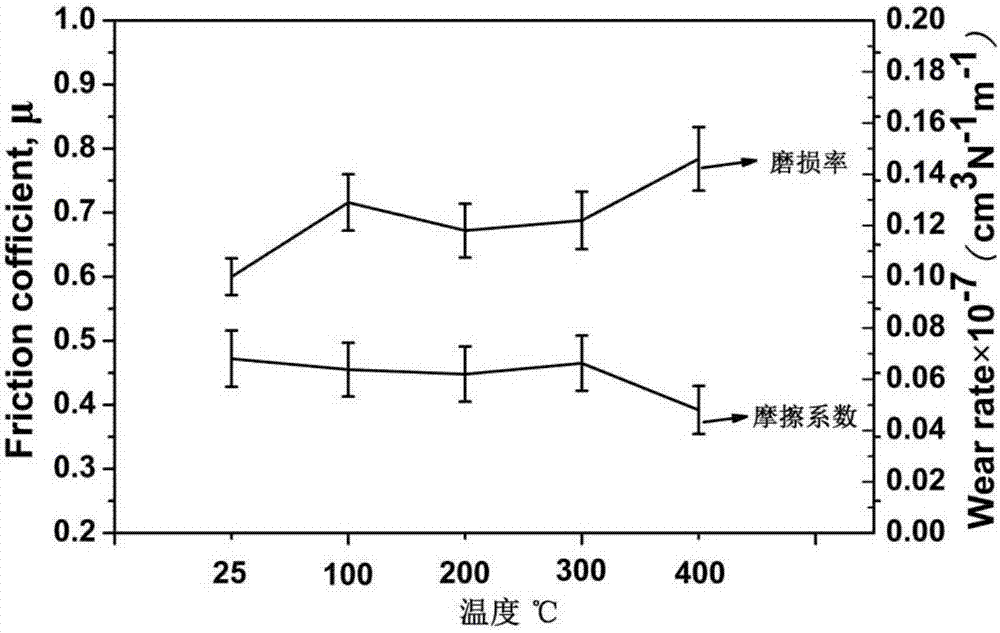

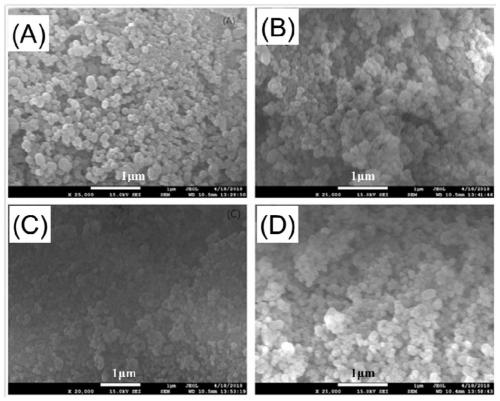

The invention discloses a high-temperature abrasion-resistant CrAlSiON based nano-composite coating. The high-temperature abrasion-resistant CrAlSiON based nano-composite coating mainly comprises an AlTiN transition layer, a CrAlSiN supporting layer and a CrAlSiON functional layer. A multi-arc ion plating technology is adopted in the coating, and the CrAlSiON based nano-composite coating with different components can be obtained by changing technological parameters. An oxygen element is led into the CrAlSiON based nano-composite coating, the existence form of oxygen in the coating is controlled by changing the depositional condition, one or more sorts of oxide which is low in friction coefficient and resistant to abrasion can be pre-formed in the coating, and the binding force between coating bodies is increased; and meanwhile, the stress between the coating bodies and the friction coefficient under a high temperature condition are lowered, and friction resistance, abrasion resistance and thermal stability of the coating are improved, so that the coating is more suitable for a more demanding high-speed cutting and high-hardness environment, and the high-temperature abrasion-resistant CrAlSiON based nano-composite coating has great application prospects in the fields of cutters and surface protection.

Owner:GUANGDONG UNIV OF TECH

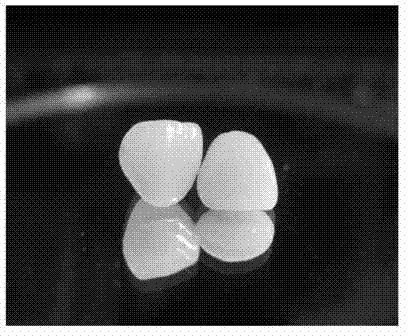

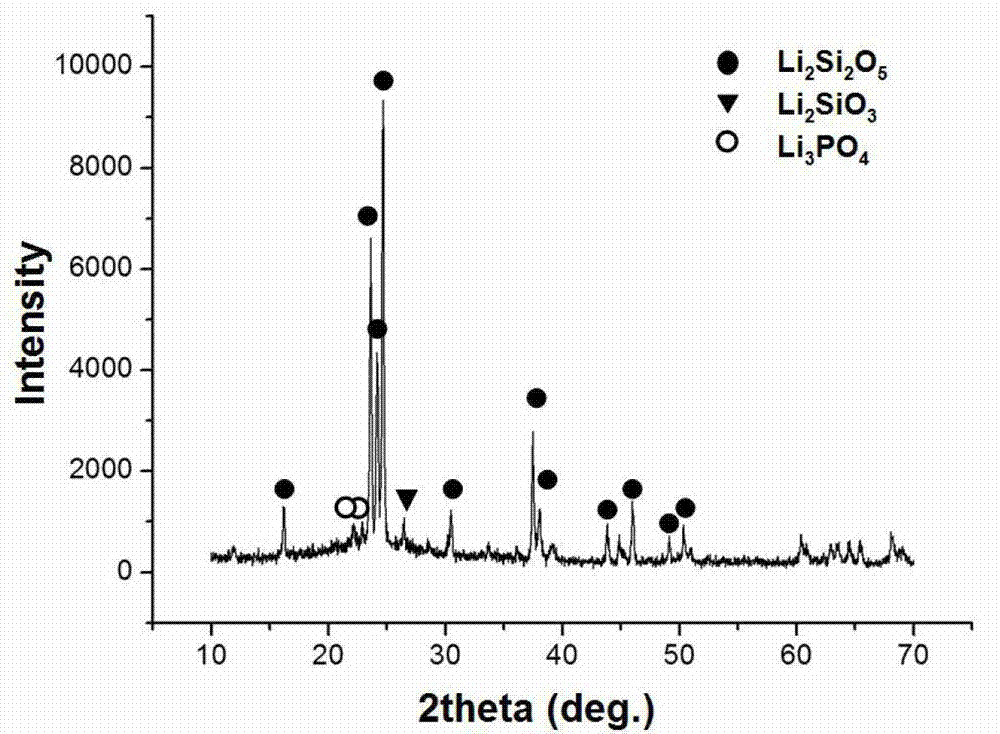

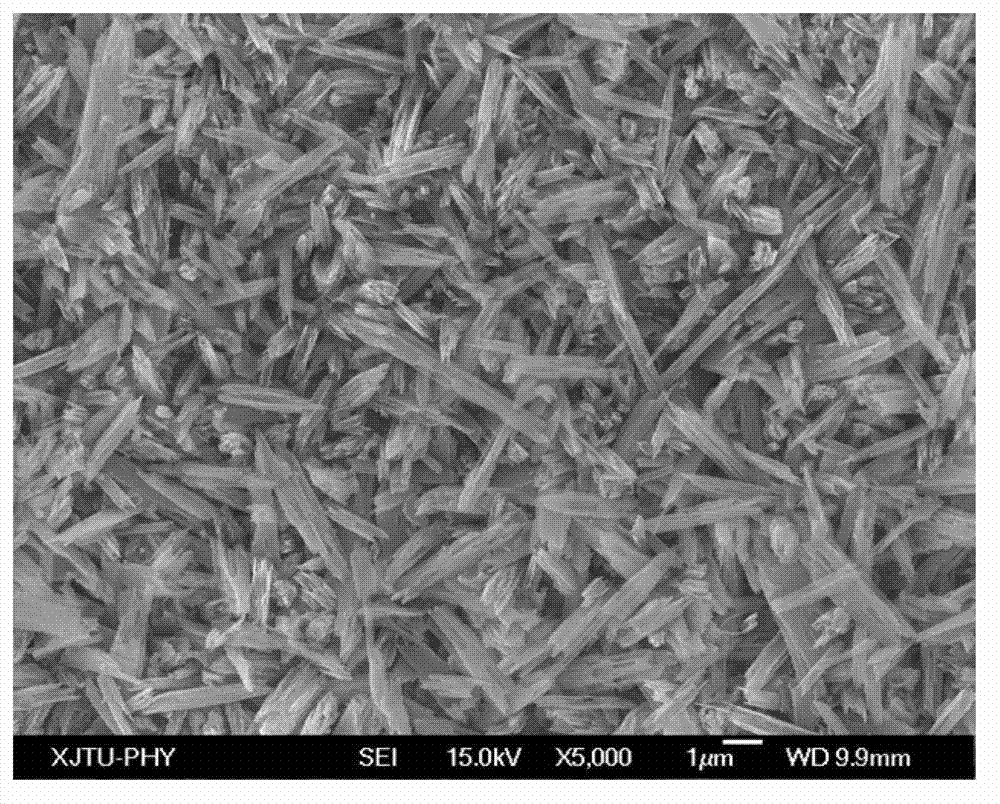

Glass ceramic for making dental prosthesis and preparation method thereof

InactiveCN103043910AGood semi-permeabilityImproved resistance to crack growthGlass particleThermal treatment

The invention discloses a glass ceramic for making a dental prosthesis and a preparation method thereof. The glass ceramic comprises the following components in percentage by weight: 56 to 59 percent of SiO2, 28 to 30 percent of Li2CO3, 3.7 to 4.0 percent of K2CO3, 2.7 to 3.0 percent of Al2O3, 2.3 to 2.4 percent of ZrO2, 1.5 to 1.6 percent of CeO2 and 2.5 to 3.0 percent of P2O5. The preparation method of the glass ceramic comprises the following steps of: uniformly mixing and ball-milling the components, and drying after uniformly mixing so as to obtain mixed powder; pouring the mixed powder into a quartz crucible to carry out founding, then pouring molten powder into deionized water and carrying out cold quenching to obtain glass particles; placing the glass particles into an agate jar and carrying out ball milling and drying to obtain glass powder; filling the glass powder into a prefabricated box to carry out cold isostatic pressure forming so as to obtain a glass powder blank; and finally, carrying out two-section crystallization thermal treatment on the glass powder blank to obtain the glass ceramic.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

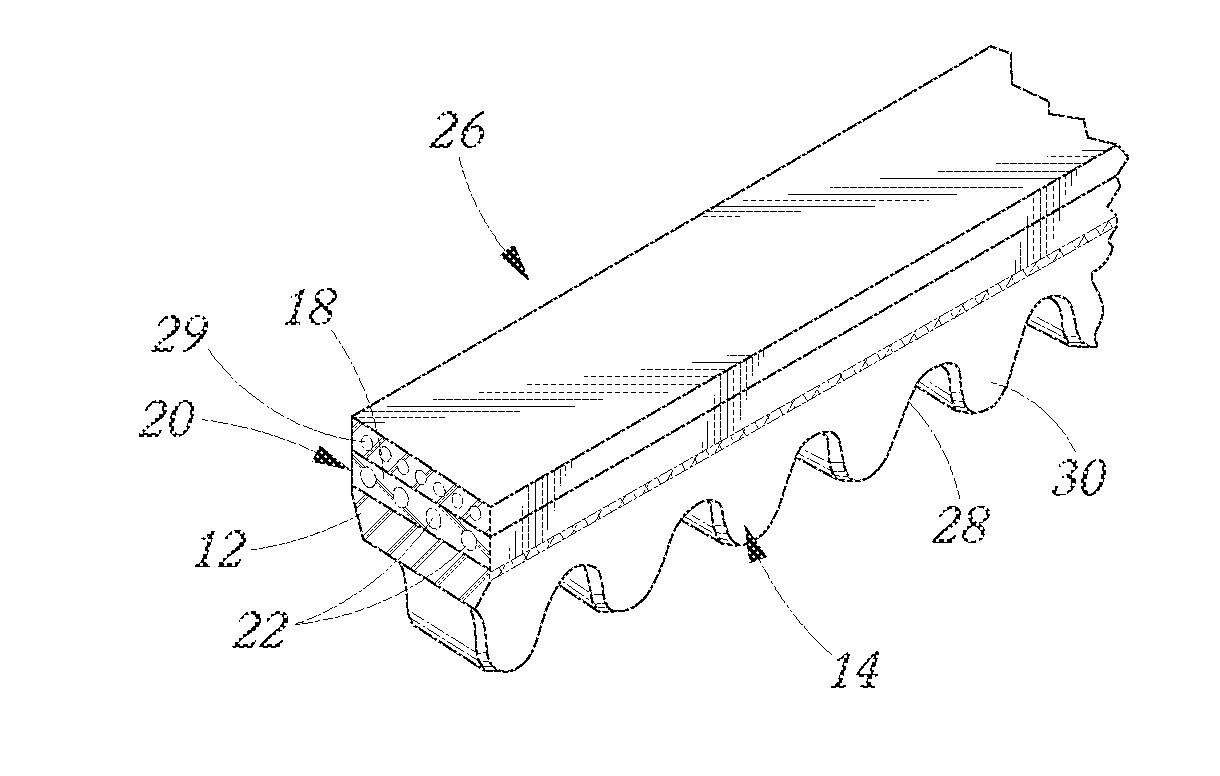

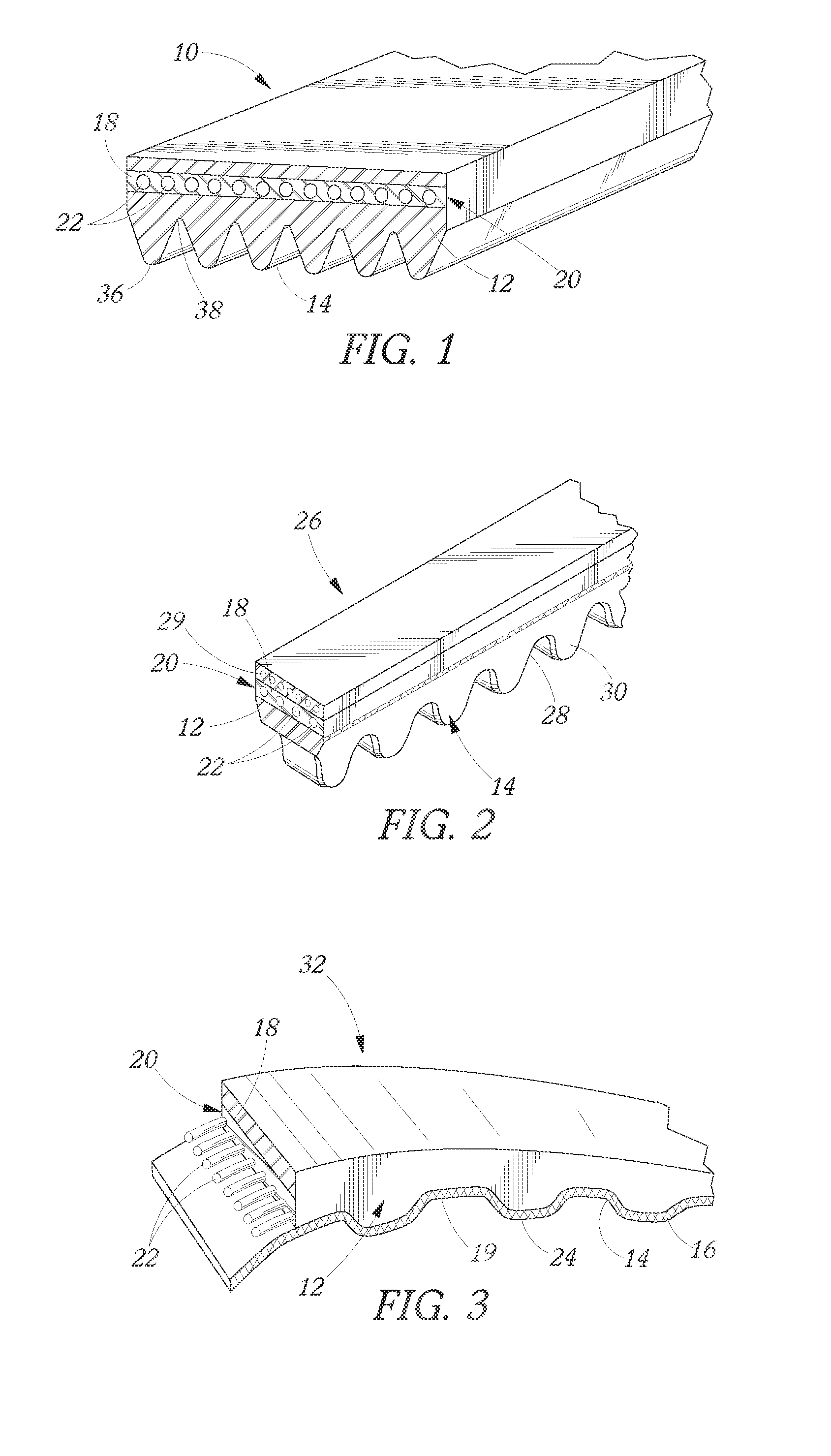

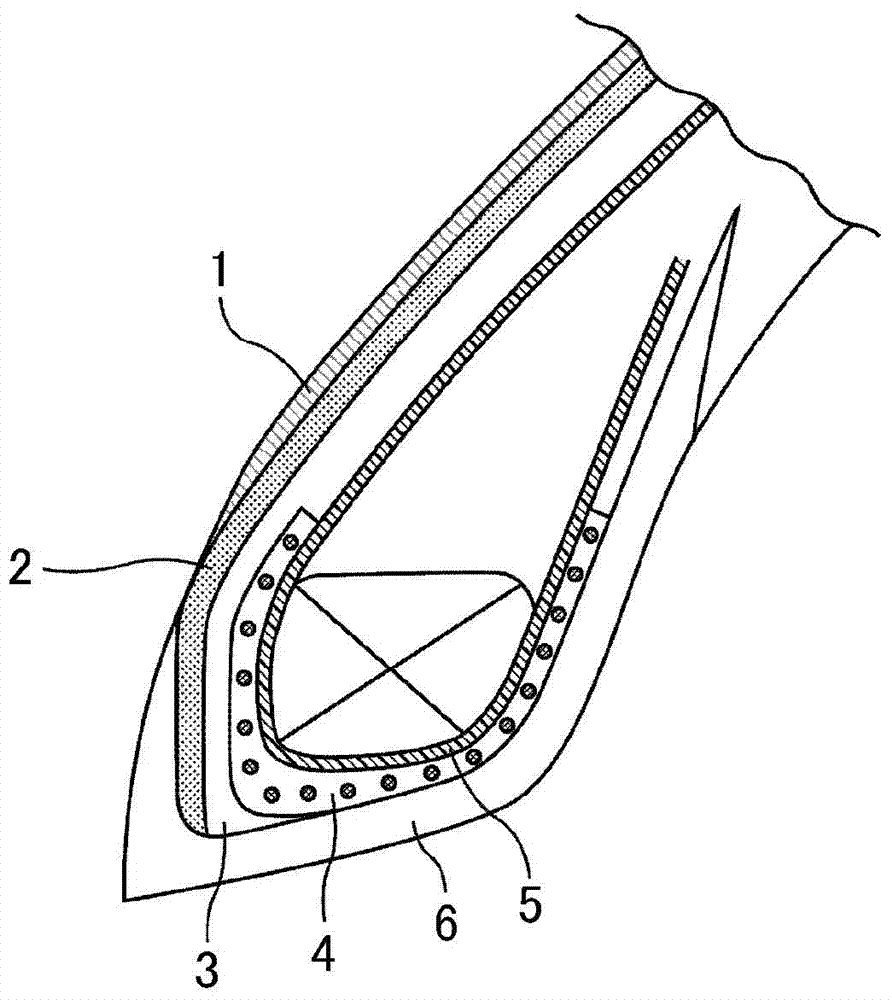

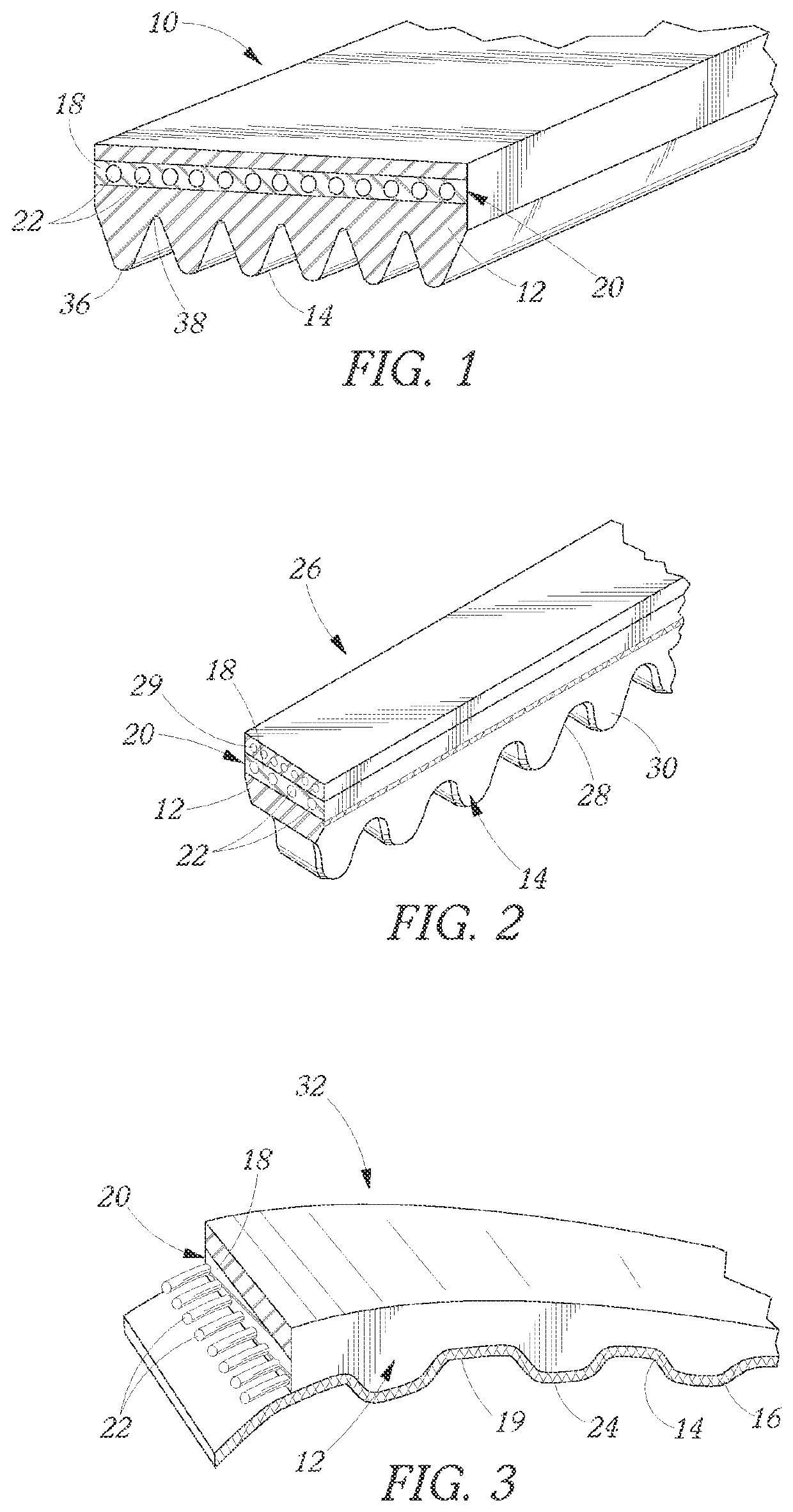

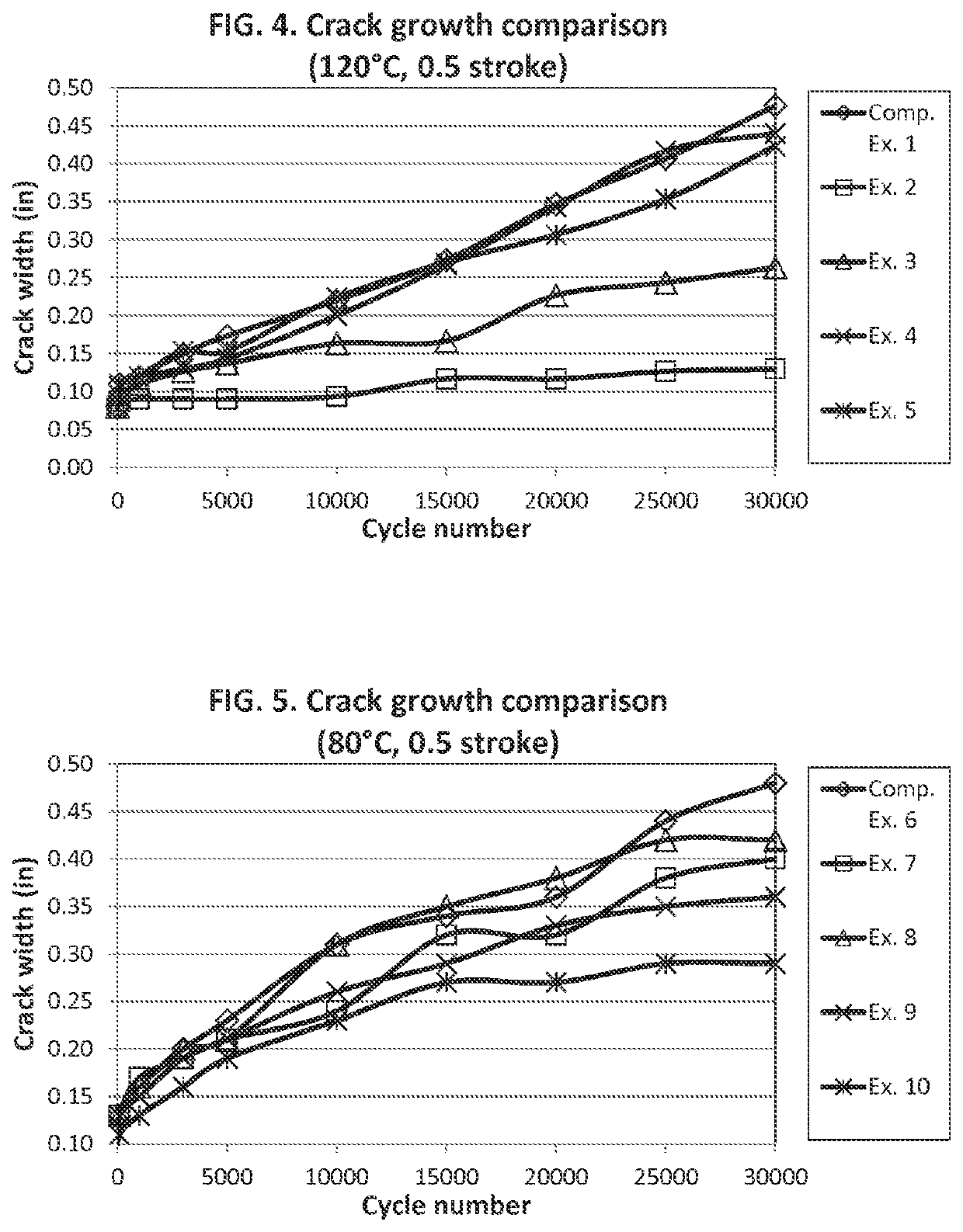

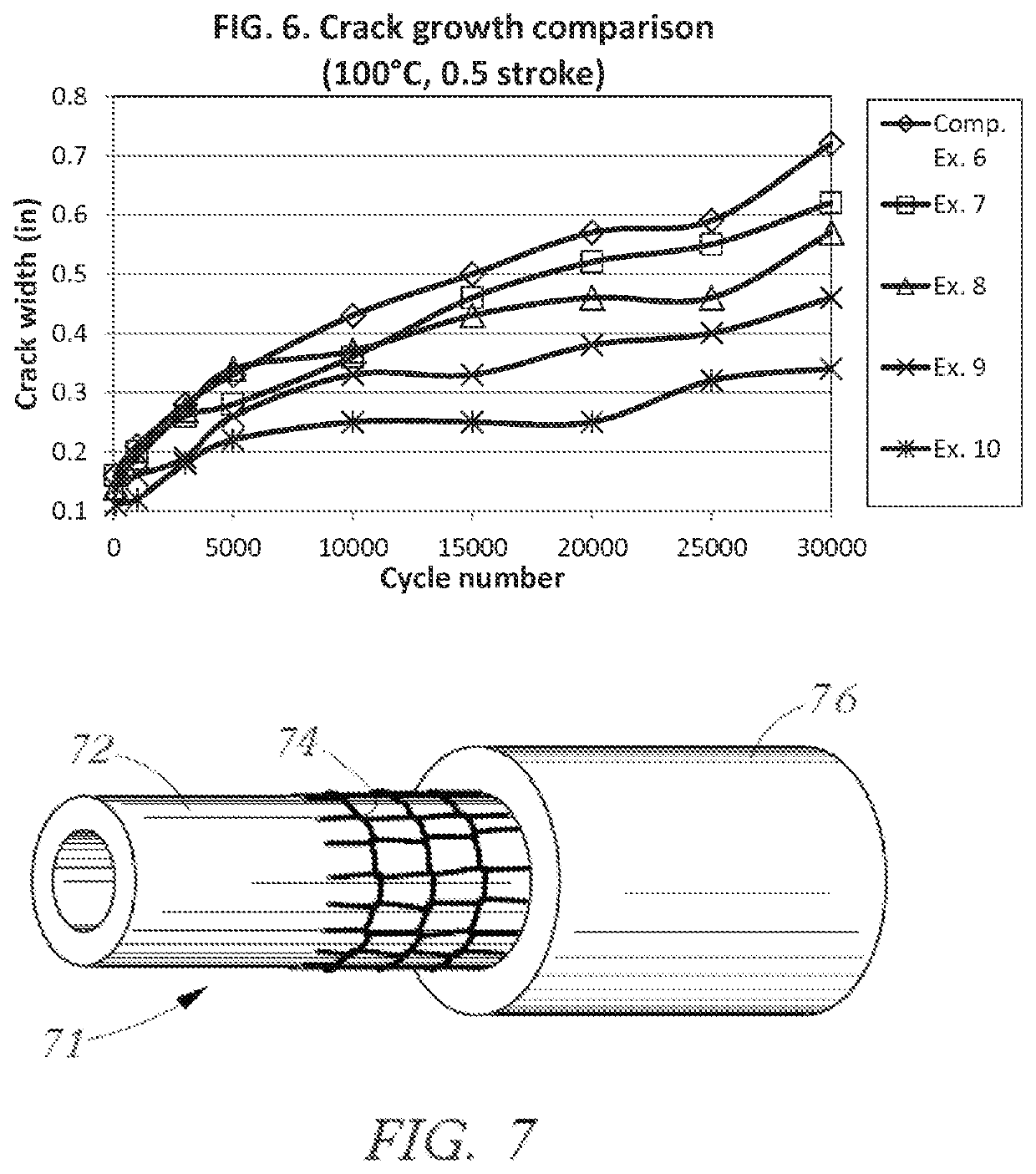

Power Transmission Belt

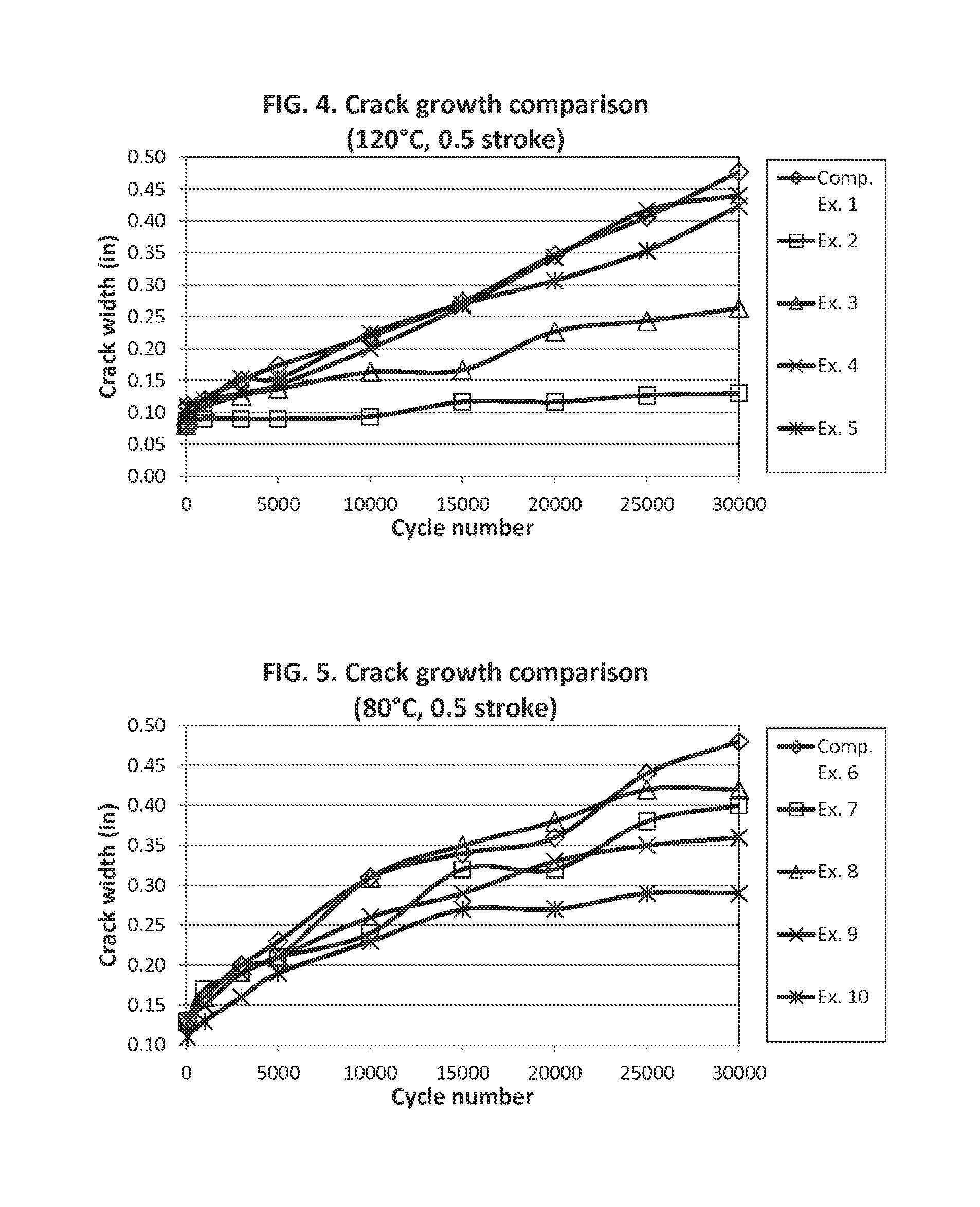

ActiveUS20150218357A1Improvement in flex crack growth performanceImproved resistance to crack growthV-beltsClosuresIonomerElastomer

A power transmission belt or hose or other dynamic article with an elastomeric body comprising a rubber composition that includes an ionomeric polymer additive, such as an ethylene-methacrylic acid copolymer or a butyl ionomer. The rubber body exhibits improved crack growth resistance over the same body composition without the ionomer additive.

Owner:THE DOW CHEM CO

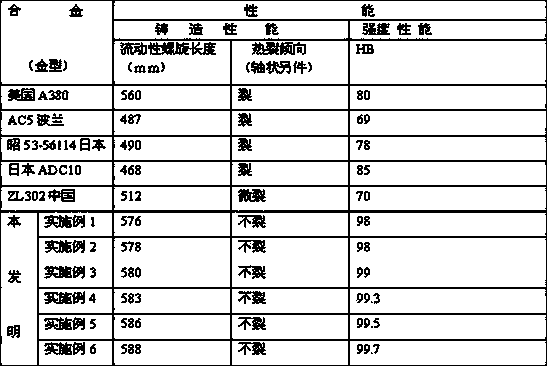

High-strength die-cast aluminum-titanium alloy

The invention discloses a high-strength die-cast aluminum-titanium alloy. The alloy consists of the following components in percentage by weight: 18-34% of zinc, 3-8% of silicon, 2-7% of copper, 0.1-0.6% of manganese, 0.02-1% of titanium, 0.01-0.08% of gallium, 0.01-0.08% of cerium, and the balance of aluminum and reasonable impurities. The high-strength die-cast aluminum-titanium alloy has advantages of excellent fatigue resistance, crack propagation resistance, corrosion resistance and heat resistance.

Owner:TIANHEXING METAL & PLASTIC SHENZHEN CO LTD

Wear-resistant and oxidation-resistant high-entropy alloy coating and preparation method thereof

ActiveCN112226758AHigh hardnessImprove high temperature performanceMetallic material coating processesMetallurgyOxidation resistant

The invention provides a wear-resistant and oxidation-resistant high-entropy alloy coating and a preparation method thereof. The alloy coating comprises, by mass, 15-21% of Fe, 15-21% of Co, 26-35% ofCr, 15-21% of Ni, 11-18% of Nb, 1-6% of Si, 0.1-1.2% of C, and 1-2% of CeO2. The coating is prepared by adopting a preset powder method and a coaxial powder feeding method. The preset powder method comprises the steps of weighing Co, Cr, Fe, FeNb, FeSi powders, FeCrC powders and CeO2 powders according to target coating components; uniformly mixing and drying at 80-150 DEG C for 1-4 hours; uniformly pre-spreading dried mixed powders on the surface of a substrate, wherein the thickness is 0.6-1.3 mm; and then laser cladding the powders on the surface of the substrate to form the wear-resistantand oxidation-resistant high-entropy alloy coating. The coaxial powder feeding method comprises the steps of firstly preparing alloy powders by adopting a smelting gas atomization method according tothe content of Co, Cr, Fe, Nb, Si and C in the coating; uniformly mixing the alloy powders with the CeO2 powders, and drying at 80-150 DEG C for 1-4 hours; putting the dried powders into a powder feeding cylinder; feeding the powders by adopting nitrogen protection; and laser cladding the powders on the surface of the substrate to form the wear-resistant and oxidation-resistant high-entropy alloycoating.

Owner:UNIV OF SCI & TECH BEIJING

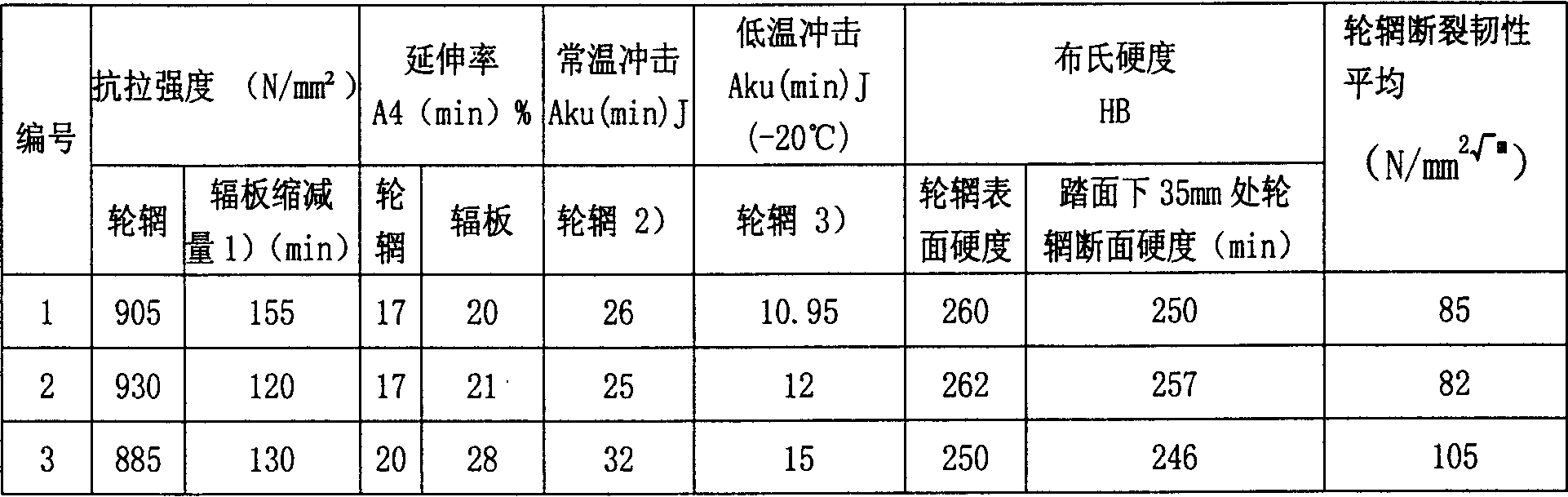

Medium carbon low alloy steel for light high speed train wheel

This invention relates to a type of midst-carbon and low-alloy steel which used for wheel of light super-speed railroad train. Account for weight it includes : 0.40-0.50%C 0.20-0.70%Si 0.50-0.80%Mn 0.20-0.30%Cr 0.015-0.035%Als S<=0.02% P<=0.02%,the rest is Fe and impurity element. The invention lowers the carbon inside steel, increases the Si, and adds trace quantity Al and Cr. Compared with the background technology, this invention has better property but lower cost.

Owner:MAANSHAN IRON & STEEL CO LTD

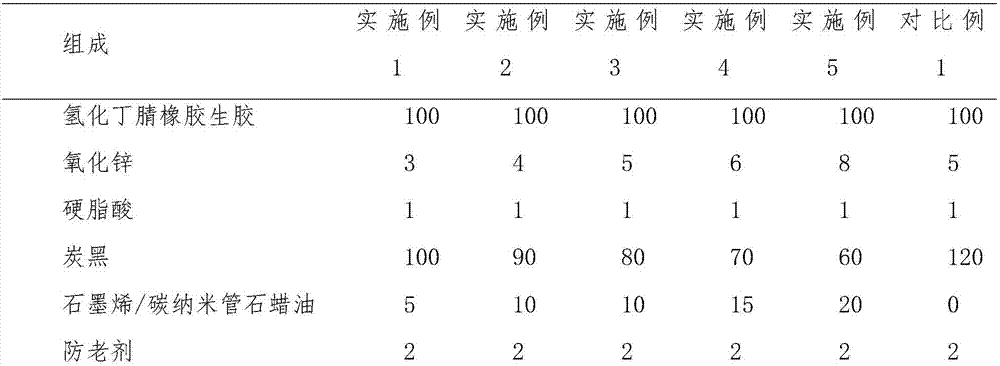

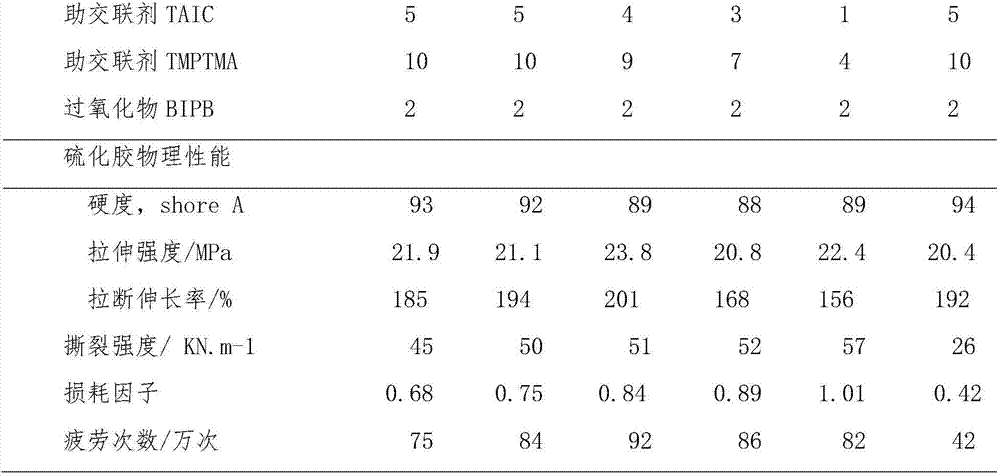

Graphene-containing HNBR (hydrogenated butadiene-acrylonitrile rubber) nanocomposite and preparation method

The invention belongs to the technical field of rubber materials and relates to a graphene-containing HNBR (hydrogenated butadiene-acrylonitrile rubber) nanocomposite and a preparation method. The graphene-containing HNBR nanocomposite is a mixture of crude HNBR, carbon black, graphene / carbon nanotube paraffin oil, an anti-aging agent, an assistant crosslinker and a vulcanizing agent. According tothe graphene-containing HNBR nanocomposite, high-frequency loss factor of HNBR is greatly increased, high-frequency vibration fatigue resistance of the HNBR material is improved, tear resistance of the HNBR is further improved, and therefore, the graphene-containing HNBR nanocomposite has the advantages beyond traditional filler. The graphene-containing HNBR nanocomposite adopts a simple technology, is low in cost, facilitates industrial production, is widely adaptive and has better economic benefit and social benefit.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

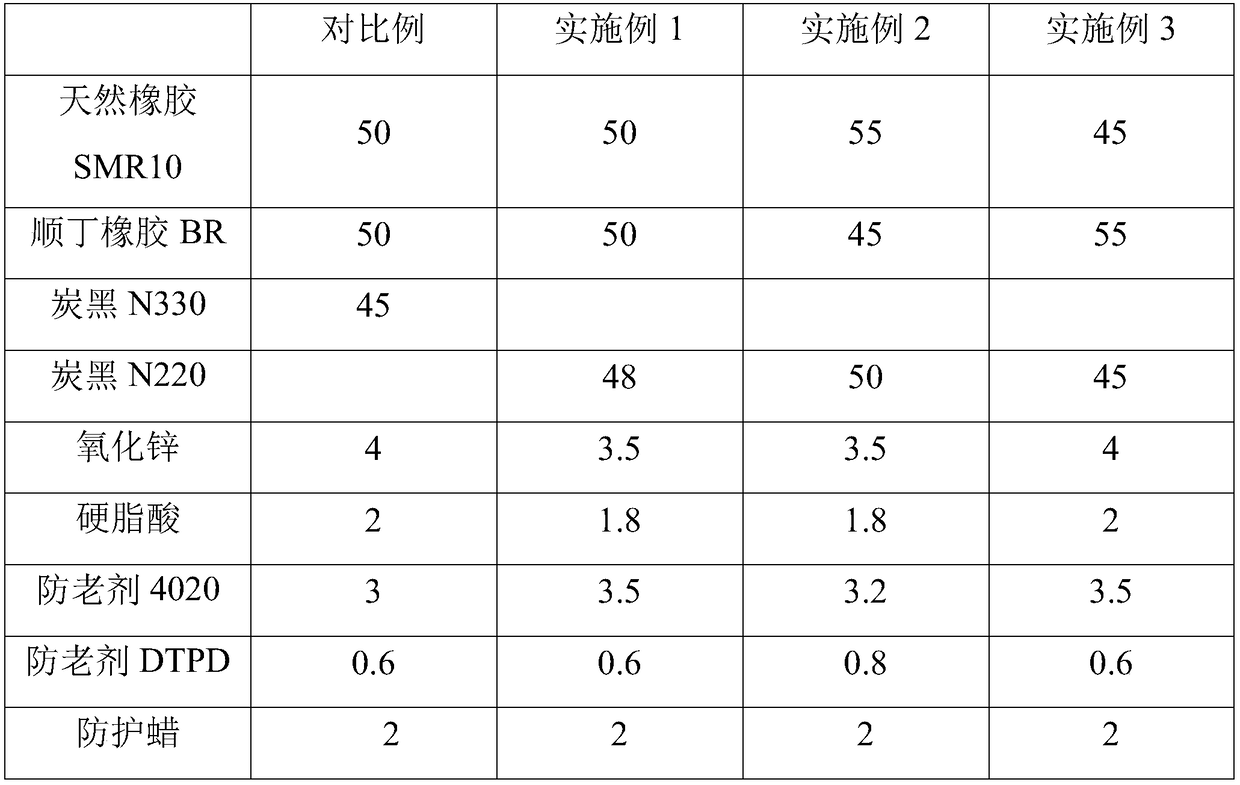

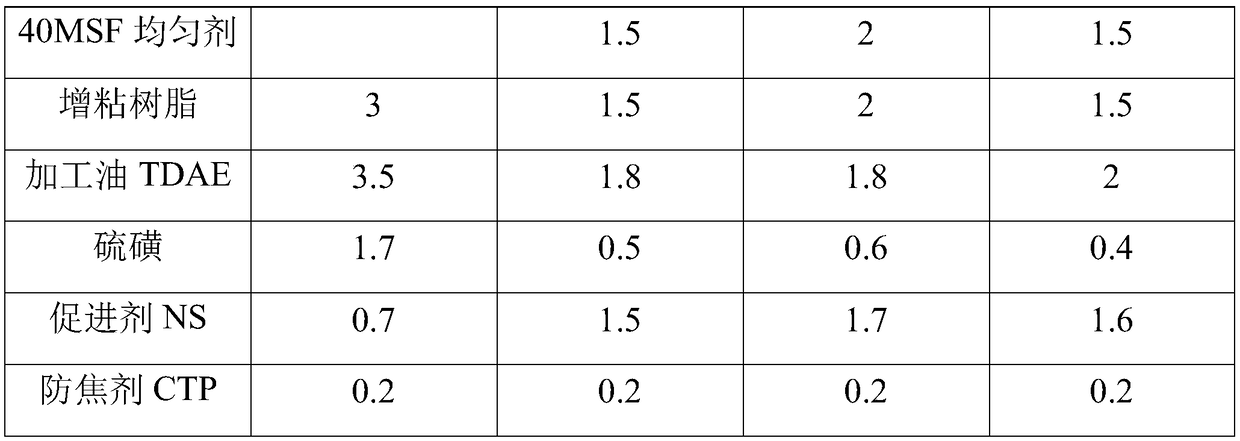

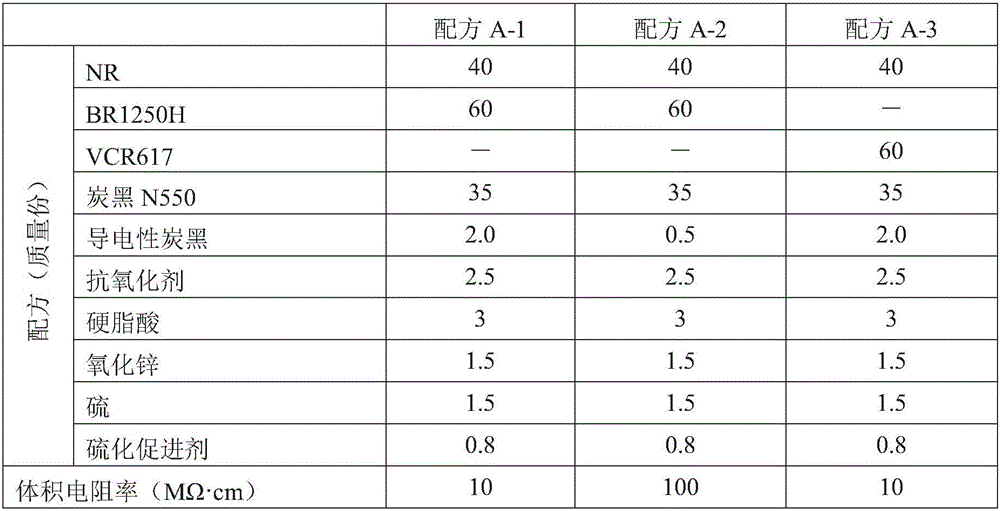

Anti-aging, tearing-resistant and crack growth-resistant rubber composition for all-steel tire sidewall and preparation method and application thereof

PendingCN109206676AImprove heat aging resistanceImproved resistance to crack growthSpecial tyresRubber materialPolymer science

The invention discloses an anti-aging, tearing-resistant and crack growth-resistant rubber composition for an all-steel tire sidewall and a preparation method and an application thereof, and relates to the technical field of rubber materials for tires. The rubber composition comprises the following raw material components in parts by weight: 40-60 parts of natural rubber, 40-60 parts of cis-butadiene rubber, 40-55 parts of carbon black, 3-5 parts of zinc oxide, 1-3 parts of stearic acid, 1-2 parts of protective wax, 2-5 parts of an anti-aging agent, 1-4 parts of tackifying resin, 1-3 parts ofprocessing oil, 0.5-1 part of sulfur, 1-3 parts of an accelerator, 1-2 parts of a homogenizer, and 0.1-0.2 part of an antiscorching agent CTP. Based on an ordinary tire sidewall formula, N220 pure carbon black with finer particle size and higher structure is used as a filling system, and the filling amount is improved to ensure the tear resistance of rubber, at the same time, the vulcanization system is adjusted, the vulcanization crosslinking is guaranteed to be dominated by single sulfur bond, and thus the heat aging resistance and the crack growth resistance are improved.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

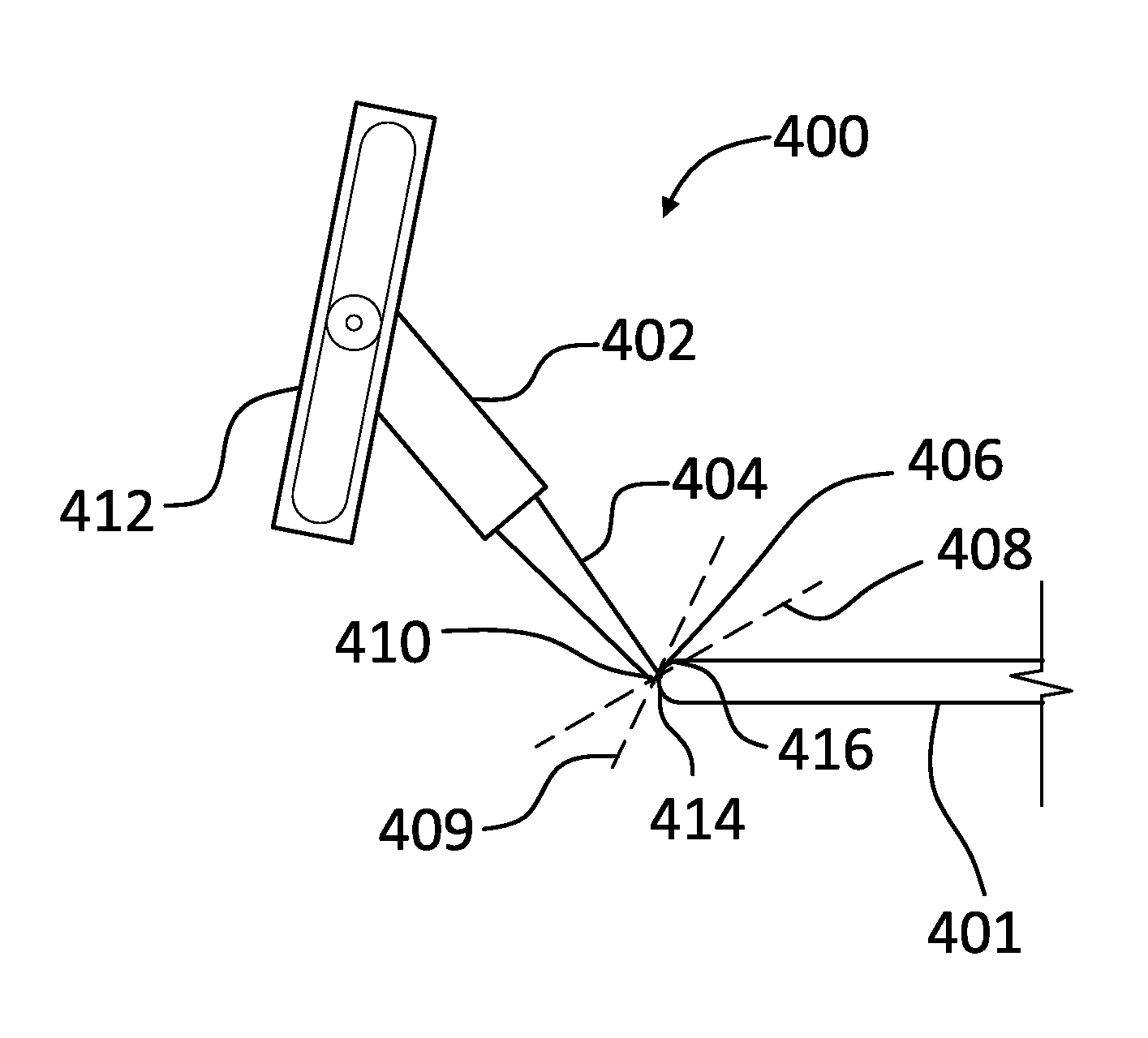

Laser melting deposition-based automobile clutch facing and preparation method thereof

InactiveCN107400886AImprove wear resistanceStable tribological propertiesTransportation and packagingMetal-working apparatusAl powderHexagonal boron nitride

The invention discloses a preparation of a laser melting deposition-based automobile clutch facing. The laser melting deposition-based automobile clutch facing is prepared by sequentially carrying out melting, high-pressure water atomization and laser melting deposition on the TiC powder, hexagonal boron nitride (hBN) powder, B powder, Ni powder and Al powder which are taken as raw materials. The clutch facing has good physical and mechanical properties and better friction properties and thermal stability. Furthermore, the technological parameters are easy to control in a preparation process, so that the preparation method of the laser melting deposition-based automobile clutch facing is suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

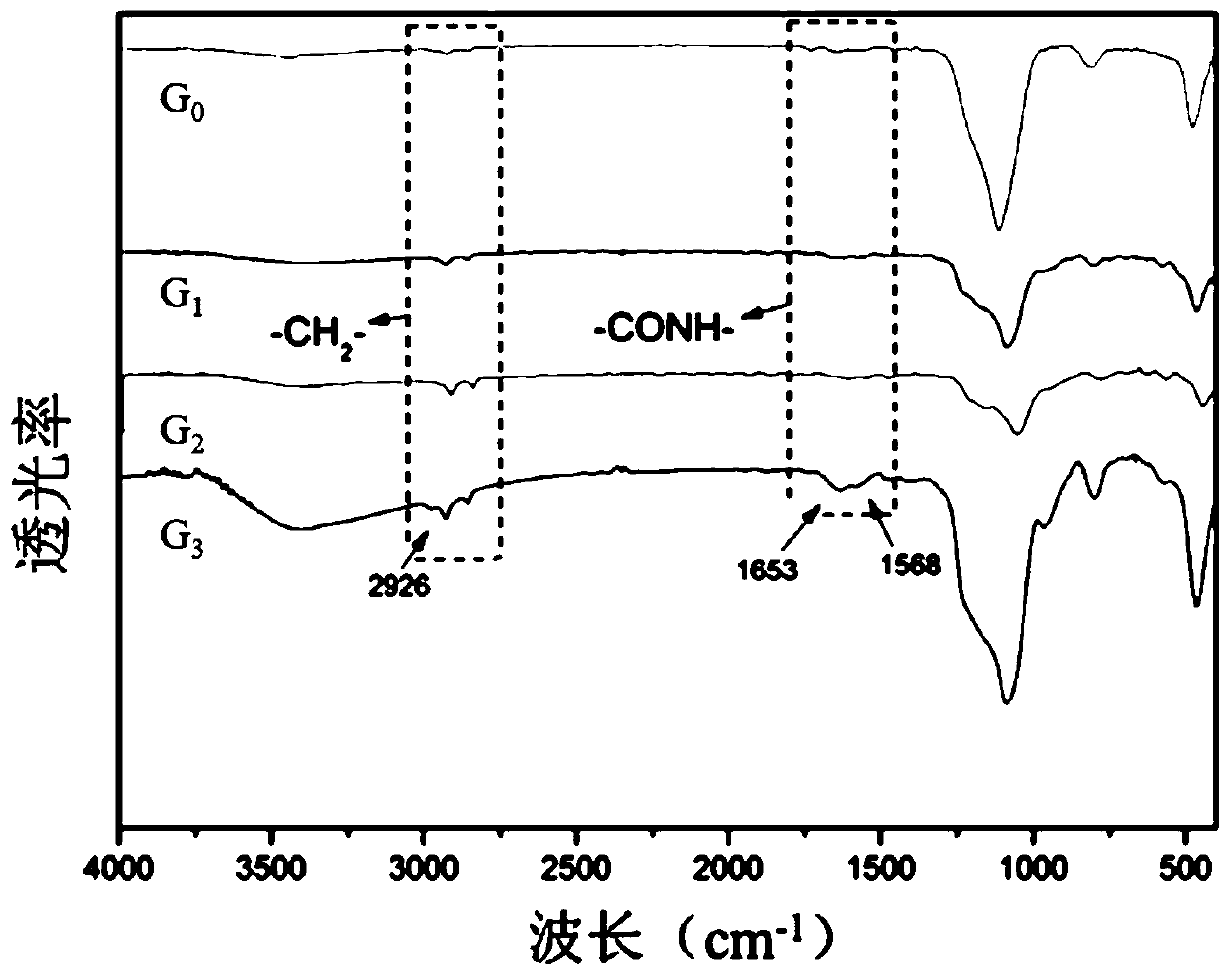

Stretchable hydrogel based on modified silica nanoparticle crosslinking agent and preparation method and application thereof

The invention belongs to the technical field of novel polymer functional materials, and discloses a stretchable hydrogel based on a modified silica nanoparticle cross-linking agent and a preparation method and application thereof. The method specifically comprises the following steps: uniformly mixing sodium alginate, acrylamide, the modified silica cross-linking agent, N, N-methylene bisacrylamide and an initiator in water, and carrying out radical polymerization to obtain a final product. The method successfully prepares a novel modified silica reinforced double network structure hydrogel (alginate / polyacrylamide). The prepared silica cross-linking agent grafted with PAMAM on the surface has strong hydrogen bonds with polymer chains, and the addition of the silica cross-linking agent remarkably improves the mechanical strength of the hydrogel while maintaining good elongation. At the same time, due to the adoption of the double network system, when the double network hydrogel undergoes tensile deformation, stress concentration can be effectively relieved, and crack propagation resistance can be increased.

Owner:GUANGZHOU UNIVERSITY

High-toughness ultrathin die-cast aluminum lithium alloy

The invention discloses a high-toughness ultrathin die-cast aluminum lithium alloy which comprises the following components in percentage by weight: 1-3% of zinc, 5-7% of silicon, 0.3-3% of copper, 0.1-10% of magnesium, 0.1-0.5% of lithium, 0.3-0.6% of strontium, 0.1-0.3% of lanthanum, 0.1-0.3% of cerium and the balance of aluminum. The high-toughness ultrathin die-cast aluminum lithium alloy disclosed by the invention has the advantages of better fatigue resistance, crack growth resistance, corrosion resistance and heat resistance.

Owner:TIANHEXING METAL & PLASTIC SHENZHEN CO LTD

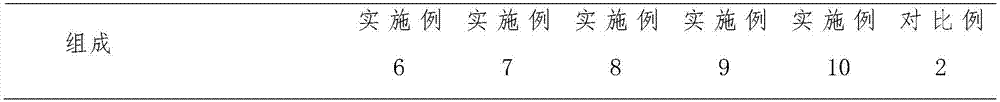

Erosion-resistant fluorine rubber nanometer composite material with graphene and method for preparing erosion-resistant fluorine rubber nanometer composite material

The invention belongs to the technical field of graphene / rubber nanometer composite materials, and relates to an erosion-resistant fluorine rubber nanometer composite material with graphene and a method for preparing the erosion-resistant fluorine rubber nanometer composite material. The erosion-resistant fluorine rubber nanometer composite material comprises, by weight, 100 parts of fluorine rubber, 0.1-15 parts of graphene, 0.5-20 parts of carbon black, 0.5-20 parts of carbon fibers, 3-7 parts of oxide or hydroxide acid acceptors, 2-5 parts of peroxide or bisphenol vulcanizing agents, 0.2-7parts of assistant cross-linking agents and 0.5-5 parts of silane coupling agents. The erosion-resistant fluorine rubber nanometer composite material and the method have the advantages that pre-dispersion treatment is carried out on the graphene by the aid of ball milling processes, accordingly, the dispersibility of the graphene in the fluorine rubber can be improved, the erosion resistance of the fluorine rubber can be effectively improved, erosion loss can be reduced by 62% as compared with fluorine rubber without graphene, the erosion loss further can be reduced by 43% as compared with fluorine rubber which is not subjected to pre-dispersion treatment and is directly additionally provided with graphene, and the erosion resistance can be obviously improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

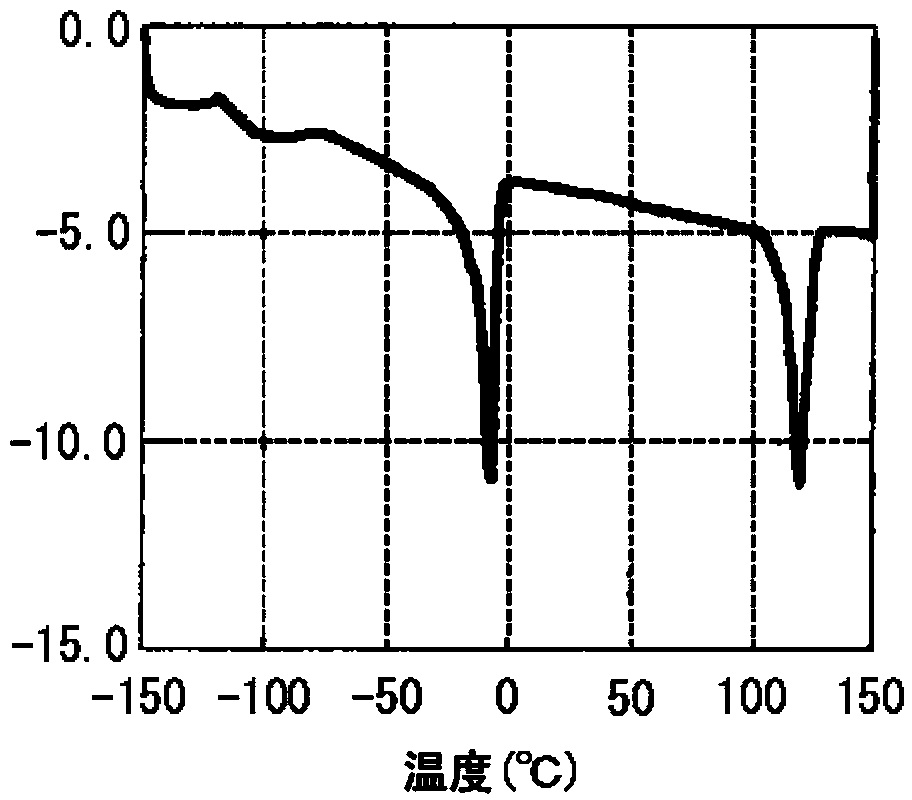

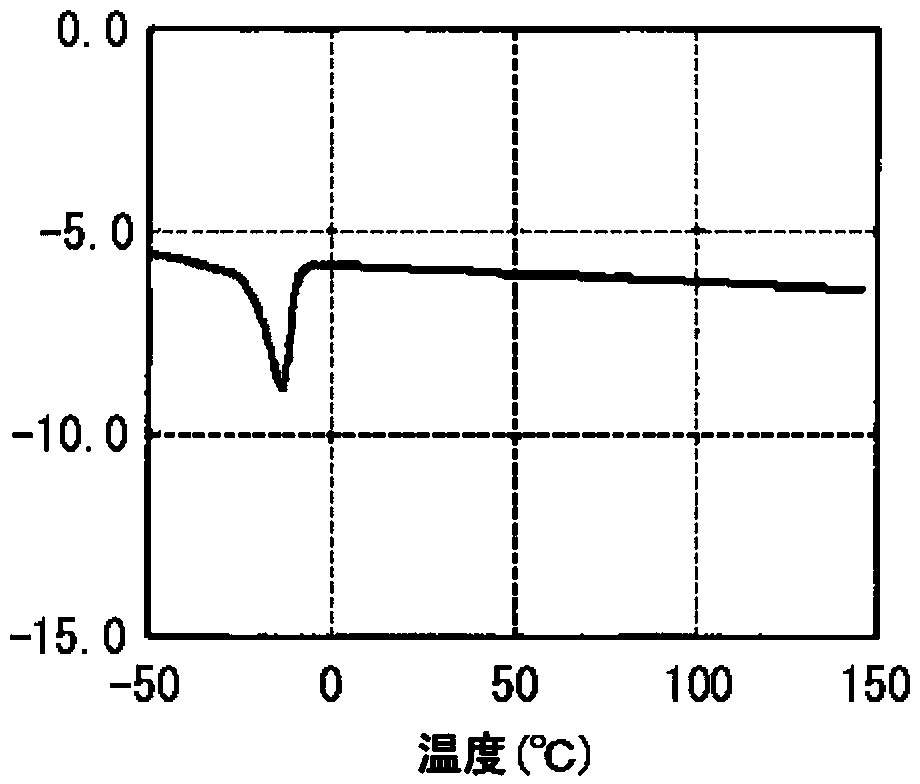

Copolymer, rubber composition, rubber composition for tire side use, crosslinked rubber composition, and tire

InactiveCN103476813AReduce the heating effectLow heat resistanceSpecial tyresWeather resistancePolymer science

Provided is a copolymer of a conjugated diene compound and a non-conjugated olefin, the copolymer being used for producing a rubber that is excellent in terms of low heat buildup, heat resistance, and ozone resistance (weather resistance). Also provided are a rubber composition containing said copolymer, a crosslinked rubber composition prepared by cross-linking said rubber composition, and a tire made by using said rubber composition or said crosslinked rubber composition. The copolymer of a conjugated diene compound and a non-conjugated olefin is characterized in that the content of 1,2 adduct moieties (including 3,4 adduct moieties) in a moiety originating from the conjugated diene compound is less than or equal to 5%.

Owner:BRIDGESTONE CORP

Cantilevered roller and manufacturing method thereof

Owner:江苏长友特钢机械有限公司

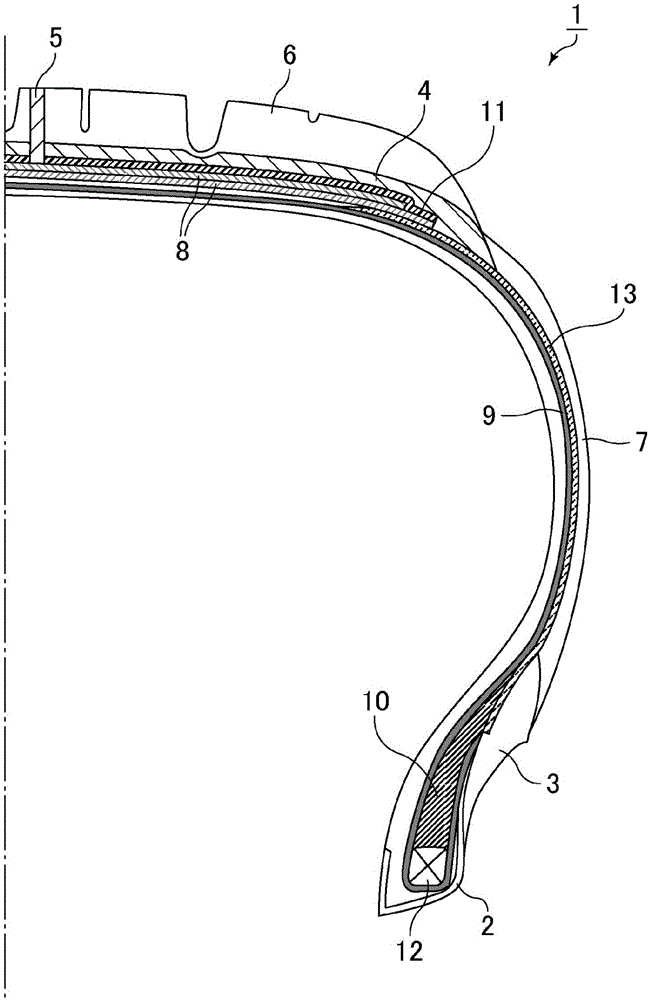

Pneumatic tire

InactiveCN106573509AImprove economyImprove conductivitySpecial tyresTyre beadsFuel efficiencyEngineering

Owner:SUMITOMO RUBBER IND LTD

Processing method

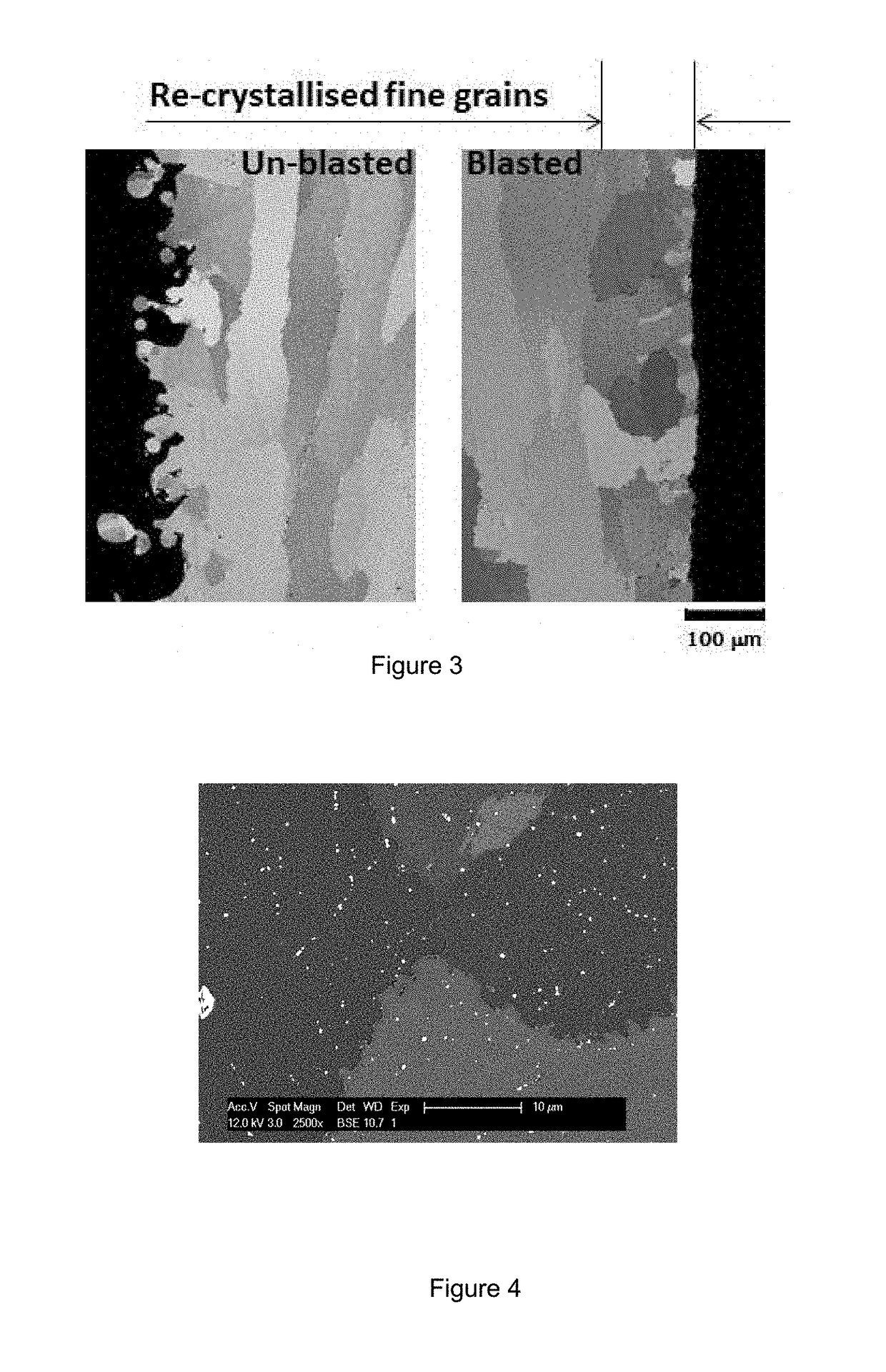

InactiveUS20180221955A1Improved resistance to crack growthMinimize surface roughnessTurbinesAdditive manufacturing apparatusSuperalloyHeat treated

The present invention provides a processing method for processing a component formed by an ALM method using a γ′-strengthened superalloy having a γ′ solvus temperature. The processing method comprises: 1) surface finishing of the component; 2) hot isostatic pressing of the component at a temperature below the γ′ solvus temperature; 3) solution heat treating the component at a temperature at or above the γ′ solvus temperature but below the solidus temperature; 4) primary aging of the component at a primary aging temperature for a first aging time; and 5) secondary aging of the component at a secondary aging temperature for a second aging time.

Owner:ROLLS ROYCE PLC

Grade-E series ship plate steel and preparing method thereof

The invention relates to grade-E series ship plate steel and a preparing method thereof and belongs to the technical field of ship plate steel. According to the grade-E series ship plate steel , the occluded foreign substance grade of the grade-E series ship plate steel is not higher than 1.5 grade, the banded structure grade of the grade-E series ship plate steel ranges from 3.0 grade to 4.0 grade, and the central grain size of the metallographic structure of the grade-E series ship plate steel is not smaller than 9.0 grade. The occluded foreign substance grade, the banded structure grade andthe grain size of the metallographic structure of the grade-E series ship plate steel are limited to form many carbide particles, the grain-boundary strength of the grade-E series ship plate steel isremarkably improved, the structure toughness is improved, crack growth is weakened, and the nil-ductility transition temperature of the grade-E series ship plate steel is reduced and is not higher than minus 40 DEG C.

Owner:SGIS SONGSHAN CO LTD

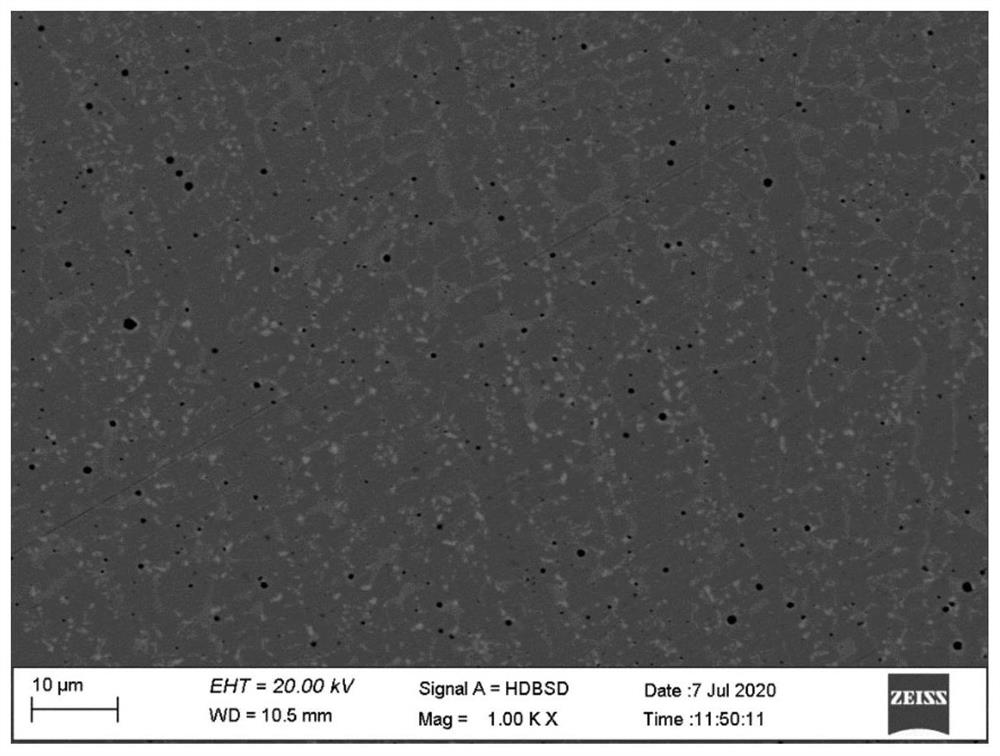

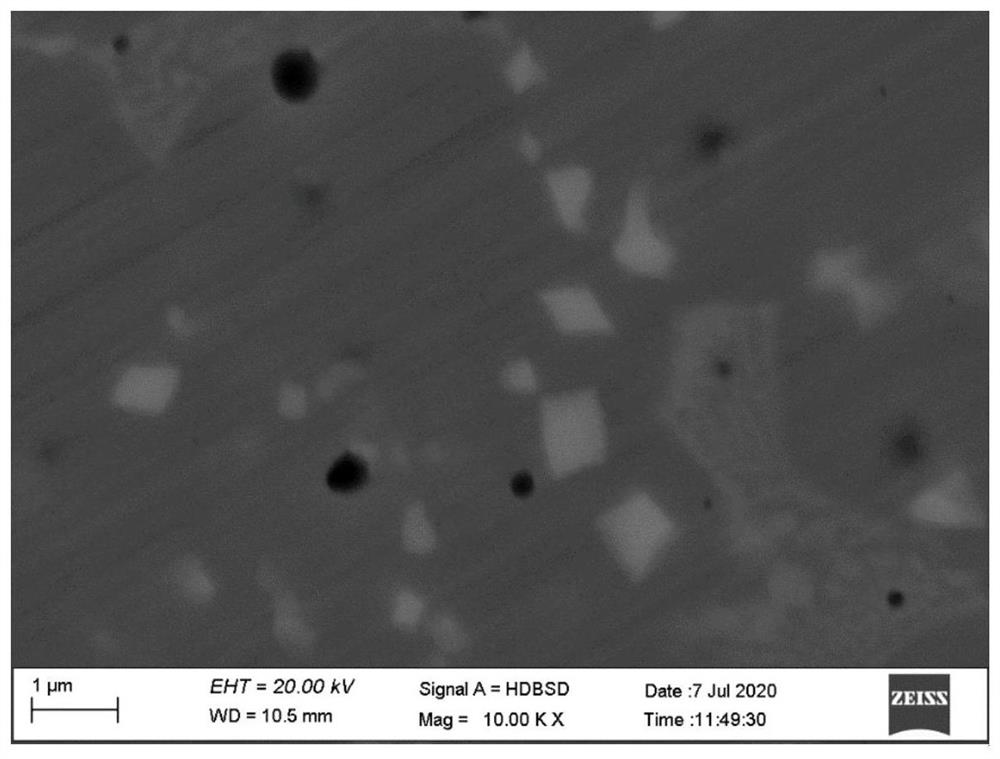

Nanocrystalline composite material for 3C product and preparation method

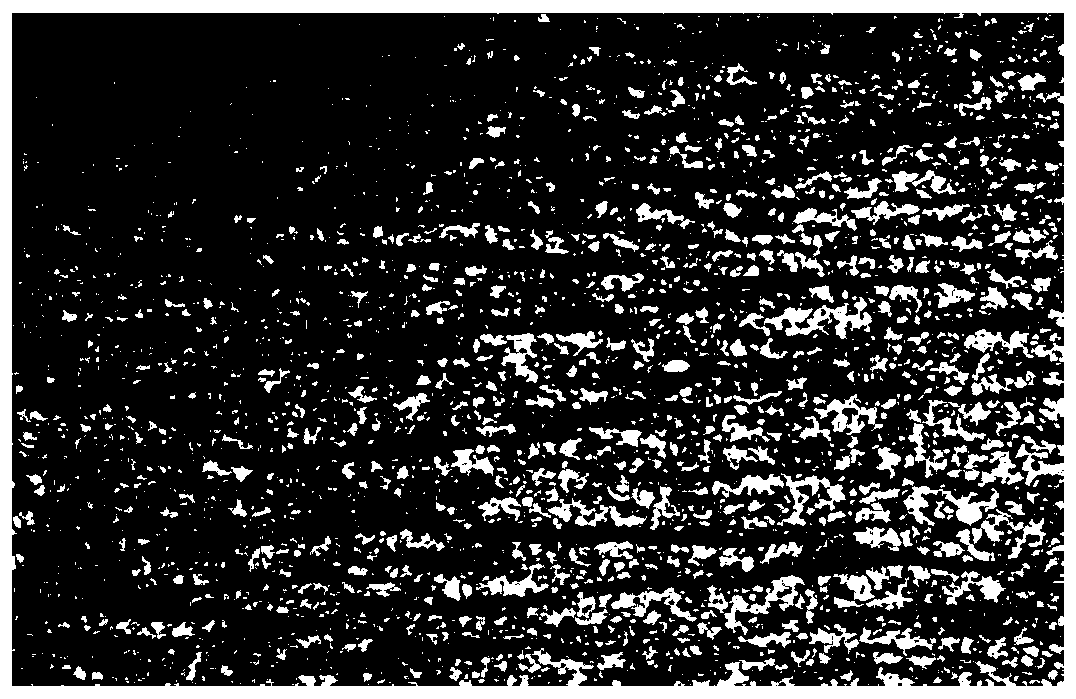

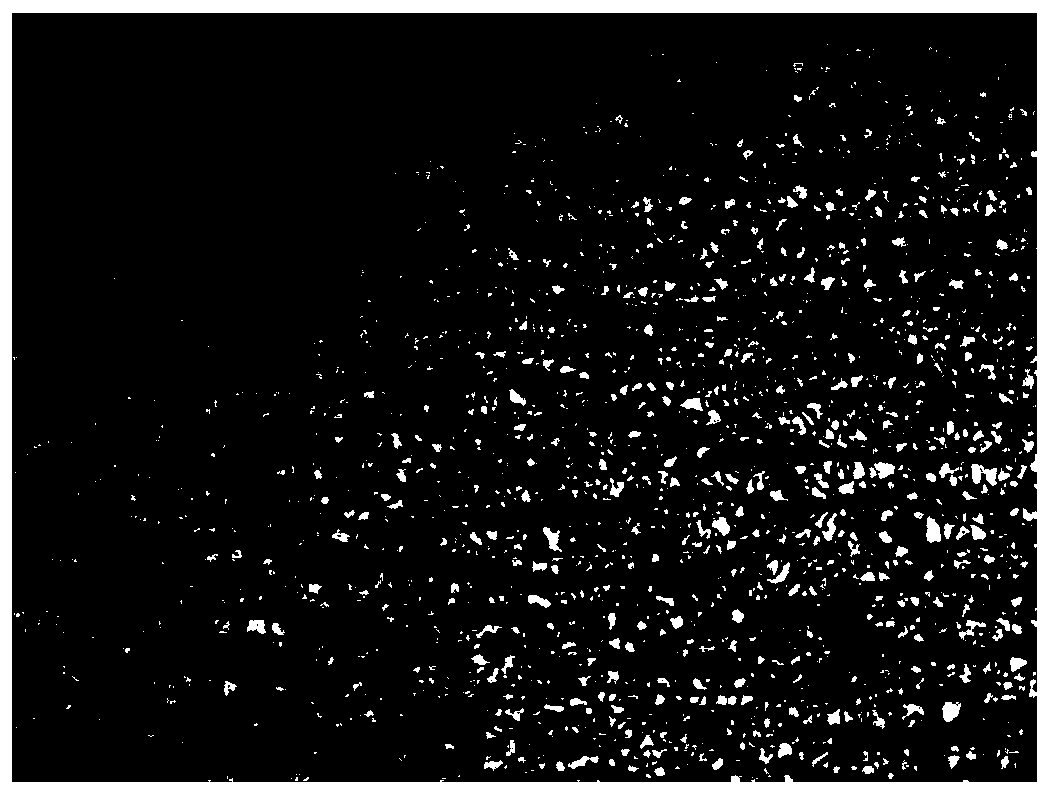

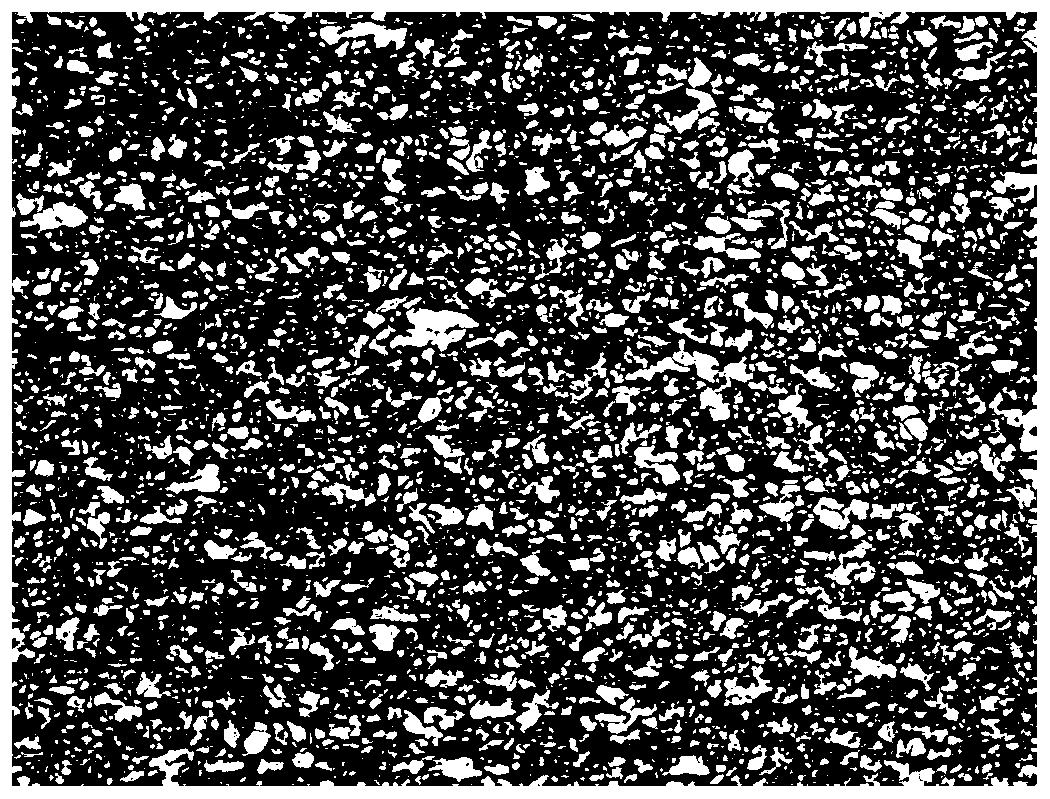

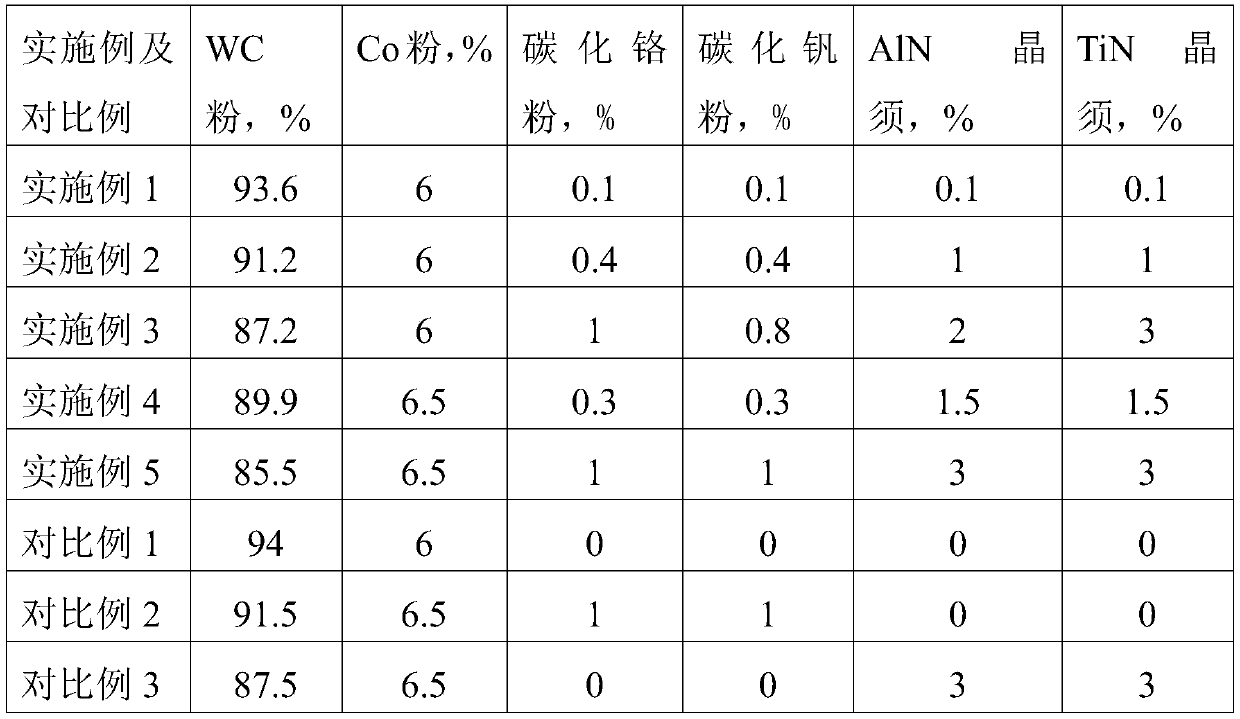

The invention provides a nanocrystalline composite material for a 3C product and a preparation method. The technical problem that in the prior art, processing materials of ''3C products'' usually cannot well meet the requirements for high strength and high hardness is solved. According to the preparation method, the nanocrystalline composite material comprises, in percentage by weight, the main materials of 6-6.5% of Co powder, 0.1-3% of AlN whiskers, 0.1-3% of TiN whiskers, 0.1-1% of chromium carbide powder, 0.1-1% of vanadium carbide powder and the balance of WC powder. According to the nanocrystalline composite material for the 3C product, the strength, hardness, toughness level and transverse fracture toughness are all greatly improved; and higher requirements of current 3C product milling and micro-drilling for high strength and high hardness of the processing materials and the requirements for high precision and a high degree of finish are met.

Owner:CHENGDU MET CERAMIC ADVANCED MATERIALS

PVC (polyvinyl chloride) profile for anti-cracking impact-resistant back net reinforcing ribs and treatment technique thereof

The invention discloses a PVC (polyvinyl chloride) profile for anti-cracking impact-resistant back net reinforcing ribs, which comprises a PVC substrate and a reinforcing agent. The reinforcing agent is composed of the following components in parts by weight: 5-10 parts of high-efficiency impact modifier based on acrylic ester polymer, 0.5-1 part of organotin stabilizing agent, 1-1.5 parts of light calcium carbonate, 0-0.5 part of active calcium, 0.05-0.1 part of toughener, 3 parts of chlorinated polyethylene, 0.08 part of oxidized wax, 0.3 part of polyethylene wax, 0.6-0.9 part of organic wax and 0.1-0.3 part of modifier. Ethyl silicate and heat-resistant pigment and filler are added into the modifier. The heat-resistant pigment and filler comprises nano smectite silicate and blocking functional filler in a mass ratio of 1.5:1:1. Compared with the prior art, the PVC profile for anti-cracking impact-resistant back net reinforcing ribs effectively reduces the problem of cracking of the reinforcing ribs due to long-time usage, and enhances the cracking resistance and impact resistance of the reinforcing ribs.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

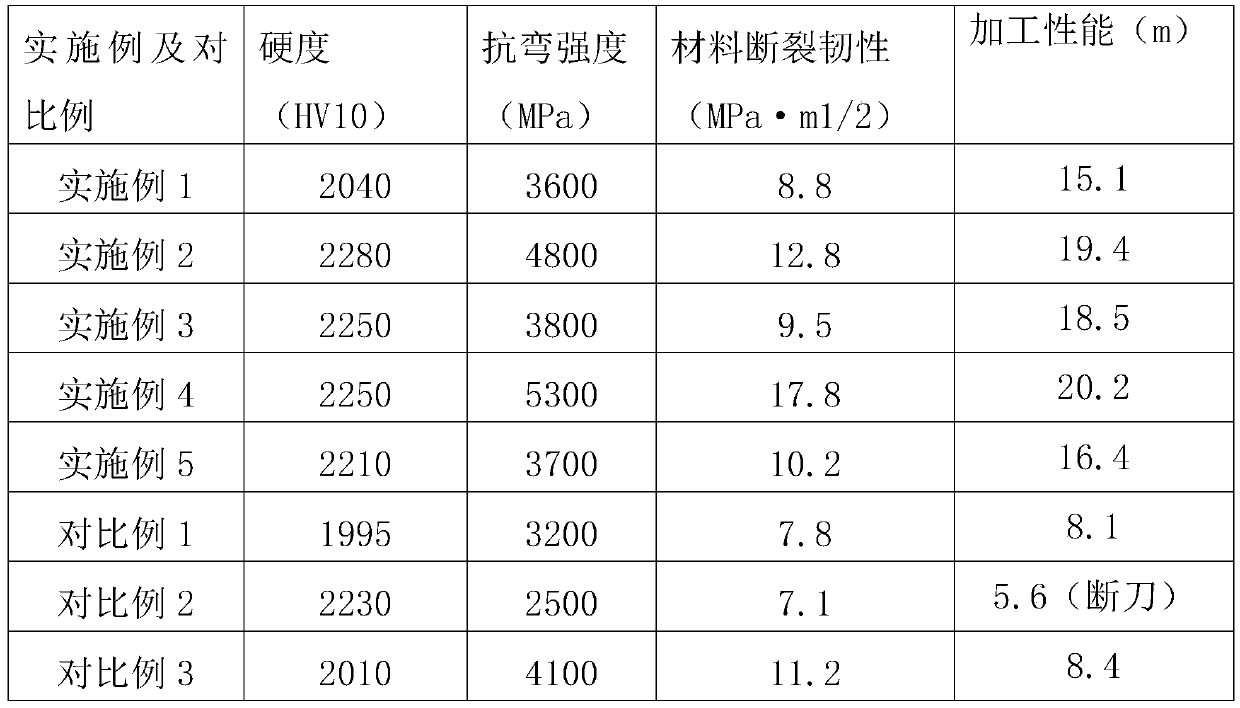

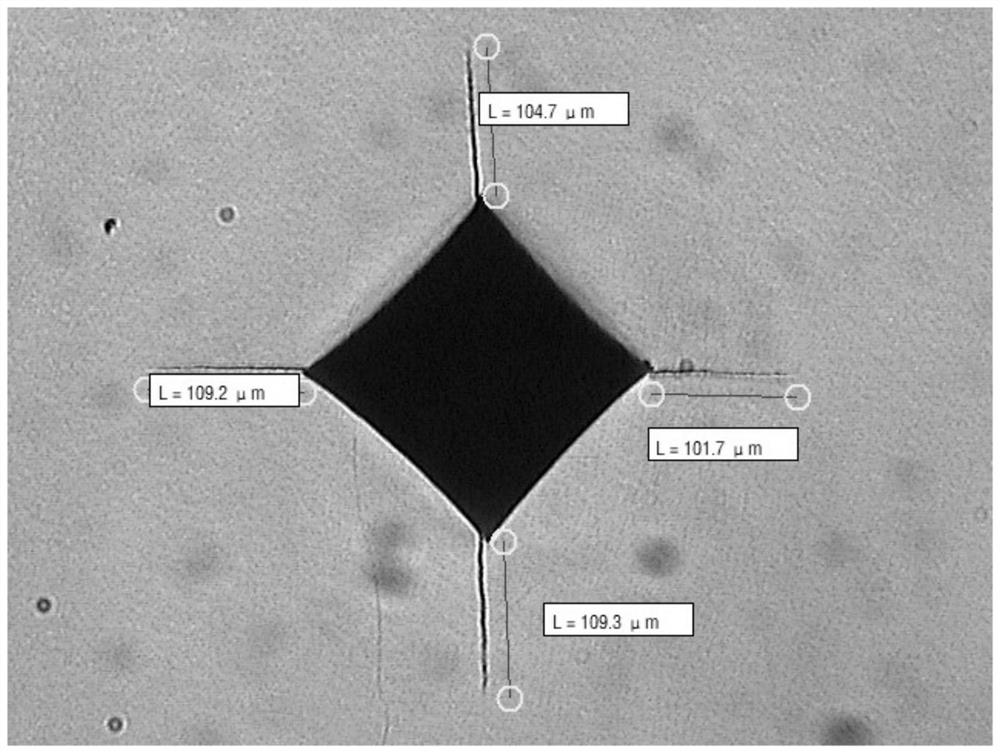

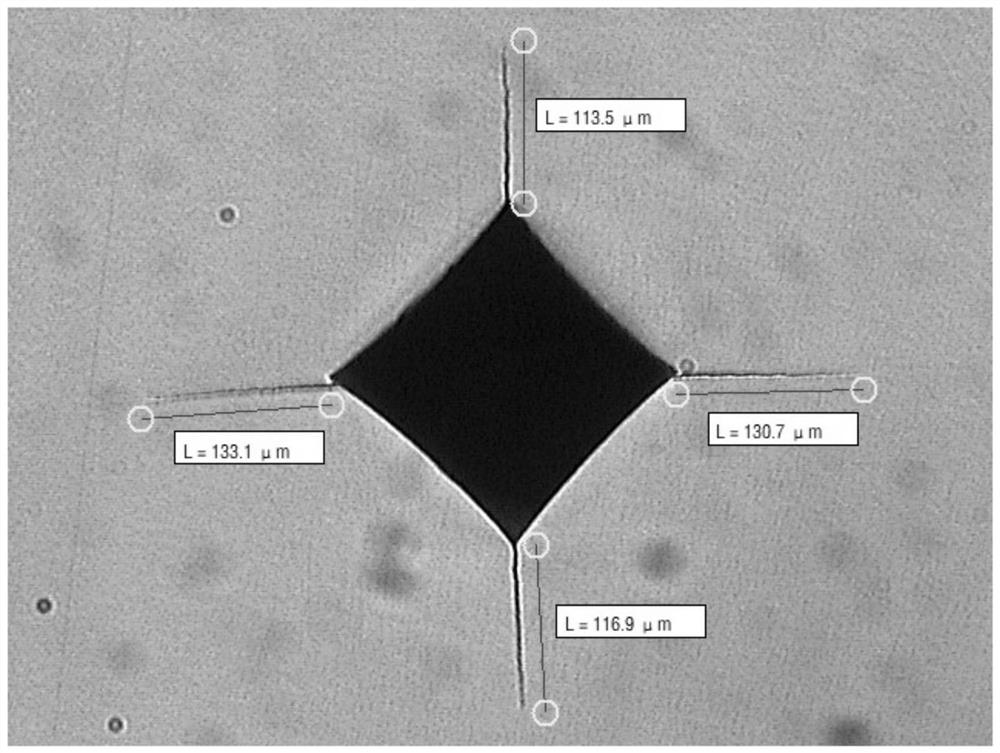

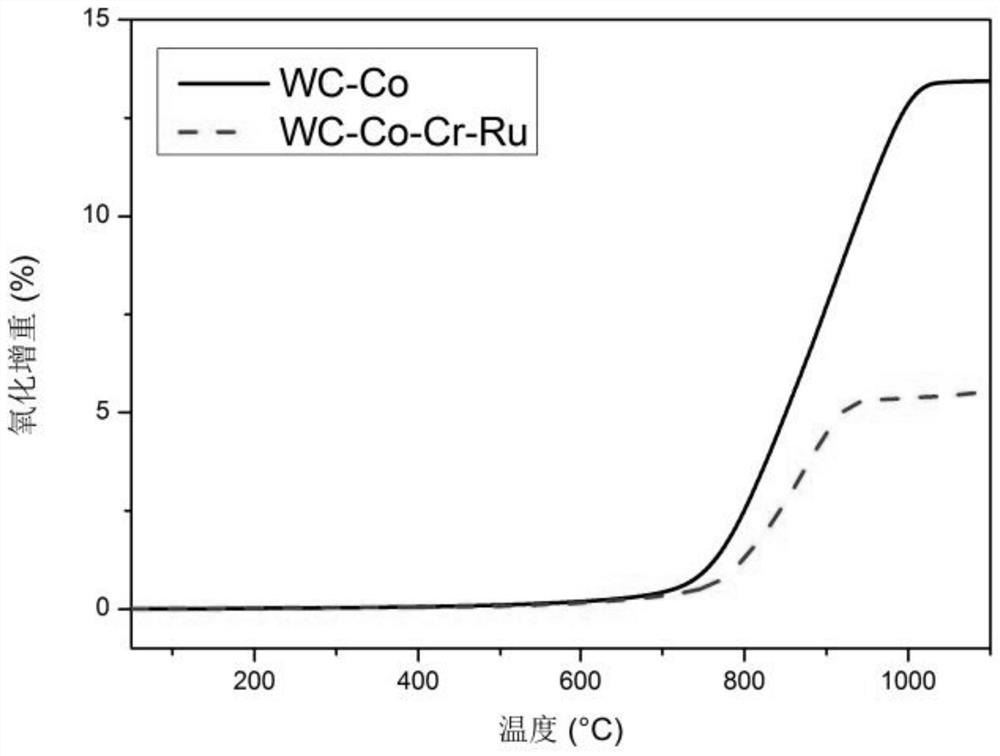

Ultra-fine grain hard alloy and preparation method thereof

The invention discloses an ultra-fine grain hard alloy and a preparation method thereof. The ultra-fine grain hard alloy is mainly prepared from the following raw materials in percentage by mass: 5%-8% of binding phase powder, 0.20%-0.80% of Cr3C2 powder, 0.25%-0.80% of Ru powder and 90.40%-94.55% of ultra-fine WC powder. According to the preparation method, all the raw materials are subjected to batching, ball milling, granulation, pressing and sintering, and the hard alloy is prepared. The Cr3C2 and the Ru are compositely added, so that the hardness of the alloy is ensured, the micromechanical property of a binding phase of the ultra-fine hard alloy is improved, the crack propagation resistance and the high-temperature oxidation resistance of an alloy material are obviously improved, and the binding wear resistance of the hard alloy is obviously improved; and the technical problem that turning machining of common high-temperature alloy materials in the fields of spaceflight, aviation, automobiles, ships and the like is difficult is solved.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

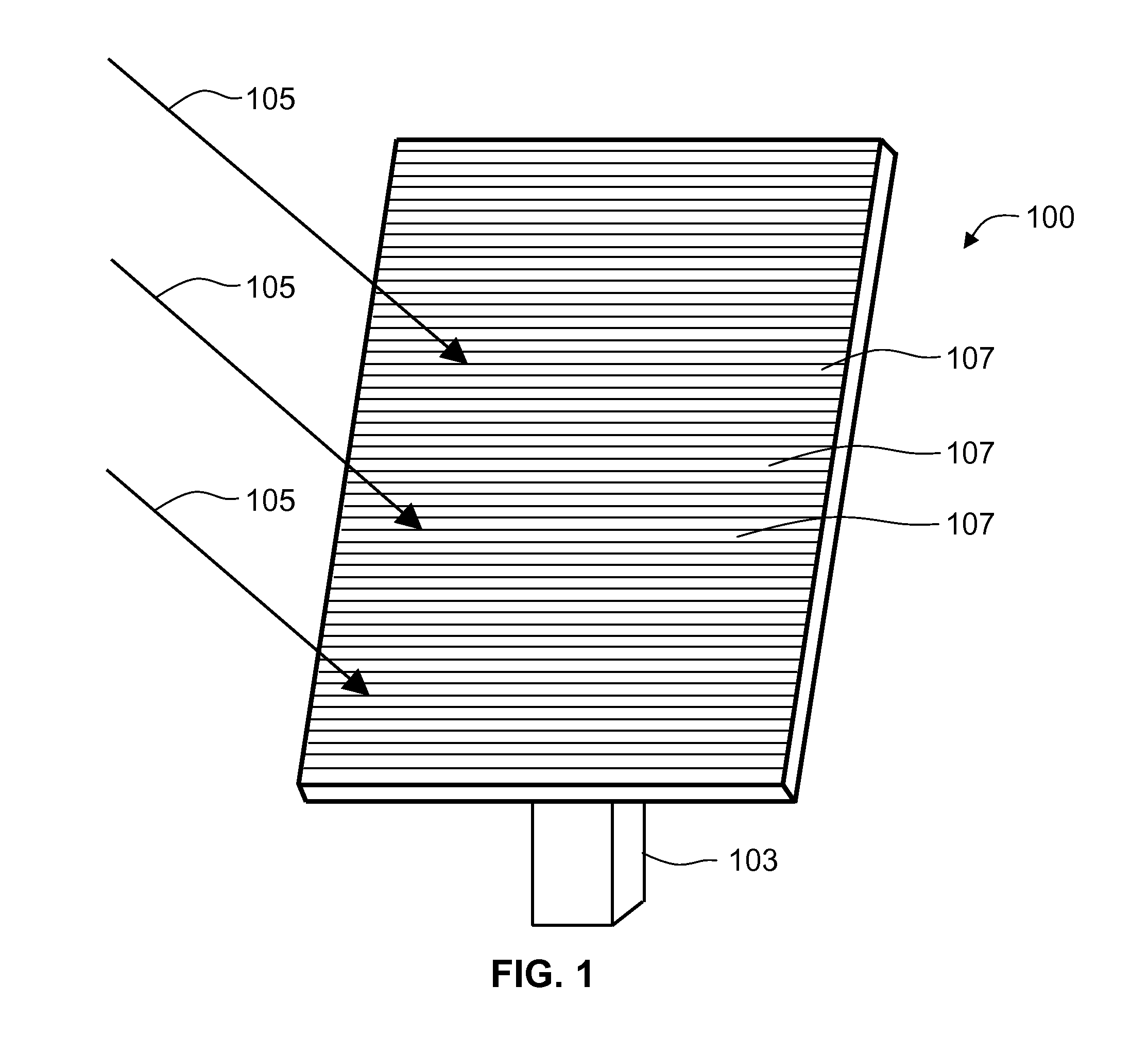

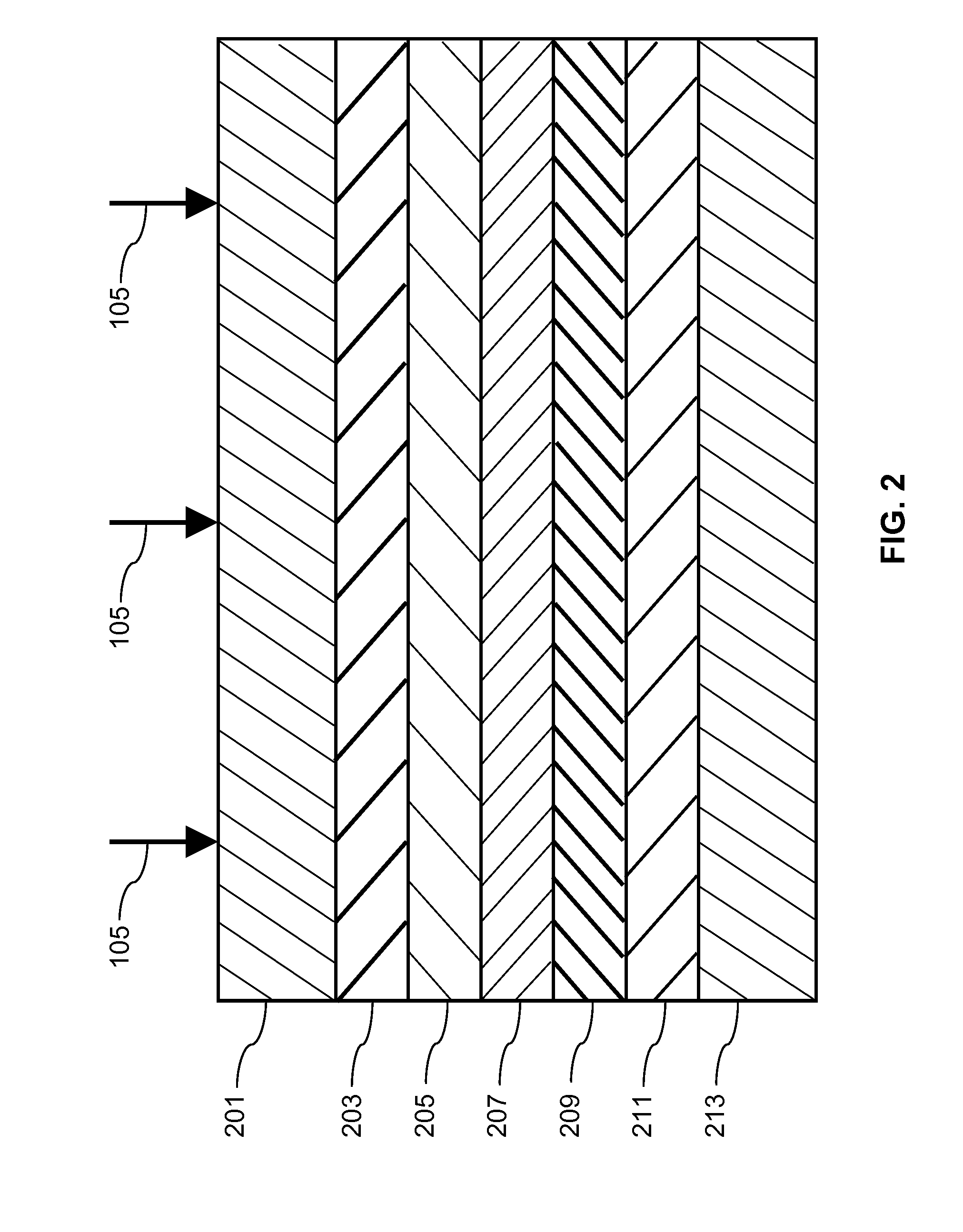

System and method for modifying an article and a modified article

InactiveUS20110308610A1Improved resistance to crack growthImprove the immunityGlass/slag layered productsPhotovoltaic energy generationEngineeringLaser

Owner:FIRST SOLAR INC (US)

A kind of high-temperature wear-resistant cralsion-based nanocomposite coating and its preparation method and application

ActiveCN106702331BReduce coefficient of frictionImprove bindingVacuum evaporation coatingSputtering coatingNanocomposite coatingHardness

The invention discloses a high-temperature abrasion-resistant CrAlSiON based nano-composite coating. The high-temperature abrasion-resistant CrAlSiON based nano-composite coating mainly comprises an AlTiN transition layer, a CrAlSiN supporting layer and a CrAlSiON functional layer. A multi-arc ion plating technology is adopted in the coating, and the CrAlSiON based nano-composite coating with different components can be obtained by changing technological parameters. An oxygen element is led into the CrAlSiON based nano-composite coating, the existence form of oxygen in the coating is controlled by changing the depositional condition, one or more sorts of oxide which is low in friction coefficient and resistant to abrasion can be pre-formed in the coating, and the binding force between coating bodies is increased; and meanwhile, the stress between the coating bodies and the friction coefficient under a high temperature condition are lowered, and friction resistance, abrasion resistance and thermal stability of the coating are improved, so that the coating is more suitable for a more demanding high-speed cutting and high-hardness environment, and the high-temperature abrasion-resistant CrAlSiON based nano-composite coating has great application prospects in the fields of cutters and surface protection.

Owner:GUANGDONG UNIV OF TECH

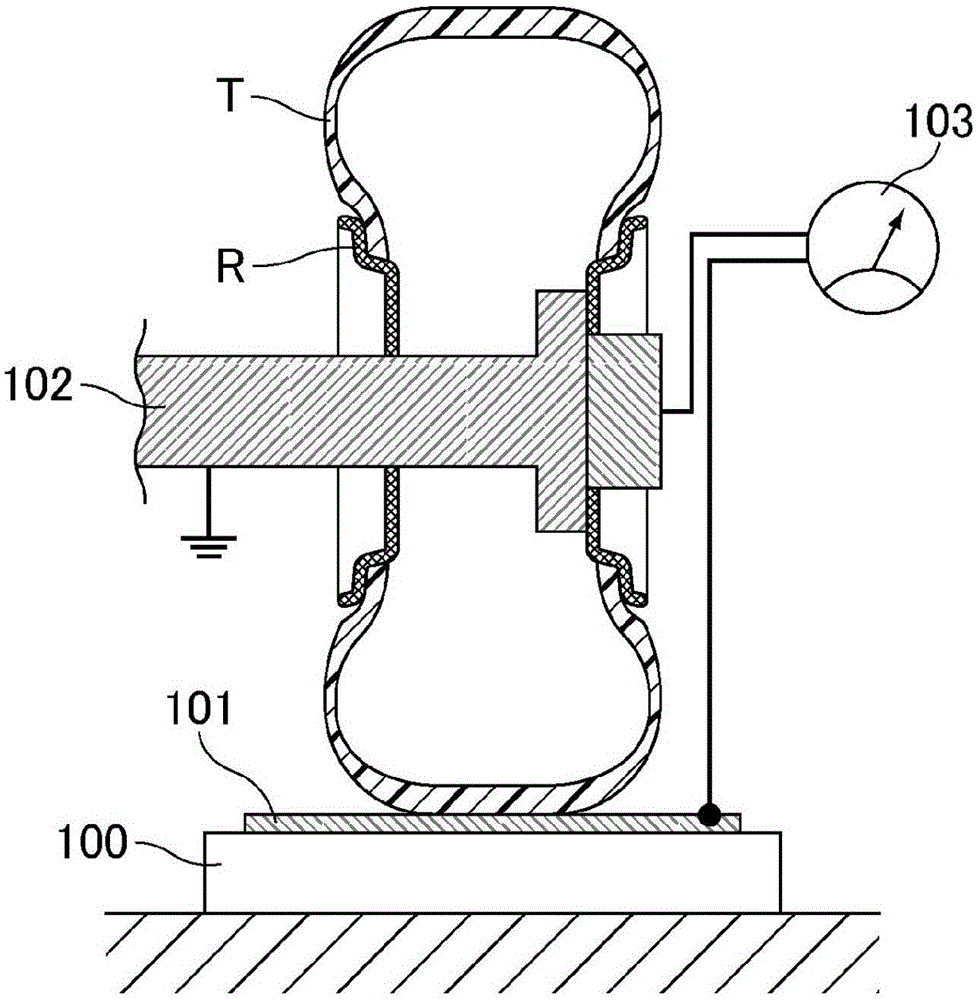

Rubber composition for inner-liner joint strip, and pneumatic tire

InactiveCN103772831AIncreased durabilityGood resistance to oxidative degradationSpecial tyresInflatable tyresPolymer scienceAlkylphenol

A rubber composition for an inner-liner joint strip is capable of improving green strength and adhesion, while maintaining good durability (oxidative degradation resistance, crack growth resistance) and good air retention properties, which are exhibited by a pneumatic tire formed from the composition. The rubber composition for an inner-liner joint strip, includes: a butyl rubber; silica and / or carbon black; and an alkylphenol-sulfur chloride condensate represented by formula (1) below, wherein a butyl rubber content is 60 to 100 mass % based on 100 mass % of the rubber component of the rubber composition, a total combined amount of the silica and the carbon black is 21 to 70 parts by mass per 100 parts by mass of the rubber component, and an amount of the alkylphenol-sulfur chloride condensate is 0.1 to 5 parts by mass per 100 parts by mass of the rubber component.

Owner:SUMITOMO RUBBER IND LTD

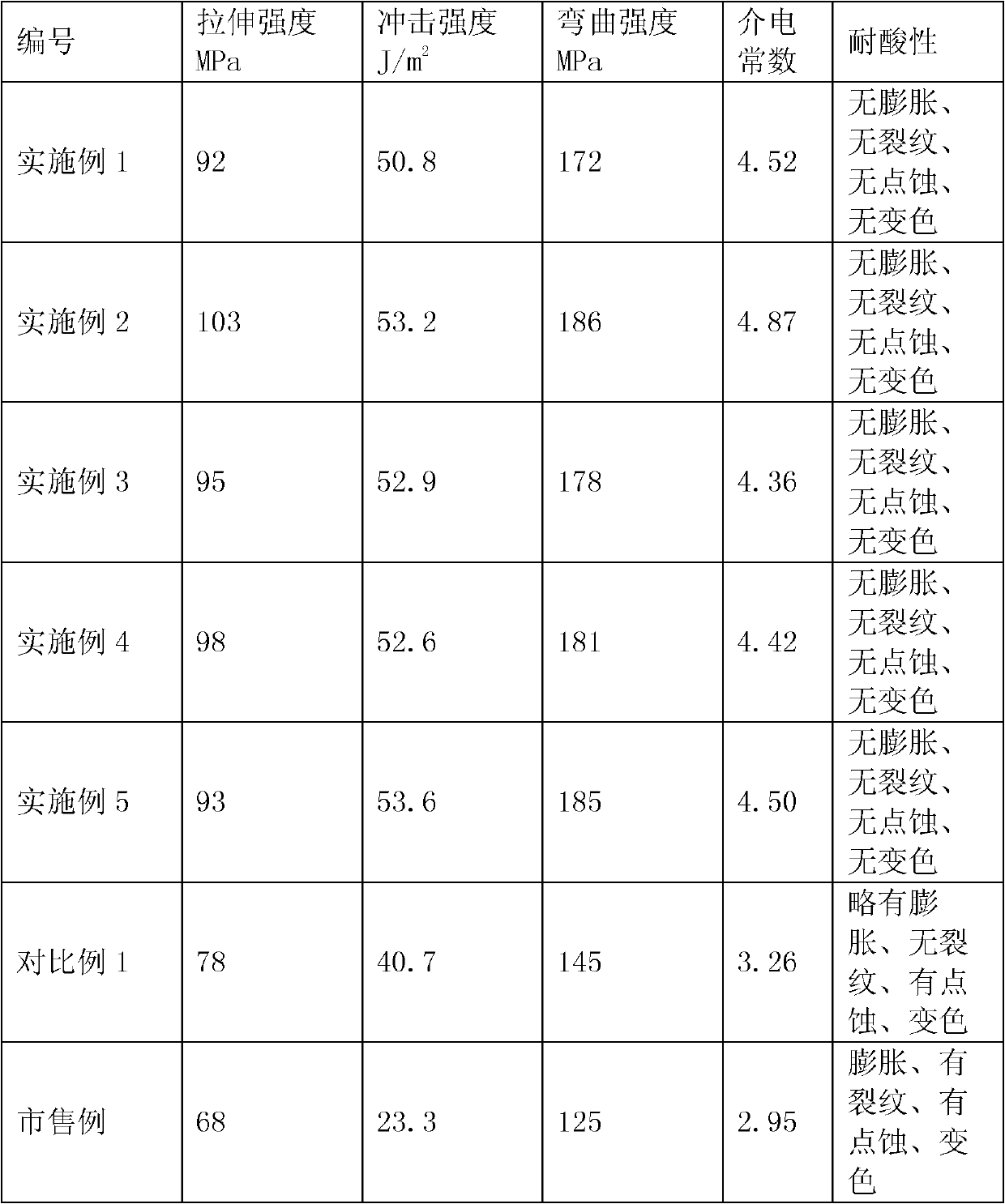

Anti-corrosion high-toughness lead storage battery plastic shell

InactiveCN111253704AUniform and stable structureHigh densityLead-acid accumulatorsCell component detailsFiberFirming agent

The invention relates to the field of lead storage battery plastic shells, particularly to an anti-corrosion high-toughness lead storage battery plastic shell, which comprises an organic-inorganic composite plate arranged on the inner side of the plastic shell, and a plastic shell body covering the outer side of the organic-inorganic composite plate, wherein the plastic shell body comprises the following components in parts by weight: 80-100 parts of an ABS resin, 10-25 parts of organic resin toughened glass fiber, 3-10 parts of chlorinated polyethylene, 10-15 parts of a flame retardant, 1-5 parts of a flame retardant synergist, 1-3 parts of a compatilizer and 0.1-0.5 part of a lubricant, and the organic-inorganic composite plate comprises the following components in parts by weight: 100 parts of glass micro-sheet, 35-50 parts of flaky cubic boron nitride, 15-30 parts of an epoxy resin and 0.05-0.1 part of a curing agent. According to the invention, the defect that the mechanical property of the lead storage battery is continuously reduced along with the prolonging of the service time due to the fact that the lead storage battery in the prior art is not corrosion-resistant is overcome, the lead storage battery has good toughness and impact resistance, the corrosion resistance is good, and the use safety of the plastic shell can be ensured for a long time.

Owner:浙江昊杨新能源科技有限公司

Zirconium diboride and short carbon fiber modified thermal shock resistant and ablation resistant SiBCN ceramic material and preparation method thereof

The invention discloses a zirconium diboride and short carbon fiber modified thermal shock resistant and ablation resistant SiBCN ceramic material and a preparation method thereof, and relates to a SiBCN ceramic material and a preparation method thereof. The invention aims to solve the problem of poor thermal shock resistance and poor ablation resistance of SiBCN ceramic at present. The SiBCN ceramic material disclosed by the invention is prepared by compounding SiBCN, short carbon fiber and ZrB2. The preparation method comprises the following steps: performing ball milling of silica powder, graphite powder, hexagonal boron nitride powder and zirconium diboride powder to obtain nano SiBCN-ZrB2 powder; compounding the SiBCN-ZrB2 powder with short carbon fiber, then performing dispersion andball milling to obtain ceramic slurry; finally, drying, levigating and sintering in turn to finish the preparation. According to the preparation method disclosed by the invention, by modifying SiBCNwith ZrB2 and Cf, the prepared SiBCN ceramic has excellent thermal shock resistance and ablation resistance, and the temperature interval of high-temperature service of the SiBCN ceramic material is expanded. The preparation method disclosed by the invention is suitable for preparing SiBCN ceramic.

Owner:HARBIN INST OF TECH

Power transmission belt

ActiveUS10703893B2Improved resistance to crack growthEasy to crackV-beltsDriving beltsElastomerIonomer

Owner:THE DOW CHEM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com