Power transmission belt

a transmission belt and power technology, applied in the direction of mechanical equipment, transportation and packaging, other domestic objects, etc., can solve the problem of challenging inventing polymers that actually self-heal cracks, and achieve the effect of improving the growth performance of flex cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

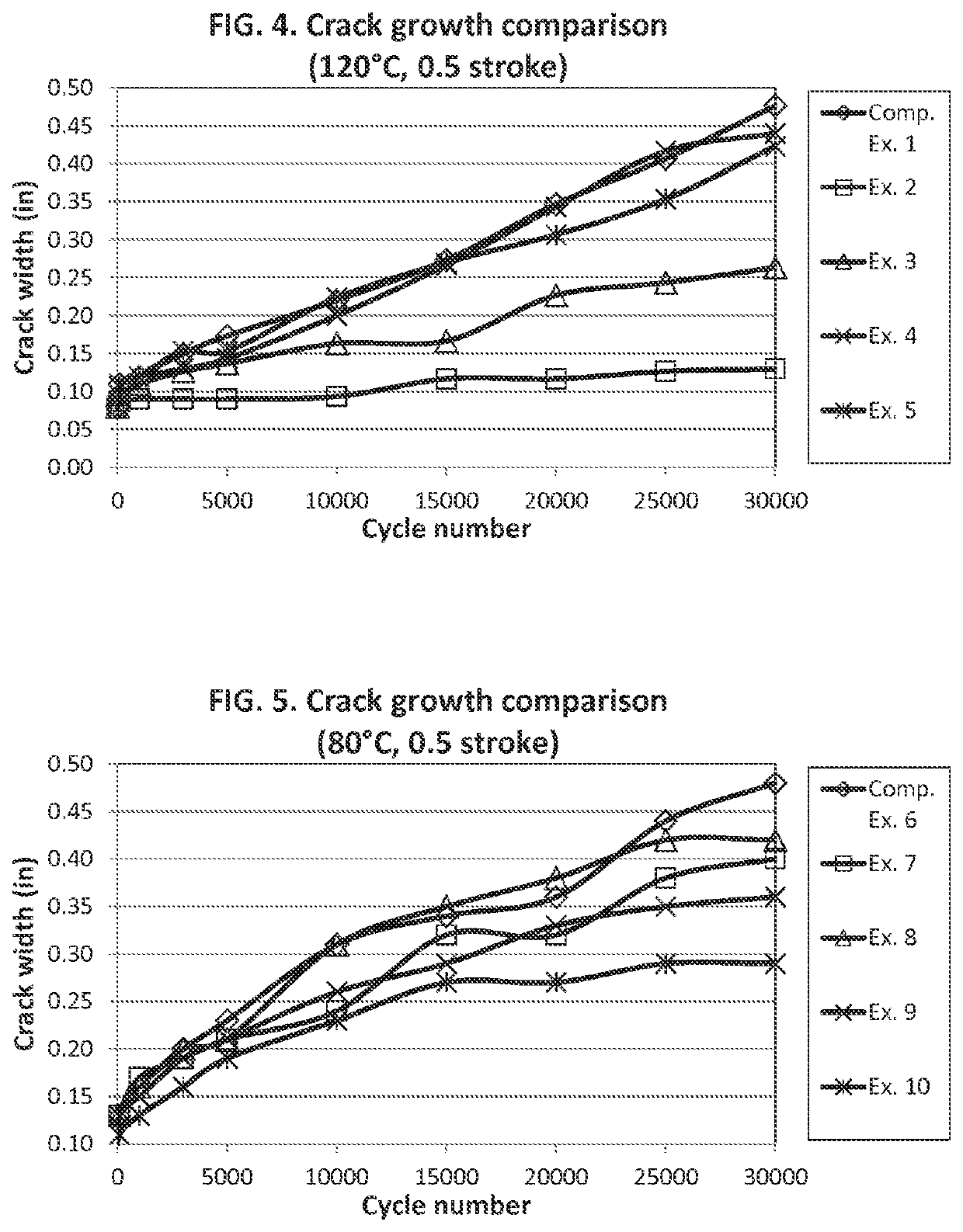

[0019]In the examples according to the invention, EMAA was used as an additive to put into a fiber-loaded ethylene-propylene-diene elastomer (EPDM) belt compound. DeMattia rubber crack growth test method was used to monitor the material crack growth. The effect of EMAA on the rubber material's static and dynamic mechanical properties was investigated as well. Two EMAA types manufactured by DuPont were used in this work, namely, EMAA and partially neutralized EMAA copolymers.

[0020]Nucrel® is a thermoplastic EMAA random copolymer sold by DuPont under that trade name. The Nucrel® 925 copolymer contains 85 weight % ethylene and 15 weight % methacrylic acid (MA), i.e., 5.4 mole % MA groups randomly distributed along the polymer chains. Nucrel® 925 has a greater average molecular weight than Surlyn® 8920. Nucrel® is commonly used as a thermoplastic molding resin or coating resin in applications involving footwear, wire and cable coating, metal coating, and glass coating. It is tough and f...

second embodiment

[0034]In the examples according to the invention, butyl ionomer was used as an ionic polymer additive to put into a fiber-loaded ethylene-propylene-diene elastomer (EPDM) belt compound. The DeMattia rubber crack growth test method was used to monitor the material crack growth. The effect of the butyl iononier on the rubber material's static and dynamic mechanical properties was investigated as well. “LanXess XLINK TP” butyl ionomer was supplied by LanXess. It is in pellet form, and the specific gravity is 0.93 g / cm3. The preparation of such butyl ionomers is described for example in U.S. Pat. No. 7,662,480 B2, U.S. Pat. No. 7,915,333 B2, and U.S. Pat. Appl. Publ. No. 2010 / 0010140 A1, all to Resendes et al., the contents of which are hereby incorporated herein by reference. Herein, “butyl ionomer” in general refers to any of the ionomeric butyl polymers described in those patent publications.

[0035]Butyl rubber is understood to be a copolymer of an isoolefin and one or more, preferabl...

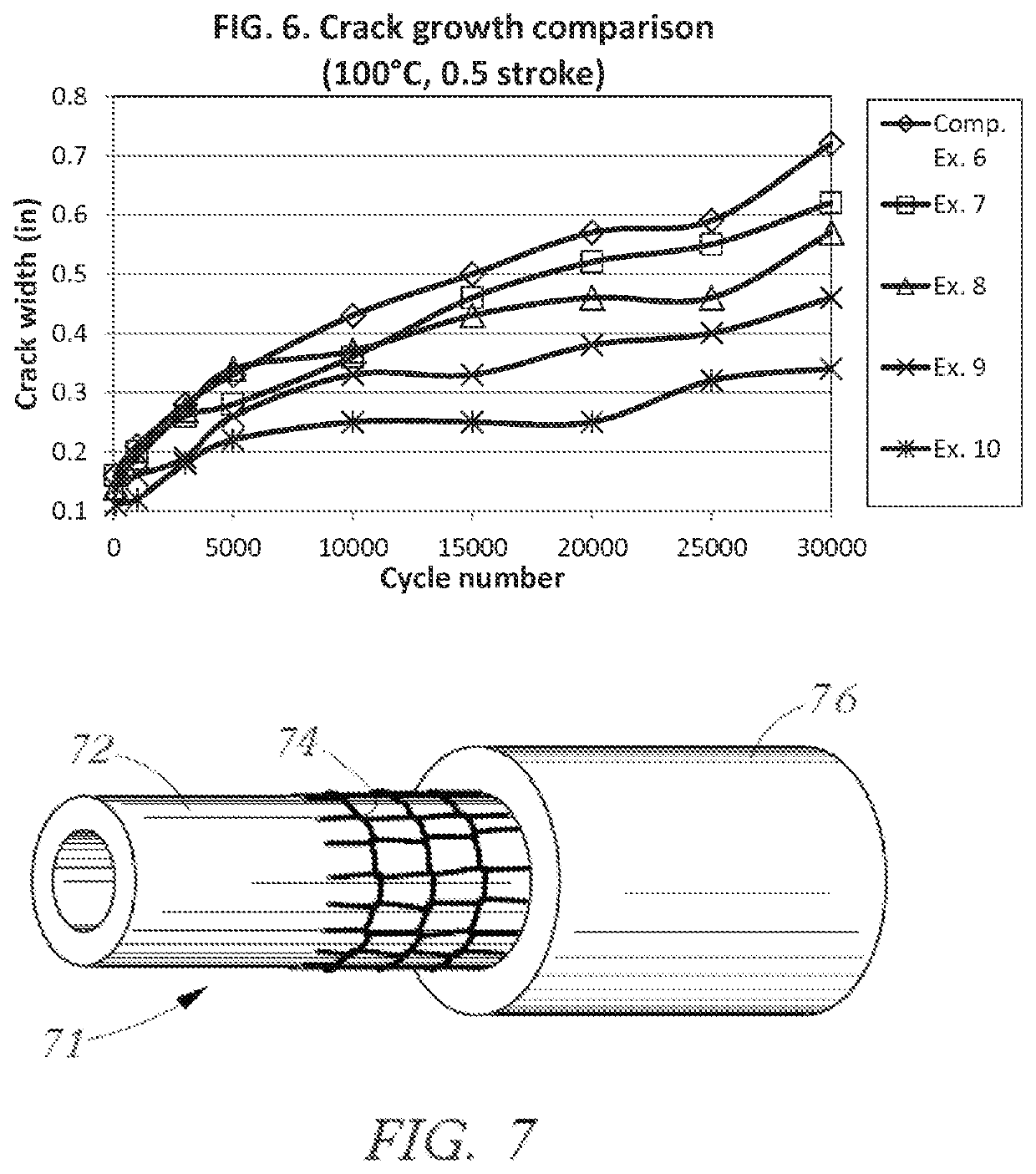

embodiment 71

[0067]Likewise hoses utilizing rubber compositions according to an embodiment of the invention may be subject to repeated pressure impulses or flexing and therefore benefit from the invention in the form of increased life and / or decreased crack growth rates. A hose typically includes one or more rubber layers and one or more reinforcement layers. The reinforcement layers may be textiles, cords or wires, which may be wrapped or wound or braided. There may also be tie layers to bond various layers together, and the tie layers may also be rubber compositions. FIG. 7 shows exemplary hose embodiment 71, including inner tube layer 72, reinforcement layer 74, and outer cover layer 76. Any of the rubber compositions utilized in the hose may advantageously include an ionomeric polymer additive as described generally herein and in connection with the specific examples herein. The ionomeric polymer additive may be polyethylene-methacrylic acid copolymer or butyl ionomer. The polyethylene-metha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com